Académique Documents

Professionnel Documents

Culture Documents

Major Industries of Pakistan

Transféré par

See_star99Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Major Industries of Pakistan

Transféré par

See_star99Droits d'auteur :

Formats disponibles

1

Major industries of Pakistan

The economy of Pakistan is relying on various major industries which are being established in

Pakistan, amongst which few of them are very much significant which are contributing a lot in

the annual GDP of the state. Below mentioned are the few very much significant and important

industries which are running in the country and are playing the vital role in stabilizing the

economy of the country.

1) Textile Industry: The textile industry is the largest industry of Pakistan. At the time of

partition, Pakistan received only 17 textile units in its share. The production of textile was very

low and a large quantity of textile had to be imported to meet the domestic, requirements. Now,

Pakistan is a prominent country for the production of textile. The textile industry accounts for

17.3% of value added, 32.2% of industrial employment and 60% of total exports. There were 354

mills operating in the textile industry in 2001-02. The installed capacity of spindles was 8841

thousand and installed capacity of looms was 10 thousand in the same year. The production of

cloth was 558 million square meters by the organized mills sector. Various steps have been taken

by the Government for the growth of the textile industry e.g. the provision of incentives, freedom

to acquire technical assistance from abroad, directly financing institutions and improvements in

management and labor efficiency etc.

2) Leather Industry: The second largest industry in regard to exports is the Leather Industry.

Contributing more than $800 million in 2009 to the foreign exchange in Pakistan, this industry

has the potential of delivering more and providing a large number of jobs by diversifying product

range and improving quality.

The leather industry in Pakistan is as old as the history of the country. During the colonial era

just a few number of tanneries were working in large cities such as Karachi, Lahore, New Delhi

etc. In the 1950s the number of well-equipped tanneries increased in Karachi, Lahore and other

major industrial cities. This number continued to rise for due to increase in demand of finished

products as well as raw material in the national and international market. There are as much as

800 Tanneries in the country engaged in producing best quality finished leather of Cow, Buffalo,

and Sheep & Goat skins.. Leather manufacturers & exporters are determined to increase export

of quality finished leather and leather products.. Leather is one of a prolific contributor to the

countrys GDP and foreign exchange earnings, The Leather Industry of Pakistan is employing

more than 500,000 people directly or indirectly at this time of age

Leather industrys core products in Pakistan are leather garments, gloves, tanned leather and

footwear. In the 50s and 60s most of the tanned leather was exported in raw form but soon after

the local tanning industry making semi-finished leather made rapid progress in making finished

products due to availability of raw material, labor and growing demand in the foreign market.

More than 450 units of leather garment manufacturers in Pakistan are producing approximately

5 million pieces against the production capacity of exceeding 7.5 million pieces. Similarly a key

sector in leather industry is the leather footwear industry which is capable of producing 200

million pairs annually and its current production is just 100 million pairs. Pakistans share in the

global skin and hides production is around 7% annually which can be doubled with just the right

amount of time and effort. One can assess that these statistics show the industrys capabilities

which are highly under-utilized.

3) Steel industry: After independence in 1947, it did not take long for Pakistan to come to the

realization that progressive industrial and economical development would be impossible without

the possession of a self reliant iron and steel making plant. The dependence on imports would

cause serious setbacks to the country along with an extortionately high import bill which would

be impossible to support.

The initial idea for a domestic iron and steel mill was put forward in the first five year plan of

Pakistan (1955 1960..In 1968 besides other factors, it was considered by the Government of

Pakistan that a basic steel industry should be established in the public sector, as public

sponsorship of the project would enable integrated development of the steel industry in the

country.

Pakistan Steel Mills: In January, 1971 Pakistan and the USSR signed an agreement under which

the latter agreed to provide techno-financial assistance for the construction of a coastal based

integrated steel mill at Karachi. The foundation stone for this massive project was laid on the

30th of December, 1973. Foundation stone of Pakistan Steel was laid on 30th December, 1973.

Pakistan Steel is Pakistan's largest industrial complex, comprising component units numbering

more than 20. Pakistan Steel is strategically located 40km south east of Karachi in close vicinity

to port Muhammed Bin Qasim. Pakistan Steel is a costal site which lies on the National Highway

and is linked to the railway network. Spread over an area of 18,600 acres (29 square miles) with

10,390 acres for the main plant, 8070 acres for the township and 200 acres for the water

reservoir.

Pakistan Steel specialize in the production of flat steel products including, billets, slabs, hot

rolled coils, cold rolled coils, galvanized sheets/coils/formed sections and corrugated sheets. We

are vital to the supply of high quality and cost effective steel products to the domestic market.

Pakistan Steel's constant efforts in continuous improvement and quality management have

resulted in accreditation in ISO 9001, 14001, 17025, SA 8000 and OHSAS 18001.

Some Facts about Pakistan Steel Mill.

Organization Name: Pakistan Steel Mills Corporation (PVT) LTD.

Foundation Stone: Laid on 30th December, 1973

Location: 40 km East of Karachi

Production Capacity: 1.1 Million Ton of Steel Expandable upto 3.0 Million Ton per annum.

Main Products: Coke, Pig Iron, Billets, Cold Rolled Sheets, Hot Rolled Sheets, Galvanized

Sheets.

Steel Mills in Private Sector: there are more than 140 steel melting induction furnaces

installed in different areas of Pakistan who are producing good quality steel to meet Pakistan's

steel requirements. Pakistan Steel mills is producing about 1 million ton per year steel where

private sector is producing 30 million ( including billet, rebars, channel and angle etc) The

other requirements are fulfilled with ship breaking and other steel products.

4) Vegetable Ghee and Cooking Oil Industry: At the time of independence oil industry was

very poor. Now there are 150 vegetable ghee and cooking oil factories in Pakistan. Out of these

26 are in the public sector with an installed capacity of 500 thousand tonnes of ghee and cooking

oil. Total production of ghee and cooking oil was 774 thousand tonnes in 2001-02. A large

quantity of cooking oil is imported to meet the domestic needs. The decline in the production of

vegetable ghee is due to lower scale turnover and operational difficulties & closing down of two

units in N.W.F.P.

5) Sugar Industry: In 1947, there were only 2 sugar factories in Pakistan, but at present there

are 77 sugar factories in the industry. During the year 2001-02 total production of sugar was

3247 thousand tonnes. Revolutionary steps are required to expand the working capacity of this

industry, which must be expanded and facilities should be provided to farmers for the production

of better crops.

6) Fertilizer Industry: There are 10 fertilizer units (6 in the public sector and 4 in the private

sector) in the country, having an installed capacity of 42,98,000 N. Tonnes (16,74,000 N. Tonnes

in the public sector and 26,24,000 N. Tonnes is the private sector). Total production of fertilizers

in 2001-02 was 5012 thousand tonnes. The low production was caused, by operational

difficulties, decline in working hours and power failure/load shedding. A number of concessions

are provided for the growth of this industry.

7) Cement Industry: At present 24 cement factories are operating in the country, out of these 4

factories are in public sector and 20 are in private sector. The installed capacity of cement is

16,300 thousand tonnes out of which 9935 thousand tonnes of cement was produced in 2001-02.

This industry has been allowed duty free import of plant and machinery.

8) Chemical Industry: There are 12 chemical factories in the country producing, soda ash,

sulphuric acid, caustic soda, chlorine gas and other chemicals. The contribution of the chemical

industry towards GNP is only 3%. This industry is not fulfilling domestic requirements, so a

large amount of foreign exchange is spent on the import of different chemicals every year.

During the time of independence, chemical industry in Pakistan was almost non-existent. Some

traditional sectors have been developed over the years. However; the Chemical Industry in

Pakistan is still at an emerging phase.

As far as the classification of the Chemical industry development of Pakistan is concerned, it can

be classified into two sectors.

1) The primary sector and

2) The secondary sector.

Primary sector industries are at a large-scale. They are capital intensive industries that comprise

refineries, natural gas, petrochemicals, metallurgical and projects based on mineral. They also

supply feed stocks to the secondary chemical industry. Secondary industries are based on feed

stocks which are either derived from primary sector of industries, or other different sources of

raw materials. These industries are less capital intensive and they are based on high, medium or

less advanced technologies.

By tradition, exports from Pakistan are basically the goods produced with low technology, feed

stocks including resources like cotton, textiles, readymade garments and leather. These include

60% of total exports. The composition and contribution in exports of average and high products

based on technology, containing chemicals, petrochemicals and other manufactured products is

very small. It has varied between 8-10% of total exports from Pakistan. On the other hand,

Pakistan possesses a very high addiction of imports of goods which are high value-added, and

are expensive. Chemicals, medicines, drugs, dyes, capital plant, equipment and machinery,

jointly account for about 40% of total imports.

Chemical industry in Pakistan is widespread, in organized & unorganized sector. It has

approximation of investment in chemical sectors between Rs.550-600 billion. The chemical

related imports constitute about 17% of the total import bill.

According to the Chemical Industry Vision 2030 the chemical industry in Pakistan has been

classified into two categories which are as follows:

1. The Primary Chemical Industry: Primary chemical industries are refineries, petrochemicals,

natural gas, metallurgical and mineral based projects. They also provide feedstock for the

secondary chemical industry.

2. The Secondary Chemical Industry: Secondary chemical industries are based on feedstock

either derived from primary industries or other alternative sources of raw material like coal,

limestone, gypsum, rock salt, silica and sulphur.

The principal objective of Secondary sector industries is to maintain connectivity between

products and materials produced by the Primary industries and are of practical use for the

national economy. The chemical industry comprises of companies that produce industrial

chemicals which are important for the economy, as it converts raw material into more than

70,000 different products.

This implies that the secondary industries rely on the primary industries for feedstock and raw

material to be used in manufacturing, processing, blending, fabricating plants for petrochemical

intermediates, polymers, plastics, steel, non-ferrous metals, minerals, agricultural and other

miscellaneous products.

These industries use medium- to highly sophisticated technology and have a range from light to

medium categories. The chemical industry is more varied than any other industry because its

products are universal.

Chemicals are important as they play the role of a building block to produce products in order to

fulfill the basic needs like, shelter, food and health.They also are central to the world of

technology, telecommunications and ofcource biotechnology. These are used to make a large

variety of consumer goods and have inputs in agriculture, manufacturing, construction and

services industries.

Chemicals in particular, are a keystone of world manufacturing, as they are an integral

component of all the manufacturing sub-sectors, including pharmaceuticals, automobiles,

textiles, furniture, electronics, construction and appliances.

Economically the market of chemicals is divided into four main categories.

Basic Chemicals which are the commodity materials including flexible material, Polymers,

Petrochemicals and other derivatives and inorganic chemicals which makes.10 35-37% of the

chemical market.

Life Sciences Include differentiated chemical and biological substances, pharmaceuticals, health

products, and crop protection chemicals makes 30% of the chemical market.

Specialty Chemicals These are high value-added chemicals with diverse end-product market.

Products include electronic chemicals, industrial gases, adhesives, sealants and catalysts.

Specialty Chemicals are sometimes referred to as fine chemicals make 11 20-25% of the

chemical market.

Consumer Products include soap, detergents, and cosmetics are only 10% of the chemical

market.

9) Jute Industry: At the time of independence there was not a single jute factory in Pakistan. By

the cooperation of PIDC, 32 factories were setup in East Pakistan and one in West Pakistan by

the time of separation of East Pakistan in 1971. At present there are 12 Jute mills in the country.

Total production of Jute goods was 81.7 thousand tonnes during 2001-02. Now a large quantity

of Raw Jute is imported from China and Bangladesh every year to meet the domestic

requirement.

10) Engineering Goods Industry: The engineering goods and capital goods produced

domestically are very helpful for economic development of a country. This industry was given

importance in the 3rd five year plan. Now we have 4 heavy engineering industries.

(1) Heavy Mechanical Complex, Texila

(2) Heavy Foundry Project, Taxila

(3) Pakistan Machine Tools Factory, Landhi

(4) Pakistan Steel Mills, Karachi.

All these are in the public sector. There are also a number of light and medium engineering

goods industries producing a lot of items.

11) Ship Building Industry: Ships are constructed at Karachi. A number of small and large

ships are made by Karachi yard and Engineering works. This factory was establised by PIDC.

Now Pakistan is selling ships and boats abroad. In all the five year plans, this industry is given

much importance.

12) Woolen and Worsted Textile Industry: There are 16 woolen mills in Pakistan. These are

located at Karachi, Nowshera, Lawrencepur, Quaidabad and Hamai. This industry is not only

meeting the worsted and woolen yam requirements of the country, but it is also exporting a large

quantity of worsted cloth and carpets to foreign countries.

13) Cigarette Industry: At present 22 factories are producing cigarettes and Biri. Our country is

self sufficient in the production of cigarettes. The raw tobacco used in the manufacturing of

cigarettes is produced domestically. During the year 2001-02, 55,318 million cigarettes were

produced in the country.

Pakistans Telecom Sector: The development of Pakistan Telecom was done from scratch. The

first step was taken by Gen Ayub Khan when Pakistan Post and Telecom were made two separate

departments to focus on their own personal and focused growths. Pakistan Telephone and

Telegraph (PT&T) was the department created to focus on telecommunication in 1962. Later in

1990 PT&T was formally transformed into Pakistan Telecommunication Corporation (PTC).

PTC formed Pakistan Telecommunication Company Limited (PTCL) to formally take care of the

telecommunication business in 1996.

Telecommunication Sector is split into four administrations that are further explained as:

Pakistan Telecommunication Company Limited: It is the primary provider of all the telecom

related services in Pakistan.

Pakistan Telecommunication Authority: It is the regulatory authority which monitors the

business and operations of private telecom, internet and pay card phone companies. It is also the

issuer of license to the new entering companies.

National Telecommunication Corporation:

government organizations and armed forces.

It provides telecommunication services to

Frequency Allocation Board: It allocated frequency to the operational companies

Current Telecom Players of Pakistan:

Currently there are five players in the telecommunication sector of Pakistan, who are providing

the best possible services to the people of Pakistan. The competition among these five has

resulted in the benefit of consumer. The call rates are so low in comparison of the initial call rates

and introduction of new packages each day have also provided customers with customized

packages according to their needs.

They players mentioned according to the years founded include:

1) Mobilink

2) Ufone

3) Telenor

4) Warid 2004

5) Zong

Mobilink 030X: Mobilink was founded on June 11, 1994 as a Public Limited

Telecom Company of Pakistan. Headquarter of the company is located in

Islamabad, Pakistan. The company is first GSM based company in South Asia.

Mobilink provides pre-paid and post-paid services to individual and corporate

clients. In addition to that Mobilink also has an online banking service known

as MobiCash.

Mobilink was the only player in the market for a long time and has always has the first movers

monopoly in the market. Mobilink won 10 MHz block for 3rd Generation spectrum on 23 April

2014 and has launched its 3G services in major cities of Pakistan and now expanding the 3g

coverage areas. Based on Subscribers Mobilink is at the top of all five telecom players. It is

leading the market with 33.42 million subscribers.

Zong 031X : Zong CMPAK formerly known as Paktel, It was the biggest

foreign acquisitions when China Mobile Launched Paktel as Zong in 2008 and

in a short time period it gained great response from people. Currently with

22.10 million mobile phone users Zong is the second largest telecom

company in terms of subscribers. Zong initially came up with aggressive

marketing campaigns but better quality and customized packages attracted

customers. Zong Headquarter is in Chak Shahzad, Islamabad. Zong is

providing voice and data services including pre-paid, post-paid, 2g, 3g, 4g,

separate internet facilities and online banking system known as Time Pay

Zong is the only network that has coverage throughout motorway in Pakistan and provides 4g

internet through out. Zong has installed solar powered cell sites in various locations. It has

countrys largest solar power telecommunication network. Its network base stations, microwave

links, IT support and transmission towers are maintained and provided by ZTE Pakistan.

Zong got 10 MHz spectrum in 2.1 GHz frequency for 3G and 10 MHz spectrum in 1.8 GHz

frequency for 4G making it Pakistans first 3G and 4G operator and paid $516 million. Zong is

powered internet services to Daewoo Buses throughout motor way

Telenor 034X : Started its operations on 15 March 2005 and currently has

31.49 million subscribers. Telenor is a private, Norwegian multinational

telecommunications company and started its operations in Pakistan in year

2005. When Telenor came to Pakistan it also got the management from

headquarters which introduced the concept of flat management in Pakistan.

It is a fast growing telecom company in Pakistan standing at the second

position in terms of number of subscribers.

It is also operating Easy Paisa as its online transaction banking system, Telenor has been very

socially responsible in Pakistan and on 23rd April, 2014 acquired 3G license and aims to cater

Pakistanis with the slogan of Internet For All.

Ufone 033X: Founded on January 29, 2001 Ufone was completely owned by PTCL, while in

2006 it became part of Ehtisalat in 2006. Ufone is one of the largest GSM services providers of

Pakistan with 17.80 million customers Ufone is at the fourth position in Pakistan. The Company

is also known for the most creative TVC productions for their latest packages and promotions.

Ufone is also having an online branchless banking system known as U-Paisa in competition to all

the players of telecom who have introduced online banking services. Ufone provides post-paid,

pre-paid and data services to individuals and corporate clients in Pakistan.

Warid 032X: Warid is owned by Middle East based Abu Dhabi Group which is

a major investor in Pakistani telecom industry. With 9.91 million subscribers

Warid stands at number fifth among all. Warid provides prepaid, postpaid,

and youth plans branded as zem, zahi, and glow. Warid also offers data plans

and branch-less banking known as Mobile Paisa. Mobile Paisa is collaboration

with Bank Alfalah, Mobile paisa allows its users to pay utility bills, transfer

money to specified recipients anywhere in the country, deposit and withdraw

cash and carry out account transfers.

Warid has its headquarter in Karachi, Warid has been focusing on its services as well as social

responsibilities towards Pakistani society as well, in 2014 Warid was awarded the Corporate

Social Responsibility Award.

14) The pharmaceutical industry in Pakistan has grown during the last few decades. At the

time of the independence of Pakistan in 1947, there were few production units in the country.

Currently Pakistan has more than 800 large volume pharmaceutical formulation units, including

those operated by 25 multinationals present in the country. The Pakistan Pharmaceutical Industry

meets around 90% of the country's demand of finished dosage forms and 4% of Active

ingredients.

The National pharma industry has shown growth over the years, particularly over the last decade.

The industry is trying to upgrade itself and today the majority industry is following local Good

Manufacturing Practices (GMP) laws, with a few in accordance with international guidance.

Currently the industry has the capacity to manufacture a variety of traditional products ranging

from simple pills to capsules, ointments and syrups.

15) The Automotive industry: has been an active and growing field in Pakistan for a long time,

however not as much established to figure in the prominent list of the top automotive industries,

having a stable annual production of 100-170 thousands only. Despite being the sixth most

populous country in the world, there has been no transfer of technology and local manufacture of

vehicle components is minimal. In total, only a few car models are being assembled in the

country. The lack of competition in the local auto industry due to the presence of just three

assemblers - and only one small car assembler - has resulted in technological stagnation of the

industry; small cars produced by Pak Suzuki, the country's largest auto assembler and a

subsidiary of Suzuki Motor Corp., in the country are globally retired models using obsolete

technology and not offering any safety features. To date, Pakistan has not enforced any

automotive safety and quality standards.

Only three international brands have passenger car assembling operations in Pakistan that

includes:

1) Toyota

2) Honda

3) Suzuki

In addition, the following brands are presently assembling heavy transport and commercial

vehicles.

1) Nissan by Gandhara Nissan

2) Kia by Dewan Farooq Motors Ltd.

3) Sinotruk by Dysin Automobile Limited

10

4) Changan

16) Energy and Utilities The energy and utilities industry is one of Pakistans key economic

divisions and has received massive attention from the public and private sectors. Recently

however, the sector has come under scrutiny for falling short in its efforts to bridge the gap

between the national demand and supply. That combined with the challenges of shortages in

skill, expertise, cost pressures and the need to present a unique window of opportunity.

Noteworthy here are two things; first that there is massive potential for growth and profit where

energy is concerned in Pakistan, and second that Pakistan is sitting on one of the largest coal

reserves in the world. The sector, thus, promises a substantial potential for growth and profit.

Sector

Sub Sector

Exploration and

Production

Oil, Gas, Integrated

Refineries

Refineries

Plant and Equipment

Pipelines, Refinery Equipment, Renewable Energy Equipment, Other

Energy Plant & Equipment

Alternative Energy

Renewable Energy Producers, Alternative Fuels

Power Producers

State Owned Entities, Private Power Producers

Utilities

Power Transmission & Distribution, Gas Transmission &

Distribution, Water, Multiutilities/ Integrated Utilities

OMCs

Oil Marketing Companies

11

17) Electricity sector in Pakistan : Electricity in Pakistan is generated, transmitted, distributed,

and retail supplied by two vertically integrated public sector utilities: Water and Power

Development Authority (WAPDA) for all of Pakistan (except Karachi), and the Karachi Electric

(K-Electric) for the city of Karachi and its surrounding areas. There are around 20 independent

power producers that contribute significantly in electricity generation in Pakistan.

For years, the matter of balancing Pakistan's supply against the demand for electricity has

remained a largely unresolved matter. Pakistan faces a significant challenge in revamping its

network responsible for the supply of electricity.

Electricity generation in Pakistan has shrunk by up to 50% in recent years due to an over-reliance

on fossil fuels. In 2008, availability of power in Pakistan falls short of the population's needs by

15%[, Pakistan was hit by its worst power crisis in 2007 when production fell by 6000 Megawatts

and massive blackouts followed suit. Load Shedding and power blackouts have become severe in

Pakistan in recent years. The main problem with Pakistan's poor power generation is rising

political instability, together with rising demands for power and lack of efficiency. Provincial and

federal agencies, who are the largest consumers, often do not pay their bills.

The country has begun diversifying its energy producing capacity by investing in wind and solar

energy parks to help offset the energy shortage while larger projects such as the Diamer-Basha

Dam and new nuclear plants are under construction.

Installed capacity

Electricity total installed capacity: 22,000 MW (2014)

Electricity Sources (2014)

o Fossil fuel 14,635 MW 64.2% of total(oil-35.2% + gas-29%)

o hydro 6,611 MW 29% of total

o nuclear 1,322 MW 5.8% of total

o average demand-17,000 MW

o shortfall-between 5,000 MW and 6,000 MW

There are four major power producers in country: WAPDA (Water & Power Development

Authority), KESC (Karachi Electric Supply Company), IPPs (Independent Power Producers) and

PAEC (Pakistan Atomic Energy Commission).

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- NISHAT TEXTILE MILLS Strategic Management Plan Final ReportDocument37 pagesNISHAT TEXTILE MILLS Strategic Management Plan Final ReportMuhammad Salman Rasheed75% (16)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- JD Team Leader HR ServicesDocument2 pagesJD Team Leader HR ServicesSee_star99Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Marketing MixDocument1 pageMarketing MixSee_star99Pas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Jet Blue CaseDocument2 pagesJet Blue CaseSee_star99Pas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- HR 62Document4 pagesHR 62See_star99Pas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- History of Human ResourceDocument4 pagesHistory of Human ResourceSee_star99Pas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Mouse Trap CaseDocument2 pagesMouse Trap CaseSee_star99Pas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Jack Pot Case StudyDocument3 pagesJack Pot Case StudySee_star99100% (1)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Chapter 1 - Speaking in PublicDocument22 pagesChapter 1 - Speaking in PublicSee_star99Pas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- EC Useful Homophones ListsDocument5 pagesEC Useful Homophones ListsAdriana BrebenelPas encore d'évaluation

- Linking Words and PhrasesDocument6 pagesLinking Words and PhrasesEdward YooPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Four Basic Steps To Hire The Right PersonDocument9 pagesFour Basic Steps To Hire The Right PersonSee_star99Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Arifeen 2012 Working PaperDocument59 pagesArifeen 2012 Working Papershafqat8396Pas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Analyzing The Audience CH 5 With QuizDocument33 pagesAnalyzing The Audience CH 5 With QuizSee_star99Pas encore d'évaluation

- Ows Software We Are To TheDocument2 pagesOws Software We Are To TheSee_star99Pas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Ows Software We Are TDocument1 pageOws Software We Are TSee_star99Pas encore d'évaluation

- Format of Synopsis: Research Methodology, Biostatistics & Medical Writing WorkshopDocument2 pagesFormat of Synopsis: Research Methodology, Biostatistics & Medical Writing WorkshopManjunath ShettyPas encore d'évaluation

- Segmentation NotesDocument5 pagesSegmentation NotesSee_star99Pas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Review of The Previous LectureDocument24 pagesReview of The Previous LectureMuhammad Usman AshrafPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Ows Software WeDocument2 pagesOws Software WeSee_star99Pas encore d'évaluation

- We Are To The Next Couple of WeeksDocument1 pageWe Are To The Next Couple of WeeksSee_star99Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Ows Software We AreDocument1 pageOws Software We AreSee_star99Pas encore d'évaluation

- Next Couple of WeeksDocument1 pageNext Couple of WeeksSee_star99Pas encore d'évaluation

- Factors That Influence The Economic Development of A CountryDocument5 pagesFactors That Influence The Economic Development of A CountrySee_star99Pas encore d'évaluation

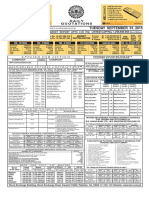

- Quote 201531augDocument32 pagesQuote 201531augSee_star99Pas encore d'évaluation

- Are To The Next Couple of WeeksDocument1 pageAre To The Next Couple of WeeksSee_star99Pas encore d'évaluation

- Chapter 4Document29 pagesChapter 4Sobia ShabeerPas encore d'évaluation

- Foreign Policy - September - October 2016Document4 pagesForeign Policy - September - October 2016Arsalan IdreesPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Quote 201501sepDocument32 pagesQuote 201501sepSee_star99Pas encore d'évaluation

- QMar 2015Document23 pagesQMar 2015See_star99Pas encore d'évaluation

- Unit 6B - PassiveDocument18 pagesUnit 6B - PassiveDavid EstrellaPas encore d'évaluation

- 20150714rev1 ASPACC 2015Document22 pages20150714rev1 ASPACC 2015HERDI SUTANTOPas encore d'évaluation

- 0n9) O6..,w48j-GDocument14 pages0n9) O6..,w48j-GMocha FurrerPas encore d'évaluation

- Determination of Hydroxymethylfurfural (HMF) in Honey Using The LAMBDA SpectrophotometerDocument3 pagesDetermination of Hydroxymethylfurfural (HMF) in Honey Using The LAMBDA SpectrophotometerVeronica DrgPas encore d'évaluation

- Nugent 2010 Chapter 3Document13 pagesNugent 2010 Chapter 3Ingrid BobosPas encore d'évaluation

- 42ld340h Commercial Mode Setup Guide PDFDocument59 pages42ld340h Commercial Mode Setup Guide PDFGanesh BabuPas encore d'évaluation

- Technical Data - Tad1342veDocument9 pagesTechnical Data - Tad1342veRachid SmailiPas encore d'évaluation

- SSC 211 ED Activity 4.1Document4 pagesSSC 211 ED Activity 4.1bernard bulloPas encore d'évaluation

- Module 17 Building and Enhancing New Literacies Across The Curriculum BADARANDocument10 pagesModule 17 Building and Enhancing New Literacies Across The Curriculum BADARANLance AustriaPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Facts About The TudorsDocument3 pagesFacts About The TudorsRaluca MuresanPas encore d'évaluation

- Growth Kinetic Models For Microalgae Cultivation A ReviewDocument16 pagesGrowth Kinetic Models For Microalgae Cultivation A ReviewJesús Eduardo De la CruzPas encore d'évaluation

- Protected PCM USB Memory Sticks For Pa3X.Document1 pageProtected PCM USB Memory Sticks For Pa3X.mariuspantera100% (2)

- Dr. Babasaheb Ambedkar Technological UniversityDocument3 pagesDr. Babasaheb Ambedkar Technological UniversityalfajPas encore d'évaluation

- Using MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsDocument8 pagesUsing MonteCarlo Simulation To Mitigate The Risk of Project Cost OverrunsJancarlo Mendoza MartínezPas encore d'évaluation

- 2002 CT Saturation and Polarity TestDocument11 pages2002 CT Saturation and Polarity Testhashmishahbaz672100% (1)

- Supreme Court Case Analysis-Team ProjectDocument5 pagesSupreme Court Case Analysis-Team ProjectJasmineA.RomeroPas encore d'évaluation

- List of Practicals Class Xii 2022 23Document1 pageList of Practicals Class Xii 2022 23Night FuryPas encore d'évaluation

- FBISE Grade 10 Biology Worksheet#1Document2 pagesFBISE Grade 10 Biology Worksheet#1Moaz AhmedPas encore d'évaluation

- Discrete Random Variables: 4.1 Definition, Mean and VarianceDocument15 pagesDiscrete Random Variables: 4.1 Definition, Mean and VariancejordyswannPas encore d'évaluation

- Brochure - Actiwhite PWLS 9860.02012013Document12 pagesBrochure - Actiwhite PWLS 9860.02012013J C Torres FormalabPas encore d'évaluation

- JSA FormDocument4 pagesJSA Formfinjho839Pas encore d'évaluation

- Service M5X0G SMDocument98 pagesService M5X0G SMbiancocfPas encore d'évaluation

- New KitDocument195 pagesNew KitRamu BhandariPas encore d'évaluation

- Test 1801 New Holland TS100 DieselDocument5 pagesTest 1801 New Holland TS100 DieselAPENTOMOTIKI WEST GREECEPas encore d'évaluation

- Machine Tools PDFDocument57 pagesMachine Tools PDFnikhil tiwariPas encore d'évaluation

- Duties and Responsibilities - Filipino DepartmentDocument2 pagesDuties and Responsibilities - Filipino DepartmentEder Aguirre Capangpangan100% (2)

- Video ObservationDocument8 pagesVideo Observationapi-532202065Pas encore d'évaluation

- INDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor PositioningDocument8 pagesINDUSTRIAL PHD POSITION - Sensor Fusion Enabled Indoor Positioningzeeshan ahmedPas encore d'évaluation

- Dreizler EDocument265 pagesDreizler ERobis OliveiraPas encore d'évaluation

- Boeing SWOT AnalysisDocument3 pagesBoeing SWOT AnalysisAlexandra ApostolPas encore d'évaluation