Académique Documents

Professionnel Documents

Culture Documents

17-Application of Nanotechnology in Understanding Concrete-Anantaramaswamy

Transféré par

Prashant PatilCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

17-Application of Nanotechnology in Understanding Concrete-Anantaramaswamy

Transféré par

Prashant PatilDroits d'auteur :

Formats disponibles

17-Application of Nanotechnology in Understanding Concrete

Profile of Ananth Ramaswamy

Ananth Ramaswamy is Professor in the Department of Civil

Engineering, Indian Institute of Science, Bangalore, India. He has

obtained his B. Tech in Civil Engineering from Indian Institute of

Technology, Madras (IITM) in 1985. He has completed his MS in

Engineering from University of California at Davis in 1986 and obtained

his doctorate in Engineering from Louisiana State University in 1992.

Prior to joining as an Assistant Professor in the Department of Civil

Engineering, IISc, he served as a lecturer in the Department of Civil

Engineering, Indian Institute of Technology, Kharagpur.

Prof. Ananth Ramaswamys research interests comprises various

interdisciplinary subjects, namely, 'Analysis and design of reinforced

concrete structures', 'pre-stressed and fiber reinforced concrete';

'Bridge Engineering'; 'Structural and Shape Optimization'; 'FRP

Composites'; 'Smart Materials and Vibration Control'.

He has

published more than 35 research papers in various international

journals, 2 book chapters and more than 45 national and international

conference papers. He has served as a reviewer for various prestigious

national and international journals.

Seminar Document- REDECON 2010

17-Application of Nanotechnology in Understanding Concrete

Application of Nanotechnology in Understanding

Concrete: An Overview

Prof. Ananth Ramaswamy

Civil Engineering Department

Indian Institute of Science, Bangalore

ananth@civil.iisc.ernet.in

Abstract:

Cement based composites are the most commonly used construction

material primarily because it is cheaper than other materials such as steel

and more readily available. While the strength properties of concrete are

less than steel, the former has the ability to flow as a suspension, take

the shape of the formwork employed and develop into a rigid solid

without external energy inputs. However, the process of hydration is a

complex multistage process comprising several chemical reactions

resulting in many intermediary hydrated products and takes place over a

long time scale. Consequently, understanding and development of

cementitious materials at the macroscopic scale has been one of trial and

error. Nanotechnology or the investigation of physio-chemical processes

at the nanometer scale has opened up the possibility of developing

Cementitious composite construction materials that are durable, and

sustainable, besides offering strength properties that are comparable to

that of steel. Presently, there is a need to control CO2 emissions

(produced by the cement industry) to retard global warming, while

meeting the pressures of rapid infrastructural development offered

effectively only by cement based composite materials. While modest

inroads on global warming have been made by changes in the cement

production process and through the use of cement substitutes like silica

fume and fly ash and recycled aggregates that may partially replace

cement demand, improved understanding of materials at smaller scales is

essential. Development of technologies like Scanning Electron Microscopy

(SEM), Atomic Force Microscopy (AFM), X-ray diffraction (XRD) and micro

/ nano-indentation in the last three decades have made small scale

investigations a reality. Use of micro and nano fibers including carbon

nano tubes (CNTs) in cement based composites has opened new vistas in

the development of alternate materials. The present study will provide a

survey of developments both experimental and analytical covering

aspects of concrete technology.

Overview:

Nanotechnology is the creation of materials and devices by controlling of

matter at the levels of atoms, molecules, and supra-molecular

(nanoscale) structures. In other words, it is the use of every small particle

of material to create new large scale materials (Mann, 2006, Sobolov and

Gutierrez, 2005). The essence of nanotechnology is the size of particles

being manipulated because the properties of materials are dramatically

Seminar Document- REDECON 2010

17-Application of Nanotechnology in Understanding Concrete

altered under a scale of the nanometer (nm), 10-9 meter (m).

Nanotechnology can be used for design and construction processes in

many areas since nanotechnology generated products have many unique

characteristics. These characteristics can, again, significantly fix current

construction problems, and may change the requirement and organization

of construction process resulting in products that are lighter and stronger

structural composites. These products include low maintenance coatings;

improved pipe joining materials and techniques; improved properties of

Cementitious materials; reduced thermal transfer rate of fire retardants

and insulations; enhanced sound absorption of acoustic absorbers; and

increased reflectivity of glass, controlling mechanical properties of

concrete, etc.

Concrete is one of the most common and widely used construction

materials. Its properties have been well studied at macro or structural

level without fully understanding the properties of the cementitious

materials at the micro level. The rapid development of new experimental

techniques makes it possible to study the properties of cementitious

materials at micro / nano-scale. These developments offer an opportunity

to understand the chemistry of hydration, evolve admixtures that result in

accelerating or retarding the set time of concrete, improve the flow ability

while inhibiting segregation of concrete, identify reasons for alkali

aggregate reactions, shrinkage and creep process at atomic / molecular

scale. Use of micro and nano silica in concrete has been observed to

control bleeding in self compacting concrete (Bigley and Greenwood,

2003; Li, 2004). While concrete cracking has been observed and studied

at macro scale extensively, healing technologies are under development

at the nano / micro scale. Similarly the use of rebars and chopped fibers

to enhance the tensile properties of concrete has been well researched at

macro scale. Developments of material at nano scale such as nano fibers,

carbon nano tubes, etc, have opened up the possibility of controlling /

arresting cracking and offer self healing features improving the tensile

characteristics of concrete to the extent of making it more ductile.

Zaki and Ragab (2009) have studied the influence of nano silica and

super-plasticizers on concrete. This study found that the properties of

concrete were improved by the use of nano powders, since nano particles

filled the voids between cement grains and also consumed a part of

calcium hydroxide that resulted in additional formation of calcium silicate

hydrate (C.S.H.) and improvements of interface structure. The study

found that the application of nano SiO2 particles with newly developed

super plasticizer (poly-carboxylic ether polymer based PCE sky) improved

the workability and strength of high performance and self-compacted

concrete since nano-SiO2 interpenetrates polymer network, and causes

the above improvements. The progress from sulphonated polymer to

polycarboxylate resulted in higher water reduction at a given workability,

lower slump loss and (43-48) % higher compressive strengths, according

Seminar Document- REDECON 2010

17-Application of Nanotechnology in Understanding Concrete

to the indicated results. The study indicated that the efficiency of nano

particles such as nano-Si02 depends on their morphology as well as the

application of effective super plasticizers which help to disperse formation

of agglomerates and improve concrete strength. Nan particles, such as

nano silica dioxide (Nano-SiO2) were found to be very effective when

mixed separately with super plasticizer (polycarboxylate base) and then

added to the 20 % remained of mixing water as mentioned in mixing

procedure. Nano-Silica concrete requires additional amount of water or

super plasticizer to maintain the same workability level. Nano-Silica

addition results in significant increase in concrete compressive strength

after 28-days up to one year and the optimum amount of nano silica is

0.5% by weight of cementitious material. Korpa and Trettin (2008) have

also shown the advantages of using nano pozzolans in concrete when

accompanied by microwave curing.

The fundamental causes of concrete creep are still an unresolved

question, and have deceived many attempts, both experimental and

theoretical in nature. While it is widely accepted that the complex creep

behavior of concrete materials is largely related to the visco-elastic

response of the primary hydration product and binding phase of hardened

Portland cement paste, the calciumsilicatehydrate (CSH), the creep

properties of CSH have never been measured directly. CSH

precipitates when cement and water are mixed, as clusters of nanoscale

colloidal particles that cannot be extracted in bulk form suitable for

macroscopic testing. Thus concrete creep properties have been probed on

the composite scale of mortar and concrete and it has been inferred that

it comprises of a short-term volumetric creep and a long-term creep

associated with shear deformation with a creep rate evolving as a power

function t_n of exponent n between 0.9 and 1 (Bazant, 1995). After years

of testing, basic questions persist regarding the physical origin of this

logarithmic creep and its link with microstructure and composition remain.

Statistical nanoindentation technique (SNT) is most suitable for the in situ

investigation of mechanical phase properties and microstructure of highly

heterogeneous hydrated composite materials. An indenter tip (e.g., 3sided pyramid Berkovich tip) is pushed orthogonally to the surface of the

cement paste, and both the load applied to the tip, and the displacement

of the tip with respect to the surface are recorded. By applying

continuum-based constitutive models to the resulting load displacement

curve, mechanical properties of the indented material are determined.

Applied to heterogeneous and multiphase materials, the SNT then

consists of carrying out a large array of such nanoindentation tests, and

by applying statistical deconvolution techniques and micromechanical

models to link microstructure to phase properties. Details of such studies

have been discussed in Constantinides et al 2006, 2007; Cheng 2004;

Famy et al. 2002, Jennings 2004, Jennings et al 2007, Mondol and Shah,

2007, Ulm et al 2004, 2007, and Vandamme et al 2007.

Seminar Document- REDECON 2010

17-Application of Nanotechnology in Understanding Concrete

Nano and micro-electrical mechanical systems (MEMS) sensors have been

developed and their use in construction to monitor and/or control the

environment condition and the materials/structure performance. One

advantage of these sensors is their dimension. Nanosensor ranges from

10-9 m to 10-5m. The micro sensor ranges from 10-4 to 10-2 m. These

sensors could be embedded into the structure during the construction

process. Smart aggregate, a low cost piezo-ceramic-based multifunctional device, has been applied to monitor early age concrete

properties such as moisture, temperature, relative humidity and early age

strength development (Saafi and Romine, 2005; Song, Gu and Mo, 2008).

The sensors can also be used to monitor concrete corrosion and cracking.

The smart aggregate can also be used for structure health monitoring.

Use of nano fibers and carbon nano tubes (CNTs) to both monitor the

structure and to alter properties of the structure are also being explored.

The disclosed system can monitor internal stresses, cracks and other

physical forces in the structures during the structures' life. It is capable of

providing an early indication of the health of the structure before a failure

of the structure can occur.

Closing remarks

Nanotechnology is an emerging area with much to offer by way of

advancements across a wide spectrum of applications. It has great

potential in the understanding and development of concrete products.

This includes characterization at material level covering cement and its

substitution at nano-size and scale, super-plasticizers and other

admixtures, and in the identification of short and long term mechanical

properties of concrete. Nano-sensor technology through development of

smart aggregates, nanofibers and CNTs for health monitoring is yet

another promising area.

References

Bazant ZP, et al. (1995) Creep and shrinkage prediction model for

analysis and design of concrete structuresModel B-3. Mater Struct

28:357365

Bigley C. and Greenwood, P, (2003). Using Silica to Control Bleed and

Segregation in Self-Compacting Concrete Concrete, vol. 37, no. 2, p.4345

Constantinides G, Ravi Chandran KS, Ulm F-J, Van Vliet KJ (2006) Grid

indentation analysis of composite microstructure and mechanics:

Principles and validation. Mat Sc Eng A 430(12):189202.

Constantinides G, Ulm F-J (2007) The nano-granular nature of CSH,

Journal of Mechanics of Physics of Solids, 55:6490

Cheng YT, Cheng CM (2004) Scaling, dimensional analysis, and

indentation measurements, Mater Sci Eng R 44(45):91149.

Korpa and Trettin (2008) Very high early strength of ultra-high

performance concrete containing nano-scale pozzolans using the

Seminar Document- REDECON 2010

17-Application of Nanotechnology in Understanding Concrete

microwave heat curing method, Advances in Cement Research, 20(4)

175-184.

Famy C, Scrivener KL, Atkinson A, Brough AR (2002) Effects of an early

or a late heat treatment on the microstructure and composition of inner

CSH products of Portland cement mortars. Cem Conc Res 32:269278.

Jennings HM (2004) Colloid model of CSH and implications to the

problem of creep and shrinkage, Mater Struct 37:5970.

Jennings HM, Thomas JJ, Gevrenov JS, Constantinides G, Ulm F-J (2007)

A multi-technique investigation of the nanoporosity of cement paste. Cem

Conc Res 37:329 336.

Li, G. (2004) Properties of High-Volume Fly Ash Concrete Incorporating

Nano-SiO2, Cement and Concrete Research, vol.34, pp.1043-1049

Mann, S. (2006) Nanotechnology and Construction, Nano-forum Report,

www.nanoforum.org, May 30, 2008.

Mondal P, Shah SP, Marks L (2007) A reliable technique to determine the

local mechanical properties at the nanoscale for cementitious materials,

Cem Concr Res 37:14401444.

Saafi, M. and Romine, P. (2005) Nano- and Micro-technology Concrete

International, Vol. 27, No. 12, p 28-34.

Sobolev, K. and Gutierrez, M. F. (2005) How Nanotechnology can

Change the Concrete World, American Ceramic Society Bulletin, vol. 84,

no. 10, p. 14-16.

Song, Gl, Gu, H. and Mo,Y. (2008) Smart Aggregates: Multi-Functional

Sensors for Concrete Structuresa Tutorial and a review, Smart

Materials Structures, vol.17.

Ulm F-J, et al. (2007) Statistical indentation techniques for hydrated

nanocomposites: Concrete, bone and shale, J Am Ceram Soc, 90:2677

2692.

Ulm F-J, Constantinides G, Heukamp FH (2004) Is concrete a

poromechanics material? A multi-scale investigation of poro-elastic

properties. Mater Struct 37:435

Vandamme M, Ulm F-J (2006) Viscoelastic solutions for conical

indentation. Int J Solids

Struct 43:31423165

Zaki, S.I. and Ragab, K.S. How Nanotechnology can change the Concrete

Industry, SBEIDCO 1st International Conference on Sustainable Built

Environment Infrastructures in Developing Countries ENSET Oran

(Algeria) - October 12-14, 2009

Seminar Document- REDECON 2010

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Totse Knowledge Thread 4Document14 pagesTotse Knowledge Thread 4negzPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- MS - Tank Cleaning and DesludgingDocument7 pagesMS - Tank Cleaning and DesludgingkoyahassanPas encore d'évaluation

- 1000 Most Common Words in English - Numbers Vocabulary For 1Document12 pages1000 Most Common Words in English - Numbers Vocabulary For 1izmitlimonPas encore d'évaluation

- Design of CanalDocument23 pagesDesign of CanalPrashant PatilPas encore d'évaluation

- Civil Structural Health Monitoring PHD PDFDocument189 pagesCivil Structural Health Monitoring PHD PDFPrashant Patil100% (2)

- Cell Organelles - NotesDocument3 pagesCell Organelles - NotesJay R ChivaPas encore d'évaluation

- Wires and Cables PDFDocument14 pagesWires and Cables PDFRomel Panis88% (8)

- Physics: OxfordDocument224 pagesPhysics: OxfordMusic Life100% (1)

- Ezstim Ii: Operator'S ManualDocument29 pagesEzstim Ii: Operator'S ManualBabajee NavirajPas encore d'évaluation

- 11-Modern Injection Techniques - Himanshu KapadiaDocument16 pages11-Modern Injection Techniques - Himanshu KapadiaPrashant PatilPas encore d'évaluation

- 18-Advancements in Prediction of Wind Loading On Tall Buildings-SureshkumarDocument22 pages18-Advancements in Prediction of Wind Loading On Tall Buildings-SureshkumarPrashant PatilPas encore d'évaluation

- 10-Composite Linings For Ground Support and Permanent LiningDocument15 pages10-Composite Linings For Ground Support and Permanent LiningPrashant PatilPas encore d'évaluation

- Recent Developments in Geotechnical EngineeringDocument10 pagesRecent Developments in Geotechnical EngineeringPrashant PatilPas encore d'évaluation

- Budapest Metro Line 4 Project OverviewDocument23 pagesBudapest Metro Line 4 Project OverviewPrashant PatilPas encore d'évaluation

- 02-Duplex Stainless Steel For Indian Construction and Architecture Application-YpsuriDocument10 pages02-Duplex Stainless Steel For Indian Construction and Architecture Application-YpsuriPrashant PatilPas encore d'évaluation

- Affordable Housing Design PerspectiveDocument5 pagesAffordable Housing Design PerspectivePrashant PatilPas encore d'évaluation

- 06-Self Supporting Roofing System-UmeshlavingiaDocument21 pages06-Self Supporting Roofing System-UmeshlavingiaPrashant PatilPas encore d'évaluation

- 01bandra Worli Sea Link Project-SantoshraiDocument29 pages01bandra Worli Sea Link Project-SantoshraiPrashant PatilPas encore d'évaluation

- 09-Mechanized Shield Tunnelling in Soft Ground-Mark MerrieDocument32 pages09-Mechanized Shield Tunnelling in Soft Ground-Mark MerriePrashant PatilPas encore d'évaluation

- 03-4000mw Mundra Ultra Mega Power Project Brief Overview-BrrangaswamyDocument23 pages03-4000mw Mundra Ultra Mega Power Project Brief Overview-BrrangaswamyPrashant PatilPas encore d'évaluation

- 04 Sustainablehomes SuryaprakashDocument15 pages04 Sustainablehomes SuryaprakashPrashant PatilPas encore d'évaluation

- 16-Geotechnical Earthquake Engineering - TgsDocument11 pages16-Geotechnical Earthquake Engineering - TgsPrashant PatilPas encore d'évaluation

- Profile of Balaji Sreenivasan: 13-Project ManagementDocument22 pagesProfile of Balaji Sreenivasan: 13-Project ManagementPrashant PatilPas encore d'évaluation

- 2013 Act Process To ImplementDocument39 pages2013 Act Process To ImplementPrashant PatilPas encore d'évaluation

- Maharashtra Management of Irrigation Systems by Farmers Act, 2005Document39 pagesMaharashtra Management of Irrigation Systems by Farmers Act, 2005Prashant PatilPas encore d'évaluation

- Tembhu Lift Irrigation Project FeaturesDocument12 pagesTembhu Lift Irrigation Project FeaturesPrashant PatilPas encore d'évaluation

- Citizen Charter 2010Document49 pagesCitizen Charter 2010Prashant PatilPas encore d'évaluation

- Maharashtra Management of Irrigation Systems by Farmers Act, 2005 PDFDocument39 pagesMaharashtra Management of Irrigation Systems by Farmers Act, 2005 PDFPrashant PatilPas encore d'évaluation

- M 1 Bitumen PresentationDocument31 pagesM 1 Bitumen PresentationHarish Kumar MahavarPas encore d'évaluation

- 02conversion TableDocument3 pages02conversion TableravirainbowPas encore d'évaluation

- TembhuDocument44 pagesTembhuPrashant Patil100% (5)

- Maharashtra Ground Water (Regulation For Drinking Water Purposes) Act, 1993Document7 pagesMaharashtra Ground Water (Regulation For Drinking Water Purposes) Act, 1993Prashant PatilPas encore d'évaluation

- Land AcquisitionAct, 1894Document26 pagesLand AcquisitionAct, 1894Prashant PatilPas encore d'évaluation

- Gate SaDocument158 pagesGate SaPrashant PatilPas encore d'évaluation

- I2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionDocument7 pagesI2N65 Series: N-Channel Power MOSFET 12A, 650volts DescriptionMariusPas encore d'évaluation

- Ship EducationDocument34 pagesShip EducationBabu MuruganPas encore d'évaluation

- Exercise 8-Life ScienceDocument2 pagesExercise 8-Life ScienceKarinaPas encore d'évaluation

- Condensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minDocument5 pagesCondensate Treatment AQUAMAT Series: For Compressor Flow Rates Up To 100 M /minBui Hoang DucPas encore d'évaluation

- WP Bdi GB 1000 2012Document10 pagesWP Bdi GB 1000 2012prijepolje72Pas encore d'évaluation

- IV Report 1-1Document11 pagesIV Report 1-1sree lekshmiPas encore d'évaluation

- Cooling Tower Research PaperDocument13 pagesCooling Tower Research PaperBhaskar KumarPas encore d'évaluation

- Physics 219 Practice Exam 1 Multiple Choice QuestionsDocument6 pagesPhysics 219 Practice Exam 1 Multiple Choice QuestionserjayprakashpatelPas encore d'évaluation

- CV Nur Atikah ShaariDocument2 pagesCV Nur Atikah ShaariMuhammad Khairuna SyahPutraPas encore d'évaluation

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDocument6 pagesAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsAvs ElectronPas encore d'évaluation

- SMC1500-2U: Product Data SheetDocument3 pagesSMC1500-2U: Product Data SheetRedes ItcPas encore d'évaluation

- Pratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342Document18 pagesPratt & Whitney Canada: Maintenance Manual MANUAL PART NO. 3034342EstebanPas encore d'évaluation

- CHEMIST LICENSURE EXAM TABLEDocument8 pagesCHEMIST LICENSURE EXAM TABLEJasmin NewPas encore d'évaluation

- Pest of PelDocument7 pagesPest of PelSaqib AkhtarPas encore d'évaluation

- Miroljub Todorović - ApeironDocument25 pagesMiroljub Todorović - Apeiron"Mycelium" samizdat publishersPas encore d'évaluation

- Engineering Physics - G. AruldhasDocument100 pagesEngineering Physics - G. AruldhasJaya sankarPas encore d'évaluation

- Ogjournal20150706 DLDocument136 pagesOgjournal20150706 DLrasyid93Pas encore d'évaluation

- Datasheet GT CT8900Document2 pagesDatasheet GT CT8900Muhammad ImranPas encore d'évaluation

- LevyDocument4 pagesLevyRamon FerreiraPas encore d'évaluation

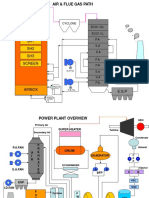

- Air & Flue Gas Path CFBCDocument2 pagesAir & Flue Gas Path CFBCJAY PARIKHPas encore d'évaluation

- Heat Exchangers of PolypropyleneDocument2 pagesHeat Exchangers of PolypropyleneTan So100% (1)

- Shell Gadinia s3 40 PDFDocument2 pagesShell Gadinia s3 40 PDFNatália ValeriaPas encore d'évaluation

- Numerical Study of The Unsteady Aerodynamics of Rotating SeedsDocument6 pagesNumerical Study of The Unsteady Aerodynamics of Rotating SeedsademargcjuniorPas encore d'évaluation