Académique Documents

Professionnel Documents

Culture Documents

TL Welding Consumables

Transféré par

Duvall AnggraitaDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TL Welding Consumables

Transféré par

Duvall AnggraitaDroits d'auteur :

Formats disponibles

DTM-UI

Welding consumables

DTM-UI

BS EN 499 MMA Covered Electrodes

E 50 3 2Ni B 7 2 H10

Covered Electrode

Yield Strength N/mm2

Toughness

Chemical composition

Flux Covering

Weld Metal Recovery

and Current Type

Welding Position

Hydrogen Content

DTM-UI

Welding consumables

Welding consumables are any products that are used up in

the production of a weld

Welding consumables may be:

Covered electrodes, filler wires and electrode wires.

Shielding or oxy-fuel gases.

Separately supplied fluxes.

Fusible inserts.

DTM-UI

Welding Consumable Standards

MIG/MAG (GMAW) TIG (GTAW)

MMA (SMAW)

BS 2901: Filler wires

BS EN 499: Steel electrodes

BS EN 440: Wire electrodes

AWS A5.1 Non-alloyed steel

AWS A5.9: Filler wires

BS EN 439: Shielding gases

electrodes

AWS A5.4 Chromium electrodes

SAW

AWS A5.5 Alloyed steel

BS 4165: Wire and fluxes

BS EN 756: Wire electrodes

BS EN 760: Fluxes

AWS A5.17: Wires and fluxes

electrodes

DTM-UI

Welding Consumable Gases

welding gases

GMAW, FCAW, TIG, Oxy- Fuel

Supplied in cylinders or storage

tanks for large quantities

Colour coded cylinders to minimise

wrong use

Subject to regulations concerned

handling, quantities and positioning

of storage areas

Moisture content is limited to avoid

cold cracking

Dew point (the temperature at which

the vapour begins to condense)

must be checked

DTM-UI

Welding Consumables

Each consumable is critical in respect to:

Size, (diameter and length)

Classification / Supplier

Condition

Treatments e.g. baking / drying

Handling and storage is critical for consumable control

Handling and storage of gases is critical for safety

DTM-UI

MMA Welding Consumables

MMA Covered Electrodes

The three main electrode covering types used in MMA welding

Cellulosic - deep penetration/fusion

Rutile - general purpose

Basic - low hydrogen

DTM-UI

MMA Welding Consumables

Welding consumables for MMA:

Consist of a core wire typically between 350-450mm in

length and from 2.5mm - 6mm in diameter

The wire is covered with an extruded flux coating

The core wire is generally of a low quality rimming steel

The weld quality is refined by the addition of alloying

and refining agents in the flux coating

The flux coating contains many elements and

compounds that all have a variety of functions during

welding

DTM-UI

MMA Welding Consumables

Function of the Electrode Covering:

To facilitate arc ignition and give arc stability

To generate gas for shielding the arc & molten metal from air

contamination

To de-oxidise the weld metal and flux impurities into the slag

To form a protective slag blanket over the solidifying and

cooling weld metal

To provide alloying elements to give the required weld metal

properties

To aid positional welding (slag design to have suitable

freezing temperature to support the molten weld metal)

To control hydrogen contents in the weld (basic type)

DTM-UI

Covered electrode inspection

1: Electrode size (diameter and length)

2: Covering condition: adherence, cracks, chips and concentricity

3: Electrode designation

EN 499-E 51 3 B

Arc ignition enhancing materials (optional!)

See BS EN ISO 544 for further information

DTM-UI

MMA Welding Consumables

Plastic foil sealed cardboard box

Courtesy of Lincoln Electric

Tin can

cellulosic electrodes

Vacuum sealed pack

extra low hydrogen electrodes

Courtesy of Lincoln Electric

rutile electrodes

general purpose basic electrodes

DTM-UI

MMA Welding Consumables

Cellulosic electrodes:

covering contains cellulose (organic material).

produce a gas shield high in hydrogen raising the arc

voltage.

Deep penetration / fusion characteristics enables welding

at high speed without risk of lack of fusion.

generates high level of fumes and H2 cold cracking.

Forms a thin slag layer with coarse weld profile.

not require baking or drying (excessive heat will damage

electrode covering!).

Mainly used for stove pipe welding

hydrogen content is 80-90 ml/100 g of weld metal.

DTM-UI

MMA Welding Consumables

Cellulosic Electrodes

Disadvantages:

weld beads have high hydrogen

risk of cracking (need to keep joint hot during welding to allow

H to escape)

not suitable for higher strength steels - cracking risk too

high (may not be allowed for Grades stronger than X70)

not suitable for very thick sections (may not be used on

thicknesses > ~ 35mm)

not suitable when low temperature toughness is required

(impact toughness satisfactory down to ~ -20C)

DTM-UI

MMA Welding Consumables

Cellulosic Electrodes

Advantages:

Disadvantages:

Deep penetration/fusion

High in hydrogen

Suitable for welding in all

positions

High crack tendency

Fast travel speeds

High spatter contents

Large volumes of shielding gas

Low deposition rates

Low control

Rough weld appearance

DTM-UI

MMA Welding Consumables

Rutile electrodes:

covering contains TiO2 slag former and arc stabiliser.

easy to strike arc, less spatter, excellent for positional

welding.

stable, easy-to-use arc can operate in both DC and AC.

slag easy to detach, smooth profile.

Reasonably good strength weld metal.

Used mainly on general purpose work.

Low pressure pipework, support brackets.

electrodes can be dried to lower H2 content but cannot be

baked as it will destroy the coating.

hydrogen content is 25-30 ml/100 g of weld metal.

DTM-UI

MMA Welding Consumables

Rutile electrodes

Disadvantages:

they cannot be made with a low hydrogen content

cannot be used on high strength steels or thick joints cracking risk too high

they do not give good toughness at low temperatures

these limitations mean that they are only suitable for general

engineering - low strength, thin steel

DTM-UI

MMA Welding Consumables

Rutile Electrodes

Advantages:

Disadvantages:

Easy to use

High in hydrogen

Low cost / control

High crack tendency

Smooth weld profiles

Low strength

Slag easily detachable

Low toughness values

High deposition possible

with the addition of iron

powder

DTM-UI

MMA Welding Consumables

Rutile Variants

High Recovery Rutile Electrodes

Characteristics:

coating is bulked out with iron powder

iron powder gives the electrode high recovery

extra weld metal from the iron powder can mean that weld

deposit from a single electrode can be as high as 180% of

the core wire weight

give good productivity

large weld beads with smooth profile can look very similar to

SAW welds

DTM-UI

MMA Welding Consumables

High Recovery Rutile Electrodes

Disadvantages:

Same as standard rutile electrodes with respect to hydrogen

control

large weld beads produced cannot be used for all-positional

welding

the very high recovery types usually limited to PA & PB

positions

more moderate recovery may allow PC use

DTM-UI

MMA Welding Consumables

Basic covering:

Produce convex weld profile and difficult to detach slag.

Very suitable for for high pressure work, thick section steel

and for high strength steels.

Prior to use electrodes should be baked, typically 350C for

2 hour plus to reduce moisture to very low levels and

achieve low hydrogen potential status.

Contain calcium fluoride and calcium carbonate compounds.

cannot be re-baked indefinitely!

low hydrogen potential gives weld metal very good

toughness and YS.

have the lowest level of hydrogen (less than 5 ml/100 g of

weld metal).

DTM-UI

MMA Welding Consumables

Basic Electrodes

Disadvantages:

Careful control of baking and/or issuing of electrodes is

essential to maintain low hydrogen status and avoid risk of

cracking

Typical baking temperature 350C for 1 to 2hours.

Holding temperature 120 to 150C.

Issue in heated quivers typically 70C.

Welders need to take more care / require greater skill.

Weld profile usually more convex.

Deslagging requires more effort than for other types.

DTM-UI

MMA Welding Consumables

Advantages

Basic Electrodes

Disadvantages

High toughness values

High cost

Low hydrogen contents

High control

Low crack tendency

High welder skill

required

Convex weld profiles

Poor stop / start

properties

DTM-UI

BS EN 499 MMA Covered Electrodes

E 50 3 2Ni B 7 2 H10

Covered Electrode

Yield Strength N/mm2

Toughness

Chemical composition

Flux Covering

Weld Metal Recovery

and Current Type

Welding Position

Hydrogen Content

DTM-UI

BS EN 499 MMA Covered Electrodes

Electrodes classified as follows:

E 35 - Minimum yield strength 350 N/mm2

Tensile strength 440 - 570 N/mm2

E 38 - Minimum yield strength 380 N/mm2

Tensile strength 470 - 600 N/mm2

E 42 - Minimum yield strength 420 N/mm2

Tensile strength 500 - 640 N/mm2

E 46 - Minimum yield strength 460 N/mm2

Tensile strength 530 - 680 N/mm2

E 50 - Minimum yield strength 500 N/mm2

Tensile strength 560 - 720 N/mm2

DTM-UI

AWS A5.1 Alloyed Electrodes

E 60 1 3

Covered Electrode

Tensile Strength (p.s.i)

Welding Position

Flux Covering

DTM-UI

AWS A5.5 Alloyed Electrodes

E 70 1 8 M G

Covered Electrode

Tensile Strength (p.s.i)

Welding Position

Flux Covering

Moisture Control

Alloy Content

DTM-UI

MMA Welding Consumables

TYPES OF ELECTRODES

(for C, C-Mn Steels)

BS EN 499 AWS A5.1

Cellulosic

E XX X C

EXX10

EXX11

Rutile

E XX X R

EXX12

EXX13

Rutile Heavy Coated E XX X RR EXX24

Basic

E XX X B

EXX15

EXX16

EXX18

DTM-UI

Electrode efficiency

up to 180% for iron powder electrodes

Mass of weld metal deposited

Electrode Eficiency =

Mass of core wire melted

75-90% for usual electrodes

DTM-UI

Covered electrode treatment

Cellulosic

electrodes

Rutile

electrodes

Vacuum

packed basic

electrodes

Use straight from the

box - No baking/drying!

If necessary, dry up to

120C- No baking!

Use straight from the pack

within 4 hours - No

rebaking!

DTM-UI

Covered electrode treatment

Basic electrodes

Baking in oven 2 hours

at 350C!

Limited number of

rebakes!

After baking, maintain in

oven at 150C

If not used within 4

hours, return to oven

and rebake!

Use from quivers at

75C

Weld

DTM-UI

Welding Consumables:

TIG Consumables

DTM-UI

TIG Welding Consumables

Welding consumables for TIG:

Filler wires, Shielding gases, tungsten electrodes (nonconsumable).

Filler wires of different materials composition and variable

diameters available in standard lengths, with applicable

code stamped for identification

Steel Filler wires of very high quality, with copper coating to

resist corrosion.

shielding gases mainly Argon and Helium, usually of highest

purity (99.9%).

DTM-UI

TIG Welding Consumables

Welding rods:

supplied in cardboard/plastic tubes

Courtesy of Lincoln Electric

must be kept clean and free from oil and dust

might require degreasing

DTM-UI

Fusible Inserts

Pre-placed filler material

Before Welding

After Welding

Other terms used include:

EB inserts (Electric Boat Company)

Consumable socket rings (CSR)

DTM-UI

Fusible Inserts

Consumable inserts:

used for root runs on pipes

used in conjunction with TIG welding

available for carbon steel, Cr-Mo steel, austenitic stainless

steel, nickel and copper-nickel alloys

different shapes to suit application

Radius

DTM-UI

Fusible Inserts

Application of consumable inserts

DTM-UI

Shielding gases for TIG welding

Argon

low cost and greater availability

heavier than air - lower flow rates than Helium

low thermal conductivity - wide top bead profile

low ionisation potential - easier arc starting, better arc

stability with AC, cleaning effect

for the same arc current produce less heat than helium reduced penetration, wider HAZ

to obtain the same arc arc power, argon requires a higher

current - increased undercut

DTM-UI

Shielding gases for TIG welding

Helium

costly and lower availability than Argon

lighter than air - requires a higher flow rate compared with

argon (2-3 times)

higher ionisation potential - poor arc stability with AC, less

forgiving for manual welding

for the same arc current produce more heat than argon increased penetration, welding of metals with high melting

point or thermal conductivity

to obtain the same arc arc power, helium requires a lower

current - no undercut

DTM-UI

Shielding gases for TIG welding

Hydrogen

not an inert gas - not used as a primary shielding gas

increase the heat input - faster travel speed and increased

penetration

better wetting action - improved bead profile

produce a cleaner weld bead surface

added to argon (up to 5%) - only for austenitic stainless

steels and nickel alloys

flammable and explosive

DTM-UI

Shielding gases for TIG welding

Nitrogen

not an inert gas

high availability - cheap

added to argon (up to 5%) - only for back purge for duplex

stainless, austenitic stainless steels and copper alloys

not used for mild steels (age embritlement)

strictly prohibited in case of Ni and Ni alloys (porosity)

DTM-UI

Welding Consumables:

MIG / MAG Consumables

(Gases Covered previously)

DTM-UI

MIG/MAG Welding Consumables

Welding consumables for MIG/MAG

Spools of Continuous electrode wires and shielding gases

variable spool size (1-15Kg) and Wire diameter (0.61.6mm) supplied in random or orderly layers

Basic Selection of different materials and their alloys as

electrode wires.

Some Steel Electrode wires copper coating purpose is

corrosion resistance and electrical pick-up

Gases can be pure CO2, CO2+Argon mixes and Argon+2%O2

mixes (stainless steels).

DTM-UI

MIG/MAG Welding Consumables

Welding wires:

carbon and low alloy wires may be copper coated

stainless steel wires are not coated

Courtesy of Lincoln Electric

Courtesy of ESAB AB

wires must be kept clean and free from oil and dust

flux cored wires does not require baking or drying

DTM-UI

Welding Consumables:

Flux Core Wire Consumables

DTM-UI

Flux Core Wire Consumables

Functions of metallic sheath:

provide form stability

to the wire

serves as current

transfer during

welding

Function of the filling powder:

stabilise the arc

add alloy elements

produce gaseous

shield

produce slag

add iron powder

Types of cored wire

DTM-UI

Seamless

Butt joint

Overlapping

cored wire

cored wire

cored wire

not sensitive to moisture

pick-up

can be copper coated, better

current transfer

thick sheath, good form

stability, 2 roll drive feeding

possible

difficult to manufacture

good resistance to

moisture pick-up

can be copper coated

thick sheath

difficult to seal the

sheath

sensitive to

moisture pick-up

cannot be copper

coated

thin sheath

easy to

manufacture

DTM-UI

Core elements and their function

Aluminium - deoxidize & denitrify

Calcium - provide shielding & form slag

Carbon - increase hardness & strength

Manganese - deoxidize & increase strength and toughness

Molybdenum - increase hardness & strength

Nickel - improve hardness, strength, toughness & corrosion

resistance

Potassium - stabilize the arc & form slag

Silicon - deoxidize & form slag

Sodium - stabilize arc & form slag

Titanium - deoxidize, denitrify & form slag

DTM-UI

Welding Consumables:

SAW Consumables

DTM-UI

SAW Consumables

Welding fluxes:

are granular mineral compounds mixed according to various

formulations

shield the molten weld pool from the atmosphere

clean the molten weld pool

can modify the chemical composition of the weld metal

prevents rapid escape of heat from welding zone

influence the shape of the weld bead (wetting action)

can be fused, agglomerated or mixed

must be kept warm and dry to avoid porosity

DTM-UI

SAW Consumables

Welding flux:

might be fused or agglomerated

supplied in bags

must be kept warm and dry

handling and stacking requires care

Courtesy of Lincoln Electric

Fused fluxes are normally not hygroscopic but particles can

hold surface moisture so only drying

Agglomerated fluxes contain chemically bonded water. Similar

treatment as basic electrodes

If flux is too fine it will pack and not feed properly. It cannot be

recycled indefinitely

DTM-UI

SAW Consumables

Fused Flux

Flaky appearance

Lower weld quality

Low moisture intake

Low dust tendency

Good re-cycling

Very smooth weld

profile

Fused Flux:

Baked at high temperature, glossy, hard and black in colour,

cannot add ferro-manganese, non moisture absorbent and

tends to be of the acidic type

DTM-UI

SAW Consumables

TYPES OF FLUX

FUSED (ACID TYPE)

name indicates method of manufacture

minerals are fused (melted) and granules produced by

allowing to cool to a solid mass and then crushing or by

spraying the molten flux into water

flux tends to be glass-like (high in Silica)

granules are hard and may appear shiny

granules do not absorb moisture

granules do not tend break down into powder when being

re-circulated

are effectively a low hydrogen flux

welds do not tend to give good toughness at low

temperatures

DTM-UI

SAW Consumables

Fused fluxes advantages:

good chemical homogeneity

easy removal of fines without affecting flux

composition

normally not hygroscopic easy storage and

handling

readily recycled without significant change in

particle size or composition

Fused fluxes disadvantages:

difficult to add deoxidizers and ferro-alloys (due to

segregation or extremely high loss)

high temperatures needed to melt ingredients limit

the range of flux compositions

DTM-UI

SAW Consumables

Agglomerated Flux

Granulated appearance

High weld quality

Addition of alloys

Lower consumption

Easy slag removal

Smooth weld profile

Agglomerated Flux:

Baked at a lower temperature, dull, irregularly shaped, friable,

(easily crushed) can easily add alloying elements, moisture

absorbent and tend to be of the basic type

DTM-UI

SAW Consumables

Agglomerated fluxes advantages:

easy addition of deoxidizers and alloying elements

usable with thicker layer of flux when welding

colour identification

Agglomerated fluxes disadvantages:

tendency to absorb moisture

possible gas evolution from the molten slag leading to

porosity

possible change in flux composition due to segregation or

removal of fine mesh particles

DTM-UI

SAW Consumables

TYPES OF FLUX

AGGLOMERATED (BASIC TYPE)

name indicates method of manufacture

basic minerals are used in powder form and are mixed with a

binder to form individual granules

granules are soft and easily crushed to powder

granules will absorb moisture and it is necessary to protect

the flux from moisture pick-up - usually by holding in a

heated silo

granules tend to break down into powder when being recirculated

are a low hydrogen flux - if correctly controlled

welds give good toughness at low temperatures

DTM-UI

SAW Consumables

Mixed fluxes - two or more fused or bonded fluxes are

mixed in any ratio necessary to yield the desired

results

Mixed fluxes advantages:

several commercial fluxes may be mixed for highly

critical or proprietary welding operations

Mixed fluxes disadvantages:

segregation of the combined fluxes during

shipment, storage and handling

segregation occurring in the feeding and recovery

systems during welding

inconsistency in the combined flux from mix to mix

DTM-UI

SAW filler material

Welding wires can be used to weld:

carbon steels

low alloy steels

creep resisting steels

stainless steels

nickel-base alloys

special alloys for surfacing applications

Welding wires can be:

solid wires

metal-cored wires

DTM-UI

SAW filler material

Welding wires:

carbon and low alloy wires are copper coated

stainless steel wires are not coated

Courtesy of Lincoln Electric

Courtesy of Lincoln Electric

wires must be kept clean and free from oil and dust

DTM-UI

SAW filler material

Copper coating functions:

to assure a good electric contact between wire

and contact tip

to assure a smooth feed of the wire through the

guide tube, feed rolls and contact tip (decrease

contact tube wear)

to provide protection against corrosion

Vous aimerez peut-être aussi

- 1.17 - Surreptitious Software Obfuscation, Watermarking, and Tamperproofing For Software ProtectionDocument1 041 pages1.17 - Surreptitious Software Obfuscation, Watermarking, and Tamperproofing For Software ProtectionGabriel DiasPas encore d'évaluation

- CIGWELDDocument244 pagesCIGWELDrodastrid5653100% (1)

- 07 Bubble BreakDocument25 pages07 Bubble BreakWeb LogueandoPas encore d'évaluation

- Weldinglectures4 6 141006115241 Conversion Gate02 PDFDocument102 pagesWeldinglectures4 6 141006115241 Conversion Gate02 PDFramuPas encore d'évaluation

- WIS5 ConsumablesDocument29 pagesWIS5 ConsumablesMNur SarhanPas encore d'évaluation

- 16 Welding ConsumablesDocument63 pages16 Welding ConsumablesJawed AkhterPas encore d'évaluation

- Acero MadridDocument46 pagesAcero MadridviyfPas encore d'évaluation

- WeldingDocument23 pagesWeldingBilal TayyabPas encore d'évaluation

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pages3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmPas encore d'évaluation

- General 2Document4 pagesGeneral 2AnandPas encore d'évaluation

- International Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas WeldingDocument60 pagesInternational Welding Inspector (IWI) : M1.1.4. Tungsten Inert Gas Weldingresky marantinanPas encore d'évaluation

- MODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsDocument7 pagesMODULE 9 - Weld and Base Metal Discontinuities Discontinuity: Discontinuity IsNsidibe Michael EtimPas encore d'évaluation

- KEMPPI Welding Technology Course: R.BanerjeeDocument78 pagesKEMPPI Welding Technology Course: R.BanerjeeAnoop KushwahaPas encore d'évaluation

- MMAWDocument21 pagesMMAWAkash PandeyPas encore d'évaluation

- Cswip 3.1 TestDocument174 pagesCswip 3.1 TestbanglvhPas encore d'évaluation

- WRIDocument51 pagesWRIHarsha Vardhan Meduri100% (1)

- Differences Between AC Welding and DC WeldingDocument2 pagesDifferences Between AC Welding and DC WeldingDevarakonda KondayyaPas encore d'évaluation

- Steel FachaDocument59 pagesSteel FachaviyfPas encore d'évaluation

- Welding Inspection CourseDocument33 pagesWelding Inspection CourseBenjapon bt7Pas encore d'évaluation

- WELDINGDocument4 pagesWELDINGArputharaj Maria LouisPas encore d'évaluation

- Types of CrackingDocument26 pagesTypes of CrackingAnonymous c3eiDyWPas encore d'évaluation

- Gtaw WeldingDocument37 pagesGtaw WeldingSadhasivam VeluPas encore d'évaluation

- WIS5 Imperfections 2006 PDFDocument81 pagesWIS5 Imperfections 2006 PDFWatcharapong Puangthaisong100% (1)

- Pickling Heat Tint For SSDocument2 pagesPickling Heat Tint For SSTuan DangPas encore d'évaluation

- Acero para BarcosDocument39 pagesAcero para BarcosviyfPas encore d'évaluation

- Preheat PDFDocument11 pagesPreheat PDFromanosky11Pas encore d'évaluation

- Alloy Steels: Dr. Indika de SilvaDocument25 pagesAlloy Steels: Dr. Indika de SilvaChandima K PriyamalPas encore d'évaluation

- Fundamentals of Welding InspectionDocument53 pagesFundamentals of Welding InspectionIlyes kPas encore d'évaluation

- BS 1724 (Bronze Welding by Gas)Document24 pagesBS 1724 (Bronze Welding by Gas)nandi_scrPas encore d'évaluation

- GMAW FundamentalsDocument18 pagesGMAW FundamentalsYusup MulyanaPas encore d'évaluation

- Heat Treatment of SteelDocument3 pagesHeat Treatment of SteelKristine ReyesPas encore d'évaluation

- MetallurgyDocument25 pagesMetallurgyPandu Damay PutraPas encore d'évaluation

- Welding Inspection, Steels - WIS 5: Multi - Choice Question Paper (MSR-WI-2)Document8 pagesWelding Inspection, Steels - WIS 5: Multi - Choice Question Paper (MSR-WI-2)Tariq Hussain0% (1)

- MEI - Aluminium MIG WeldDocument56 pagesMEI - Aluminium MIG WeldSaravana Kumar100% (1)

- Unit II - mt1Document24 pagesUnit II - mt1Mareeswaran Maruthamuthu M0% (1)

- En 15085-2020-What Has ChangedDocument2 pagesEn 15085-2020-What Has ChangedBoran YelkenciogluPas encore d'évaluation

- Welding DefectDocument33 pagesWelding DefectabdoPas encore d'évaluation

- Welding Questions For ExamDocument6 pagesWelding Questions For ExamshivPas encore d'évaluation

- Cswip Exams 1 PDFDocument65 pagesCswip Exams 1 PDFFethi BELOUISPas encore d'évaluation

- Inspection of The Hot Dipped Galvanizing ProcessDocument5 pagesInspection of The Hot Dipped Galvanizing ProcessIrinaPas encore d'évaluation

- CSWIP 3.1 - Question With Answer and Explanation - Part 16 - General Technical KnowledgeDocument7 pagesCSWIP 3.1 - Question With Answer and Explanation - Part 16 - General Technical KnowledgeDENSIN0% (1)

- Question Excerpt From CSWIP 3Document4 pagesQuestion Excerpt From CSWIP 3Ekor JohnPas encore d'évaluation

- Cswip3.2 Content ONLYDocument3 pagesCswip3.2 Content ONLYSathishkumar. KPas encore d'évaluation

- GMAWDocument12 pagesGMAWsushant47Pas encore d'évaluation

- Welding Questions and AnswersDocument6 pagesWelding Questions and Answersengrzia76Pas encore d'évaluation

- SMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFDocument11 pagesSMAW, FCAW, and SAW High-Strength Ferritic Deposits - The Challenge Is Tensile Properties PDFbiancogallazziPas encore d'évaluation

- Defects and Discontinuities: Boiler and Mechanical PowerDocument78 pagesDefects and Discontinuities: Boiler and Mechanical PowerthejusPas encore d'évaluation

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindPas encore d'évaluation

- How To Write A Welding Procedure SpecificationDocument10 pagesHow To Write A Welding Procedure SpecificationHoang LamPas encore d'évaluation

- Saudi Aramco Standards: WeldingDocument12 pagesSaudi Aramco Standards: WeldingGEORGE IVANPas encore d'évaluation

- 08 PawDocument30 pages08 PawAnupam KushwahaPas encore d'évaluation

- Appendix English 2016Document180 pagesAppendix English 2016Adil Hasanov100% (1)

- Welding ConsumablesDocument86 pagesWelding ConsumablesLương Hồ Vũ100% (1)

- 14-WIS5 Consumables 2006Document76 pages14-WIS5 Consumables 2006Rob WillestonePas encore d'évaluation

- Fundamentals of WeldingDocument79 pagesFundamentals of WeldingdselvakuuPas encore d'évaluation

- 15 MM 74Document28 pages15 MM 74Sravan Kumar50Pas encore d'évaluation

- Overview of Advanced Welding ProcessesDocument55 pagesOverview of Advanced Welding ProcessesSaravanan RajendranPas encore d'évaluation

- WIS5 Consumables PDFDocument29 pagesWIS5 Consumables PDFnikafiqPas encore d'évaluation

- BrazingDocument115 pagesBrazingcheveresan123Pas encore d'évaluation

- Introduction To Ss Welding & Tig Weld: Er.A.Baranibas. Be., M.SC., DisDocument41 pagesIntroduction To Ss Welding & Tig Weld: Er.A.Baranibas. Be., M.SC., DisaravindanPas encore d'évaluation

- Arc WeldingDocument26 pagesArc WeldingAkshay PadekarPas encore d'évaluation

- 1 - Classful Ip AddressingDocument6 pages1 - Classful Ip AddressingBiruk Tesfaye Legesse100% (1)

- 1.basic Electrical Engineering Lecture Part-1Document17 pages1.basic Electrical Engineering Lecture Part-1jimvalenciaPas encore d'évaluation

- Infinix NOTE 5 Stylus Quick Guide: Together We Can!Document16 pagesInfinix NOTE 5 Stylus Quick Guide: Together We Can!LescribeurPas encore d'évaluation

- Universal Law of GravitationDocument17 pagesUniversal Law of GravitationScionPas encore d'évaluation

- Back To Basics in Optical Communications TechnologyDocument178 pagesBack To Basics in Optical Communications TechnologyAyanPas encore d'évaluation

- Transmission Line TowersDocument3 pagesTransmission Line TowersSoumik Dandapat100% (2)

- Sensor Gaurd Installation and Maintenance ManualDocument57 pagesSensor Gaurd Installation and Maintenance ManualCapacitacion TodocatPas encore d'évaluation

- Presentation On Drowsiness Detection SystemDocument11 pagesPresentation On Drowsiness Detection Systemmovies downloaderPas encore d'évaluation

- Nut & Bolt ScienceDocument3 pagesNut & Bolt SciencetanujaayerPas encore d'évaluation

- Career Indecision and Career Anxiety in High SchooolDocument19 pagesCareer Indecision and Career Anxiety in High SchooolP.CPas encore d'évaluation

- Engineering Properties of Soil PDFDocument55 pagesEngineering Properties of Soil PDFJam Apizara Chaizalee100% (1)

- SAP QM Calibration MethodDocument3 pagesSAP QM Calibration MethodvrkattulaPas encore d'évaluation

- Ec2203-Unit IV Memory Devices Digital ElectronicsDocument38 pagesEc2203-Unit IV Memory Devices Digital ElectronicsKarthikeyan_Go_952567% (6)

- PDF Sesion de Aprendizaje de Comunicacion Leemos y Cantamos Canciones Criollas Lambayecanas - CompressDocument6 pagesPDF Sesion de Aprendizaje de Comunicacion Leemos y Cantamos Canciones Criollas Lambayecanas - CompressJulia Navarro CheroPas encore d'évaluation

- 50 Input Output Practice Questions 1606810110009 OBDocument17 pages50 Input Output Practice Questions 1606810110009 OBJavid QuadirPas encore d'évaluation

- LogDocument7 pagesLogHerdi YantoPas encore d'évaluation

- Carbanions Carbocations and CarboradicalsDocument21 pagesCarbanions Carbocations and CarboradicalsAnaAmaruPas encore d'évaluation

- Microstructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringDocument5 pagesMicrostructure Characteristics and Performance of Dissimilar Welds Between Magnesium Alloy and Aluminum Formed by Friction StirringLeidy Silvana Chacón VelascoPas encore d'évaluation

- CNS - Types of CiphersDocument47 pagesCNS - Types of Ciphersmahesh palemPas encore d'évaluation

- What Is Lincdoc?Document2 pagesWhat Is Lincdoc?Daniel O'Leary0% (1)

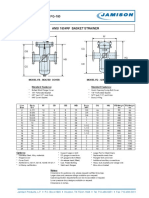

- FB-150 FQ-150 Basket StrainerDocument1 pageFB-150 FQ-150 Basket Strainerklich77Pas encore d'évaluation

- Inform: Extending PhoenicsDocument42 pagesInform: Extending PhoenicsrsigorPas encore d'évaluation

- Processing Sequence When Posting An EventDocument5 pagesProcessing Sequence When Posting An EventSrinivas ManchiPas encore d'évaluation

- Precima Frenos FDW ATEX Operating InstructionsDocument6 pagesPrecima Frenos FDW ATEX Operating InstructionsToni RenedoPas encore d'évaluation

- SolutionsDocument8 pagesSolutionsJavid BalakishiyevPas encore d'évaluation

- Theories and Methods of Two Way Slab Design-5-8-2017Document3 pagesTheories and Methods of Two Way Slab Design-5-8-2017amerta 4320Pas encore d'évaluation

- Sheet Pile Analysis Sheet v1.07-18.1Document2 pagesSheet Pile Analysis Sheet v1.07-18.1SES DESIGN100% (1)

- Programming: Simon ScheideggerDocument90 pagesProgramming: Simon ScheideggerRuben KempterPas encore d'évaluation