Académique Documents

Professionnel Documents

Culture Documents

IBOP Maintenance

Transféré par

Sasan AbbasiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

IBOP Maintenance

Transféré par

Sasan AbbasiDroits d'auteur :

Formats disponibles

INSIDE BLOWOUT PREVENTERS VALVES

OPERATION AND MAINTENANCE PROCEDURE REV 2

04/10

ASSEMBLY PROCEDURE FOR THE INSIDE BLOWOUT

PREVENTER VALVES

4.0 HYDROSTATIC TEST FOR THE INSIDE BLOWOUT

PREVENTER VALVE

1.0 SCOPE

1.1. This procedure will provide general instructions

regarding assembling the Inside Blowout

Preventer valves.

2.0 REFERENCES

2.1. The latest revision of the following specifications

may be used to obtain additional information

regarding this procedure.

API Specification 7-1 latest edition.

Bill of materials.

3.0 ASSEMBLY PROCEDURE

3.1. Clean the Upper and Lower Subs and all internal

parts.

3.2. Visually inspect for signs of damage or wear.

3.3. Fit the Dart with a new elastomer.

The

elastomer must be compatible with the drilling

environment.

3.4. Place the Spring over the Dart stem.

3.5. Install the Guide into the Body.

3.6. Insert the Dart and Spring in the Body and

through the Guide.

3.7. Apply thread compound to connections on the

Body, the Lower Sub and the Stab Body.

Recommended: Thread compound base is to

include 40% to 60% (by weight) finely powdered

zinc.

3.8. Screw the Body into the Sub and make up the

connection with chain tongs or equivalent.

Torque the Body and Sub to the make up torque

value specified per API Specification RP7G. (

Foot/Lb). Individual make up torque values will

be in the accompanying data book.

4.1. Testing shall be performed in accordance with

the test pressure and procedure stipulated in

API SPEC 7-1.

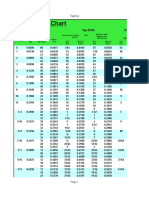

HYDROSTAT IC TEST ING PRESSURES

MINIMUM PRESSURE

WORKING RATING

psi

5000

10,000

15,000

MPa

34.5

68.9

103.4

MAXIMUM HYDROSTATIC

SHELL TEST PRESSURE

psi

10,000

15,000

22,500

MPa

68.9

103.4

155.1

Note: test pressure shall be stabilized prior to the

timing start for holding pressure.

4.2. Lubricate the pin and box connections of the

valve.

4.3. Install the test plug and cap on the connections

of valve assembly to be tested.

4.4. With valve hanging Pin up and Box down, install

pressure line to bottom of valve (box

connection).

4.5. With the bleed valve on top of the test plug in

the open position, fill the valve with water until

the water bleeds through the open valve.

Agitate the valve and actuate the bleed valve

several times to eliminate any trapped air in the

valve body.

4.6. Close the bleed valve.

4.7. Pressurize the Valve body to the recommended

pressure per API SPEC 7-1

4.7.1. Engage pump and pressure to required

test pressure from the table above and

stabilize. After stabilization of pressure,

the valve will be held at pressure for three

(3) minutes minimum with no detectable

pressure drop or leakage.

4.7.2. At the elapse of the three minutes, the

pressure will be reduced to zero.

4.7.3. Engage pump a second time to required

test pressure and hold for a minimum of 10

minutes.

4.8. If pressure is held, release pressure. After the

pressure is released, open the bleed valve on

the top of the test plug and release the pressure

trapped inside.

22397 White Oak Drive Conroe, Texas 77306-8859 Tel: 281-399-8771 Fax: 281-399-8773 www.packardint.com

1/3

INSIDE BLOWOUT PREVENTERS VALVES

OPERATION AND MAINTENANCE PROCEDURE REV 2

04/10

4.9. Turn the valve over and remove the test plug

from the Upper Sub. Install a pressure line to

the bottom (pin) connection of valve.

4.10. Using the release rod, push against the dart and

fill it with water. The water level is to be above

the internals and into the Sub. Release the dart.

DISASSEMBLY PROCEDURE FOR

BLOWOUT PREVENTER VALVE

THE

INSIDE

1.0 SCOPE

This procedure will provide general instructions regarding

disassembly of the Inside Blowout Preventer valves.

2.0 REFERENCES

4.11. Pressurize the valve to the working pressure.

Hold the pressure for five minutes minimum with

no detectable pressure drop or leakage.

4.12. Release the pressure on the assembly.

4.13. If the valve does not test, disassemble, clean,

reassemble, and retest the valve to the

requirements as outlined in this procedure.

5.0 INSTALLING THE STAB BODY ASSEMBLY

5.1. Insert the release rod through ID of the lifting

handle from the pin end of the Stab Body.

2.1. The latest revision of the following specifications

may be used to obtain additional information

regarding this procedure.

API Specification 7-1 latest edition.

Bill of materials.

3.0 DISASSEMBLY PROCEDURE

3.1. Remove Stab Body

3.2. Remove the Releasing Handle.

3.3. Remove the Releasing Rod.

5.2. Screw the releasing handle into the threaded

hole of the Stab Body.

3.4. Inspect all components for wear or damage.

5.3. Apply thread compound to the connections on

The Sub and Stab Body. Recommended: The

compound base is to include 40% to 60% (by

weight) finely powdered zinc.

3.5. Clean parts, replace wore or damaged ones and

assemble the Stab Body Assembly (refer to 5.0

to reassemble the Stab Body).

5.4. Insure the Releasing Handle is loose.

3.6. Break the connection between the Body and the

Sub.

5.5. Screw the Stab Body into the box end of the

IBOP Sub.

3.7. Remove all internal parts.

3.8. Remove Elastomeric Seal from the Dart.

5.6. Depress the Releasing Rod to open the Valve.

5.7. Tighten the Releasing Handle.

3.9. Thoroughly clean all parts and valve body.

Worn or damaged parts should be replaced prior

to re-assembly.

22397 White Oak Drive Conroe, Texas 77306-8859 Tel: 281-399-8771 Fax: 281-399-8773 www.packardint.com

2/3

INSIDE BLOWOUT PREVENTERS VALVES

OPERATION AND MAINTENANCE PROCEDURE REV 2

04/10

PREPARING THE INSIDE BLOWOUT PREVENTER

VALVE FOR INSTALLATION

6.3. Store standing on pin, or laying on its side in a

controlled environment with the Releasing Rod

depressed and the Release Handle tightened.

1.0 SCOPE

1.1. This procedure will provide general instructions

regarding installation of the Inside Blowout

Preventer valves.

2.0 REFERENCES

2.1. The latest revision of the following specifications

may be used to obtain additional information

regarding this procedure.

API Specification 7-1 latest edition.

Bill of materials.

3.0 INSTALLATION PROCEDURE

3.1. Clean the shipping thread compound from the

threaded connections.

Release Rod

Release Handle

Stab Body

Sub

Dart + Dart Seal

3.2. Apply thread compound suitable for drill string

use.

3.3. Recommended: Thread Compound base is to

include 40% to 60% (by weight) finely powdered

zinc.

Wave Spring

NOTE: Failure to follow the above procedure explicitly

may result in damage and subsequent premature

valve failure.

Guide

STORAGE OF THE IBOP ASSEMBLY

4.0 SCOPE

4.1. This procedure will provide general storage

instructions of an Inside Blowout Preventer

valve.

Body

5.0 REFERENCES

5.1. The latest revision of the following specifications

may be used to obtain additional information

regarding this procedure.

API Specification 7-1 latest edition.

Bill of materials.

6.0 STORAGE PROCEDURE

6.1. If the valve is returning from service in the drill

string, disassemble and clean and re-assemble

with serviceable components.

6.2. Ensure thread protectors are installed.

ISO9001:2008 # 0163

API # 7-1-0207

22397 White Oak Drive Conroe, Texas 77306-8859 Tel: 281-399-8771 Fax: 281-399-8773 www.packardint.com

3/3

Vous aimerez peut-être aussi

- User Manual: Mechanical WashpipeDocument60 pagesUser Manual: Mechanical WashpipeIvan Villarreal LopezPas encore d'évaluation

- Deadline AnchorDocument27 pagesDeadline AnchorLucio Reyes MetelínPas encore d'évaluation

- DG450 Hook Parts ListDocument8 pagesDG450 Hook Parts ListHala Dawod50% (2)

- Piston Separator TW714Document12 pagesPiston Separator TW714Mihai Matei100% (3)

- 250-HXI-700 - Oct 13 2010Document184 pages250-HXI-700 - Oct 13 2010Carlos100% (1)

- WWW 018999Document39 pagesWWW 018999Andhie OsloPas encore d'évaluation

- D-GASSERS Orizontal + Vertical PDFDocument2 pagesD-GASSERS Orizontal + Vertical PDFciucalata880% (1)

- Mast Leg Weight Indicator: Part Number TW1001 Revision ADocument20 pagesMast Leg Weight Indicator: Part Number TW1001 Revision ALuis Eduardo Albarracin RugelesPas encore d'évaluation

- DG450 HOOK 大钩: Parts List 5-B)Document8 pagesDG450 HOOK 大钩: Parts List 5-B)waleed100% (1)

- Varco Ibop Valves PDFDocument50 pagesVarco Ibop Valves PDFEl Arbi LAKHDARIPas encore d'évaluation

- Canrig TM80/120 SpecsDocument16 pagesCanrig TM80/120 Specsaris4silveyraPas encore d'évaluation

- Titan Class Type "B" Reset Relief Valve Operations & Maintenance ManualDocument20 pagesTitan Class Type "B" Reset Relief Valve Operations & Maintenance ManualJuan LorenzoPas encore d'évaluation

- FloatValve 4-13 PDFDocument8 pagesFloatValve 4-13 PDFcaballero_tigrePas encore d'évaluation

- Master and Casing Bushing - ACEWELDocument8 pagesMaster and Casing Bushing - ACEWELcristinelb100% (1)

- D30E200 Hook-Block - Operations Manual (30780000 Rev.0) American BlockDocument29 pagesD30E200 Hook-Block - Operations Manual (30780000 Rev.0) American BlockMaria Julieta Calderon Ortiz100% (2)

- FORUM General Catalog Handling Tools 2017Document88 pagesFORUM General Catalog Handling Tools 2017Eduardo Braga100% (1)

- Oil Country TongsDocument79 pagesOil Country TongsKevin PaulPas encore d'évaluation

- 1562+Fz35 35闸板防喷器+用户手册a0 英文Document34 pages1562+Fz35 35闸板防喷器+用户手册a0 英文Jaya Manggala SaktiPas encore d'évaluation

- Swivel Tool CatalogDocument16 pagesSwivel Tool CatalogVishal RamsookPas encore d'évaluation

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDocument12 pagesAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- Catalog 720475Document2 pagesCatalog 720475Игорь Ширенин100% (1)

- 120 Ton Power Swivels PISDocument17 pages120 Ton Power Swivels PISgheorghePas encore d'évaluation

- P-400 Swivel & UniflexDocument4 pagesP-400 Swivel & UniflexIvan Villarreal LopezPas encore d'évaluation

- M/D Totco'" Inell: 1 Part Number 26-61 Revision ADocument47 pagesM/D Totco'" Inell: 1 Part Number 26-61 Revision AAndres Navarro50% (2)

- CanrigBJWPC ICO Manual PDFDocument42 pagesCanrigBJWPC ICO Manual PDFCarlos Patiño SuarezPas encore d'évaluation

- Master Bushing-Insert Bowls - API 7KDocument2 pagesMaster Bushing-Insert Bowls - API 7KcristinelbPas encore d'évaluation

- TM-517 AOI Piston Separator ManualDocument32 pagesTM-517 AOI Piston Separator ManualAndi Yusuf50% (2)

- Gardener Denver PZ8 SpecsDocument2 pagesGardener Denver PZ8 SpecsExpertum99Pas encore d'évaluation

- WWW - Incar.tw-Kelly Spinner ManualDocument6 pagesWWW - Incar.tw-Kelly Spinner ManualSachin KumarPas encore d'évaluation

- Manual Farr 14-50Document166 pagesManual Farr 14-50JAVIER EDUARDO MANTILLA BUITRAGO100% (1)

- Inverted Washpipe ManualDocument9 pagesInverted Washpipe ManualGhassan ALkikiPas encore d'évaluation

- Packard CatalogDocument22 pagesPackard Catalogcrni roko100% (1)

- P QUIP Swab and Pony RodDocument5 pagesP QUIP Swab and Pony Rodkrishnsgk0% (1)

- FMS 275 ManualDocument62 pagesFMS 275 ManualRagesh Raghavan100% (2)

- NXT-M Bop TMSDocument1 pageNXT-M Bop TMSSasan Abbasi100% (1)

- Parts List EMI 450Document185 pagesParts List EMI 450Mauricio Garcia100% (1)

- Varco BushingsDocument1 pageVarco BushingsVision100% (1)

- SL 450 Swivel User's ManualDocument19 pagesSL 450 Swivel User's ManualHala DawodPas encore d'évaluation

- WF400 07048Document146 pagesWF400 07048Junior Francisco QuijanoPas encore d'évaluation

- 06-Brake Rims & BandsDocument11 pages06-Brake Rims & BandsMartinez Mauricio Martinez GomezPas encore d'évaluation

- Bba de Lodos Dampener - Instruction - Manual - Rev - DDocument10 pagesBba de Lodos Dampener - Instruction - Manual - Rev - Desteban monterrosa lopez100% (3)

- HHF-1600 Direct-Drive Pump Utilization Parts ListDocument27 pagesHHF-1600 Direct-Drive Pump Utilization Parts ListJohn Simanca100% (1)

- Swivel (水龙头)Document16 pagesSwivel (水龙头)Omar Fathy100% (1)

- 7838 Brake Care and OperationDocument54 pages7838 Brake Care and OperationMarutpal Mukherjee100% (1)

- HH-Rotary Table ZP175 - ZP205 PDFDocument3 pagesHH-Rotary Table ZP175 - ZP205 PDFYosed L SantosPas encore d'évaluation

- Manual-0002 CDocument87 pagesManual-0002 CBoedi SyafiqPas encore d'évaluation

- Southwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListDocument10 pagesSouthwest Oilfield Products, Inc.: Mud Pump Expendable Parts ListCarlos Alberto Perdomo100% (1)

- WPI C or CHD Tubing Spider Manual Rev1Document14 pagesWPI C or CHD Tubing Spider Manual Rev1Dean Rein100% (1)

- Demco Gate Valve PDFDocument56 pagesDemco Gate Valve PDFyacine3516100% (1)

- Retsco/Demco Mud Guns: Bottom TypeDocument1 pageRetsco/Demco Mud Guns: Bottom TypeGregory StewartPas encore d'évaluation

- A Continental Emsco Company: F-350 Thru F-750 Crankshaft AssemblyDocument1 pageA Continental Emsco Company: F-350 Thru F-750 Crankshaft Assemblydedy HPas encore d'évaluation

- Annular Dissassembly ExtractDocument2 pagesAnnular Dissassembly ExtractAshraf GabrPas encore d'évaluation

- #HB-1-81 22SR Lip Manual PDFDocument22 pages#HB-1-81 22SR Lip Manual PDFLucas Maldonado100% (1)

- Annular Bop Packing Elements: Otu Se (Axs)Document2 pagesAnnular Bop Packing Elements: Otu Se (Axs)JoseManuelDominguezHuertaPas encore d'évaluation

- Demco DM Iom PDFDocument24 pagesDemco DM Iom PDFAshok SureshPas encore d'évaluation

- Api 7K & ASTME 165E/E709Document1 pageApi 7K & ASTME 165E/E709engmuhmudPas encore d'évaluation

- Manual Air Blast 300Document13 pagesManual Air Blast 300Mario EprataPas encore d'évaluation

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranPas encore d'évaluation

- Valvula de Control ProporcionalDocument8 pagesValvula de Control ProporcionalAlex ReañoPas encore d'évaluation

- Series 808Y Installation InstructionsDocument4 pagesSeries 808Y Installation InstructionsFEBCOPas encore d'évaluation

- 1930PA enDocument1 page1930PA enSasan Abbasi100% (1)

- Logan Welded Cup Junk SubsDocument2 pagesLogan Welded Cup Junk SubsSasan AbbasiPas encore d'évaluation

- Assistant Barge Supervisor 9-16-04Document3 pagesAssistant Barge Supervisor 9-16-04Sasan AbbasiPas encore d'évaluation

- Tap Drill CalculatorDocument1 pageTap Drill CalculatorSasan AbbasiPas encore d'évaluation

- Drill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsDocument7 pagesDrill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsSasan AbbasiPas encore d'évaluation

- 77 3001 TypeDDocument8 pages77 3001 TypeDSasan AbbasiPas encore d'évaluation

- LaMOT RD CatalogDocument20 pagesLaMOT RD CatalogSasan Abbasi0% (1)

- Corrosion AllowanceDocument35 pagesCorrosion AllowanceReni Mutiara Sari50% (2)

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaPas encore d'évaluation

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- Ifu 5902152 Emgy DSCNT DviceDocument12 pagesIfu 5902152 Emgy DSCNT DviceSasan AbbasiPas encore d'évaluation

- Cylinder To Regulator AdaptorsDocument2 pagesCylinder To Regulator AdaptorsSasan AbbasiPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesDocument7 pages(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiPas encore d'évaluation

- Pipe Racking System OJTDocument20 pagesPipe Racking System OJTDanang PrasetioPas encore d'évaluation

- Optimist Tuning GuideDocument9 pagesOptimist Tuning GuideSasan AbbasiPas encore d'évaluation

- Hard Versus Soft Shut inDocument15 pagesHard Versus Soft Shut inAgus AlexandriPas encore d'évaluation

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- U BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealDocument1 pageU BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealSasan AbbasiPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- Rig MoveDocument10 pagesRig MoveSasan AbbasiPas encore d'évaluation

- Imperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)Document1 pageImperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)OSCAR BUSTOSPas encore d'évaluation

- 0080A-60.3118 PublicationDocument1 page0080A-60.3118 PublicationSasan AbbasiPas encore d'évaluation

- Diverter SDocument12 pagesDiverter SSasan AbbasiPas encore d'évaluation

- Draw WorksDocument32 pagesDraw WorksSasan AbbasiPas encore d'évaluation

- 4 - Figures and Tables - Fluid FlowDocument22 pages4 - Figures and Tables - Fluid FlowCarlosCD17Pas encore d'évaluation

- Introduction To Regional PlanningDocument27 pagesIntroduction To Regional Planningadeeba siddiquiPas encore d'évaluation

- 28 ESL Discussion Topics Adult StudentsDocument14 pages28 ESL Discussion Topics Adult StudentsniallPas encore d'évaluation

- Fall 20122Document98 pagesFall 20122DobarCovek67% (3)

- Bank OD Account in Tally 1Document3 pagesBank OD Account in Tally 1yashusahu180Pas encore d'évaluation

- Hybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and DemonstratedDocument4 pagesHybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and Demonstratedmohamad theibechPas encore d'évaluation

- Department of Labor: BC Retaining Wall CodeDocument2 pagesDepartment of Labor: BC Retaining Wall CodeUSA_DepartmentOfLaborPas encore d'évaluation

- Unseen Passage 2Document6 pagesUnseen Passage 2Vinay OjhaPas encore d'évaluation

- Quizlet Table 7Document1 pageQuizlet Table 7JosielynPas encore d'évaluation

- Stitch2421 1 Kit PDFDocument8 pagesStitch2421 1 Kit PDFJoshua Robertson100% (1)

- Exam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)Document10 pagesExam C - HANATEC142: SAP Certified Technology Associate - SAP HANA (Edition 2014)SadishPas encore d'évaluation

- Portfolio Eelco Maan - 06-2017Document25 pagesPortfolio Eelco Maan - 06-2017tungaas20011Pas encore d'évaluation

- Cases To Examine - EuthanasiaDocument1 pageCases To Examine - EuthanasiadamianmackytPas encore d'évaluation

- Classical School of Thought: Ms. Salma ShaheenDocument62 pagesClassical School of Thought: Ms. Salma ShaheenQasim Ali100% (1)

- GENUS Clock Gating Timing CheckDocument17 pagesGENUS Clock Gating Timing Checkwasimhassan100% (1)

- Helical Coil FlowDocument4 pagesHelical Coil FlowAshish VermaPas encore d'évaluation

- Asme Bladder Accumulator DatasheetDocument3 pagesAsme Bladder Accumulator DatasheetSamad A BakarPas encore d'évaluation

- H I Ôn Thi Aptis & Vstep - Tài Liệu - Anna MaiDocument4 pagesH I Ôn Thi Aptis & Vstep - Tài Liệu - Anna Maihanh.mt2022Pas encore d'évaluation

- FO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1Document2 pagesFO - Course Transition Info - Acknowledgement - SIT50422 - Dip Hospitality Management - V1nitesh.kc06Pas encore d'évaluation

- A Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofDocument65 pagesA Dessertation Report Submitted in Partial Fulfillment of Requirements For The Award of The Degree ofMadhavpokale100% (1)

- About TableauDocument22 pagesAbout TableauTarun Sharma67% (3)

- Architecture of Neural NWDocument79 pagesArchitecture of Neural NWapi-3798769Pas encore d'évaluation

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementDocument52 pagesCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- (IGC 2024) 2nd Circular - 0630Document43 pages(IGC 2024) 2nd Circular - 0630VictoriaPas encore d'évaluation

- JAMB Syllabus For BiologyDocument27 pagesJAMB Syllabus For BiologyOluebube UchennaPas encore d'évaluation

- AC AMMETER / Moving Iron: Model AECDocument33 pagesAC AMMETER / Moving Iron: Model AECRoonar Aponte NoaPas encore d'évaluation

- Sorting Algorithms in Fortran: Dr. Ugur GUVENDocument10 pagesSorting Algorithms in Fortran: Dr. Ugur GUVENDHWANIT MISEPas encore d'évaluation

- Taxonomy: Family StaphylococcaceaeDocument40 pagesTaxonomy: Family StaphylococcaceaeMarissa Terrado SorianoPas encore d'évaluation

- Claudio MonteverdiDocument2 pagesClaudio MonteverdiBrendan LynchPas encore d'évaluation

- Maven MCQDocument55 pagesMaven MCQANNAPUREDDY ANIL KUMAR REDDY CSEPas encore d'évaluation

- EHR StandardsIndia - August 2013-32630521Document54 pagesEHR StandardsIndia - August 2013-32630521kartiksinhPas encore d'évaluation

- Workbook to Accompany Maintenance & Reliability Best PracticesD'EverandWorkbook to Accompany Maintenance & Reliability Best PracticesÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- A Complete Guide to Safety Officer Interview Questions and AnswersD'EverandA Complete Guide to Safety Officer Interview Questions and AnswersÉvaluation : 4 sur 5 étoiles4/5 (1)

- Gas-Liquid And Liquid-Liquid SeparatorsD'EverandGas-Liquid And Liquid-Liquid SeparatorsÉvaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Chemical Process Safety: Learning from Case HistoriesD'EverandChemical Process Safety: Learning from Case HistoriesÉvaluation : 4 sur 5 étoiles4/5 (14)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemD'EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemPas encore d'évaluation

- Guidelines for Auditing Process Safety Management SystemsD'EverandGuidelines for Auditing Process Safety Management SystemsPas encore d'évaluation

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsD'EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsÉvaluation : 4 sur 5 étoiles4/5 (11)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Rules of Thumb for Maintenance and Reliability EngineersD'EverandRules of Thumb for Maintenance and Reliability EngineersÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Introduction to Petroleum Process SafetyD'EverandIntroduction to Petroleum Process SafetyÉvaluation : 3 sur 5 étoiles3/5 (2)

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisD'EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- The Invisible Rainbow: A History of Electricity and LifeD'EverandThe Invisible Rainbow: A History of Electricity and LifeÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsD'EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsPas encore d'évaluation

- Tensor Technology Guide: Tensor Ring Benefits and UsesD'EverandTensor Technology Guide: Tensor Ring Benefits and UsesÉvaluation : 5 sur 5 étoiles5/5 (2)

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesD'EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Plutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersD'EverandPlutopia: Nuclear Families, Atomic Cities, and the Great Soviet and American Plutonium DisastersÉvaluation : 4 sur 5 étoiles4/5 (32)

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- Redefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesD'EverandRedefining Work Health and Safety: Systems, Strategies, and Progressive ApproachesPas encore d'évaluation

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsD'EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (4)