Académique Documents

Professionnel Documents

Culture Documents

Restoration of City Hall, Dublin - Civic Trust Paper

Transféré par

AlanCarolan0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues4 pagesA case study of the restoration of City Hall

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentA case study of the restoration of City Hall

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues4 pagesRestoration of City Hall, Dublin - Civic Trust Paper

Transféré par

AlanCarolanA case study of the restoration of City Hall

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 4

Dublin Civic Trust, 2003

RESTORATION OF CITY HALL

Engineering Aspects

By

Michael Hough And Brian Mahony

A restoration project on City Hall lasting two years was completed in 2000 revealing a splendid example of 18th

century architecture. The building was constructed between 1769 and 1779 following one of the first recorded

instances of an architectural prize where Thomas Cooley succeeded over James Gandon and 60 other entrants. City

Hall predates both the Custom House and the Four Courts.

1768

1769

1798

1800

1814

1851

1852

1852

1866

1898

1915

1916

1922

1922

1926

1998

History of City Hall

One of the first recorded architectural prizes for design

Construction of the Royal Exchange commenced

Temporary military depot by the British authorities

Daniel OConnell spoke against the Act of Union

Original front balustrade collapsed

Royal Exchange purchased by Dublin Corporation

Renamed City Hall. Partitions and South stairs added

First meeting of Dublin City Council

Front balustrade reinstated

Mosaic floor installed

Wall paintings added to rotunda

Garrisoned by insurgents during Easter Rising

Temporary headquarters of Irish Provisional Government

Michael Collins funeral departs

New steel supports to Dome

Major restoration to return to original configuration

The original ground floor consisted of one

space with the central rotunda supported on a

mushroom vaulted structure on the lower ground

floor. Dublin Corporation took possession of the

building in 1851 and converted the ambulatory

surrounding the rotunda into offices by constructing

various walls. To restore the ground floor to its

original single space the nineteenth century walls

were removed below first floor as part of the

restoration. Many of these walls supported chimneys

from lower ground to roof and were retained from

first floor upwards. The flues from these chimneys

had cut through the timbers at first floor, which

supported the original walls at first floor level.

Temporary works were erected to support the upper

level walls and chimneys allowing the ground level

Dublin Civic Trust, 2003

masonry to be removed. Large timbers supporting

the floors were removed at first floor allowing a

system of steel beams to be erected as permanent

supports. Original secondary timbers were cut back

to allow for removal of the main beams and the

erection of the new steels. The support of these

secondary timbers was achieved by extending them to

the main steel with an arrangement of steel angles

saddled each side of the timber. Figures 1 and 2

Figure 1. Steel saddle sketch

Figure 2. Steel Saddle and Splice junction

illustrate this detail.

The Victorian stairs was removed between

ground and first floor and retained above. The

removal of the sub-dividing partitions, raised floors

and the South staircase at ground floor level has

reintegrated the surrounding ambulatories with the

central rotunda.

A new lift was added as part of the

restoration project allowing access to all floors. The

lift is raised and lowered by a single acting ram with

over 10m of travel necessitating a circular shaft

penetrating approximately 13m below lower ground

level. A truly vertical shaft of 320mm diameter was

required to ensure the necessary tolerance for the ram

and a steel liner with a concrete surround forms this.

Due to the limited headroom in achieving access to

the lower ground floor level there was no suitable

drilling rig in the country. A specialist contractor

Figure 3. Panoramic Lift

from the UK was hired to undertake the coring of the

13m deep shaft. With the aid of a custom built rig the

excavation was completed, although after many

breakdowns and difficulties. When the lift pit was

excavated fragments of the old city wall were

discovered forcing a relocation of the drilling rig and

reducing the tolerance in the oversized drilling. The

excavated shaft partially filled with water making the

verticality check very difficult. A steel template of

the required shaft plus clearance for concrete was

made up. A plumb line was dropped from first floor

to the centre of the shaft. The line location was then

recorded at ground level. The steel template was then

lowered into the shaft and with the same support

point checked at ground to ensure no deviation.

The building includes two open well stone

staircases commonly referred to as cantilevered stone

staircases. Over the years settlement of the main

building had caused cracking in the stone treads.

Prior to renovation both of these stairs were supported

in part by beams on cast iron columns, which had

been erected in the mid nineteenth century. Some

steps and landings had cracked through requiring

Figure 4. Analysis of Step

Dublin Civic Trust, 2003

replacement. Initial investigation revealed the steps

were tailed into the wall by approximately 100mm.

This depth of embedment ruled out cantilever action

as a means of support although initial stress

calculations had suggested as much (Figure 4). It was

therefore essential that in each case the lower step

packs with the plywood providing torsional restraint

and vertical support. This is the basic structural

mechanism of the cantilevered stone staircase. Two

types of these stairs exist, one with plain treads and

one with rebated treads.

In the case of cantilevered stairs with plain

treads the lower step in each case provides vertical

support as does the wall. When load is applied to the

step the front corner at the wall tends to lift but is

resisted by the embedment in the wall. This action

generates torsion in the step which increases back to

the wall. Vertical load is transmitted down the flight

Figure 5. Embedment of step

offered some vertical support.

Technical papers reviewing various stairs

and identifying the structural actions involved helped

develop our understanding of the principles. A paper

by Sam Price of Price and Myers gives good

illustration of the structural mechanism involved in

the support of these stairs. In the paper he describes

how during the construction of a staircase made with

second hand railway sleepers cantilevering out of a

Figure 6. Railway sleeper stairs

reinforced concrete wall the discovery was made.

The sleepers were set about 100mm apart to ensure

the required rise and so were completely independent

of each other. When the treads were inserted into

tight fitting opes in the plywood shutter and small

packs provided at the outer edge the treads could

easily support a person.

Investigation of the

structural mechanism involved revealed that vertical

load was transferred from tread to tread through the

Figure 7. Cantilevered stone stairs.

but some amount is also transferred to the wall.

The second type of stairs has rebates

between the steps, generally with the upper steps

notched onto the back of the lower. This rebate

allows horizontal forces to be transmitted between

steps and the resulting couple resists torsion.

Therefore the torsion in rebated steps does not

increase back to the support. The rebated detail also

allows some inclined plate action to act. City Hall's

stairs have rebated treads. We also found that the

detail trapped treads in place and where a step had

failed progressive failure may have been prevented.

A number of the treads in the stairs were

cracked, some close to the wall and others midway

along. Specialist subcontractors replaced the cracked

treads.

The stairs was propped at the step

immediately above the damaged step and the

damaged tread carefully removed. These treads had

originally been fixed into the wall with lead wedged

into the joints to ensure a tight fit. New steps were

matched to the dimensions of the originals and

inserted into place. New sections of stone were

Dublin Civic Trust, 2003

grafted in for the nosings and the cast iron balustrade

was removed and refurbished.

Probably the most intriguing part of the

stairs is the landings where a similar torsional

mechanism is relied upon to provide support but with

the significantly wider landings some bending would

also be expected. Two landings needed to be

replaced due to significant cracking. One of these

landings occurred at a door ope where there was no

wall above to provide the necessary resistance to

torsional forces (Figure 8). This appears to have been

a flaw in the original design and would have

necessitated immediate propping.

In the final

configuration a steel support bracket was erected

below the landing. Landings were erected in two

halves keyed together and leaded (Figure 9). Both

stairs were load tested with 5kN/m2, 125% of the

design imposed load and the deflections were

measured as not exceeding 0.4mm.

City Hall is now a major cultural and tourist

attraction offering exhibitions of Dublin City and

artefacts including the magnificence of the restored

Thomas Cooley building.

Figure 8. Supported Landing

Figure 9. Placing of landing

Project Team

Project Architect

Historic Building Consultant

Structural Engineer

Services Engineer

Contractor

Stonework External

Stonework Internal

Plasterwork

Metalwork

Ronan Boylan, Dublin Corporation

Paul Arnold

Barrett Mahony

PJ Dunphy Engineers

Dunwoody and Dobson

Conservation and Restoration Ltd.

Sanderwood Stone

Andrew Smith and Sean Henderson

Bushy Park Ironwork

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Guide To Protected Structures - LisneyDocument2 pagesGuide To Protected Structures - LisneyAlanCarolanPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Example of A Good BriefDocument1 pageExample of A Good BriefAlanCarolanPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Asbestos: Don't Risk It! Stop & ThinkDocument4 pagesAsbestos: Don't Risk It! Stop & ThinkAlanCarolanPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Arup Reinforcement Detailing ManualDocument4 pagesArup Reinforcement Detailing ManualAlanCarolanPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Sample-Based Approach To Applying For A Disability Access CertificateDocument51 pagesA Sample-Based Approach To Applying For A Disability Access CertificateAlanCarolanPas encore d'évaluation

- Masonry-1-Introduction To Eurocode 6Document8 pagesMasonry-1-Introduction To Eurocode 6udersin100% (1)

- Environmental StatementDocument30 pagesEnvironmental StatementAlanCarolanPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Beginner Student Workbook RevitDocument323 pagesBeginner Student Workbook RevitAlanCarolan100% (7)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- A Core Is A Body of Material, Usually Sand, Used To Produce ADocument12 pagesA Core Is A Body of Material, Usually Sand, Used To Produce AMuhammad AhmadPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Veer 200206Document36 pagesVeer 200206combilPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Main Ingredient in Traditional Acrylic Resin Temporary Materials For Intraoral Fabrication IsDocument4 pagesThe Main Ingredient in Traditional Acrylic Resin Temporary Materials For Intraoral Fabrication IscheliisandiegoPas encore d'évaluation

- Drawing InstrumentsDocument11 pagesDrawing InstrumentsJayWinner100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- 5 Paper MacheDocument10 pages5 Paper Macheapi-215979386Pas encore d'évaluation

- Cpar - Module 2Document13 pagesCpar - Module 2Lester EstoquiaPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Family Album: Photography Versus Memory in Sigfried Kracauser's Writings On PhotographyDocument16 pagesA Family Album: Photography Versus Memory in Sigfried Kracauser's Writings On PhotographyGeraldine TedderPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Aspects of Drama and Dramaturgy: Dramatic Art Dramatic Types Dramatic DevicesDocument48 pagesAspects of Drama and Dramaturgy: Dramatic Art Dramatic Types Dramatic DevicesLüntsüba Quinker Atsa0% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- 55 65听力文本Document81 pages55 65听力文本cccw32518Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Klara and The SunDocument10 pagesKlara and The SunBobby Reddy20% (5)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- A Conversation With The Noise Scenes in PDFDocument29 pagesA Conversation With The Noise Scenes in PDFSteve BessePas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Gec-8 Art Appreciation: Post-Competency ChecklistDocument17 pagesGec-8 Art Appreciation: Post-Competency ChecklistRoselle SambajonPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Kahramaa General Specification of Mainlaying Materials - 2005Document78 pagesKahramaa General Specification of Mainlaying Materials - 2005Lepanto Sakyod100% (1)

- Why Is 3009 Glass UsedDocument3 pagesWhy Is 3009 Glass UsedseajoemathewPas encore d'évaluation

- Berndt RM Berndt CH The World of The First Australians An inDocument574 pagesBerndt RM Berndt CH The World of The First Australians An inronwerter6Pas encore d'évaluation

- Dwnload Full South Western Federal Taxation 2016 Comprehensive 39th Edition Hoffman Solutions Manual PDFDocument36 pagesDwnload Full South Western Federal Taxation 2016 Comprehensive 39th Edition Hoffman Solutions Manual PDFcatholeshrineuxsl100% (13)

- Ancient AstronautsDocument2 pagesAncient AstronautsRichard Cassaro100% (1)

- Ideal Home - Complete Guide To Christmas 2016 PDFDocument148 pagesIdeal Home - Complete Guide To Christmas 2016 PDFpetru555100% (2)

- Dargah PresentationDocument19 pagesDargah PresentationAlapati Lakshmi KumarPas encore d'évaluation

- CultureDocument55 pagesCultureRajiv KumarPas encore d'évaluation

- Ancient Greek ArtDocument42 pagesAncient Greek Artkarina AlvaradoPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

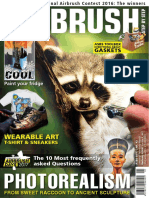

- Airbrush Step by Step - January-March 2017 English EditionDocument68 pagesAirbrush Step by Step - January-March 2017 English EditionAnonymous Xm1OjrJzqy100% (1)

- Bach OzdobnikiDocument24 pagesBach OzdobnikiDorota Kowalska100% (1)

- Alan Manken PowerpointDocument20 pagesAlan Manken Powerpointapi-265979570Pas encore d'évaluation

- Noua Specificatie Enel-MecaDocument61 pagesNoua Specificatie Enel-MecaAnne KelleyPas encore d'évaluation

- The History of Aborigine Ogboni FraternityDocument6 pagesThe History of Aborigine Ogboni Fraternitymarioa_3Pas encore d'évaluation

- Animation Lesson 1 - Intro TLPDocument2 pagesAnimation Lesson 1 - Intro TLPJanella KhatePas encore d'évaluation

- Ooooooo Oooooooooo 789Document6 pagesOoooooo Oooooooooo 789Ali Ozan MemetoğluPas encore d'évaluation

- Project Types PDFDocument14 pagesProject Types PDFSmita ShrawgePas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)