Académique Documents

Professionnel Documents

Culture Documents

API2000 Tank Calcs

Transféré par

HuzefaFDDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

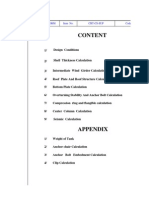

API2000 Tank Calcs

Transféré par

HuzefaFDDroits d'auteur :

Formats disponibles

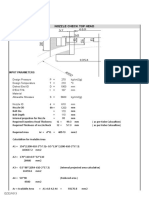

Tank shell fit for purpose calculations

Company

Hydrotestic test conditionsWater density

Tank Id

Design code

Shell Material

Tank diameter

Tank height

Design pressure

No. shell courses

Filling height

D

H

Pd

m

m

24.40

13.20

mbar

20.00

7

top

The following formula is used in calculating

the required minimal thickness of shell

courses:

t m in

bottom

Course

Product

No.

height

height

Minimum Allowable

kg/l

1.00

12.80

Joint

calc.

Installed

measured

Minimal

Integrity

Yield

Stress

Efficiency

thickness

thickness

thickness

check

factor

Factor

incl. CA

[m]

[m]

[ N/mm2]

1.89

1.49

210

0.667

6

5

1.89

1.89

3.37

5.26

210

210

0.667

0.667

4

3

1.89

1.89

7.14

9.03

210

210

2

1

1.89

1.89

10.91

12.80

210

210

per DEP

[mm]

[mm]

[mm]

[mm]

1.00

1.19

6.00

6.00

3.00

OK

1.00

1.00

2.80

4.41

6.00

6.00

6.00

6.00

3.00

4.41

OK

OK

0.667

0.667

1.00

1.00

6.02

7.62

7.00

8.00

7.00

8.00

6.02

7.62

OK

OK

0.667

0.667

1.00

1.00

9.23

10.84

10.00

11.00

10.00

11.00

9.23

10.84

OK

OK

Product density

kg/l

0.75

Max fill height

12.80

13.20

D

98 . .( h 0.3) p CA

20 .S D .E

S = maximum allowable stress in N/mm2 (see 5.7)

E = joint efficiency factor

H = height from the lower edge of the course under

consideration to the top of the shell in metres

D = nominal diameter of tank in metres

p = design pressure in mbar (ga)

CA = corrosion allowance in mm (for special cases

only, to be specified in requisition; normally zero)

w = maximum density of product to be stored in g/ml

(a value of 1.00 shall be used even where the product

to be stored is lighter)

Course

Product conditions:

top

k=0.67 (new) or 0.8(fit for purpose)

bottom

Course

Course

Product

No.

height

height

Minimum Allowable

Joint

calc.

Installed

measured

Minimal

Integrity

Yield

Stress

Efficiency

thickness

thickness

thickness

check

factor

Factor

incl. CA

[m]

[m]

[ N/mm2]

7

6

1.89

1.89

1.49

3.37

210

210

0.67

0.67

5

4

3

1.89

1.89

1.89

5.26

7.14

9.03

210

210

210

2

1

1.89

1.89

10.91

12.80

210

210

per DEP

[mm]

[mm]

[mm]

[mm]

1.00

1.00

0.93

2.14

6.0

6.0

6.0

6.0

3.00

3.00

OK

OK

0.67

0.67

0.67

1.00

1.00

1.00

3.35

4.55

5.76

6.0

7.0

8.0

6.0

7.0

8.0

3.35

4.55

5.76

OK

OK

0.67

0.67

1.00

1.00

6.97

8.18

10.0

11.0

10.0

11.0

6.97

8.18

OK

OK

OK

Compression Ring calculations

Calculation for compression area as required (BS2654, section 8.5.2) :

Tank diameter

D

m

Tank radius

R

m

Tank height

H

m

Design pressure

p

mbar

Design windspeed

Vw

m/s

T52

24.40

12.20

13.20

20.00

45.00

Allowable compressive stress

Sc

N/mm2

120.00

Roofplate thickness (annular)

SG(density) of steel

deadload roof plates

tr

mm

kg/m3

mbar

5.00

7850.00

3.93

kg/m2

slope

degr

11.30

slope 1:5

Ar

mm2

4989

tr

ts

mm

5.00

Wh =

335

mm

6.00

62.27

Wc =

162

mm

1674

Roof slope

Required compression area

Calculation for section area as avaialble :

WT Roofplates

WT Top Course

Radius of roof curvature

R2

mm

m

Area D (Roof Wh)

AD

mm2

unless other wise specified

39.25

50. p.R 2

S C .TAN ( )

, with p less roof weight

T o p C u rb 1

R o o f s lo p e 1 : 5

WT

Area of angle 1

150

150

10

Area of angle 2

Area C (shell Wc)

Available compression area (Aac=AD+An+AC)

Conclusion :

AT1

mm2

2900

AT1

mm2

AC

mm2

974

Aa

mm2

5548

approx.

T o p C u rb 2

R a d iu s

Aa>Ar, L-Profile is OK!

Maximum internal pressure

Maximum design pressure

Wc

TopCurb Angle

Pd

W T

mbar

24.5

s h e ll

See API650, section F.4.1.

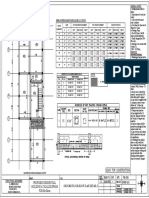

Wind Load Condition

see BS2654, section 7.3.2.7

Tank diameter

Tank height

D

H

Vw

design wind speed

design vacuum

Calc. Factor

Top course thickness-CA

H e=hcourse

Va

K

tmin

t min

t

m

m

24.40

13.20

m/s

mbar

m

45.00

6.00

8.883

6.00

95000

3 .563 V

H p =K

Course

Course

No.

height

hc[m]

thickness

t [mm]

7

6

5

4

3

2

1

1.89

6.00

1.89

6.00

1.89

6.00

1.89

7.00

1.89

8.00

1.89

10.00

bottom

1.89

11.00

sum(transposed)

Max permitted spacing (unstiffed)

Min. No. of secondary wind girders required

Other shapes with equivalent section

modulus may be used. The section

modulus may include a portion of the

shell for a distance of 16 times shell

plate thickness above and below the

stiffener.

Course

He

Cummel.

Transposed

[m]

width [m]

1.89

1.89

1.89

1.28

0.92

0.53

0.41

8.80

6.499

1.00

8.80

6.91

5.03

3.14

1.86

0.94

0.41

top

2 +580 v a

5

min

3

DEP 70.51.10.11-Gen.Use for Va: 2.5 mbar (ga) for non-pressure fixed

roof tanks; 5.0 mbar (ga) for open top floating roof tanks; 6.0 mbar (ga)

for low and high pressure fixed roof tanks / BS2654, section 7.3.2.6 Use

for Va: 5 mbar (ga) for non-pressure; 8.5 mbar for other

H E = H e

K=

Design vacuum

No. of windgirders installed

Tank diameter

(m)

MIN Stiffener

size

(mm)

D 20

20 D 36

36 D 48

48 > D

100 x 65 x 8

125 x 75 x 8

150 x 90 x 10

200 x 100 x 12

HE

Hp (H1)

OK!

Tank Venting Calculations API2000

Data Given :

Diameter

Height

7.6

7.6

m

m

25

25.0

ft

ft

Tank capacity

Code

Design pressure

Design vacuum

Flash point product

347

Low

20

6

176

m3

Pressure

mbar

mbar

2185

Low

8.03

2.41

349

barrels

Pressure

inch w.c.

inch w.c.

Max pump-in rate

Max pump-out rate

80

20

Tank insulated ?

Hot Climate

N

no

0

mm

182

m2

Insulation thicknes

Environmental factor

Wetted area

metric

U.S.

C

m /hour

o

m3/hour

503

126

N

no

0

1

1964

F

barrels/h

barrels/h

o

inch

ft

SCFH = Standard Cubic Feet of air per Hour

(1) Normal outbreathing (Pressure relief) requirements:

Required venting capacity for normal pressure relief due to pumping-in

Required capacity= (6xSCFH )x(Max pump-in rate)

Required capacity=

3018

SCFH

Required venting capacity for normal pressure relief due to thermal outbreathing

see table II-collumn 3 of API2000, 2.4.2 for product with flash point >100 oF (INTERMEZZO-I)

Required capacity=

1312

SCFH air

Total required normal pressure relief capacity

=

3018

1312

4330

123

SCFH air

m3/hour

(2) Normal inbreathing (Vacuum relief) requirements:

Required venting capacity for normal vacuum relief due to pumping-out

Required capacity= (5.6 SCFH)x(Max pump-out rate)

Required capacity=

704

SCFH

Required venting capacity for normal vacuum relief due to thermal inbreathing

see table II-collumn 2 of API2000, 2.4.2

Required capacity=

2185

SCFH air

Correction for climate

2185

if applicable

Total required normal vacuum relief capacity

=

704

2185

2890

82

(3) Emergency venting

Emergency venting required in accordance with API 2000, section 4.3.3.2, Table 3

Required capacity Q=

-3809

m3/hour (incl. the environmental factor)

-134194 SCFH air

SCFH air

m3/hour

Tank Venting Calculations API2000

Data Given :

Diameter

Height

24.0

14.5

m

m

79

47.4

ft

ft

Tank capacity

Code

Design pressure

Design vacuum

Flash point product

6537

Low

20

6

-40

m3

Pressure

mbar

mbar

41111

Low

8.03

2.41

-40

barrels

Pressure

inch w.c.

inch w.c.

Max pump-in rate

Max pump-out rate

900

900

Tank insulated ?

Hot Climate

Insulation thicknes

Environmental factor

Wetted area

metric

U.S.

C

m /hour

o

m3/hour

N

no

0

mm

689

m2

5659

5659

N

no

0

1

7419

F

barrels/h

barrels/h

o

inch

ft

SCFH = Standard Cubic Feet of air per Hour

(1) Normal outbreathing (Pressure relief) requirements:

Required venting capacity for normal pressure relief due to pumping-in

Required capacity= (12xSCFH )x(Max pump-in rate)

Required capacity= 67914

SCFH

Required venting capacity for normal pressure relief due to thermal outbreathing

see table II-collumn 3 of API2000, 2.4.2 for product with flash point >100 oF (INTERMEZZO-I)

Required capacity= 34926 SCFH air

Total required normal pressure relief capacity

= 67914

34926

102840

2919

SCFH air

m3/hour

(2) Normal inbreathing (Vacuum relief) requirements:

Required venting capacity for normal vacuum relief due to pumping-out

Required capacity= (5.6 SCFH)x(Max pump-out rate)

Required capacity= 31693

SCFH

Required venting capacity for normal vacuum relief due to thermal inbreathing

see table II-collumn 2 of API2000, 2.4.2

Required capacity= 34926 SCFH air

Correction for climate 34926 if applicable

Total required normal vacuum relief capacity

= 31693

34926

66619

1891

(3) Emergency venting

Emergency venting required in accordance with API 2000, section 4.3.3.2, Table 3

Required capacity Q=

19910

m3/hour (incl. the environmental factor)

701353 SCFH air

SCFH air

m3/hour

Vous aimerez peut-être aussi

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraPas encore d'évaluation

- Dps-3-1206-013-E1782-A4-2 (Final)Document449 pagesDps-3-1206-013-E1782-A4-2 (Final)Siva baalanPas encore d'évaluation

- Maz - Design - Separator Capacity EvaluationDocument5 pagesMaz - Design - Separator Capacity EvaluationNaeem HussainPas encore d'évaluation

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- Design of 5 Tons Capacity Cone Bottom STDocument26 pagesDesign of 5 Tons Capacity Cone Bottom SThgagselim2012Pas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagPas encore d'évaluation

- Toyo - Heat Exchanger-1Document70 pagesToyo - Heat Exchanger-1alokbdas100% (1)

- Heat Transfer in Jacketed Vessels: Customary US SIDocument60 pagesHeat Transfer in Jacketed Vessels: Customary US SIDHAVALESH AMPas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument14 pagesStorage Tank Design Calculation - Api 650: Close Floating Roofhgagselim2012Pas encore d'évaluation

- V-710 CPRP-7Document22 pagesV-710 CPRP-7balajikrishnanPas encore d'évaluation

- TBE Inlet Separator V 2100 FLNG2Document6 pagesTBE Inlet Separator V 2100 FLNG2halipzramlyzPas encore d'évaluation

- Design of Welded Steel Storage Tanks in Accordance With API650 Job DataDocument4 pagesDesign of Welded Steel Storage Tanks in Accordance With API650 Job DatamirzacogoPas encore d'évaluation

- ASMEDocument10 pagesASMESalvador MalagoPas encore d'évaluation

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarPas encore d'évaluation

- Open TankDocument27 pagesOpen Tankhgagselim2012Pas encore d'évaluation

- API 650 Tank Design 5Document31 pagesAPI 650 Tank Design 5gon972001Pas encore d'évaluation

- DJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDocument37 pagesDJM MBA PCS CA 007 Deethanizer Reboiler E 1401 Rev BDIANTOROPas encore d'évaluation

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- CALIB053 - Mathcad 15 EquationsDocument8 pagesCALIB053 - Mathcad 15 Equationsilie_vlassaPas encore d'évaluation

- 302 - Nozzle Design Tool Ver E4.01Document2 pages302 - Nozzle Design Tool Ver E4.01Honey TiwariPas encore d'évaluation

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedPas encore d'évaluation

- Steam Pressure DropDocument8 pagesSteam Pressure DropDavid Muñoz CastroPas encore d'évaluation

- Bectel ASME Process Cal R2Document21 pagesBectel ASME Process Cal R2Sivakumar SelvarajPas encore d'évaluation

- Erosion Velocity CalculationsDocument9 pagesErosion Velocity CalculationsMANISH GUPTAPas encore d'évaluation

- ETHANOL (6.0D X 8.825 H), Rev. 0Document26 pagesETHANOL (6.0D X 8.825 H), Rev. 0Sangramkeshari BejaPas encore d'évaluation

- Absorption Column CalcDocument65 pagesAbsorption Column CalcCHANADASPas encore d'évaluation

- WS-CA-PR-024 - Atmospheric & Low Preesure Tank VentingDocument4 pagesWS-CA-PR-024 - Atmospheric & Low Preesure Tank Ventinghhvg100% (1)

- Art - 'S TEMA DesignationsDocument4 pagesArt - 'S TEMA Designationsmuhammad_asim_10Pas encore d'évaluation

- Mechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Document38 pagesMechanical Calculation For Crude Oil Storage Tanks (TK-6001 6020)Hamid MansouriPas encore d'évaluation

- Fresh HDO Storage TankDocument42 pagesFresh HDO Storage TankHgagselim SelimPas encore d'évaluation

- Nozzle & FlangeDocument14 pagesNozzle & FlangeRaghPas encore d'évaluation

- THK Design CalculationDocument3 pagesTHK Design CalculationalexnomitaPas encore d'évaluation

- Acrobat Document2 PDFDocument15 pagesAcrobat Document2 PDFKhepa BabaPas encore d'évaluation

- Stress at Junction of Shell & HeadDocument13 pagesStress at Junction of Shell & HeadRey Fiedacan100% (2)

- Nozzle Check Top Head: Input ParametersDocument2 pagesNozzle Check Top Head: Input ParametersRaj Sharma100% (1)

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniPas encore d'évaluation

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinPas encore d'évaluation

- Braced Legs ClaculationsDocument2 pagesBraced Legs Claculationssumit_waghmarePas encore d'évaluation

- D9.03XLS Storage Tank Heating Design - GGGGGDocument3 pagesD9.03XLS Storage Tank Heating Design - GGGGGBarmar Sbahi0% (1)

- Sp-210-E-103 Rev 0Document7 pagesSp-210-E-103 Rev 0Natarajan RavisankarPas encore d'évaluation

- Pressure Vessel Design 2018 VER BDocument61 pagesPressure Vessel Design 2018 VER BBob FitcherPas encore d'évaluation

- Calculation of Heat and Mass BalanceDocument16 pagesCalculation of Heat and Mass BalanceHEMANTPas encore d'évaluation

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraPas encore d'évaluation

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDocument4 pagesVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinPas encore d'évaluation

- Self-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document29 pagesSelf-Supported Cone Roof: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)amokhta0% (1)

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Top Pipe MomentDocument2 pagesTop Pipe Momentrsubramani100% (1)

- U-Tube Heat Exchanger Design: Tubes SpecDocument8 pagesU-Tube Heat Exchanger Design: Tubes SpecVipul SharmaPas encore d'évaluation

- Weight Estimation of Vessels AppsDocument26 pagesWeight Estimation of Vessels Appsdhavalesh1Pas encore d'évaluation

- Calculation Cover SheetDocument6 pagesCalculation Cover SheetAnonymous a4Jwz14WPas encore d'évaluation

- PT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsDocument7 pagesPT System (2500 m3/hr) (Check The Flow) : Gravity Line CalculationsAnshuman ChoudhuryPas encore d'évaluation

- API2000 Tank Venting CalcsDocument5 pagesAPI2000 Tank Venting Calcsapminshull88% (8)

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarPas encore d'évaluation

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBo100% (1)

- Ductulator May 2010Document10 pagesDuctulator May 2010Arshavin Watashi WaPas encore d'évaluation

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument31 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofNguyễn Duy HưngPas encore d'évaluation

- Maximum PressureDocument83 pagesMaximum Pressureanhhung80Pas encore d'évaluation

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalPas encore d'évaluation

- W2 - Fundementals of SepDocument36 pagesW2 - Fundementals of Sephairen jegerPas encore d'évaluation

- CPhI Japan InformationDocument22 pagesCPhI Japan InformationctyvtePas encore d'évaluation

- The Benefits of RunningDocument1 pageThe Benefits of Runningefendi odidPas encore d'évaluation

- TC 000104 - VSL MadhavaramDocument1 pageTC 000104 - VSL MadhavaramMK BALAPas encore d'évaluation

- Lead Avr PDFDocument9 pagesLead Avr PDFsiddharthPas encore d'évaluation

- Community Medicine DissertationDocument7 pagesCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Sindh Rescue 1122 Test Sample PapersDocument12 pagesSindh Rescue 1122 Test Sample PapersMAANJONY100% (1)

- Test Questions For Oncologic DisordersDocument6 pagesTest Questions For Oncologic Disorderspatzie100% (1)

- Practice Problems Mat Bal With RXNDocument4 pagesPractice Problems Mat Bal With RXNRugi Vicente RubiPas encore d'évaluation

- Site Quality ManualDocument376 pagesSite Quality ManualsPas encore d'évaluation

- Workshop Manual Transporter 2016 19-29Document157 pagesWorkshop Manual Transporter 2016 19-29samuelePas encore d'évaluation

- BS7-Touch Screen PanelDocument96 pagesBS7-Touch Screen PanelEduardo Diaz Pichardo100% (1)

- Extraordinary GazetteDocument10 pagesExtraordinary GazetteAdaderana OnlinePas encore d'évaluation

- Coles Recipe MagazineDocument68 pagesColes Recipe MagazinePhzishuang TanPas encore d'évaluation

- Kenwood Report FinalDocument43 pagesKenwood Report Finaltooba siddiquiPas encore d'évaluation

- Cash and Cash Equivalents ReviewerDocument4 pagesCash and Cash Equivalents ReviewerEileithyia KijimaPas encore d'évaluation

- FRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012Document19 pagesFRM Valuation & Risk Models Dowd, Chapter 2: - Hosted by David Harper Cfa, FRM, Cipm - Published April 22, 2012BeastPas encore d'évaluation

- Creamy and Thick Mushroom Soup: IngredientsDocument8 pagesCreamy and Thick Mushroom Soup: IngredientsSheila Mae AramanPas encore d'évaluation

- G.f.roof Beam & Slab DetailDocument1 pageG.f.roof Beam & Slab Detailahmad anasPas encore d'évaluation

- High CarbonDocument2 pagesHigh CarbonKarisoPas encore d'évaluation

- BARCODESDocument7 pagesBARCODESChitPerRhosPas encore d'évaluation

- PowderCoatingResins ProductGuide 0Document20 pagesPowderCoatingResins ProductGuide 0zizitroPas encore d'évaluation

- Photoperiodism Powerpoint EduDocument12 pagesPhotoperiodism Powerpoint EduAlabi FauziatBulalaPas encore d'évaluation

- 2017 LT4 Wiring DiagramDocument10 pages2017 LT4 Wiring DiagramThomasPas encore d'évaluation

- Lohmann GuideDocument9 pagesLohmann GuideRomulo Mayer FreitasPas encore d'évaluation

- Human Rights Law - Yasin vs. Hon. Judge Sharia CourtDocument7 pagesHuman Rights Law - Yasin vs. Hon. Judge Sharia CourtElixirLanganlanganPas encore d'évaluation

- RestraintsDocument48 pagesRestraintsLeena Pravil100% (1)

- Sonesse 30 Databook NewestDocument32 pagesSonesse 30 Databook Newestsunii19847908Pas encore d'évaluation

- Durock Cement Board System Guide en SA932Document12 pagesDurock Cement Board System Guide en SA932Ko PhyoPas encore d'évaluation

- Rar Vol11 Nro3Document21 pagesRar Vol11 Nro3Valentine WijayaPas encore d'évaluation