Académique Documents

Professionnel Documents

Culture Documents

The Effect of Surface Topography of Retrieved Femoral Heads On The Wear of UHMWPE Sockets 1997 Medical Engineering Physics

Transféré par

Lopez RamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Effect of Surface Topography of Retrieved Femoral Heads On The Wear of UHMWPE Sockets 1997 Medical Engineering Physics

Transféré par

Lopez RamDroits d'auteur :

Formats disponibles

PII: S1350-4533(97)00032-5

Med. Eng. Phys. Vol. 19, No. 8, pp. 711719, 1997

1997 IPEM Published by Elsevier Science Ltd

Printed in Great Britain

13504533/97 $17.00 + 0.00

The effect of surface topography of retrieved

femoral heads on the wear of UHMWPE sockets

R. M. Hall*, P. Siney, A. Unsworth* and B. M. Wroblewski

*Centre for Biomedical Engineering, School of Engineering, University of

Durham, Durham DH1 3LE, UK; Centre for Hip Surgery, Wrightington Hospital,

Appley Bridge, Wigan WN6 9EP, UK

Received 8 December 1996, accepted 17 July 1997

ABSTRACT

The study was undertaken to investigate the association, if any, between the surface roughness of 35 explanted

femoral heads and the clinical wear factors of the corresponding polyethylene sockets. The wear of the socket was

measured using a shadowgraph technique. The surface topography was investigated using a Rodenstock RM 600

non-contacting profilometer, and six parameters were used to characterise the roughness. Further, qualitative inspections of the femoral surface were undertaken using both a Joel JSM-IC-848 scanning electron microscope and a Zeiss

Axiotech microscope with a differential interference contrast facility. Two parameters were found to correlate with the

clinical wear factor, namely the skewness of the amplitude distribution function, Sk, and the arithmetic mean

roughness, Ra. Simple parameters describing the peak heights of the asperities were found not to have a significant

association with the clinical wear factor. The exponent in the power relationship between the arithmetic mean roughness and kclinical was found to be equal to 0.5 (SE: 0.2). This value is significantly smaller than that found in

laboratory experiments and may be due to the non-uniform nature of the roughening of the femoral head, three-body

wear and the effect of other clinical factors on the wear process. Further, extremely strong correlations were detected

between the differing roughness parameters, which would suggest that any attempt to deduce which one is the most

important in affecting the wear of the polymeric counterface is fraught with difficulty. However, further investigation

of those parameters, such as the reduced peak height or the material filled profile peak area, which may better describe

the effect of the counterface on the wear of the UHMWPE surface would appear to be prudent. 1997 IPEM

Published by Elsevier Science Ltd

Keywords: Wear, surface topography, UHMWPE, total hip replacement

Med. Eng. Phys., 1997, Vol. 19, 711719, December

1. INTRODUCTION

The wear of ultra-high molecular weight polyethylene (UHMWPE) components remains a key

issue in joint replacement surgery, especially of

the lower limb1,2. The wear process may lead to

component loosening and the eventual requirement for revision surgery3. Of those parameters

which may lead to excessive wear, changes in the

surface roughness of the femoral head are currently thought to be important and have been

investigated extensively in the laboratory49. As

well as affecting the volume of debris produced,

laboratory experimentation has demonstrated

that particle morphology is influenced by the

roughness of the counterface10,11. In particular,

rougher surfaces tend to produce more particles

with sub-micron dimensions. It is these subCorrespondence to: R. M. Hall, Academic Department of Orthopaedic Surgery, Clinical Sciences Building, St Jamess University Hospital, Beckett Street, Leeds LS9 7TF, UK. Tel: 0113 206 4186,

0113 233 2132; fax: 0113 206 6791.

micron particles which are considered to have the

greatest effect in eliciting an immune response

which eventually leads to bone resorption. Recent

clinical evidence of a wide range of particle sizes,

similar to those found for different counterface

roughnesses in vitro, has been reported, although

the observations were not correlated with the topography of the retrieved femoral heads11.

A number of studies have investigated the

changes in the surface topography of previously

implanted femoral components. In particular,

Isaac et al.12 studied the surface roughness of 35

Charnley heads in which the maximum value of

the arithmetic mean roughness (Ra) from a number of scans across each specimen was recorded.

A significant increase in the surface roughness,

relative to that found on new femoral heads, was

recorded. A further study by Isaac et al.13, whilst

reporting similar increases in surface roughness

for a larger cohort of joints, did not observe a

strong correlation between the rate of penetration, P/t, and the Ra value. This result con-

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

firmed an earlier observation made by Atkinson

et al.14. This lack of association between P/t

and Ra is in contrast to studies undertaken in the

laboratory in which an extremely strong correlation was found to exist4,8. The lack of association

clinically may be due to a number of factors,

including the observation that the changes in topography across the femoral surface are not uniform, and additional wear due to third bodies.

Work previously undertaken on explanted femoral heads has observed multidirectional scratching, especially in areas on or adjacent to the presumed area of contact15,16. This qualitative

observation was confirmed quantitatively by Hall

et al.17 who observed no significant difference

between five roughness parameters when measured in either the anteriorposterior or medial

lateral directions.

A number of different devices can be used to

make a quantitative assessment of the surface topography of the explanted femoral heads18. The

most frequently used method of appraisal employs

the contacting profilometer in which a stylus is

drawn across the surface on which the texture is to

be investigated. A second set of devices comprises

optical profilometers, which can be further split

into groups such as interference and laser stylus

instruments. These types of device may be advantageous in situations where distortions of, or damage to, the surface may occur. The results gained

from these non-contacting instruments may deviate from those obtained from more conventional

contacting profilometers. These discrepancies are

dependent on the difference in the vertical and

horizontal resolutions of the instruments and the

precise nature of the surface under investigation.

Traditional stylus techniques are still considered

almost exclusively in the standards literature19.

It is the aim of this study to investigate the interrelationship between those topographical changes

that occur in vivo and the wear of the ultra-high

molecular weight polyethylene (UHMWPE)

socket. In particular, the association between the

clinical wear factor, kclinical, and six parameters

used to characterise the surface is analysed.

2. EXPERIMENTAL PROCEDURE

Thirty-five prostheses were acquired from revision

surgery at the Centre for Hip Surgery, Wrightington Hospital. The artificial joints were all of the

Charnley type (Thackray/DePuy International,

Leeds) comprising a single-piece stainless steel

stem and an all-UHMWPE socket (Figure 1). The

components are fixed in position with the aid of

bone cement. The mean period of implantation

was 12.0 (SD: 4.7) years while the mean age at

primary surgery was 54 (SD: 14) years. The mean

patient weight was 710 (SD: 150) N. Thirty-three

of the sockets were found to be loose at revision

surgery.

Quantitative assessment of the surface topography was achieved by using a Rodenstock RM 600

profilometer at the National Physical Laboratory

(NPL) which utilises the focus error detection

principle20,21. Twenty scans were taken from each

of the femoral heads in areas which were considered to be in contact with the socket and, in

general, this coincided with the most heavily

scratched region. Each profile consisted of a

1.4 mm evaluation length, le, with a cutoff of

0.2 mm and contained 770 sampling points.

Twenty-two surface parameters were calculated

once the profiles had been acquired. Six parameters were investigated further. Definitions of

these parameters and the reasons for their

inclusion in the study are presented in Table 1. In

particular, those parameters that have been used

in the assessment of wear in the orthopaedic

environment have been included. The excluded

parameters, including the mean peak-to-valley

height, Rz, and the mean spacing of the profile

irregularities, Sm, were thought not to have a

strong influence on the wear of the polymeric surface. The mean of each of the chosen parameters

across the twenty profiles was calculated.

Qualitative assessment of the femoral heads was

undertaken using both scanning electron (Joel

JSM-IC848) and optical (Zeiss Axiotech)

microscopy. A differential interference contrast

(DIC) facility22 was available on the optical microscope and was found to be particularly suitable for

observing small changes in the slope of features

on the surface of the head (e.g. marks left after

polishing). The objective lenses used were 5,

10, 20 and 50, which allowed overall magnifications of 50, 100, 200 and 500 times respectively. Features of interest were recorded on photographic film. Images on the SEM were recorded

using an image capture system.

The changes in the volume of the internal

socket bore, V, were recorded using the shadowgraphic technique which has been explained

extensively elsewhere23. In brief, a mould is taken

of the internal bore of the socket and projected

onto a screen at a given magnification. A profile

is recorded of the wear plane, and the centres of

the femoral head with respect to the worn and

unworn surfaces of the socket are recorded using

a circular template. The distance between the

centres of the circular template in these two positions is the penetration depth, P. The angle of

penetration, , is the angle between the direction

of penetration and the plane defining the open

face of the socket. The total change in the bore

volume, V, can then be calculated from the

modified form of the equation presented by Kabo

et al.24. Simulator investigations of the wear of

Charnley sockets have revealed a creep component to the volume change in the socket bore,

which is of the order of 30 mm3 25. This is small

compared to the mean volume change of approximately 550 mm3 for explanted Charnley prostheses and was therefore neglected in this analysis26. Thus the total volume change in the internal

bore of the socket was assumed to be attributable

to wear alone.

In keeping with the in vitro analysis, a clinical

wear factor, kclinical, was derived using the empirical wear equation:

V = kclinical Ldx

0

712

(1)

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

Figure 1 Explanted Charnley acetabular and femoral components.

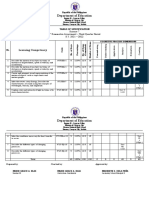

Table 1 Surface roughness parameters used to describe the topography of the explanted femoral heads

Parameter

Definition

Arithmetic mean roughness, Ra

Reason for assessment

Ra =

Frequently used in assessing the surface

roughness of the counterface in the wear of

orthopaedic polymers. Cited in BS 7251 Part

4 with respect to the maximum roughness of

the surface of a femoral head

1

zdx

l

0

Root mean square roughness, Rq

Rq =

Often used as an alternative to Ra. The

parameter gives a greater weighting to the

larger deviations from the reference line

1 2

z dx

l

0

Peak to valley height, Rt

Distance between the highest peak and lowest May be used as a measure of counterface

valley within one evaluation length

imperfections, but does not distinguish

between peaks and valleys

Peak height, Rp

Distance between the mean line and the

highest peak within one evaluation length

Mean peak height, Rpm

Mean distance between the highest peak and Less prone to exceptional peaks than Rp. The

the mean line in five consecutive sampling

mean peak height can be used in providing

lengths

information on profile shape in conjunction

with the mean peak to valley height

Skewness, Sk

1

Sk =

(Rq)3

z3p(z)dz

where L is the load across the articulating surface

and x the sliding distance. Equation (1) was simplified by Atkinson et al.14, using motion and loading curves originally observed by Paul27 such that

the integral on the right-hand side was reduced to

I = Ldx = 2.376NMr

Counterface imperfections with exceptional

peaks (esp. scratches) above the mean line

have been shown to have the greatest effect

on the wear of the polymeric surface

(2)

where M is the weight of the patient, r the radius

Provides information on the shape of the

amplitude distribution function. The skewness

indicates whether or not there is a

disproportionate number of high peaks or

deep valleys

of the femoral head and N the number of cycles

undergone by the prosthesis during the period of

implantation. A value of N was calculated using

the formula presented by Wallbridge and Dowson28 in which N varies as a function of both age

and implantation period.

The interrelationship between the variables was

undertaken using Spearmans rank correlation

test. Initial analysis between each of the surface

roughness parameters and the clinical wear factor

was also performed using this non-parametric test,

713

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

Table 2 Summary of those values deduced from penetration depth

measurements or clinical records

Parameter

Median value

(interquartile range)

Penetration depth (mm)

Wear volume (mm3)

Number of cycles

I (N m)

kclinical (mm3 [N m]1)

2.3 (0.73.4)

608 (274920)

1.69 107 (1.032.09 107)

3.05 108 (1.634.13 108)

1.51 106 (1.092.51 106)

but was supplemented with the regression of a

power function similar to that performed by Dowson et al.8. All the analyses were accomplished

using the STATA 4.0 statistical analysis package29.

3. RESULTS

A summary of the results for the shadowgraphic

measurements and the subsequent calculations of

the wear volumes are presented in Table 2. Also

presented are the calculations for median values

of the estimated number of cycles undergone by

the prostheses while in vivo, the parameter, I, in

Equation (2) and the clinical wear factor, kclinical.

Observations of the femoral heads indicated a

wide range of scratch densities (Figure 2) as well

as scratch sizes. On the heads where less damage

had occurred, original polishing marks were

observed which tended to be of a more unidirectional nature. Polishing pits were also revealed by

the DIC microscopy, which tended to have oriented tails in which the direction was correlated

with the polishing marks (Figure 3). These were

observed on new as well as retrieved specimens.

On two heads, raised features were observed

which were consistent with a preferentially polished surface in which grain boundaries protruded (Figure 4).

The SEM studies revealed greater detail,

especially in the horizontal plane, of the scratch

morphologies. The scratch widths tended to vary

in size but most were less than 2m. Build-up of

material either side of the scratches was also

observed, although this was often interrupted by

further damage to the surface (Figure 5). In

addition to the scratches, more localised indentations were also observed, but with a topography

unlike that of the polishing pits.

As well as studying the surfaces of the femoral

heads, a sample of the worn acetabular regions

was also investigated using SEM microscopy. Most

areas showed evidence of abrasive wear, in terms

of scratches, as well as adhesive features. Material

was also found to be embedded in the UHMWPE

which may contribute to the scratching of the femoral head or may contribute to three-body wear

processes when released. On a qualitative level,

the amount of embedded material varied appreciably.

The median values and interquartile ranges of

the six surface roughness parameters are

presented in Table 3. Quantitative assessment indicated strong correlations between the different

surface amplitude parameters (Table 4). As one

would expect, the strongest correlation of all was

between Ra and Rq (Figure 6). However, only poor

correlations were observed between the skewness

of the amplitude distribution function and the

amplitude parameters. Initial assessment of the

correlation between the clinical wear factor and

each of these parameters indicated only marginally significant associations between either the

skewness (r = 0.374, P = 0.027) or the arithmetic

mean roughness (r = 0.284, P = 0.099) and kclinical

(Figure 7 and Table 5). Using the empirical model,

first presented by Dowson et al.8 in analysing such

data, the only significant association appeared to

be between Ra and the clinical wear factor (Table

5). Here, the exponent was found to have a value

of 0.5 (SE: 0.2). However, the presence of one or

Figure 2 DIC micrograph image of a heavily scratched area on the surface of an explanted head.

714

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

Figure 3 DIC micrograph of polishing pits observed on a portion of the heads. Note the tails eminating from the pits and that their direction

appears to be oriented with the polishing marks.

Figure 4 DIC micrograph of raised features observed on two explanted femoral heads which may be due to the grain structure of the stainless steel.

two outliers may affect the overall significance of

the result.

4. DISCUSSION

As observed in other studies of retrieved femoral

head prostheses, multidirectional scratches

existed across much of the surface, but with varying densities. The microscopic examination

revealed that, while lightly damaged surfaces have

isolated scratches, this was not generally the case

in the regions where the greatest portion of the

contact was assumed to exist. It was observed that

as the scratch density increased then so did the

severity, in terms of damage, of individual

scratches, and this was confirmed by the linear

tendency between both the single amplitude parameters (Rt or Rp) and the arithmetic mean roughness, Ra. This has important implications for modelling of the femoral surface in laboratory

experiments. Until recently it has been usual to

relate the laboratory wear factor, k, to the uniform

surface roughness as measured by an Ra value.

Using pin-on-plate apparatus with distilled water

as the lubricant, Dowson et al.8 were the first to

show the following empirical relationship between

k and Ra:

k = 4 105R1.2

(3)

a

Analysing the data presented by Weightman

715

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

Figure 5 SEM micrograph of the material build-up either side of a scratch. It was noted that the build-up was not uniform along the length

of the scratch.

Table 3 Summary of those parameters gained from the measurement of surface texture

Parameter

Median value

(interquartile range)

Arithmetic mean roughness, Ra (nm)

Root mean square roughness, Rq (nm)

Peak-to-valley height, Rt (nm)

Peak height, Rp (nm)

Mean peak height, Rpm

Skewness, Sk

62 (4180)

96 (75145)

1080 (8201550)

500 (400690)

240(200390)

0.28(1.340.38)

and Light4 in which serum rather than water was

used as the lubricant, the exponent was of the

order of 1.4. However, later experiments by Dowson et al.6 illustrated that the wear factor of the

softer polymeric surface could be inflated dramatically in the presence of prominent individual

scratches on the metallic counterface. This was

especially true if these scratches were oriented

perpendicular to the direction of articulation.

Further, it was noted that it was the material buildup on either side of the scratches that was the

major cause of this increased wear. Single indents

appeared to raise the wear factor only marginally.

Fisher et al.9 recently confirmed this finding,

although the effects of scratches with heights of

material pile-up of the order of 1m were even

Figure 6 Relationship between the arithmetic mean surface roughness, Ra, and the root mean square roughness, Rq.

more dramatic. However, the explanted femoral

surface fits neither of these descriptions since it is

not a uniformly rough surface, although it may

tend to this situation if the head is severely damaged. Neither is a single prominent scratch often

observed in the presumed contact region,

although one could surmise that this could be the

case for a brief period early in the joints life. In

fact, the topography of the femoral head lies

somewhere between these two extremes and the

effects of the topography of the counterface on

Table 4 Matrix displaying the correlations (Spearmans rank) between the different surface roughness parameters

Ra

1.0000

Rq

0.9351

(0.000)

0.7218

(0.000)

0.7344

(0.000)

0.8311

(0.000)

0.0644

(0.705)

Ra

Rt

Rp

Rpm

Sk

716

1.0000

0.8127

(0.000)

0.8234

(0.000)

0.8727

(0.000)

0.1248

(0.461)

Rq

1.0000

0.8184

(0.000)

0.8184

(0.000)

0.1293

(0.446)

Rt

1.0000

0.8838

(0.000)

0.1347

(0.429)

Rp

1.0000

0.0253

(0.882)

Rpm

1.0000

Sk

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

Figure 7 Dependency of the clinical wear factor, kclinical, on the

mean skewness, Sk, recorded for each femoral head.

the softer polymeric material are a weighted integration of the effects of all the individual scratches

with some sort of orientational parameter

attached. The polishing pits observed on the less

damaged areas of the head appeared not to have

any lip around their edges, and therefore it could

be assumed they may not have any significant

affect on the wear of the UHMWPE socket.

Isaac et al.12 investigated retrieved acetabular

components and noted that over fifty per cent had

cement embedded within the articulating surface.

Further, it was demonstrated that bone cement

had a detrimental effect on the roughness of the

metallic counterface. There is a high probability

that the material embedded in the surfaces of

sockets investigated in this study was bone cement.

Bone may also ingress into the surface of the polymeric bearing and cortical bone, in particular, has

been shown to be of sufficient hardness to scratch

the surface of a stainless steel counterface30.

In terms of correlations between the clinical

wear factor and the roughness parameter, only

two were observed to have any significant association. The power function fit of k against Ra produced an exponent which was significantly different from zero but considerably lower than the

values gained from the studies by Dowson et al.8

or Weightman and Light4. This difference in

exponent may be due to a number of factors,

including the previously mentioned observation

that the surface roughness of the explanted heads

is not uniform. Further, the lubricating regimes

may be very different between simple wear

machines and the in vivo environment. The other

amplitude roughness parameters produced no

exponent values that were significantly different

from zero. The marginally significant association

between the skewness and the clinical wear factor

is not too surprising. A negatively skewed surface,

that is one with a few exceptional valleys but no

prominent peaks, is often considered to be a good

bearing surface in that it will reduce the abrasive

wear of the counterface relative to one with a positively skewed amplitude distribution function31.

The poor correlation between the peak-to-valley

height and the clinical wear factor may be

explained by the fact that the parameter does not

distinguish between valleys and peaks. Further,

this roughness parameter is heavily influenced by

very high individual asperities or deep valleys

which in themselves do not have a great influence

on the wear process across the whole counterface,

as indicated by Dowson et al.6. The weak association between Rp or Rpm and the clinical wear factor seems at first to be problematical since it is

the material above the mean line, especially that

formed by scratches, that has the greatest effect

on the wear of the UHMWPE. However, these

parameters, as with the Rt value, are affected by

singular asperities and do not reflect the spatial

extent of the pile-up formed around the side of

the indentations (Figure 8). These peak height

parameters may have some significance in laboratory experiments in which there are a few prominent scratches of uniform height. However, in a

clinical situation the build-up of material varies

between scratches and even along a single scratch.

In addition, these laboratory tests normally have

scratches which are well in excess of the height

changes on the surrounding surface and therefore have an unusually high and disproportionate

effect on the wear of the opposing polymeric surface. On an explanted head, however, a number

of scratches may exist in close proximity and,

whilst the largest scratch may have the greatest

effect, the role of the others cannot be ignored.

Further, the loci mapped out by a feature on the

femoral head with a detrimental effect on the

Figure 8 Schematic diagram illustrating the inability of the peak

height parameters, Rp and Rpm, to distinguish between single

asperities and material build-up adjacent to scratches. It is the latter

which have the greatest effect on the wear of the UHMWPE surface.

Table 5 Degree of association between the surface roughness parameters and the clinical wear factor measured by the Spearmans rank

correlation coefficient and the value of the exponent in the empirical model used by Dowson et al.8 (the P-values are given in parentheses)

Roughness parameter

Spearmans rank correlation coefficient

Ra

Rq

Rt

Rp

Rpm

Sk

0.284

0.248

0.004

0.130

0.211

0.374

(P

(P

(P

(P

(P

(P

=

=

=

=

=

=

0.099)

0.151)

0.981)

0.457)

0.225)

0.027)

Exponent

0.54,

0.40,

0.07,

0.26,

0.47,

SE

SE

SE

SE

SE

0.23

0.26

0.28

0.29

0.30

(P

(P

(P

(P

(P

=

=

=

=

=

0.02)

0.13)

0.79)

0.37)

0.13)

717

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

wear of the UHMWPE will probably not cover the

zone of contact between the bearing surfaces32. In

this situation, accelerated wear will occur only in

the zones which intersect with these loci while

adjacent areas will wear at a lower rate. Thus a

situation will arise in which the load is supported

by the lower rate zone only and the effect of the

highly damaged region will be negated, at least

intermittently.

It seems likely, however, that damage to the

femoral head does indeed cause excessive wear of

the polyethylene socket. Wroblewski et al.33 noted

that the surface roughness of four femoral heads,

which were coupled with sockets of low wear and

long implant periods, were relatively undamaged.

The problem lies in choosing a single or a range

of roughness parameters which may adequately

describe the relationship between topography and

wear. Multiple linear regression may be used, with

relatively uncorrelated independent variables, in

an attempt to identify correlations that may have

been masked by variations in the other explanatory parameters. Indeed, this approach was

applied here using Sk and Ra but, while the initial

results indicated an improvement in the strength

of the correlations between these variables and

the clinical wear factor, further investigations

revealed problems with data specification,

especially with respect to the arithmetic mean

roughness. Another possibility is to investigate

additional sets of parameters which may describe

more clearly the surface topography of the counterface and its effect on the wear of the socket.

An alternative may be those parameters that are

derived from the bearing area curve, such as the

reduced peak height or the material filled profile

peak area31. These parameters are related to the

asperities above the core roughness and may give

a better description of the material pile-up on

either side of the scratches. They will also give

some weighting to the length of the scratch, provided a three-dimensional image of the surface is

acquired. As a consequence this will overcome the

problems associated with the peak height parameters, Rpm and Rp, used here.

A further complication that can arise from the

measurement of the surface topography is the

problem of sampling. It is important to know

which results from a particular set of profiles or

areas are the most representative. In this study,

the mean values of the twenty profiles for each

femoral head, all gained from the presumed

region of contact, were used, whilst in the study

by Isaac et al.13 the maximum Ra from a series of

traces was utilised. Use of the maximum Ra value

is not a robust measure of the overall roughness

and may in itself be unduly influenced by exceptional values. As mentioned previously, the path

mapped out by the trace corresponding to the

maximum Ra value will most probably not cover

the whole contact zone. Therefore, it will not

exert such a large influence as might be expected

from the extrapolation of results gained in simple

screening tests in which the whole face of a polymeric pin comes in contact with a perpendicular

scratch on the metal counterface. It would be pru-

718

dent to suggest that the measurements should be

taken from the areas which appear to have the

greatest damage and that a sufficient number of

profiles has to be taken in order to get a representative sample. Further investigations need to be

undertaken to assess the minimum sample size

required both in terms of the number of evaluation lengths undertaken and the total joint

count. A standard protocol also needs to be

designed to assist in the comparison of results

between different research groups.

A further cause of the relatively poor correlation between roughness and wear is the variations in certain clinical parameters that are not

taken into account in the calculation of kclinical. In

particular, the activity rates of patients for any

given age were considered to be constant whereas

clinical evidence has shown it to vary by as much

as a factor of ten34. Other parameters not considered are the original diagnosis for primary surgery that may subsequently affect gait and activity.

5. CONCLUSIONS

The correlations between a selection of parameters characterising the surface texture and the

clinical wear factor were, in general, poor with

only two, the skewness, Sk, and the arithmetic

mean roughness, Ra, warranting further investigation. This is in contrast to the in vitro situation

where the correlation between Ra and k tends to

be stronger and the effect of the former on the

latter more pronounced. Factors accounting for

the difference between the clinical and laboratory

situation are the variability in the surface roughness on explanted femoral heads, the influence of

other clinical variables (e.g. patient activity),

three-body wear from cement and bone debris,

and that scratches may not affect the whole contact area. The use of laboratory wear tests, whilst

providing extremely useful information on the

fundamental tribology of orthopaedic materials,

may not accurately reflect the in vivo situation

even in the narrow confines of the surface topography of the bearing surface. In terms of specifying which parameters should be used in

assessing the surface texture of femoral heads in

relation to the wear of the socket, considerable

work still needs to be undertaken. In particular,

further investigation of the parameters derived

from the bearing area curve, for example the

reduced peak height and material filled profile

peak area, is urgently required. These parameters

are more representative of the peak topography

than the simpler parameters, Rp and Rpm, which

were found to be unsuitable in describing the

effects of texture on the wear of the UHMWPE.

ACKNOWLEDGEMENTS

The research has been funded solely by the

Arthritis and Rheumatism Council for Research

(ARC) under grant No. U0505 and the authors

wish to record their appreciation.

Wear and surface topography in retrieved hip prostheses: R. M. Hall et al.

REFERENCES

1. Howie, D. W., Haynes, D. R., Rogers, S. D., McGee, M.

A. and Pearcy, M. J., The response to particulate debris.

Orthopedic Clinics of North America, 1993, 24, 571581.

2. Harris, W. H., Osteolysis and particle disease in hipreplacementa review. Acta Orthopaedica Scandinavica,

1994, 65, 113123.

3. Wroblewski, B. M., Cementless versus cemented total hiparthroplastya scientific controversy. Orthopedic Clinics of

North America, 1993, 24, 591597.

4. Weightman, B. and Light, D., The effect of the surface

finish of alumina and stainless-steel on the wear rate of

UHMW polyethylene. Biomaterials, 1986, 7, 2024.

5. McKellop, H. and Clarke, I., Wear of artificial joint

materials in laboratory tests. Acta Orthopaedica Scandinavica, 1988, 59, 349352.

6. Dowson, D., Taheri, S. and Wallbridge, N. C., The role

of counterface imperfections in the wear of polyethylene.

Wear, 1987, 119, 277293.

7. Cooper, J. R., Dowson, D. and Fisher, J., The effect of

transfer film and surface roughness on the wear of lubricated ultra-high molecular weight polyethylene. Clin.

Mater., 1993, 14, 295302.

8. Dowson, D., El-Haby Diab, M.M., Gillis, B.J. and Atkinson, J.R., The influence of counterface topography on

the wear of ultra-high molecular weight polyethylene

under wet and dry conditions. In Proc. Int. Symp. on Polymer Wear and its Control, St Louis, 1984, publ. American

Chemical Society, New York, pp. 226232.

9. Fisher, J., Firkins, P., Reeves, E. A., Hailey, J. L. and Isaac,

G. H., The influence of scratches to metallic counterfaces

on the wear of ultra-high molecular weight polyethylene.

Proc. Inst. Mech. Engrs, 1995, 209H, 263264.

10. Cooper, J. R., Dowson, D. and Fisher, J., Macroscopic and

microscopic wear mechanisms in ultra-high-molecularweight polyethylene. Wear, 1993, 162, 378384.

11. Hailey, J. L., Ingham, E., Stone, M., Wroblewski, B. M.

and Fisher, J., Ultra-high molecular weight polyethylene

wear debris generated in vivo and in laboratory tests; the

influence of counterface roughness. Proc. Inst. Mech.

Engrs, 1996, 210H, 310.

12. Isaac, G. H., Atkinson, J. R., Dowson, D. and Wroblewski,

B. M., The role of cement and roughening upon the penetration rate of femoral heads into acetabular cups of

Charnley prostheses. J. Bone Joint Surg. [Br.], 1986, 68,

496.

13. Isaac, G. H., Wroblewski, B. M., Atkinson, J. R. and Dowson, D., A tribological study of retrieved hip prostheses.

Clin. Orthop., 1992, 115125.

14. Atkinson, J. R., Dowson, D., Isaac, J. H. and Wroblewski,

B. M., Laboratory wear tests and clinical observations of

the penetration of femoral heads into acetabular cups

in total replacement hip joints. 3. The measurement of

internal volume changes in explanted Charnley sockets

after 216 years in vivo and the determination of wear

factors. Wear, 1985, 104, 225244.

15. Wroblewski, B. M., Revision Surgery in Total Hip Arthroplasty. Springer-Verlag, London, 1990.

16. Jasty, M., Bragdon, C. R., Lee, K., Hanson, A. and Harris,

W. H., Surface damage to cobaltchrome femoral-head

prostheses. J. Bone Joint Surg. [Br.], 1994, 76B, 7377.

17. Hall, R. M., Unsworth, A., Siney, P. and Wroblewski, B.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

M., The surface topography of retrieved femoral heads.

J. Mater. Sci.: Materials in Medicine, 1996, 7, 739744.

Wong, W. P., Mainsah, E., Sullivan, P. J. and Stout, K. J.,

On instruments and measurement techniques of three

dimensional surface topography. In Three Dimensional

Surface Topography; Measurement, Interpretation and Applications, Vol. 1, ed. K. J. Stout. Penton Press, London,

1994.

British Standards Institution, British Standard BS 7251,

Orthopaedic joint prostheses. Part 4: Specification for

bearing surfaces of hip joint prostheses.

Braat, J. J. M., Read out of optical discs. In Principles of

Optical Disc Systems, 3rd edn, ed. G. Bouwhuis. Adam

Hilger, Bristol, 1987.

Visscher, M. and Struik, K. G., Optical profilometry and

its application to mechanically inaccessible surfaces. Part

1: Principles of focus error detection. Precis. Eng., 1994,

16, 192198.

Bousfield, B., Surface Preparation and Surface Microscopy of

Materials. John Wiley & Sons, Chichester, 1994.

Hall, R. M., Unsworth, A., Craig, P. S., Hardaker, C.,

Siney, P. S. and Wroblewski, B. M., Measurement of wear

in retrieved acetabular sockets. Proc. Inst. Mech. Engrs,

1995, 209H, 233242.

Kabo, J. M., Gebhard, J. S., Loren, G. and Amstutz, H.

C., In vivo wear of polyethylene acetabular components.

J. Bone Joint Surg. [Br.], 1993, 75B, 254258.

Elloy, M., Simulator testing of joint prostheses: The need

for realistic simulator testing. In Proc. SERC/IMechE

Annual Expert Meeting: Failure of Joint Prostheses, Bury St

Edmunds, 1993, publ. Mech. Engrs Pub. Ltd, pp. 7982.

Hall, R. M., Unsworth, A., Siney, P. and Wroblewski, B.

M., Wear in retrieved Charnley acetabular sockets. Proc.

Inst. Mech. Engrs, 1996, 210, 197207.

Paul, J. P., Forces transmitted by joints of the human

body. Proc. Inst. Mech. Engrs, 1967, 181, 815.

Wallbridge, N. C. and Dowson, D., The walking activity

of patients with artificial joints. Engineering in Medicine,

1982, 11, 9596.

StataCorp, Stata Statistical Software. Release 4.0. Stata Corporation, College Station, TX.

Caravia, L., Dowson, D., Fisher, J. and Jobbins, B., The

influence of bone and bone cement debris on the counterface roughness in sliding wear tests of ultra-high molecular weight polyethylene on stainless steel. Proc. Inst.

Mech. Engrs, 1990, 204H, 6570.

Sander, M., A Practical Guide to the Assessment of Surface

Texture. Feinpruf Perthen GmbH, Gottingen, 1991.

Bragdon, C. R., OConnor, D. O., Lowenstein, J. D., Jasty,

M. and Syniuta, W. D., The importance of multidirectional motion on the wear of polyethylene. Proc. Inst.

Mech. Engrs, 1996, 210H, 157165.

Wroblewski, B. M., McCullagh, P. J. and Siney, P. D.,

Quality of the surface finish of the head of the femoral

component and the wear rate of the socket in long term

results of Charnley low-friction arthroplasty. Proc. Inst.

Mech. Engrs, 1992, 206H, 181183.

Feller, J. A., Kay, P. R., Hodgkinson, J. P. and Wroblewski,

B. M., Activity and socket wear in the Charnley low-friction arthroplasty. J. Arthroplasty, 1994, 9, 341345.

719

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Week 3 Forecasting HomeworkDocument4 pagesWeek 3 Forecasting HomeworkMargot LaGrandPas encore d'évaluation

- YR7 Revision Sheet - Working ScietificallyDocument6 pagesYR7 Revision Sheet - Working ScietificallyNisha zehra100% (1)

- PEGN Undergraduate FlowchartDocument1 pagePEGN Undergraduate FlowchartLopez RamPas encore d'évaluation

- Petroleum Engineering Course ArrangementDocument1 pagePetroleum Engineering Course ArrangementLopez RamPas encore d'évaluation

- Petroleum Engineering Undergraduate Curriculum 2014 FlowchartDocument1 pagePetroleum Engineering Undergraduate Curriculum 2014 FlowchartLopez RamPas encore d'évaluation

- PEGN Undergraduate FlowchartDocument1 pagePEGN Undergraduate FlowchartLopez RamPas encore d'évaluation

- Articulo Impresion 3dDocument6 pagesArticulo Impresion 3dLopez RamPas encore d'évaluation

- Articulo Impresion 3dDocument6 pagesArticulo Impresion 3dLopez RamPas encore d'évaluation

- Correlación de Imágenes 2DDocument6 pagesCorrelación de Imágenes 2DLopez RamPas encore d'évaluation

- Aramis 11617Document5 pagesAramis 11617Lopez RamPas encore d'évaluation

- Teaching With CES EduPack PDFDocument24 pagesTeaching With CES EduPack PDFLopez RamPas encore d'évaluation

- Engineering Simulation Solutions For Offshore and SubseaDocument41 pagesEngineering Simulation Solutions For Offshore and SubseaLopez RamPas encore d'évaluation

- A Battery Powered Constant Current Stimulator For Motor End Point Detection 1997 Medical Engineering PhysicsDocument4 pagesA Battery Powered Constant Current Stimulator For Motor End Point Detection 1997 Medical Engineering PhysicsLopez RamPas encore d'évaluation

- Aramis Image CorrelationDocument8 pagesAramis Image CorrelationLopez RamPas encore d'évaluation

- Theory & Design of Pressure Vessels PDFDocument319 pagesTheory & Design of Pressure Vessels PDFShree BiradarPas encore d'évaluation

- Pressure Vessel Hand Book - Magesey - 12th Edition-Eugene F MegyesyDocument251 pagesPressure Vessel Hand Book - Magesey - 12th Edition-Eugene F MegyesyajivakkomPas encore d'évaluation

- Diseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionDocument641 pagesDiseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionCristian Lizaraso Pérez100% (1)

- Guía para ASME VIII Div 1.Document313 pagesGuía para ASME VIII Div 1.Lopez RamPas encore d'évaluation

- Diseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionDocument641 pagesDiseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionCristian Lizaraso Pérez100% (1)

- Drill Pipe Performance DataDocument35 pagesDrill Pipe Performance DatasnatajPas encore d'évaluation

- Diseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionDocument641 pagesDiseño de Elementos de Máquinas - V. M. Faires (4ta Edición) SolucionCristian Lizaraso Pérez100% (1)

- ARTÍCULO MasDeteccaoFalhaindustriaProcessoDocument16 pagesARTÍCULO MasDeteccaoFalhaindustriaProcessoLopez RamPas encore d'évaluation

- ARTÍCULO MasDeteccaoFalhaindustriaProcessoDocument16 pagesARTÍCULO MasDeteccaoFalhaindustriaProcessoLopez RamPas encore d'évaluation

- Arte PoveraDocument13 pagesArte PoveraSohini MaitiPas encore d'évaluation

- Various Executions MA: Series Foodstuffs ExecutionDocument17 pagesVarious Executions MA: Series Foodstuffs ExecutionKyriakos MichalakiPas encore d'évaluation

- RPT 2020 DLP Science Year 1 KSSR Semakan 2017 (PART2)Document22 pagesRPT 2020 DLP Science Year 1 KSSR Semakan 2017 (PART2)Nithia MuniandyPas encore d'évaluation

- English Solved SP3Document6 pagesEnglish Solved SP3Prem PatelPas encore d'évaluation

- Line Scan (Switch Hook) : NamesDocument3 pagesLine Scan (Switch Hook) : NamesUsairumPas encore d'évaluation

- ITEM ANALYSIS - MATH 9 EmeraldDocument5 pagesITEM ANALYSIS - MATH 9 EmeraldLiz Rabaya IntiaPas encore d'évaluation

- Mendelian & Modern Genetics: General Biology 2Document51 pagesMendelian & Modern Genetics: General Biology 2sannsannPas encore d'évaluation

- Ancient AstronomyDocument26 pagesAncient AstronomyRodel RamosPas encore d'évaluation

- Gravity Distribution Systems: A System Design and ConstructionDocument40 pagesGravity Distribution Systems: A System Design and ConstructionTooma DavidPas encore d'évaluation

- h1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFDocument14 pagesh1 Styleclearboth Idcontentsection0the Only Guide To Commercial Fisheries Reviewh1jbfch PDFgalleymark22Pas encore d'évaluation

- MCR3U Unit #1 NotesDocument12 pagesMCR3U Unit #1 NotespersonPas encore d'évaluation

- 6480 49 35800 2 10 20230801Document12 pages6480 49 35800 2 10 20230801samsidar nidarPas encore d'évaluation

- Timetable 12 Jan 2022Document54 pagesTimetable 12 Jan 2022abcPas encore d'évaluation

- Simulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine DesignDocument24 pagesSimulation LAB (CAE) M.Tech I-I Sem Mechanical Engineering Machine Designjeevan scplPas encore d'évaluation

- Week 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationDocument8 pagesWeek 4 and 5 Non-Verbal Communication: 4.1 The Importance of Nonverbal CommunicationNovilia FriskaPas encore d'évaluation

- BYRGMv 3Document30 pagesBYRGMv 3tajsisPas encore d'évaluation

- Word Formation - Open Cloze Exercises Unit 1Document2 pagesWord Formation - Open Cloze Exercises Unit 1Fatima Luz RuizPas encore d'évaluation

- HG - Grade 12 - Module 3 - October 14Document19 pagesHG - Grade 12 - Module 3 - October 14RhasmineKyle BeltranPas encore d'évaluation

- SM2 Polygon of ForcesDocument11 pagesSM2 Polygon of ForcesMel DPas encore d'évaluation

- Department of Education: Learning CompetencyDocument2 pagesDepartment of Education: Learning CompetencyShaira May Tangonan CaragPas encore d'évaluation

- Exp 3 Rahul Singh 2k20-A18-12Document8 pagesExp 3 Rahul Singh 2k20-A18-12Dummy Account-Rahul SinghPas encore d'évaluation

- Sheree Hendersonresume 2Document3 pagesSheree Hendersonresume 2api-265774249Pas encore d'évaluation

- Academic Calendar - ARUDocument5 pagesAcademic Calendar - ARUEmmanuella NnodimPas encore d'évaluation

- Humanistic TheoryDocument28 pagesHumanistic TheoryNano KaPas encore d'évaluation

- Weekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Document2 pagesWeekly Home Learning Plan (Q3) Self-Learning Module 4 (Week 5)Richie MacasartePas encore d'évaluation

- Product Data Sheet: Product Description Technical SpecificationDocument1 pageProduct Data Sheet: Product Description Technical SpecificationYASHICA VAITTIANATHANPas encore d'évaluation

- Filtergehà Use - Beutel Und - Kerzen - enDocument5 pagesFiltergehà Use - Beutel Und - Kerzen - ennabila OktavianiPas encore d'évaluation

- English 900 - 01Document147 pagesEnglish 900 - 01Hnin Hnin AungPas encore d'évaluation