Académique Documents

Professionnel Documents

Culture Documents

Production of Chips of Porang (Amorphophallus Oncophyllus) by Slicing Machine With Rotating Double Cutters

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Production of Chips of Porang (Amorphophallus Oncophyllus) by Slicing Machine With Rotating Double Cutters

Droits d'auteur :

Formats disponibles

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

Production of Chips of Porang

(Amorphophallus Oncophyllus) by Slicing Machine

With Rotating Double Cutters

Kristinah Haryani 1

1

Chemical Engineering Dept.,

Faculty of Engineering, UNDIP

Semarang, Indonesia

Suharto2

2

Mechanical Engineering Dept.,

Semarang State Polytechnic,

Semarang, Indonesia

Suryanto3

3

Mechanical Engineering Dept

Semarang State Polytechnic,

Semarang, Indonesia

Abstract Chips of porang (amorphophallus oncophyllus) is slice of tubers of porang as a main material for

glucomannan flour-making. Glucomannan flour containing high glucomannan is very useful to the food industry,

non-food and health. Chips of porang production among the farmers in Magelang, Central Java, still use manual

method that resulting low chips quality that does not meet for further processing, namely manufacturing of flour

glucomannan. This applied research is intended to design the tubers chips maker with double rotating cutters to

produce chips of uniform and the same thickness. The method used is engineering design approach starting from

process of machine design, manufacture engine components, and engine performance testing. The result is a slicing

machine with rotating cutters for producing chips of porang with the specifications: length dimension: 1000 (mm),

width 750 (mm), height 1000 (mm), the weight of the machine: 85 (kg), the drive unit: motor gasoline of 5.5 HP. It

was found that best performance of cutting process of the rotating double cutters is at 120 rpm, cutter angle of

inclination is of 30o, and production capacity is of 310 kg per hour.

Keywords chips of porang, rotating double cutters

I. INTRODUCTION

Tubers of porang (amorphophallus oncophyllus) or in Indonesia often called iles-iles including araceae family that

grows in warm sub-tropical climate to tropical areas like East Asia, South China, Japan, to Indonesia as in [1]. Tubers of

porang size varies from diameter of 100 mm to 200 mm with a weight of up to 1 kg as shown in Figure 1. Chips are

sliced tubers of porang with a thickness of 8 mm that has been dried. Tubers of porang flour obtained by milling process

and filtered with 80 mesh. Glucomannan flour contained the resulted porang flour can be separated by applying cyclone

separation method. Through the process of cyclone glucomannan flour mass separated from lighter mass of flour

potassium oxalate. Thus the manufacture of qualified chips of porang is the starting point of glucomannan flour

production. Learn the process of making glucomannan flour starting from tubers of porang crops, washing, slicing,

drying, flouring, flour separation, purification processes, to obtain a high starch content of glucomannan. Based on

experiments the ratio of wet tubers of porang compared to dry porang chips is 7 : 1, it means that 7 (seven) kilograms of

wet tubers of porang will become 1 (one) kilogram of dry chips through a washing, slicing, and drying processes.

Previous studies such as [2]describes porang glucomannan flour is quite high (15-64% dry basis). Referrence [3]

explained that porang tubers are used as raw material for the food industry since 1000 and last year in Japan and China.

Furthermore, [4]; [5], and [6] explained that glucomannan is a soluble fiber content of foods with a high water, low in

calories and specific hydrocoloid. Utilization of tubers of porang into flour is one option for easy storage and processing

into food, non-food, and healthcare.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -26

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

Figure 1. Tubers of porang with size of 100 to 150 mm in diameter

Figure 2. Production processes from tubers into chips of porang

There are three main stages to produce chips of porang, i.e. (1) washing; (2) slicing; and (3) drying. Figure 2 shows the

stages of the process of making chips from tubers of porang. The process of making chips are generally done manually

with a single cutter as illustrated Figure 3. The wet chips resulted from slicing process are then dried on open air. The

process of making these chips do not guarantee the quality of the resulting dry chips for the process of glucomannan flour

quality. This leads to the development of slicing method using double cutters mounted on a rotating stand. The objective

of development of slicing method is to increase chips productivity and quality of the chips that appropriate to

glucomannan flour-making industry.

Figure 3. Manual method of chips porang production and drying chips resulted

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -27

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

Slicing process of tubers of porang to produce chips that done manually has shortcomings on the uniformity of sizes

resulted and low quality of chips. Slicing the tubers manually also potentially be accident on the operator's hands. The

use of double cutters on a rotating holder for the manufacture of wet chips increase productivity and uniformity of shape

and size of the chips, comfort and safety for the operator.

This applied research is intended to produce a simple tubers of porang slicing machine generated by gasoline engine, by

which these research activities starting from the design, manufacture, and testing of performance of the slicing machine.

Benefits of the machine will be usefull for the farmers to produce chips of porang easily and cheaply.

II. METHOD

This applied research is of engineering approach based on three main activities, namely designing, manufacturing and

testing. This method of applying engineering approach is an exercise as of expressed by [7], [8], [9], that applied research

is research being undertaken with a view to implementing, testing, and evaluating the ability to provide solutions to

certain problems in practice.

First, the design process is inisiated by functional aspect of the designed machine, cost of manufacture of the machine,

cost of operation of the machine, time of manufacture, aspects of ergonomics, ease of finding the machine components

that available on local market, ease of maintenance and repair, security in the operation of the machine, and aesthetics,

then set one design selection. All of these considerations are then carried out to be a technical drawing to illustrate the

prototype of the machine. Based on the technical drawing the process of making machines are begun, in which all

componnents of the machines are manufactured or supplied. Then the assembly of the machine is then conducted

accordingly. Testing of the machine performance is then carrie out to determine if it can work properly or not. If the

machine is not functioning properly then do repairs machines to perform well in line with expectations. Figure 4 shows

the process of flow diagram to manufacture the machines.

Figure 4. Process of flow diagram to manufacture the machines

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -28

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

DESIGN PROCESS. Design considerations include the following: (1) use of a single cutter is done manually and is less

efficient and prone to operator; (2) thickness of the slice desired is 8 s.d 10 (mm); (3) tubers of porang containing

potassium oxalate itchy skin contact; (4) tubers of porang size ranges from 100 to 150 (mm); (5) production capacity of

the wet chips is 300 (kg / h) with a slice direction and a uniform thickness. Based on these considerations the design

process starting from (1) selection of materials for construction, (2) calculation and analysis of the strength of materials,

which includes cutting force, torque, cutting power, gears, pulleys, belts, shafts, pins, bearings, fasteners, cutter material,

and rotating cutters holder by using formulas elements of machines and machine design as in [10], [11]. While working

drawings were made following the ISO standardization of componnents in [12] . Result of the design process is working

drawings of prototype of slicing machine with rotating cutters for producing chips of porang shown in Figure 5.

Figure 5. Prototype of slicing machine with rotating cutters for producing chips of porang

MANUFACTURING COMPONENTS. The process of manufacturing of machine components based on the design of working

drawings. Manufacturing of components will be done mainly for special components of the machine designed according

to the needs. Other components are standard components which are generally available through procurement. The

manufacture of special components primarily using a lathe, milling, drilling machines, bench work, and welding with the

calculation of working time and production costs. The following components are to be manufactured: cutters, rotating

disc with double cutters, shaft, body stand, mounting for gasoline engine, hopper input and output tunnel. The standard

components are bearings, gears, belts, pulleys, and gasoline engine unit.

ASSEMBLY. Assembly is a process of preparation and pooling all component parts into a device or machine that has a

specific function as already designed. Assembly begins with preparing the components that have been made and standard

components prepared. If the componnents are joined perfectly and occupied the correct position, then the machine will

ready to be tested for the operation of slicing of tubers of porang.

Working mechanism of slicing machine with rotating cutters for producing chips of porang:

(a) Check carefully all parts of the machine accordingly;

(b) Turn on the key to start the gasoline engine and control its steady rotation;

(c) Enter tubers of porang into hopper (with its load itself tubers of porang will drop down through a double rotating

cutters);

(d) After slicing process the resulted chips will drop on the tunnel output;

(e) Thick of chips can be set using the regulator screw cutters to be 8 to 10 (mm) in thick. The hole in the disc is made

at least three times of chips thick to facilitate resulting chips easily dropped out and not damaged or broken;

(f) The process of slicing tubers of porang carried out through double rotating cutters horizontally and tubers of

porang entered through two input hopper;

(g) If the tubers of porang is running out, put the next tubers of porang respectively;

(h) Operate the machine to produce chips of porang repeatedly, in order to work optimally with the resulted chips of

uniform shapes and sizes;

(i) Place the chips resulted from collector under the out put tunnel to drying process area.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -29

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

III. RESULT AND DISCUSSION

SLICING MACHINE WITH ROTATING CUTTERS. Process of flow diagram to manufacture the machines has been realized

accordingly and the slicing machine with rotating cutters has been resulted as illustrated on Figure 6. Slicing machine

with rotating cutters for producing chips of porang is designed to help people of Magelang, Central Java, who processing

tubers of porang into chips. This activity is carried out as public service program conducted by Team of Hi-Link Program

(2016-2018), Semarang State Polytechnic, Semarang, in collaboration with the Service of Agriculture, Animal

Husbandry and Fisheries Affairs, Magelang City in order to improve the local economy through the cultivation,

processing and utilization of tubers of porang. Production of chips manually have been constrained by the low quality of

chips resulted and sustainability of production in order to meet consumer needs at Magelang City.

(a) Covered

(b) Uncovered

Figure 6. Slicing machine with rotating cutters for producing chips of porang

NAME OF MACHINE

POWER GENERATOR

CAPACITY

SIZE OF CHIPS PRODUCED

DIMENSION

WEIGHT

MACHINE SPECIFICATIONS :

: SLICING MACHINE WITH ROTATING CUTTERS FOR PRODUCING CHIPS OF PORANG

: GASOLINE ENGINE 5,5 (HP)

: 300 (KG/HOUR)

: 8 TO 10 MM IN THICK

: 100 X 75 X 100 (CM)

: 85 (KG)

Novelty of this slicing machine is on the cutter design that is easily available in the local market. When the cutter is

getting dull, it can be removed and replaced easily. The size of chips resulted by this machine is 8 to 10 (mm) in thick.

Figure 7. Percentage of quality and varieties of thickness of chips

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -30

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

REMARKS:

QUALITY A = THICK AND UNIFORM SHAPE, CLEAN AND PERFECT

QUALITY B = THICK AND UNIFORM SHAPE, CLEAN AND UNPERFECT

QUALITY C = THICK AND NON-UNIFORM SHAPE, DIRTY AND BROKEN

SIZE OF TUBERS OF PORANG IS 100 TO 150 MM IN DIAMETER, AND AVERAGE EACH WEIGHT IS 1,5 KG

PERFORMANCE TESTING OF THE M ACHINE. Testing the performance of the machine is an attempt to determine the

performance chips of porang resulted based on test functions and the work of the machine. The testing process is done

with cutter type and rotation variables of the machine. In doing so the test is to observe the results of slicing of tubers of

porang. The results of all the tests performed are recorded and tabulated as test data. Results of testing the performance of

the machine shown in Figure 7 and Table 1.

It was found that quality of chips resulted depends on thick of cutter, angle of cutting edge, cutter rotation speed. The

best result of quality of chips was found on the following parameters: thick of cutter of 2 mm, angle of edge of 30o, and

cutter rotation speed of 140 rpm. With these parameters the slicing machine can produce 300 kg/hour chips of porang by

entering input of tubers of porang1,5 kg (average). The quality of chips of porang yielded were quality A (80%), B (20%),

and C (0%).

Figure 8. Tubers of Porang and Chips of Porang

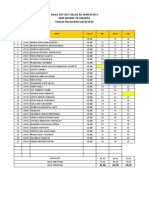

TABLE 1

PERFORMANCE TESTING OF THE SLICING MACHINE FOR PRODUCTION CHIPS OF PORANG

NR.

EXPERIMENT

1

2

3

4

5

6

7

8

9

10

THICKNESS

OF CUTTER (MM)

5

5

5

5

5

2

2

2

2

2

ANGLE OF

CUTTING EDGE

45

45

45

45

45

30

30

30

30

30

CUTTER ROTATION

SPEED (RPM)

90

105

140

150

160

90

105

140

150

160

TIME

(SECOND)

18

18

18

17

15

17

16

15

14

13

QUALITY OF CHIPS

RESULTED

A=75%; B=25%; C=0

A=77%; B=23%; C=0

A=78%; B=22%; C=0

A=77%; B=23%; C=0

A=78%; B=22%; C=0

A=83%; B=17%; C=0

A=84%; B=16%; C=0

A=85%; B=15%; C=0

A=82%; B=18%; C=0

A=81%; B=19%; C=0

IV. CONCLUSIONS

Effort to overcome shortcomings in production of chips of porang, especially in Magelang City, using manual slicing

device can be alternatively to switch operating the slicing machine with rotating cutters for producing chips of porang as

already designed and tested. The specifications of the machine are as follows: capacity of chips production 300 kg/hour,

dimension 1000 x 750 x 1000 mm, weight 85 kg, and power generation of gasoline engine 5,5 HP. It was found that the

best result of quality of chips will be reached with the following parameters: thick of cutters 2 mm, angle of edge 30o,

and cutter rotation speed 140 rpm. In addition upon these parameters the slicing machine can produce 300 kg/hour chips

of porang based on average weight each tubers of 1,5 kg. The quality of chips of porang yielded were: quality A (85%),

B (150%), and C (0%). By operating this machine safety of the operator can be assured compared with operating of hand

slicing device.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -31

International Journal of Innovative Research in Advanced Engineering (IJIRAE) ISSN: 2349-2763

Issue 09, Volume 3 (September 2016)

www.ijirae.com

ACKNOWLEDGMENT

The authors extend special thanks to the Director of Semarang State Polytechnic, Head of Service of Agriculture,

Animal Husbandry and Fisheries Affairs, Magelang City, and Chairman of Research and Public Service Center

(P3M), Semarang State Polytechnic, Semarang, upon which a collaboration between these institutions can be

conducted for Hi-Link Program for Public Service (2016-2018) funded by Ministry of Research, Technology, and

Higher Education, Republic of Indonesia.

REFERENCES

[1] Ambarwati, E., R. H. Murti, Haryadi, A. Basyir, dan S. Widodo. 2000. Eksplorasi dan Karakterisasi Iles-iles. LP

Universitas Gadjah Mada bekerjasama dengan PAATP Balitbangtan, Yogyakarta.

[2] Anni Faridah, Simon Bambang Wijanarko, Aji Sutrisno, & Bambang Susilo, 2014. Optimasi Produksi

TepungPorangdari Chip Porang secara Mekanis dengan Metode Respons.

[3] Zhang, Y., Xie, B., & Gan, X., 2005. Advance in Apllication of Konjac Glucomannan and its Derivatives.

Carbohydrate Polimers, 60, 27-31.

[4] Katsuraya, K., Okuyama, K., Hatanaka, K., Oshima K., Sato, T., & Matsuzaki, K., 2003. Contitution of Konjac

Glucomannan: Chemical Anlysis and 13C NMR Spectroscopy. Carbohydrate Polymers, 53, 183-189.

[5] Gao, S.J, & Nishinari, K. 2004. Effect of Degree of Acetilation on Gelation of Konjac Glucomannan.

Biomacromolecules, 5, 175-185.

[6] Yang, X. H., Zhu, W.L., dan Yan, J.F., 2006. A Time Temperature Rheological Study of Konjac Glucomannan

Hydrocolloid. Journal of Biomaterial Science, 17 (12), 5359.

[7] Husein Umar, 2008. Metode Penelitian untuk Skripsi dan Tesis Bisnis. Jakarta. Raja Grafindi Persada.

[8] Endang Mulyatiningsih, 2012. Metode Penelitian Terapan Bidang Pendidikan. Bandung. Alfabeta.

[9] Sugiyono. 2013. Metode Penelitian Pendidikan (Pendekatan Kuantitatif, Kualitatif, dan R & D). Bandung. Alfabeta.

[10] Sularso & Kiyokatsu Suga, 1997. Dasar Perencanaan dan Pemilihan Elemen Mesin. Jakarta. PT Pradnya Paramita,

[11] Khurmi, R.S. & Gupta, J.K., 1980. A. Text Book of Machine Design. Eurasia Publishing House (Pvt) Ltd.

[12] G. Takhesi Sato, & N. Sugiarto Hartanto.2005, Menggambar Mesin Menurut Standar ISO, Jakarta, PT Pradnya

Paramita.

_________________________________________________________________________________________________

IJIRAE: Impact Factor Value SJIF: Innospace, Morocco (2015): 3.361 | PIF: 2.469 | Jour Info: 4.085 |

Index Copernicus 2014 = 6.57

2014- 16, IJIRAE- All Rights Reserved

Page -32

Vous aimerez peut-être aussi

- Chlorine: International Thermodynamic Tables of the Fluid StateD'EverandChlorine: International Thermodynamic Tables of the Fluid StatePas encore d'évaluation

- Laboratory Corrosion Testing PDFDocument7 pagesLaboratory Corrosion Testing PDFeid elsayedPas encore d'évaluation

- Study The Effect of Urea As Inhibitor For Corrosion in Mild Steal in 2204 - CDocument4 pagesStudy The Effect of Urea As Inhibitor For Corrosion in Mild Steal in 2204 - CAbdulrazzaqAL-MalikyPas encore d'évaluation

- Corrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyDocument15 pagesCorrosion Resistance of Cerium-Doped Zinc Calcium Phosphate Chemical Conversion Coatings On AZ31 Magnesium AlloyMichael Merino CrispinPas encore d'évaluation

- Portable Hardness Testing - Principles and ApplicationsDocument8 pagesPortable Hardness Testing - Principles and ApplicationsvrapciudorianPas encore d'évaluation

- 3 Tin and Its AlloyDocument22 pages3 Tin and Its AlloymohansaiPas encore d'évaluation

- Risky Septian Proposal KP PT Salim Ivomas Pratama TBKDocument12 pagesRisky Septian Proposal KP PT Salim Ivomas Pratama TBKRisky SeptianPas encore d'évaluation

- Smart Materials An Overview and Their ApplicationsDocument6 pagesSmart Materials An Overview and Their ApplicationsAbu Bakr M. SaeedPas encore d'évaluation

- Chapter 10 Lead PDFDocument12 pagesChapter 10 Lead PDFjessy eghPas encore d'évaluation

- Line Pipe ASTMDocument1 pageLine Pipe ASTMBanu ChandarPas encore d'évaluation

- PEstel AnalysisDocument3 pagesPEstel AnalysisDeepak SinghPas encore d'évaluation

- Geothermal Case Study CompetitionDocument16 pagesGeothermal Case Study CompetitionTimSenator TERRAPas encore d'évaluation

- Case - GCS Competition IPFEST 2020Document16 pagesCase - GCS Competition IPFEST 2020GloriaPas encore d'évaluation

- Marketing PlanDocument2 pagesMarketing PlanSrinivas NandikantiPas encore d'évaluation

- Current Efficiency in Electrometallurgy (Revision)Document18 pagesCurrent Efficiency in Electrometallurgy (Revision)harishidaytPas encore d'évaluation

- KImia Material Padatan - Lecture 14 PDFDocument51 pagesKImia Material Padatan - Lecture 14 PDFMilani ErnawatiPas encore d'évaluation

- Viscosity of WaterDocument1 pageViscosity of WaterSuvadeep DalalPas encore d'évaluation

- Cerium Doped HydroxyapatiteDocument16 pagesCerium Doped Hydroxyapatitekelvinhoh83Pas encore d'évaluation

- Pusher CentrifugeDocument4 pagesPusher Centrifugeberkay100% (1)

- Sma Negeri 78 Jakarta Hasil Try Out Kelas Xii Semester 5Document11 pagesSma Negeri 78 Jakarta Hasil Try Out Kelas Xii Semester 5EdwardoPas encore d'évaluation

- Jurnal Komposit PDFDocument7 pagesJurnal Komposit PDFYudhistira 'ndin' Atmin LukitoPas encore d'évaluation

- CFD ExercisesDocument6 pagesCFD ExercisesJohn Paul CristobalPas encore d'évaluation

- Wettability (Kemampubasahan) (Compatibility Mode)Document38 pagesWettability (Kemampubasahan) (Compatibility Mode)Ujang Daud SeptianPas encore d'évaluation

- Evaluation of The Spitzkasten Classifier in Terms of Hydraulic Velocity and Mass RecoveryDocument41 pagesEvaluation of The Spitzkasten Classifier in Terms of Hydraulic Velocity and Mass RecoveryAllen DimayugaPas encore d'évaluation

- 131 Homework 3 SolutionDocument7 pages131 Homework 3 SolutionJamie BarbosaPas encore d'évaluation

- Examination of Steel Castings (ASME VIII Div 1)Document3 pagesExamination of Steel Castings (ASME VIII Div 1)karuna346100% (1)

- Properties of Sea WaterDocument30 pagesProperties of Sea WaterHalima akterPas encore d'évaluation

- Exploration KerinciDocument6 pagesExploration KerinciNovia Pirma Yeni PirdausPas encore d'évaluation

- Msds - Natrium SilikatDocument5 pagesMsds - Natrium SilikatTantriyaniPas encore d'évaluation

- Alternative Process of Glucose To Be SorbitolDocument3 pagesAlternative Process of Glucose To Be SorbitolNabilatun SholikhaPas encore d'évaluation

- Electrochemical Degradation of Remazol Red RB 133 Using Sacrificial ElectrodesDocument23 pagesElectrochemical Degradation of Remazol Red RB 133 Using Sacrificial ElectrodesGlobal Research and Development ServicesPas encore d'évaluation

- 4.0 Solid-State Nucleation and Growth PDFDocument17 pages4.0 Solid-State Nucleation and Growth PDFLEONARD NYIRONGOPas encore d'évaluation

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument25 pagesWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsIben Abdallah ZouhourPas encore d'évaluation

- Time Trap AnalysisDocument22 pagesTime Trap AnalysiswongsosoegaliPas encore d'évaluation

- TorefaksiDocument4 pagesTorefaksirifkasyaputriPas encore d'évaluation

- Chapter 2Document48 pagesChapter 2hazmi_omarPas encore d'évaluation

- Analisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanDocument10 pagesAnalisis Kekuatan Tarik, Kekerasan, Dan Struktur PengelasanNurkholis NurkholisPas encore d'évaluation

- Serie (Conducción en Estado Estable)Document6 pagesSerie (Conducción en Estado Estable)Arturo CoPaPas encore d'évaluation

- Cellulose Acetate Uv FilmDocument7 pagesCellulose Acetate Uv FilmLara Faith AshantiPas encore d'évaluation

- Standard Lesson PlanDocument13 pagesStandard Lesson PlanMarconi QuiachonPas encore d'évaluation

- Chapter 13 - Applications and Processing of CeramicsDocument26 pagesChapter 13 - Applications and Processing of CeramicsAngelino PimentelPas encore d'évaluation

- Sizing Heat ExchangersDocument8 pagesSizing Heat Exchangerstyberius7Pas encore d'évaluation

- Tentangg Posisi Pengelasan PDFDocument7 pagesTentangg Posisi Pengelasan PDFIan NikoPas encore d'évaluation

- Mechanical Actuation SystemsDocument14 pagesMechanical Actuation SystemsnkchandruPas encore d'évaluation

- Tutorial 1 Hmete 510Document3 pagesTutorial 1 Hmete 510TINOTENDASHE MAKONESEPas encore d'évaluation

- Vacuum Oxygen DecarburizationDocument11 pagesVacuum Oxygen DecarburizationSradha Suman100% (1)

- NIST R5078 Steam TablesDocument76 pagesNIST R5078 Steam Tablesgjh100% (1)

- Electrical Conductivity of Biodiesel : TABLE 1 - ASTM D2624 Conductivity Test ResultsDocument2 pagesElectrical Conductivity of Biodiesel : TABLE 1 - ASTM D2624 Conductivity Test ResultsTri RachmantoPas encore d'évaluation

- CH-440 NanotechnologyDocument22 pagesCH-440 NanotechnologyAndrew SionPas encore d'évaluation

- Sequential Leaching For The Production of Alumina From A Nigerian ClayDocument7 pagesSequential Leaching For The Production of Alumina From A Nigerian ClayPuturrú De Fuá100% (1)

- International Journal of Heat and Mass Transfer PDFDocument11 pagesInternational Journal of Heat and Mass Transfer PDFGrad Oana0% (1)

- 1 s2.0 S1364032116305366 MainDocument15 pages1 s2.0 S1364032116305366 MainMeita PratiwiPas encore d'évaluation

- Iron and SteelDocument6 pagesIron and SteelkhansaaaPas encore d'évaluation

- MSDS - Dipsol L-800 (Na HSO3) (Plating) PDFDocument6 pagesMSDS - Dipsol L-800 (Na HSO3) (Plating) PDFEbit FristaPas encore d'évaluation

- PowerPoint Presentation Solar Water HeatersDocument16 pagesPowerPoint Presentation Solar Water HeatersDawid AmutenyaPas encore d'évaluation

- Latihan Soal Bab 1 Viskositas Dan Mekanisme Perpindahan Momentum 1. Calculation of Viscosities of Gas Mixtures at Low DensityDocument27 pagesLatihan Soal Bab 1 Viskositas Dan Mekanisme Perpindahan Momentum 1. Calculation of Viscosities of Gas Mixtures at Low DensityFettyPas encore d'évaluation

- MetalografiDocument40 pagesMetalografisunaryoPas encore d'évaluation

- Development of Coconut Milk Extractor BTLED IA 4A 1.editedDocument31 pagesDevelopment of Coconut Milk Extractor BTLED IA 4A 1.editedJoevan VillaflorPas encore d'évaluation

- 109am - 5.EPRA JOURNALS-5089Document7 pages109am - 5.EPRA JOURNALS-5089ashraf.imraishPas encore d'évaluation

- Modular Multilevel Converter With PS-PWM Technique and Shorting Algorithm For Battery Management of An Electric VehicleDocument8 pagesModular Multilevel Converter With PS-PWM Technique and Shorting Algorithm For Battery Management of An Electric VehicleIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Brain Haemorrhage Segmentation Using Discrete Wavelet TransformDocument5 pagesBrain Haemorrhage Segmentation Using Discrete Wavelet TransformIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Review of Various Biometric Authentication TechniquesDocument7 pagesReview of Various Biometric Authentication TechniquesIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Comparative Study of RCC and Steel Structures For Different Floor HeightsDocument5 pagesComparative Study of RCC and Steel Structures For Different Floor HeightsIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Effect of Automatic Lighting Fads (Fish Aggregating Devices) On Stationary Lift Net in Kepulauan Seribu, IndonesiaDocument7 pagesEffect of Automatic Lighting Fads (Fish Aggregating Devices) On Stationary Lift Net in Kepulauan Seribu, IndonesiaIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Characterization and Washability Studies of Raw Coal of BaluchistanDocument8 pagesCharacterization and Washability Studies of Raw Coal of BaluchistanIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- A Brief Review of Future Precision Strike Missile SystemsDocument19 pagesA Brief Review of Future Precision Strike Missile SystemsIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Analysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsDocument5 pagesAnalysis of Fiber Reinforced Plastic Needle Gate For K.T. WeirsIJIRAE- International Journal of Innovative Research in Advanced EngineeringPas encore d'évaluation

- Types of Production Systems and Their AutomationDocument15 pagesTypes of Production Systems and Their AutomationRoHan ShaRmaPas encore d'évaluation

- Manufacturing Technology - Short NotesDocument5 pagesManufacturing Technology - Short NotesdevaPas encore d'évaluation

- Heat Treatment GC - 08Document54 pagesHeat Treatment GC - 08kr_abhijeet72356587Pas encore d'évaluation

- Fanuc 11m Programming Manual PDFDocument2 pagesFanuc 11m Programming Manual PDFTodd100% (1)

- KGV Bi MDocument3 pagesKGV Bi MArmando Palacios EscuderoPas encore d'évaluation

- Product Leaflet - Portable CNC Cutting MachineDocument2 pagesProduct Leaflet - Portable CNC Cutting Machineabhics67Pas encore d'évaluation

- Pilani Campus: Practice, EDD, BITS PilaniDocument3 pagesPilani Campus: Practice, EDD, BITS PilaniRitik GuptaPas encore d'évaluation

- My ForgingDocument20 pagesMy ForgingRam Janm SinghPas encore d'évaluation

- MCMT Unit-3 PPQDocument2 pagesMCMT Unit-3 PPQN Dhanunjaya Rao BorraPas encore d'évaluation

- MD320 General InformationDocument5 pagesMD320 General InformationVladimir VallePas encore d'évaluation

- Coolants CoolantManagementDocument2 pagesCoolants CoolantManagementHeineken Ya Praneetpongrung100% (1)

- NL Superbolt TensionersDocument39 pagesNL Superbolt Tensionersmohit_mgPas encore d'évaluation

- SafDocument1 pageSaframkeshmit_413125668Pas encore d'évaluation

- Five-Axis Milling Machine Tool Kinematic Chain Design and AnalysisDocument16 pagesFive-Axis Milling Machine Tool Kinematic Chain Design and AnalysisAnte Dabro100% (1)

- Drilling: Bachelor of EngineeringDocument48 pagesDrilling: Bachelor of EngineeringramadanPas encore d'évaluation

- ACG2071 Managerial AccountingDocument12 pagesACG2071 Managerial AccountingKavita SinghPas encore d'évaluation

- Is 3815Document15 pagesIs 3815mishra_198250% (2)

- All About GearsDocument12 pagesAll About GearsIyappanPas encore d'évaluation

- A ResumeDocument2 pagesA ResumeMark L. mayerPas encore d'évaluation

- Turbocharger Choice: MAN B&W Diesel A/S S26MC Project GuideDocument10 pagesTurbocharger Choice: MAN B&W Diesel A/S S26MC Project GuideyuniardimzPas encore d'évaluation

- Chapter 27 Workholding Devices For Machine Tools: MET 33800 Manufacturing ProcessesDocument15 pagesChapter 27 Workholding Devices For Machine Tools: MET 33800 Manufacturing Processesangrypotato10Pas encore d'évaluation

- Ecoroll Catalog en Web PDFDocument92 pagesEcoroll Catalog en Web PDFcristian100% (1)

- Turbo List of KangyueDocument13 pagesTurbo List of Kangyuemmc83Pas encore d'évaluation

- ME2258 Lab ManualDocument14 pagesME2258 Lab ManualMURALIGOCAM_29070605Pas encore d'évaluation

- Basic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDocument34 pagesBasic Machine Processes: Identify The Basic Concepts of The Manufacturing ProcessesDeepti KanadePas encore d'évaluation

- Tolerancing Notes On 18.9Document29 pagesTolerancing Notes On 18.9Anantha KumarPas encore d'évaluation

- Vision Industrial ExpoDocument8 pagesVision Industrial ExpoMurli IyerPas encore d'évaluation

- TC600 e PDFDocument12 pagesTC600 e PDFSalar SalahiPas encore d'évaluation

- Manual Gates DesignDocument117 pagesManual Gates DesignmariodruPas encore d'évaluation