Académique Documents

Professionnel Documents

Culture Documents

PVC-II Outage Time Line OCT-16

Transféré par

Mehroz KhanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PVC-II Outage Time Line OCT-16

Transféré par

Mehroz KhanDroits d'auteur :

Formats disponibles

Page 1 of 2

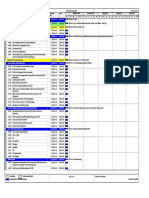

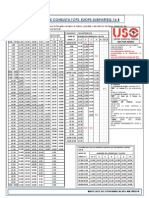

PVC-II Outage OCT-2016

TIME LINE

On 03 rd OCT, 2016

Following are the job plan during this outage.

The outage is planned for 12 hrs.

S#

Description

Hand Over

time

Date

Work Group

Take over

time

DATE

Poly-2E

1

V/A StartTime

23:00

2-Oct-16

Operations

1:00

3-Oct-16

PLY2E VCM charging spool and FV-VC012 inspection & cleaning.

1:00

3-Oct-16

Stationary

9:00

3-Oct-16

Poly-2E Pressure unit Filters & Coupling inspection/replacement for

abnormal sound rectification.

1:00

3-Oct-16

Machinery

9:00

3-Oct-16

FIL-2E top covers opening for PVC lumps cleaning and filter housing

inspection by INSP

1:00

3-Oct-16

Stationary

11:00

3-Oct-16

Pressure Test Start Time

10:00

3-Oct-16

Operations

11:00

3-Oct-16

Rinsing Start Time

11:00

3-Oct-16

Operations

11:30

3-Oct-16

A/V Start Time / End Time

11:30

3-Oct-16

Operations

13:00

3-Oct-16

Poly-3E

8

Poly-3E Pressure unit Filters & Coupling inspection/replacement for

abnormal sound rectification.

1:30

3-Oct-16

Machinery

4:00

3-Oct-16

FIL-3E top covers opening for PVC lumps cleaning and filter housing

inspection by INSP

1:30

3-Oct-16

Stationary

5:00

3-Oct-16

Poly 1E

10

VSP-P126 overhauling & body-cleaning to rectify jamming issue.

3:30

3-Oct-16

Instrument/Stat

18:00

3-Oct-16

11

Poly-1E Pressure unit Filters & Coupling inspection/replacement for

abnormal sound rectification.

4:00

3-Oct-16

Machinery

13:00

3-Oct-16

12

CH-2 pot one hose removal for specs verification.

4:00

3-Oct-16

Stationary

13:00

3-Oct-16

13

FIL-1E top covers opening for PVC lumps cleaning and filter housing

inspection by INSP

4:00

3-Oct-16

Stationary

13:00

3-Oct-16

TK-1G

14

V/A start time

4:30

3-Oct-16

Operations

6:30

3-Oct-16

15

TK1G spools & instruments inspection

6:00

3-Oct-16

Instruments

9:00

3-Oct-16

16

TK1G PSV-S151 u/s spool.

6:00

3-Oct-16

Stationery

9:00

3-Oct-16

17

Pressure Test

9:00

3-Oct-16

Operations

10:00

3-Oct-16

18

Rinsing

10:00

3-Oct-16

Operations

10:30

3-Oct-16

19

A/V Start

10:30

3-Oct-16

Operations

12:00

3-Oct-16

TK-2G

20

Rinsing Start Time

7:30

3-Oct-16

Operations

8:00

3-Oct-16

21

TK-2G SOP N2 line connector replacement due to leakage.

8:00

3-Oct-16

Stationary

11:00

3-Oct-16

HE-1G, CL-1G

22

Rinsing Start Time

7:30

3-Oct-16

Operations

8:00

3-Oct-16

23

HE1G hot side spool removal for TR rectification.

8:30

3-Oct-16

Stationary

12:30

3-Oct-16

file:///var/www/apps/conversion/tmp/scratch_3/332997144.xls

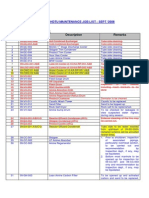

Page 2 of 2

S#

24

Description

PU-3G/4G recycle line de-blocking.

Hand Over

time

Work Group

Take over

time

Date

DATE

8:30

3-Oct-16

Stationary

12:30

3-Oct-16

TK-3H

25

Rinsing start time

8:00

3-Oct-16

Operations

8:30

3-Oct-16

26

PU-11H/12H both discharge line valves PM to rectify hard to operate

problem.

9:00

3-Oct-16

Stationary

12:00

3-Oct-16

Dryer Area

27

Dryer Area shutdown

8:00

3-Oct-16

Operations

9:00

3-Oct-16

28

CE1H bowl flushing from inspection window with "karcher gun"

9:00

3-Oct-16

Machinery

12:00

3-Oct-16

29

Balancing of CE1H motor to resolve high motor vibration issue.

9:00

3-Oct-16

Machinery

21:00

3-Oct-16

30

BL2H/3H damper vanes inspection and opening to be verified.

9:00

3-Oct-16

Machinery

21:00

3-Oct-16

31

BL3H impeller inspection against high vibration.

9:00

3-Oct-16

Machinery

21:00

3-Oct-16

32

SC1H machinery PM

9:00

3-Oct-16

Machinery

21:00

3-Oct-16

33

Mesh size of BL2H suction duct inside Fil1H housing to be made coarser

after evaluation so that unnecessary DP can be eliminated and BL2H flow

can be increased.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

34

Tie-ins for relocation of PVC1 secondary screen FL1503 (SC3H) and

PM1602 (RV1H) alongside SC1H.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

35

BL-2H suction chute replacement

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

36

Flash dryer cleaning from bottom end flange.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

37

SC-1H chutes replacement required.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

38

SC1H opening for tray dimensions and internal inspection

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

39

Hot Job: SC1H inlet line tie-in for Y-spool installation.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

40

Hot Job: Floor cutting for routing of piping.

10:00

3-Oct-16

Stationary

21:00

3-Oct-16

41

Hot Job: SC1H balancing line tie-in for SC3H after spool removal.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

42

Hot job: TK8H top cover modification for new nozzles.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

43

Cold work: Tie-in from M1H d/s for RV1H purge air.

10:00

3-Oct-16

Stationary

21:00

3-Oct-16

44

TK-1H vent line inspection and de-blocking.

9:00

3-Oct-16

Stationary

21:00

3-Oct-16

45

SC3H & RV1H LCP installation, motors power connection, control

connections.

9:00

3-Oct-16

Electrical

21:00

3-Oct-16

46

Control & power cable laying for SC3H & RV1H motors.

9:00

3-Oct-16

Instruments

21:00

3-Oct-16

47

Jobs on I/O panel in rack room and MCC for inst related jobs on SC3H

and RV1H.

9:00

3-Oct-16

Instruments

21:00

3-Oct-16

48

Fil-1H purging with PA.

9:00

3-Oct-16

Operations

21:00

3-Oct-16

9:00

3-Oct-16

Machinery

16:00

3-Oct-16

10:00

3-Oct-16

Stationary/Ops

16:00

3-Oct-16

10:00

3-Oct-16

Stationary

16:00

3-Oct-16

Miscellaneous Jobs

49

50

PU-4251A seal leakage rectification.

PU18H discharge WW line flushing using Fire Water

51

TK-4C jacket drain line bottom drain both valves replacement due to

passing issue.

file:///var/www/apps/conversion/tmp/scratch_3/332997144.xls

Vous aimerez peut-être aussi

- Tie-In Schedule 2016.09.26 PDFDocument14 pagesTie-In Schedule 2016.09.26 PDFArdina AzizahPas encore d'évaluation

- 03 2359 03 P 3 004 Rev 3 Span Analysis ReportDocument872 pages03 2359 03 P 3 004 Rev 3 Span Analysis Reporticemage1991100% (1)

- Notes: Table 3.1: Separation and Spacing Table (Distance in Metre)Document1 pageNotes: Table 3.1: Separation and Spacing Table (Distance in Metre)aahmed2001Pas encore d'évaluation

- Project Schedule Alto Maipo - 122014Document3 pagesProject Schedule Alto Maipo - 122014Manuel Pizarro PérezPas encore d'évaluation

- Scanned From A Xerox Multifunction DeviceDocument49 pagesScanned From A Xerox Multifunction DeviceAnand NarayananPas encore d'évaluation

- Main Group 3 Equipment For CargoDocument13 pagesMain Group 3 Equipment For CargoVladi GasperPas encore d'évaluation

- 3 WlaDocument9 pages3 WlaAshishKumar RavalPas encore d'évaluation

- GB1516 Sac 240 CV RP 0006 - ADocument10 pagesGB1516 Sac 240 CV RP 0006 - AkkkkPas encore d'évaluation

- Nhon Trach 2 - 750Mw Combined Cycle Power Plant ProjectDocument41 pagesNhon Trach 2 - 750Mw Combined Cycle Power Plant ProjectHuynh Thanh TamPas encore d'évaluation

- TSM 26 SdcuDocument3 pagesTSM 26 SdcuWaleed HassanPas encore d'évaluation

- Tunnel Operational ControlDocument41 pagesTunnel Operational ControlJoshua Evans100% (1)

- Morichal 2 Week Look Ahead PMDocument5 pagesMorichal 2 Week Look Ahead PMCarlos NegrinPas encore d'évaluation

- 3.8M C-BAND RX/TX Antenna System: 4096-535 Revision JDocument36 pages3.8M C-BAND RX/TX Antenna System: 4096-535 Revision JRoshan KarnaPas encore d'évaluation

- PresentationDocument16 pagesPresentationதுரைராஜ் இலட்சுமணன்Pas encore d'évaluation

- Ash KKSDocument56 pagesAsh KKSAnonymous ahdhFMaPas encore d'évaluation

- DEWA Sub StationDocument18 pagesDEWA Sub StationVishram Deo86% (7)

- Total Total: Al Sho AL SHOUMOS Residential Complex Phase I at Al Bleaida - ShaDocument4 pagesTotal Total: Al Sho AL SHOUMOS Residential Complex Phase I at Al Bleaida - ShakhalidPas encore d'évaluation

- HDT Job List For AUG '08Document3 pagesHDT Job List For AUG '08Alex LeePas encore d'évaluation

- Pipe VelocityDocument7 pagesPipe Velocityنور القمرPas encore d'évaluation

- Specification - Tunnel Waterproofing and Drainage SpecificationDocument33 pagesSpecification - Tunnel Waterproofing and Drainage SpecificationAlhad Panwalkar100% (1)

- Testing & Commissioning Plan-Introduction-Cl35-130-Pro-El-Swi-001-Rev-00-30.10.2021Document10 pagesTesting & Commissioning Plan-Introduction-Cl35-130-Pro-El-Swi-001-Rev-00-30.10.2021Francisco Aguirre VarasPas encore d'évaluation

- Sawamlah SS, 3 Weeks Schedule Update Till 21.01.2014Document17 pagesSawamlah SS, 3 Weeks Schedule Update Till 21.01.2014William E. NuevoPas encore d'évaluation

- Daily Inspection Schedule of 19-03-2013Document5 pagesDaily Inspection Schedule of 19-03-2013Mohamed El Amine BouazzaPas encore d'évaluation

- Manual VT+660Document21 pagesManual VT+660alejjavierdelgadoPas encore d'évaluation

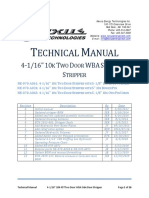

- Nexus 4in 10k 2-Door WBA Stripper Manual - REV 13Document26 pagesNexus 4in 10k 2-Door WBA Stripper Manual - REV 13Pastor Velasquez100% (1)

- MUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Document28 pagesMUK-62-MGT-AIC-09010 Rev A Lime & Soa Ash Erec. and Install. Proced. 110314Suresh MahalingamPas encore d'évaluation

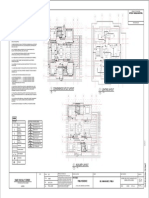

- Electrical PlansDocument2 pagesElectrical Plansberolyan0688% (8)

- Brigade Combat Team's TOEDocument209 pagesBrigade Combat Team's TOEDavid Goldovt-Ryzhenkov100% (8)

- Series 1388 - 3.8мDocument30 pagesSeries 1388 - 3.8мrtv_domoratskayaPas encore d'évaluation

- QAWTP 40in GV Actuation SurveyDocument23 pagesQAWTP 40in GV Actuation SurveykarthikPas encore d'évaluation

- Test EquipmentDocument473 pagesTest EquipmentSantrupta PandaPas encore d'évaluation

- WEFIC WELLHEAD Rig Book KOM-103013-03 REV 0Document258 pagesWEFIC WELLHEAD Rig Book KOM-103013-03 REV 0tongsabaiPas encore d'évaluation

- Hazard Analysis PDFDocument74 pagesHazard Analysis PDFAnonymous voA5Tb0Pas encore d'évaluation

- Keo ReportDocument22 pagesKeo ReportJoshua EvansPas encore d'évaluation

- InstrumentLst&Datasheets Rev0 PDFDocument34 pagesInstrumentLst&Datasheets Rev0 PDFEnrique FuentesPas encore d'évaluation

- 16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureDocument17 pages16" Utue Ka-Ubit PP Gas Pipeline Nitrogen Purging ProcedureRichard Nwachukwu92% (12)

- DOZERDocument182 pagesDOZERBradley Gandy82% (11)

- Liquid Ammonia Handling Automation - Sis PLCDocument30 pagesLiquid Ammonia Handling Automation - Sis PLCSanthiraj SathannaPas encore d'évaluation

- Vessel'S Midnight Ullage ReportDocument33 pagesVessel'S Midnight Ullage ReportnawhiPas encore d'évaluation

- FLIGTIMELIMITATIONDocument1 pageFLIGTIMELIMITATIONelsaraoPas encore d'évaluation

- Review of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Document35 pagesReview of Orifice Plate Steam Traps: ORNL/TM-2000/353/R1Omar Ezzat100% (1)

- 189 010 - en 15.710057 V3.0Document12 pages189 010 - en 15.710057 V3.0balzac191Pas encore d'évaluation

- Provision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectDocument41 pagesProvision of Flow Assurance Study For Nam Con Son 2 Gas Pipeline ProjectManh Tien HoangPas encore d'évaluation

- Vacuum Breaker Valve Data SheetDocument4 pagesVacuum Breaker Valve Data SheetMathivanan AnbazhaganPas encore d'évaluation

- LeaksDocument9 pagesLeaksIvan KryskoPas encore d'évaluation

- Systra Documents Status List - Rev1 - HgeDocument22 pagesSystra Documents Status List - Rev1 - HgeHicham GPas encore d'évaluation

- VIT154 - DrainageConcept - 2006!01!19Document12 pagesVIT154 - DrainageConcept - 2006!01!19Huynh Thanh TamPas encore d'évaluation

- 502mva Transformer Installation ScheduleDocument4 pages502mva Transformer Installation ScheduleNaukhez A. KashifPas encore d'évaluation

- Test Forms For SSDocument105 pagesTest Forms For SSRakesh Kumar75% (4)

- 107 GE CN17 0001.01 Ejemplo Resumen de TuberiaDocument34 pages107 GE CN17 0001.01 Ejemplo Resumen de Tuberiagiova2006Pas encore d'évaluation

- Burst and Pressure - Full ReportDocument18 pagesBurst and Pressure - Full ReportEspion BenPas encore d'évaluation

- Hazard AnalysisDocument74 pagesHazard AnalysisMatthew Adeyinka0% (1)

- Skill Development On P25ABC LOSES DIS FLOW.Document5 pagesSkill Development On P25ABC LOSES DIS FLOW.00083583rfPas encore d'évaluation

- A00 Upcwpr0040 UbDocument89 pagesA00 Upcwpr0040 UbRhoteram VikkuPas encore d'évaluation

- Barton Floco Positive Displacement MetersDocument40 pagesBarton Floco Positive Displacement MetersChoirul ImamPas encore d'évaluation

- Sewage Disposal Works: Their Design and ConstructionD'EverandSewage Disposal Works: Their Design and ConstructionPas encore d'évaluation

- Practical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentD'EverandPractical Rules for the Management of a Locomotive Engine in the Station, on the Road, and in cases of AccidentPas encore d'évaluation

- Pneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshD'EverandPneumatic and Hydrautic Conveying of Both Fly Ash and Bottom AshPas encore d'évaluation

- Brochurev26 PDFDocument4 pagesBrochurev26 PDFMehroz KhanPas encore d'évaluation

- Book 1Document3 pagesBook 1Mehroz KhanPas encore d'évaluation

- 1183Document4 pages1183Mehroz KhanPas encore d'évaluation

- 33 3768ns0810 348 357Document10 pages33 3768ns0810 348 357Mehroz KhanPas encore d'évaluation

- Brinesolution Msds Amer enDocument6 pagesBrinesolution Msds Amer enMehroz KhanPas encore d'évaluation

- UTY-PP TRs Waivers To Be Taken by OPs.Document10 pagesUTY-PP TRs Waivers To Be Taken by OPs.Mehroz KhanPas encore d'évaluation

- Ural GasDocument3 pagesUral GasMehroz KhanPas encore d'évaluation

- 36 Hours in LahoreDocument14 pages36 Hours in LahoreMehroz KhanPas encore d'évaluation

- Plug DesignDocument1 pagePlug DesignMehroz KhanPas encore d'évaluation

- Ural GasDocument3 pagesUral GasMehroz KhanPas encore d'évaluation

- Rollers + Bearings + Belts + ConveyorsDocument2 pagesRollers + Bearings + Belts + ConveyorsMehroz KhanPas encore d'évaluation

- What Is QualityDocument18 pagesWhat Is QualityMehroz KhanPas encore d'évaluation

- At EngroDocument2 pagesAt EngroMehroz KhanPas encore d'évaluation

- Supply Chain TerminologyDocument5 pagesSupply Chain TerminologyMehroz KhanPas encore d'évaluation

- Report On Cocacola SCMDocument17 pagesReport On Cocacola SCMMehroz KhanPas encore d'évaluation

- 4 2 LeastCommonMultipleActivityDocument3 pages4 2 LeastCommonMultipleActivityHim BazPas encore d'évaluation

- Good Deal of The Mechanics of Materials Can Be Introduced Entirely Within The Confines ofDocument1 pageGood Deal of The Mechanics of Materials Can Be Introduced Entirely Within The Confines ofMehroz KhanPas encore d'évaluation

- FDT AbbDocument12 pagesFDT AbbMehroz KhanPas encore d'évaluation

- Cim - Robotics + Material HandlingDocument5 pagesCim - Robotics + Material HandlingMehroz KhanPas encore d'évaluation

- First Floor (Clinex Pharmacy) 290 Q, Phase II, Ghazi Road, DHA Lahore PH: 042 3 5708350-51Document1 pageFirst Floor (Clinex Pharmacy) 290 Q, Phase II, Ghazi Road, DHA Lahore PH: 042 3 5708350-51Mehroz KhanPas encore d'évaluation

- Stirling Design Calculations For Alpha Type Based On Certain TheoriesDocument10 pagesStirling Design Calculations For Alpha Type Based On Certain TheoriesMehroz Khan100% (2)

- Stirling Design Calculations For Alpha Type Based On Certain TheoriesDocument10 pagesStirling Design Calculations For Alpha Type Based On Certain TheoriesMehroz Khan100% (2)

- Boiler Design Documents Appraisal ProcedureDocument11 pagesBoiler Design Documents Appraisal ProcedureMuhammad SaeedPas encore d'évaluation

- Actual TestDocument5 pagesActual TestMehroz KhanPas encore d'évaluation

- AnalogiesDocument4 pagesAnalogiesMehroz KhanPas encore d'évaluation

- Uni DetailsDocument23 pagesUni DetailsMehroz KhanPas encore d'évaluation

- Mechanical & Aerospace EngineeringDocument6 pagesMechanical & Aerospace EngineeringMehroz KhanPas encore d'évaluation

- Assignment: Industrial Safety & EnvironmentDocument1 pageAssignment: Industrial Safety & EnvironmentMehroz KhanPas encore d'évaluation

- Is Supply Chain Management More Than PurchasingDocument10 pagesIs Supply Chain Management More Than PurchasingMehroz KhanPas encore d'évaluation

- Simple (Ideal) Vapor Compression Refrigeration Cycle ProblemsDocument3 pagesSimple (Ideal) Vapor Compression Refrigeration Cycle Problemssajawal hassanPas encore d'évaluation

- Converção de AçosDocument16 pagesConverção de Açoshelton dziedzicPas encore d'évaluation

- Camara Vivotek IP7361Document74 pagesCamara Vivotek IP7361TecnoSmartPas encore d'évaluation

- ANtenna PropagationDocument63 pagesANtenna PropagationPrasanna PandeyPas encore d'évaluation

- Ce 506 Prestressed Concrete Design: M R M M MDocument2 pagesCe 506 Prestressed Concrete Design: M R M M Mbadr amPas encore d'évaluation

- WISKA Cable Glands and Junction Boxes English PDFDocument216 pagesWISKA Cable Glands and Junction Boxes English PDFtony6868Pas encore d'évaluation

- 3D Printing Research Paper - Various Aspects PDFDocument6 pages3D Printing Research Paper - Various Aspects PDFhipovemicPas encore d'évaluation

- Design and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesDocument26 pagesDesign and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesVijay SakharePas encore d'évaluation

- IR2200 - IR2800 - IR3300 Error CodeDocument7 pagesIR2200 - IR2800 - IR3300 Error CodeTiger DineshPas encore d'évaluation

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanPas encore d'évaluation

- Instructions VbamDocument2 pagesInstructions VbamAustin Yu LiuPas encore d'évaluation

- Cama Stryker Sv2-Service ManualDocument117 pagesCama Stryker Sv2-Service ManualjoelpalzaPas encore d'évaluation

- Low Noise, High Frequency MEMS Accelerometers /: ADXL1001 ADXL1002Document14 pagesLow Noise, High Frequency MEMS Accelerometers /: ADXL1001 ADXL1002Phi MacPas encore d'évaluation

- Road Geometry & Transition CurveDocument8 pagesRoad Geometry & Transition CurveNann Kay Thari KyawPas encore d'évaluation

- Air Compressor Anatomy 101Document20 pagesAir Compressor Anatomy 101Rahul ChandrawarPas encore d'évaluation

- Marking and Ordering Code System (Capacitors)Document6 pagesMarking and Ordering Code System (Capacitors)José TurinPas encore d'évaluation

- Red MarsDocument16 pagesRed Marsfz.fathima50% (2)

- Siebel MAADocument31 pagesSiebel MAAboddu24Pas encore d'évaluation

- 30 StabilizersDocument29 pages30 StabilizersnjileoPas encore d'évaluation

- Project Management Dashboard TemplateDocument10 pagesProject Management Dashboard Templateindra prasetyaPas encore d'évaluation

- 6 Energy Calculation: UDEC Version 4.0Document28 pages6 Energy Calculation: UDEC Version 4.0Rakshit MishraPas encore d'évaluation

- Va Mri Design Plan Drawings and LayoutDocument19 pagesVa Mri Design Plan Drawings and Layoutkusnanto erinPas encore d'évaluation

- NAME Dendi Panji Nugraha: Career ExperiencesDocument4 pagesNAME Dendi Panji Nugraha: Career ExperiencesAsep Ricky HerdiansyahPas encore d'évaluation

- VAV CablingDocument2 pagesVAV Cablingsripriya01Pas encore d'évaluation

- Kata LogDocument48 pagesKata LogsofiakeramikPas encore d'évaluation

- SS2 Agv200 0300 01Document12 pagesSS2 Agv200 0300 01RaymondIlyasPas encore d'évaluation

- Bicmos InvertersDocument10 pagesBicmos InvertersLily SharmaPas encore d'évaluation

- Chemistry Practicals Class 12Document32 pagesChemistry Practicals Class 12Eshan Trivedi40% (5)

- Manual HL R 3830Document52 pagesManual HL R 3830Kent BinkerdPas encore d'évaluation