Académique Documents

Professionnel Documents

Culture Documents

Falcon c1000

Transféré par

jlfyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Falcon c1000

Transféré par

jlfyDroits d'auteur :

Formats disponibles

FALCON CONTINUOUS CONCENTRATOR

Model C1000

INSTALLATION, OPERATIONS AND MAINTENANCE MANUAL

(INCLUDING SUPPORT MANUALS / DOCUMENTATION)

MINSUR SA

Cancha 35 Project

Sepro Contact Details:

Telephone:

Fax:

Email:

Sepro Mineral Systems Corp.

Unit 101A 9850 201st Street

Langley, British Columbia

Canada, V1M 4A3

(+1) (604) 888-5568

(+1) (604) 888-5521

service@seprosystems.com

C1000-R3.1

Installation, Operations and Maintenance Manual

CLIENT NAME

Minsur SA

PROJECT

Cancha 35 Project

EQUIPMENT TYPE

C1000 Concentrator

PROJECT REFERENCE NO

26438

EQUIPMENT SERIAL NO(S)

C1000-1491, 1492

AUTOPAC SERIAL NO(S)

E830018

EQUIPMENT LOCATION

Peru

PURCHASE ORDER NO

4600017597

MANUAL VERSION

C1000-R3.1

SHIPPING DATE

October 2015

Client Notes:

Sepro Mineral Systems Corp.

Dear Valued Customer,

We would like to take this opportunity to thank you for choosing Sepro Mineral Systems Corporation to supply

your mineral processing equipment.

Sepro has been in the business for decades, and has the expertise, people power, and experience to solve even the

most difficult recovery applications. Our equipment has enriched the operations of small scale artisanal miners to

the largest mining sites of the world.

We are dedicated to the performance of our equipment and provide after sale service and support in order to

ensure that our products run smoothly and efficiently. Our knowledgeable and experienced personnel are

available to contact any time via email and telephone to support the function of our equipment.

We look forward to working with you on this project and any future endeavors you may have.

Yours sincerely,

Dave Hornick

VP-Sales

Sepro Mineral Systems Corp.

Office Telephone: 1.604.888.5568

Website: www.seprosystems.com

C1000-R3.1

Installation, Operations, and Maintenance Manual

Before placing the machine on flooring other than a concrete base, a qualified engineer must ensure the

floor can carry the relevant loads.

Maintenance/repair work should be carried out by trained personnel familiar with the maintenance

instructions. They should also be aware of the nearest firefighting equipment, first aid equipment and

the quickest and safest route for leaving the equipment in case of emergency.

Where a Permit to Work system is in force, this should be complied with.

Safety Precautions General

Temporary guarding or scaffolding used while servicing plant MUST be to standards laid down in

relevant Statutory Regulations.

Personnel MUST only use designated access and walkways.

Keep all access and walkways clear and free from any obstructions.

ALL lifting tackle must be approved and tested to withstand loads to be raised as laid down in relevant

Statutory and Site Regulations.

Before placing any machinery on flooring, access or walkway, a qualified engineer must be consulted

regarding the load carrying properties of the relevant floor area.

Sepro Mineral Systems Corp.

C1000-R3.1

Installation, Operations, and Maintenance Manual

Safety

WARNING: Injury to personnel will result if the procedures outlined in this manual are not

followed.

In the interest of personal safety and care of the machine, we strongly recommend the following safety

instructions be carried out.

Authorization

Operating and maintenance work should be carried out according to Health & Safety and Site

Regulations. All maintenance procedures carry their own level of risk. Properly trained personnel should

carry out necessary risk assessments and be able to recognize safety hazards.

Personnel wishing to operate, or adjust the equipment, should first have permission from the recognized

authority or senior personnel. A Permit-to-Work system, correctly implemented, will ensure that the

necessary precautions are taken to make the safe for maintenance or repair work, and so forth.

Routine Maintenance

WARNING: Before working on any part of the equipment it is essential that it is isolated

mechanically and electrically.

The following precautions should be observed when maintenance is carried out on the equipment:

Isolate electrical power by switching off and electrically locking out and isolating the starter; taking

into account of residual voltage from VFD inverters and so forth.

Ensure suitable warning notices are displayed indicating that maintenance work is being carried out.

Warning notices must be displayed indicating that maintenance work is being carried out.

Wear protective equipment, e.g. hard hats, overalls, steel toed boots, gloves, hearing protection and eye

protection at all times of operation and maintenance.

Wear efficient respirator in dust laden areas.

DO NOT operate machinery without guards securely in place.

Lifting tackle must be approved and tested to withstand the required loads.

Safety blocks MUST be fitted when equipment is raised before working under the equipment.

Sepro Mineral Systems Corp.

C1000-R3.1

Installation, Operations, and Maintenance Manual

Sepro Mineral Systems Corp. Equipment Warranty

Sepro equipment is tested and inspected before leaving the factory. Our equipment is warranted to be free

from defects in material or workmanship for a period of 18 months from the date of shipment or 5,000

operating hours, whichever comes first. This warranty is limited to the repair or replacement of parts other

than designated wear parts when operated and maintained properly in accordance with the owners manual.

In no event shall Sepro be liable for any direct, indirect, incidental or consequential damages resulting from

the sale or use of the product during or after the term of this warranty.

Sepro Warranty Return Policy

Return Defective Parts: To obtain warranty service during the warranty period, notify Sepro and return

parts (freight prepaid) to Sepro for inspection. If problem is caused by defects in material or workmanship

then Sepro will repair or at our option, replace the defective part.

Order Emergency Replacements: If required in emergency situations where no suitable spare parts are on

site, a replacement part may be ordered from Sepro (and shipped from closest inventory stock to avoid

down-time) while failed parts are being returned to Sepro for evaluation by Sepro or its suppliers for

possible warranty repair or replacement (or credit at customers request). It is strongly recommended that

critical parts be carried as spares on site by the customer as per the owners manual.

Transportation Costs: All shipping, duty or related costs associated with warranty claims to transport the

parts to/from Sepro factory are the responsibility of the customer.

Entire Written Warranty

This warranty is expressly made by Sepro Mineral Systems Corp. and accepted by purchaser by act of

purchase in lieu of all other warranties, including warranties of merchantability and fitness for particular

purpose, weather written, oral, expressed, implied or statutory. Sepro neither assumes, nor authorizes any

other person, employee, associate or agent to assume for it any other liability with respect to its equipment

or designs. Sepro shall not be liable for normal wear and tear nor any contingent, incidental or

consequential damage or expense due to partial or complete inoperability of its equipment for any reason

whatsoever.

This warranty is entirely contingent upon buyers cooperation in returning parts to Sepro and permitting

inspection (by Sepro or original manufacturer) to investigate defects prior to repair or replacement of parts.

Warranty parts may be subject to pro-rata charge based upon Sepros estimate of normal service life

realized from the part.

This warranty shall not apply to equipment or parts thereof that have been altered or repaired outside of the

Sepro factory, or damaged by improper installation, application or subject to misuse, abuse, neglect or

accident. Commissioning or service by third party other than Sepro could void warranty if not carried out

correctly.

Sepro makes no warranty and accepts no liability with respect to equipment, parts, components or

accessories supplied by Sepro but manufactured by others. The warranty which applies is that offered by

their respective manufactures as facilitated by Sepro.

Sepro Mineral Systems Corp.

C1000-R3.1

Installation, Operations, and Maintenance Manual

Document Conventions

Throughout this manual the words CAUTION, WARNING, and NOTE are used to indicate procedures and

areas of maintenance and operations which require operator attention and focus.

Users of this manual must familiarize themselves with these indicators before attempting to install, operate,

or maintain Sepro Equipment.

The following explains each type of label:

Caution: An operating procedure or practice which, if not correctly followed could result in

damage or destruction of equipment and property.

WARNING: An operating procedure or practice which, if not followed could result in

personal injury or loss of life.

Note: An operating procedure, condition which is essential to observe.

Sepro Mineral Systems Corp.

C1000-R3.1

Installation, Operations, and Maintenance Manual

Change Log

Revision

Date

Sections/Pages

Affected

Remarks

3.1

August 2015

All

Revised Format

Front Material Added

Sepro Mineral Systems Corp.

C1000-R3.1

Installation, Operations, and Maintenance Manual

2015 Sepro Mineral Systems Corp.

All rights reserved.

Printed in Canada

Revision Number 3.1 (08/1/2015)

This document is provided to Sepro clients for informational and training use only. Sepro clients may make

printed or electronic copies for the sole purpose of use and distribution among their own users.

The information and illustrations in this document are private and confidential belonging to Sepro Mineral

Systems Corp. Except for the above provision, no part of this document may be reproduced, transmitted,

transcribed or stored in a retrieval system in any form and by any means, electronic, mechanical and

otherwise without the prior written permission of Sepro Mineral Systems Corp.

The information in this document is provided for information use only and is subject to change without

notice. Information in this document has been carefully checked and is believed to be accurate. However,

Sepro Mineral Systems Corp. assumes no responsibility or liability for errors or inaccuracies that may be

contained in this document or in the use to which it may be put.

All third-party trademarks, trade names or company names that appear in this document are used for

identification and reference only and are the property of their respective owners.

Customer Care:

Sepro Mineral Systems Corp.

Unit 101A 9850 201 Street

Langley, British Columbia, Canada V1M 4A3

Office: [1] 604.888.5568

Fax: [1] 604.888.5521

Toll Free: + [1] 800.990.5568

North America

Web: www.seprosystems.com

Email: service@seprosystems.com

Sepro Mineral Systems Corp.

Vous aimerez peut-être aussi

- Ws Tyler Uml Class PartsDocument4 pagesWs Tyler Uml Class Partsyolimar escorciaPas encore d'évaluation

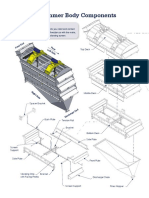

- H-Class / Hummer Body Components: How Do I Order?Document2 pagesH-Class / Hummer Body Components: How Do I Order?yolimar escorciaPas encore d'évaluation

- Valu King Screen 1Document3 pagesValu King Screen 1RAUL PEREZ NEGREIROSPas encore d'évaluation

- Excel Crusher Foundation ReviewDocument46 pagesExcel Crusher Foundation ReviewJonathan Pareja vasquezPas encore d'évaluation

- HEWITT, Dual 2e13 FeederDocument64 pagesHEWITT, Dual 2e13 FeederCarlos anderson Sossa ChaverraPas encore d'évaluation

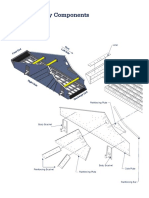

- S-Class Ty-Speed Body PartsDocument6 pagesS-Class Ty-Speed Body Partsyolimar escorciaPas encore d'évaluation

- Simu Presentacion Exam3Document1 pageSimu Presentacion Exam3Edwin Barboza DuranPas encore d'évaluation

- General Instructions: For Installation and MaintenanceDocument71 pagesGeneral Instructions: For Installation and MaintenanceWilliam VillamizarPas encore d'évaluation

- Hewitt (Nordberg), Floatex ShakeoutDocument34 pagesHewitt (Nordberg), Floatex ShakeoutCarlos anderson Sossa ChaverraPas encore d'évaluation

- Manual PartsDocument125 pagesManual PartsAlejandro AguirrePas encore d'évaluation

- Terex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsDocument6 pagesTerex Simplicity Vibrating Feeders: Terex Minerals Processing SystemsestramilsolutionPas encore d'évaluation

- TC15 SparepartsDocument89 pagesTC15 Sparepartseaglego00Pas encore d'évaluation

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyPas encore d'évaluation

- sw100 200Document3 pagessw100 200HansSalasPas encore d'évaluation

- Liner Development Process SummaryDocument3 pagesLiner Development Process SummaryJorge VillalobosPas encore d'évaluation

- Replacement Parts: Model 2500DCV (H) Portable Vertical Shaft ImpactorDocument44 pagesReplacement Parts: Model 2500DCV (H) Portable Vertical Shaft ImpactorEDWINPas encore d'évaluation

- Alimentateur PDFDocument4 pagesAlimentateur PDFestramilsolutionPas encore d'évaluation

- Impactors Telsmith.Document17 pagesImpactors Telsmith.Enso E Rosales FPas encore d'évaluation

- I44v2 Parts Manual 04-05-2018Document201 pagesI44v2 Parts Manual 04-05-2018brianpung.122Pas encore d'évaluation

- Striker Track Mounted Impact Crusher BrochureDocument16 pagesStriker Track Mounted Impact Crusher Brochure채경호Pas encore d'évaluation

- Travel Satefy El Congo 002Document27 pagesTravel Satefy El Congo 002Santiago MaldonadoPas encore d'évaluation

- En One Point WearDocument3 pagesEn One Point WearMichael DavisPas encore d'évaluation

- Nordberg SUPERIOR® Gyratory CrushersDocument12 pagesNordberg SUPERIOR® Gyratory Crushersyauri30Pas encore d'évaluation

- QD bushing specification dimensions chartDocument11 pagesQD bushing specification dimensions charteng_moh04Pas encore d'évaluation

- Ws Tyler XL Class PartsDocument6 pagesWs Tyler XL Class Partsyolimar escorciaPas encore d'évaluation

- NMDC Travel Safety India 001Document31 pagesNMDC Travel Safety India 001Santiago MaldonadoPas encore d'évaluation

- Manuel Pieces DetacheesDocument77 pagesManuel Pieces DetacheesPatrice GuilhaumonPas encore d'évaluation

- Terex Jaques Torrent ScreensDocument16 pagesTerex Jaques Torrent ScreensKarin AndersonPas encore d'évaluation

- Premiertrak 400X Technical Specification Rev 1 - 01.01.2019Document24 pagesPremiertrak 400X Technical Specification Rev 1 - 01.01.2019Andres AstudilloPas encore d'évaluation

- Mobile granite crushing plant 150t/hDocument4 pagesMobile granite crushing plant 150t/hSolomon MiPas encore d'évaluation

- Manual de Partes de Cono K300 Tijuana 222Document82 pagesManual de Partes de Cono K300 Tijuana 222Vanessa BenitezPas encore d'évaluation

- 5JTANordberg Cone ReplacementDocument32 pages5JTANordberg Cone ReplacementLmf DanielPas encore d'évaluation

- 74.terex® WC1000 Wheeled Cone and Inclined Screen Plant - EDocument4 pages74.terex® WC1000 Wheeled Cone and Inclined Screen Plant - EHữu Dũng Nguyễn50% (2)

- PDF Manual r900 With Mondial Amp Cat 70Document48 pagesPDF Manual r900 With Mondial Amp Cat 70help3rPas encore d'évaluation

- J-1480 Mastercopy Spare PartsDocument163 pagesJ-1480 Mastercopy Spare PartsbrunoPas encore d'évaluation

- TV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsDocument4 pagesTV Series Vertical Shaft Impact Crushers: Highly Efficient Crushing SolutionsJose grievis Giron perichePas encore d'évaluation

- Chancadora SecDocument138 pagesChancadora SecHerbert100% (1)

- METSO DOA Dimesion ReportDocument8 pagesMETSO DOA Dimesion ReportNaresh KumarPas encore d'évaluation

- ECT Symons 7s For SaleDocument2 pagesECT Symons 7s For SaleOrlando MelipillanPas encore d'évaluation

- Timken Split Block SAF HU CatalogDocument126 pagesTimken Split Block SAF HU Catalogmans2014100% (1)

- Ch440CONE CRUSHER WPC Wujing Crusher SparesDocument12 pagesCh440CONE CRUSHER WPC Wujing Crusher SparesAllen ChenPas encore d'évaluation

- APPENDIX A1 - 313L2 Specific ManualDocument41 pagesAPPENDIX A1 - 313L2 Specific ManualMiguel Angel RodriguezPas encore d'évaluation

- Manual de Partes Zaranda Modelo TSH6203 Terex PDFDocument44 pagesManual de Partes Zaranda Modelo TSH6203 Terex PDFHenry DiazPas encore d'évaluation

- Paneles Autolimpiantes MetsoDocument4 pagesPaneles Autolimpiantes Metsodaniel floresPas encore d'évaluation

- Manual: STPEF0710 and STPEF0912 Jaw CrusherDocument14 pagesManual: STPEF0710 and STPEF0912 Jaw CrusherMANUEL ALBERTO CORTES ZARATEPas encore d'évaluation

- Account StatementDocument10 pagesAccount StatementShiv JoshiPas encore d'évaluation

- BOQ-SCREEN-TATA STEEL-14-JUL-2020Document9 pagesBOQ-SCREEN-TATA STEEL-14-JUL-2020Mohammad Adil100% (1)

- Trio TV85B VSI Parts Manual AbelDocument34 pagesTrio TV85B VSI Parts Manual AbelvictorpalaciossPas encore d'évaluation

- Systems: WashingDocument6 pagesSystems: WashingVinPas encore d'évaluation

- Purchased Part Specification: Extended DescriptionDocument1 pagePurchased Part Specification: Extended DescriptionWilliam VillamizarPas encore d'évaluation

- Improper Crusher Feeding: Jaw CrushersDocument1 pageImproper Crusher Feeding: Jaw CrushersbfygPas encore d'évaluation

- Cerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18Document5 pagesCerro Verde Production Unit Expansion: Ludowici Vibrating Screens Installation Sequence Document No. SN-100462-MD18jhonPas encore d'évaluation

- Complete Track RangeDocument17 pagesComplete Track RangeBenjamin MurphyPas encore d'évaluation

- Dewatering Screens Spec Sheet: Series 9000Document2 pagesDewatering Screens Spec Sheet: Series 9000ekrem0867Pas encore d'évaluation

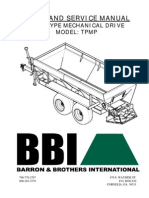

- Parts and Service Manual: Pull-Type Mechanical Drive Model: TPMPDocument29 pagesParts and Service Manual: Pull-Type Mechanical Drive Model: TPMPozgurturunc4Pas encore d'évaluation

- SIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Document7 pagesSIG-De-21 Lógica de Control Con Interruptores de Temperatura - TD03-B108-E-11Jorge PalacioPas encore d'évaluation

- F-Class / Ty-Rock Body Components: How Do I Order?Document6 pagesF-Class / Ty-Rock Body Components: How Do I Order?yolimar escorciaPas encore d'évaluation

- Current Revision Approved: Upper Frame Hydraulics, 68SbsDocument1 pageCurrent Revision Approved: Upper Frame Hydraulics, 68Sbscapslive_001Pas encore d'évaluation

- Pump General Industry High-Pressure Sunflo Technical ManualDocument30 pagesPump General Industry High-Pressure Sunflo Technical Manualmohammad100% (1)

- PPG 1622A ManualDocument38 pagesPPG 1622A Manualk_ndres841Pas encore d'évaluation

- Selenoid eDocument9 pagesSelenoid ejlfyPas encore d'évaluation

- GekkoDocument6 pagesGekkojlfyPas encore d'évaluation

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocument3 pages2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyPas encore d'évaluation

- The GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...Document18 pagesThe GMSG Guideline For Determining The Bond Efficiency of Industrial Gri...jlfyPas encore d'évaluation

- GekkoDocument6 pagesGekkojlfyPas encore d'évaluation

- Regulador de PrecionDocument7 pagesRegulador de PrecionjlfyPas encore d'évaluation

- Posibles Soluciones en La OperaciónDocument3 pagesPosibles Soluciones en La OperaciónjlfyPas encore d'évaluation

- 2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenanceDocument3 pages2.0 Equipment Information: IPJ 1500 User Instructions: Operations, MaintenancejlfyPas encore d'évaluation

- Filtro de AireDocument7 pagesFiltro de AirejlfyPas encore d'évaluation

- Parametros OperativosDocument5 pagesParametros OperativosjlfyPas encore d'évaluation

- Digital PresureDocument11 pagesDigital PresurejlfyPas encore d'évaluation

- Motor FalconDocument4 pagesMotor FalconjlfyPas encore d'évaluation

- Posibles Soluciones en La OperaciónDocument3 pagesPosibles Soluciones en La OperaciónjlfyPas encore d'évaluation

- Falcon C ConcentradoDocument6 pagesFalcon C ConcentradojlfyPas encore d'évaluation

- Condiciones de OperacionDocument2 pagesCondiciones de OperacionjlfyPas encore d'évaluation

- Seguridad y TransporteDocument6 pagesSeguridad y TransportejlfyPas encore d'évaluation

- ComisionamientoDocument2 pagesComisionamientojlfyPas encore d'évaluation

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument6 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyPas encore d'évaluation

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyPas encore d'évaluation

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument8 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyPas encore d'évaluation

- 5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForceDocument4 pages5.8.1 Figure 5.8.1 RPM vs. G'S: Falcon Data Sheet: Separation "G" ForcejlfyPas encore d'évaluation

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument8 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyPas encore d'évaluation

- Especificaciones 2Document8 pagesEspecificaciones 2jlfyPas encore d'évaluation

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocument6 pagesRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyPas encore d'évaluation

- C1000-R3.1 Installation, Operations, and Maintenance ManualDocument6 pagesC1000-R3.1 Installation, Operations, and Maintenance ManualjlfyPas encore d'évaluation

- Rinse AUTO Is The Standard Operating Mode For Most ApplicationsDocument6 pagesRinse AUTO Is The Standard Operating Mode For Most ApplicationsjlfyPas encore d'évaluation

- Descripcion FalconDocument4 pagesDescripcion FalconjlfyPas encore d'évaluation

- Jaw Part3Document6 pagesJaw Part3jlfy100% (1)

- Bearing and Eccentric Shaft PartsDocument6 pagesBearing and Eccentric Shaft PartsjlfyPas encore d'évaluation

- Technical specifications for JR3 multi-axis force-torque sensor modelsDocument1 pageTechnical specifications for JR3 multi-axis force-torque sensor modelsSAN JUAN BAUTISTAPas encore d'évaluation

- Anti Jamming of CdmaDocument10 pagesAnti Jamming of CdmaVishnupriya_Ma_4804Pas encore d'évaluation

- NLP Business Practitioner Certification Course OutlineDocument11 pagesNLP Business Practitioner Certification Course OutlineabobeedoPas encore d'évaluation

- Maharashtra Auto Permit Winner ListDocument148 pagesMaharashtra Auto Permit Winner ListSadik Shaikh50% (2)

- PowerPointHub Student Planner B2hqY8Document25 pagesPowerPointHub Student Planner B2hqY8jersey10kPas encore d'évaluation

- Ecc Part 2Document25 pagesEcc Part 2Shivansh PundirPas encore d'évaluation

- Uses and Soxhlet Extraction of Apigenin From Parsley Petroselinum CrispumDocument6 pagesUses and Soxhlet Extraction of Apigenin From Parsley Petroselinum CrispumEditor IJTSRDPas encore d'évaluation

- Evaluative Research DesignDocument17 pagesEvaluative Research DesignMary Grace BroquezaPas encore d'évaluation

- Inborn Errors of Metabolism in Infancy: A Guide To DiagnosisDocument11 pagesInborn Errors of Metabolism in Infancy: A Guide To DiagnosisEdu Diaperlover São PauloPas encore d'évaluation

- JM Guide To ATE Flier (c2020)Document2 pagesJM Guide To ATE Flier (c2020)Maged HegabPas encore d'évaluation

- Gabinete STS Activity1Document2 pagesGabinete STS Activity1Anthony GabinetePas encore d'évaluation

- LSMW With Rfbibl00Document14 pagesLSMW With Rfbibl00abbasx0% (1)

- Day 4 Quiz - Attempt ReviewDocument8 pagesDay 4 Quiz - Attempt ReviewĐỗ Đức AnhPas encore d'évaluation

- Oxgen Sensor Cat WEBDocument184 pagesOxgen Sensor Cat WEBBuddy Davis100% (2)

- Managerial EconomicsDocument3 pagesManagerial EconomicsGuruKPOPas encore d'évaluation

- Precision Machine Components: NSK Linear Guides Ball Screws MonocarriersDocument564 pagesPrecision Machine Components: NSK Linear Guides Ball Screws MonocarriersDorian Cristian VatavuPas encore d'évaluation

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiDocument8 pagesCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiPas encore d'évaluation

- GFS Tank Quotation C20210514Document4 pagesGFS Tank Quotation C20210514Francisco ManriquezPas encore d'évaluation

- ITP Exam SuggetionDocument252 pagesITP Exam SuggetionNurul AminPas encore d'évaluation

- Mosfet 101Document15 pagesMosfet 101Victor TolentinoPas encore d'évaluation

- Listening Exercise 1Document1 pageListening Exercise 1Ma. Luiggie Teresita PerezPas encore d'évaluation

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDocument16 pagesConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanPas encore d'évaluation

- Developing the cycle of maslahah based performance management system implementationDocument27 pagesDeveloping the cycle of maslahah based performance management system implementationM Audito AlfansyahPas encore d'évaluation

- Test Bank For Fundamental Financial Accounting Concepts 10th by EdmondsDocument18 pagesTest Bank For Fundamental Financial Accounting Concepts 10th by Edmondsooezoapunitory.xkgyo4100% (48)

- Uniform-Section Disk Spring AnalysisDocument10 pagesUniform-Section Disk Spring Analysischristos032Pas encore d'évaluation

- Philippine Population 2009Document6 pagesPhilippine Population 2009mahyoolPas encore d'évaluation

- Wheeled Loader L953F Specifications and DimensionsDocument1 pageWheeled Loader L953F Specifications and Dimensionssds khanhPas encore d'évaluation

- 4 Factor DoeDocument5 pages4 Factor Doeapi-516384896Pas encore d'évaluation

- AA ActivitiesDocument4 pagesAA ActivitiesSalim Amazir100% (1)

- Laryngeal Diseases: Laryngitis, Vocal Cord Nodules / Polyps, Carcinoma LarynxDocument52 pagesLaryngeal Diseases: Laryngitis, Vocal Cord Nodules / Polyps, Carcinoma LarynxjialeongPas encore d'évaluation

- The User's Journey: Storymapping Products That People LoveD'EverandThe User's Journey: Storymapping Products That People LoveÉvaluation : 3.5 sur 5 étoiles3.5/5 (8)

- Design for How People Think: Using Brain Science to Build Better ProductsD'EverandDesign for How People Think: Using Brain Science to Build Better ProductsÉvaluation : 4 sur 5 étoiles4/5 (8)

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Transformed: Moving to the Product Operating ModelD'EverandTransformed: Moving to the Product Operating ModelÉvaluation : 4 sur 5 étoiles4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureD'EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveD'EverandUnderstanding Automotive Electronics: An Engineering PerspectiveÉvaluation : 3.5 sur 5 étoiles3.5/5 (16)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryD'EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryÉvaluation : 4 sur 5 étoiles4/5 (5)

- Operational Amplifier Circuits: Analysis and DesignD'EverandOperational Amplifier Circuits: Analysis and DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableD'EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginablePas encore d'évaluation

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsD'EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideD'EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesD'EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertÉvaluation : 3 sur 5 étoiles3/5 (2)

- Electrical Principles and Technology for EngineeringD'EverandElectrical Principles and Technology for EngineeringÉvaluation : 4 sur 5 étoiles4/5 (4)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsD'EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- 507 Mechanical Movements: Mechanisms and DevicesD'Everand507 Mechanical Movements: Mechanisms and DevicesÉvaluation : 4 sur 5 étoiles4/5 (28)

- Iconic Advantage: Don’t Chase the New, Innovate the OldD'EverandIconic Advantage: Don’t Chase the New, Innovate the OldÉvaluation : 4 sur 5 étoiles4/5 (1)