Académique Documents

Professionnel Documents

Culture Documents

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0284285 A1

Transféré par

deni.sttnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0284285 A1

Transféré par

deni.sttnDroits d'auteur :

Formats disponibles

US 20070284285A1

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2007/0284285 A1

(43) Pub. Date:

Stepanik et al.

(54)

METHOD OF UPGRADING A HEAVY OIL

FEEDSTOCK

(52)

US. Cl. ..................................................... .. 208/106

(57)

(76) Inventors:

Terence Mitchell Stepanik,

PinaWa (CA); Christopher Barton

Saunders, PinaWa (CA); John

Wesley Barnard, Lac du Bonnet

(CA)

Dec. 13, 2007

ABSTRACT

A pretreatment process is described for heavy hydrocarbon

oil feedstock, such as oils extracted from tar sands. The

feedstock is passed through a heated, continuous ?oW elec

tron or X-ray treatment Zone. The process is designed to

alloW the feedstock to be conditioned With ozone-containing

air, steam or a hydrogen donor gas prior to electron/X-ray

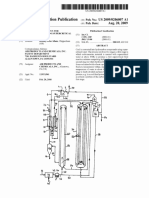

treatment. The ozone-containing air stream may be the

Correspondence Address:

ADE & COMPANY INC.

2157 Henderson Highway

WINNIPEG, MB R2G1P9

stream produced in the electron treatment Zone. After con

(21) Appl. No.:

11/758,216

ditioning, the heavy oil is heated to a speci?ed temperature

and uniformly treated With high-energy beams of electrons

or X-rays. Akey feature of the invention is the electron/X-ray

(22) Filed:

Jun. 5, 2007

treatment Zone may use multiple accelerators or a beam

Related US. Application Data

(60)

Provisional application No. 60/812,099, ?led on Jun.

9, 2006.

splitter to ensure acceptable dose distributions in the ?owing

feedstock. Another key feature is the recirculation of vola

tiles back into the feedstock. According to the novel feature,

the process produces a treated feedstock having a loWer

average molecular Weight and boiling point than the original

Publication Classi?cation

(51)

feedstock, Without signi?cant coke formation. The fraction

of gas oil collected during distillation is increased signi?

Int. Cl.

C10G 9/00

(2006.01)

cantly.

Light

Fractions

2%

Vent Line

20

Distillation

Llnc #1

Prcheater

50

Feedstock

Steam & 4'2

Hydrogen

#

Donor Gas

+ 20

A 26;

EB Treatment Zone

#7

Ozone

Containing Air

2L}

Heavier

Electron Accelerator

Fractions

Facility

Cooling

Air

Dec. 13, 2007

US 2007/0284285 A1

METHOD OF UPGRADING A HEAVY OIL

FEEDSTOCK

[0001]

This application claims the bene?t under 35 U.S.C.

119(e) of US. provisional application Ser. No. 60/812,099,

?led Jun. 9, 2006.

[0008] Method for Oils and Oil Residua Re?ning, Patent

of Republic of KaZakstan N 4676 of 16 Jul. 1996 (Priority

of KaZakstan N 9404341 of 14 Apr. 1994).

[0009] Zaykin Y. A., Zaykina R. F., Nadirov N. K., Mirkin

G. System for Complex Natural and Industrial Chemical

Compounds Reprocessing and Regeneration. Priority of

KaZakstan 970592.1 of 26 Jul. 97.

[0010] Chesnokov B. P., Nadirov N. K., Kiryshatov O. A.,

Kiryshatov A. I., Zaykin Y. A., Zaykina R. F., Vaytsul A. N.

FIELD OF THE INVENTION

Method for Chemical Reactions Initiations During Oil and

Oil Products Processing and Device for Its RealiZation.

[0002] This invention relates to the upgrading of a heavy

oil feedstock, for example bitumen extracted from tar sands.

This pretreatment process can be tailored for the speci?c

hydrocarbon mixture used and the ?nal upgraded oil prop

erties desired. The process variables include electron dose,

dose rate, temperature during electron treatment, pressure

Priority of Russia N 97-10-7263/25 (007710).

[0011] Mirkin G., Nadirov N. K., Zaikina R. F., Zaikin Y.

A. System for processing and re?ning chemical composi

tions. Priority of USA N 09/100, 453 of 06/19.

[0012] Other related references include:

and selective additives to enhance the electron e?ect.

[0013] Reference 1: G. M. Panchenko, A. V. Putilov, T. N.

Zhuravlov et al. Investigations of the basic rule of the

radiation thermal cracking of N-hexadecane. High Energy

BACKGROUND

[0003]

Heavy oil and bitumen consist of large hydrocar

Chemistry, v. 15, #5, 1981, p. 426

[0014] In Reference 1, the process Was demonstrated With

n-hexane. The gamma dose rate changed from 7.8 up to 16.7

bon molecules. Upgrading processes add hydrogen atoms

Gy/ s, the maximally absorbed dose constituted 20 kGy. The

and/or remove carbon atoms, Which converts the bitumen

autoclave pressure depended on temperature and conditions

of the experiment and did not exceed 10 MPa. The experi

into a product similar to conventional light crude oil.

[0004] The direct upgrading of heavy crude oils is di?i

cult. Distillation typically yields loW levels of distillates.

The remaining residual oils cannot be added in signi?cant

ments Were conducted at temperatures from 300 to 400 C.

amounts to ?uid catalytic crackers because of the extraor

duction volumes of heavy oil.

[0015] Reference 2: G. I. Zhuravlov, S. V. VoZnesenskiy,

dinarily high levels of metals and carbon residue, Which

result in a high level of hydrogen generation and high coke

on catalyst respectively. Therefore, coking, Which is one of

several thermal cracking processes, has traditionally been

the process of choice for upgrading heavy oils. While coking

does remove a signi?cant amount of the metals and carbon

residue, the quality of the produced liquids is poor. They are

high in sulfur, ole?ns, diole?ns and heavy aromatics and, as

a result, require a substantial amount of additional

hydrotreating.

[0005] One alternative to coking is visbreaking, Which is

another Widely applied thermal cracking process for the

conversion of residual oils (J. F. LePage et al.; Resid and

Heavy Oil Processing, Editions Technip, Paris, France,

1992). Thermal visbreaking is characteriZed by high tem

The experimental conclusions included the possibility of

using a high-temperature nuclear reactor to irradiate pro

I. V. Borisenko et al. Radiation-thermal effect on the heavy

oil residium, High Energy Chemistry, v. 25, #1, 1991, p. 27.

[0016] According to Reference 2 gas oil Was subjected to

radiation thermal cracking at temperatures of 300 to 400

C. in the dose range 50 to 200 kGy, With a gamma dose rate

of 5.1 Gy/ s. This study shoWed that the loW dose rate RTC

process increased the conversion of molecular Weight com

pounds by 50 to 100% as compared to the thermal process

alone. Irradiation also contributed to the process of sulphur

removal of the light oil products obtained. As in Reference

1, the authors described an industrial process of applying

heat and radiation from a nuclear reactor.

perature and short residence time; so that, unlike coking, the

[0017] Reference 3: N. K. Nadirov, R. F. Zaykina, Yu. A.

Zaykin. State and perspectives of radiation treatment of

heavy oil and natural bitumen. NIIETF KaZGY, NPO

cracking reactions are terminated before coke is made.

KaZneftebitum, Alma-Ata, Kazakhstan (1995).

Visbreaking alone does not signi?cantly change the heteroa

[0018] Reference 3 presented the results of a study of RTC

of a mixture of heavy oil fractions With boiling point of

greater than 400 C., using a 4 MeV linear accelerator. The

tom content (S, N), metals or asphaltene content of the feed.

Its sole function is molecular Weight (e.g. boiling range)

reduction and, hence, loWering of viscosity.

[0006] An issue With thermal visbreaking is that visbreak

ing and other mild thermal processes result in cleavage of

the alkyl side chains from asphaltenes, resulting in the

dose rate Was varied from 1 to 4 kGy/s, With an absorbed

dose of 1 to 40 kGy. Both static and ?oWing experiments

Were completed. Under these irradiation conditions, the

optimal temperature for the RTC process Was 400 to 420 C.

asphaltenes precipitating and subsequently forming depos

The output of gasoline fractions With a boiling temperature

its, Which, if not controlled, foul processing equipment With

coke. (R. C. Schucker and C. F. KeWeshan, The Reactivity

of Cold Lake Asphaltenes, Prepr. Div. Fuel Chem., Amer.

Chem. Soc., 1980, 25(3), 155-165). Solvent extraction ofthe

asphaltenes is possible, but results in high energy consump

of less than 200 C. Was 50% higher than that for thermal

tion for solvent removal and larger equipment siZes. There

fore, there remains a need in the art for improvements to

heavy feed upgrading that Will overcome the above short

comings.

cracking alone. The gasoline fraction obtained had a high

octane range (76 to 80) and loW sulfur content. The per

centage of aromatic and naphthenes compounds also

increased With the RTC process than With thermal cracking

alone.

[0019] Reference 4: Wu G., Katsumura Y., et al. Effect of

radiation on the thermal cracking of n-hexadecane, Ind. And

The process of radiation-thermal cracking (RTC)

Eng. Chem. Res.i1997, 36, N6, p. 1973

[0020] Reference 4 describes liquid and gas-phase RTC

and its individual fractions Was investigated by Soviet

scientists and these data are presented in the folloWing

documents:

cracking of n-hexane at 300 to 400 C., With gamma

irradiation. The liquid phase Was irradiated With dose rates

ranging from 150 to 460 Gy/h and the gas phase Was

[0007]

Dec. 13, 2007

US 2007/0284285 A1

irradiated with dose rates ranging from 240 to 560 Gy/h. It

was shown that irradiation abruptly increased the process

rate, not affecting the set of ?nal carboniferous cracking

products. A large amount of molecular hydrogen was formed

by radiation thermal cracking.

[0021]

Reference 5: A. K. Pikaev. New elaboration of

radiation technology in Russia (review). High Energy

Chemistry, v.33, #1, 1999, p. 3

[0030]

The use of steam in the hydrocarbon stream

requires larger furnace capacity and equipment than would

be necessary for the hydrocarbon without steam. Further,

when steam is used, energy and equipment must be provided

to generate and superheat the steam.

[0031] A variety of attempts have been made to pretreat

heavy hydrocarbon feedstock to render it suitable for ther

mal cracking. An option is the vaporization of the feedstock

with large quantities of steam to create a very low system

[0022] Reference 5 describes development work to com

mercialiZe RTC using gamma irradiation in a closed static

system. The volume of the test vessel was 120 cm3. The

results obtained from this higher volume experiment corre

sponded to literature data in the temperature range of 250 to

300 C. The volume of light gas fractions was increased by

up to 5%, with a lowering of viscosity of the remaining oil.

carbon to remove the asphaltene and coke precursors.

Another attempt is the thermal pretreatment of resids to

A large amount of hydrogen, saturated and unsaturated

hydrocarbons, and hydrogen sulphide were also identi?ed in

al.) and similarly, the pre-treatment of hydrocarbon feed

the reaction vessel.

[0023] Reference 6: R. F. Zaykina, Yu. A. Zaykin, T. B.

Mamonova, and N. K. Nadirov, Radiation-thermal process

ing of high-viscous oil from KaraZhanbas ?eld, Rad. Phys.

Chem., 60 (2001) 211-221.

[0024]

Reference 6 examined the RTC process for high

viscous oil from KaraZhanbas, using electron beam (EB)

treatment from a 2 MeV, 4 kW linear accelerator. The unique

feature of their experimental set-up was that the oils were

heated from 2000 C. to 400 C. by continuous EB treatment,

and the volatiles were removed from the oil during irradia

tion. The study con?rmed that total dose and dose rate

partial pressure (Gartside, US. Pat. No. 4,264,432). Others

have proposed solvent extraction pretreatment of the hydro

yield a heavy hydrocarbon, then catalytically hydrotreating

a portion of the heavy hydrocarbon feedstock before the

steam cracking step (US. Pat. No. 4,065,379, Soonawala, et

stock by initial catalytic cracking to produce a naphtha or

naphtha-like feed for ultimate thermal cracking (US. Pat.

No. 3,862,898, Boyd, et al.). These processes all improve the

cracking of heavy hydrocarbon, however, in most instances

the process suffers from either the expense of large steam

dilution equipment or the unsatisfactory increase of tar and

coke accumulation in the process equipment.

[0032] Known attempts to upgrade a heavy oil feedstock

have thus far yielded unsatisfactory results.

SUMMARY

impact both the yield and the composition of the gas oil

[0033] According to one aspect of the invention there is

provided a method of upgrading a heavy oil feedstock, the

fractions with boiling temperatures up to 350 C. The

mechanisms associated with the formation of aromatic

hydrocarbons were also discussed.

method comprising:

stock;

[0025] Reference 7: Yu. A. Zaykin and R. F. Zaykina,

Simulation of radiation-thermal cracking of oil products by

reactive oZone-containing mixtures, Rad. Phys. Chem, 71

(2004) 475-478.

[0026] Reference 7 described the bene?ts of combining

perature;

RTC and oZonolysis to lower the temperature required to

maximiZe the gas oil fractions with boiling points below

350 C. The RTC process required a preheating temperature

of 420 C., while bubbling oZone-containing air through the

oil lowers the required treatment temperature by 15 to 20 C.

This combined process was shown to reduce the concentra

tion of high-molecular weight aromatic compounds as well.

[0027] Reference 8: R. F. Zaykina, Yu. A. Zaykin, Sh. G.

Yagudin and l. M. Fahruddinov, Speci?c approaches to

[0034]

[0035]

[0036]

forming a continuous ?ow of the heavy oil feed

heating the continuous ?ow to a prescribed tem

cracking the heavy oil feedstock in the continuous

?ow by directing electrons or x-rays at the continuous ?ow.

[0037] The method may include recycling a separated

portion comprising volatiZed parts back into the continuous

?ow prior to electron and/or x-ray cracking.

[0038] Constituents of the continuous ?ow subsequent to

electron/x-ray cracking can be varied by varying an amount

of the separated portion recycled back into the continuous

?ow.

[0039]

A separated portion, comprising parts of the con

tinuous ?ow which are volatiZed when heating the ?ow to

said prescribed temperature, are preferably recycled back

into the ?ow.

radiation processing of high-sulfuric oil, Rad. Phys. Chem.,

[0040]

71 (2004) 467-470.

x-ray treatment, may include adding to the ?ow a selected

[0028] Reference 8, a follow-on to Reference 7, describes

the bene?cial effects of the RTC/oZonolysis process for the

desuphuriZation of light fractions of gas oil and considerably

reduced the total amount of sulphur concentrated in high

Conditioning the continuous ?ow prior to electron/

one or more of oZone, steam, a hydrogen donor gas, or

recycling back into the ?ow a portion of the continuous ?ow

which is volatiZed when preconditioning.

[0041]

Electron/x-ray cracking is preferably done at or

molecular weight compounds.

near atmospheric pressure.

[0029] A typical process for upgrading hydrocarbon feed

[0042] The continuous ?ow may be mixed during elec

tron/x-ray cracking by providing ba?les in a path of the ?ow

or by providing moving mixing blades in a path of the ?ow.

stock is the thermal cracking process. lllustratively, process

?red heaters are used to provide the requisite heat for the

reaction. The feedstock ?ows through a plurality of coils

within the ?red heater, the coils being arranged in a manner

that maximiZes the heat transfer to the hydrocarbon ?owing

through the coils. In conventional coil pyrolysis, dilution

steam is used to inhibit coke formation in the cracking coil.

A further bene?t of high steam dilution is the inhibition of

the coke deposition in the exchangers used to rapidly quench

the cracking reaction. An illustration of the conventional

process is seen in US. Pat. No. 3,487,121 (Hallee).

[0043]

The electrons or x-rays are directed at the continu

ous ?ow from a plurality of opposing directions.

[0044] As described herein a continuous ?ow process for

the upgrading of a heavy oil feedstock may comprise the

steps of preheating the feedstock, electron or x-ray cracking

said feedstock, using electron beams from an accelerator, at

conditions that will produce a cracked product stream hav

ing a lower average molecular weight and boiling point than

said feedstock without signi?cant coke formation; collecting

Dec. 13, 2007

US 2007/0284285 A1

from said product stream light ends that volatilize, including

any Water that might be in the stream; and feeding both the

volatiZed product stream and the heated liquid product

stream to the heavy oil distillation process.

[0045]

The feed may comprise a heavy oil stream having

an API gravity of less than 20.

[0046] The electron accelerator may be either a pulsed or

continuous beam design, With a beam poWer ranging from 1

to 700 kW and a beam energy ranging from 1 to 12 MeV.

[0047] The electron/x-ray treatment Zone may be vented,

With the volatiZed gas stream being sent to the distillation

process directly or circulated through the feedstock preheat

ing tank prior to being sent to the distillation process.

[0048] Air may be circulated through the feedstock stor

[0057] Referring noW to the overall process shoWn in FIG.

1, the feedstock is ?rst formed into a continuous ?oW

through a ?rst ?oW line #1 prior to entering the inlet of a

pre-heater (20) in series With the ?rst ?oW line and Which

preheats the feedstock to a prescribed temperature. The How

exits an outlet of the pre-heater (20) at a second ?oW line #2

to be directed into an inlet of an electron treatment Zone (22)

in series With the second ?oW line #2. Within this Zone (22),

the How is subjected to electrons generated from an electron

accelerator facility (24). After treatment the How exits an

outlet of the Zone (22) through a third ?oW line #6 Which

directs the How to a ?rst inlet of a distillation unit (26) Where

the various fractions of hydrocarbons in the How are sepa

rated and passed onto subsequent re?ning operations.

age tank to incorporate oZone into the feedstock. OZone is

[0058]

produced during the electron treatment of air.

?rst ?oW line 1, prior to entering the pre-heater (20), the

[0049]

hydrogen donor gas, or both, to the feedstock either prior to

heating or just before electron or x-ray treatment.

[0050] The method may further include arranging a por

feedstock may be preconditioned by the addition of steam

and a hydrogen donor gas injected into either into ?oW line

#1 prior to entering the pre-heater (20) or into ?oW line #2

betWeen the pre-heater (20) and the electron treatment Zone

tion of the continuous How to comprise hydrocarbons having

a boiling point loWer than said prescribed temperature prior

to electron or x-ray cracking by maintaining under pressure

operated at loW pressure such that any parts of the How

The pretreatment system may introduce steam or a

Turning noW more particularly to the How at the

(22).

[0059]

The pre-heater (20) in the illustrated embodiment is

in the continuous ?oW at least a portion of hydrocarbons

Which are volatiZed due to the preheating can be vented from

volatiZed during heating.

an auxiliary outlet of the pre-heater (20) through a vent line

[0051]

#3 to a control valve (28) in series With the vent line #3. The

control valve then determines Whether the vented volatiles

are fed directly to the distillation unit (26) at an auxiliary

inlet of the distillation unit separate from How line #6 or

alternatively fed through an additional ?oW line #4 for

One embodiment of the invention Will noW be

described in conjunction With the accompanying draWings in

Which:

BRIEF DESCRIPTION OF THE DRAWINGS

[0052] FIG. 1 is schematic illustration of a preferred

embodiment of the method of upgrading a heavy oil feed

stock according to the present invention.

[0053] In the draWings like characters of reference indi

cate corresponding parts in the different ?gures.

DETAILED DESCRIPTION

[0054]

The present invention relates to a process for

upgrading petroleum feedstocks, using a combination of

electron cracking, With and Without added oZone, steam or

hydrogen, at conditions that Will not produce signi?cant

amounts of coke. Suitable feedstocks for use in the present

invention include heavy and reduced petroleum crude oil;

petroleum atmospheric distillation bottoms; petroleum

injection back into the continuous flow at How line #2 just

prior to entering the electron treatment Zone (22).

[0060] Similarly the electron treatment Zone (22) may also

be vented from an auxiliary outlet at vent line #5 to remove

any parts Which are volatiZed during the electron treatment.

A control valve #30 in series With the vent line #5 receives

the volatiles vented from the electron treatment Zone and

then subsequently controls Whether these volatiles are either

directed back into the continuous ?oW at How line #2 just

prior to entering the electron treatment Zone, or alternatively

directed to the distillation unit (26) along With the volatiles

vented from the pre-heater through vent line #3.

[0061] The electrons may be directed at the How from

multiple directions to ensure that substantially the entirety of

the How is subjected to electron beams.

[0062] When pre-treating or pre-conditioning the feed

vacuum distillation bottoms, or residuum; pitch; asphalt and

stock prior to entering the pre-heater (20), a conditioning

tar sand bitumen. Such feeds Will typically have a Conrad

son carbon content of at least 5 Wt. %, generally from about

5 to 50 Wt. %. As to Conradson carbon residue, see ASTM

Test Dl89-l65.

tank may be provided in series With the How line 1 of the

How prior to entering the pre-heater. The pre-treatment or

pre-conditioning may comprise the addition of one or more

of oZone, steam or a hydrogen donor gas as noted above.

[0055] Electron cracking, as employed herein, usually

[0063]

results in about 15 to 70 Wt. % conversion of the heavy oil

heavy oil feedstock is ?rst formed as a continuous ?oW

feed to loWer boiling products (boiling temperature <350o

Which is heated to a prescribed treatment temperature prior

C.). This conversion rate is typically 50% to 100% higher

than using the current thermal cracking process. The entire

group of reactions takes place in the electron treatment

Zone; and the average residence time of the feed in the

treatment Zone is a function of the poWer of the machine

being used and the design of the How chamber. The resi

dence time has to be suf?cient to alloW the feed stream to

absorb l to 50 k] of electrons per kilogram of feedstock,

depending on the composition of the initial feed.

[0056]

Our process is typically carried out at or near

atmospheric pressure; hoWever, some improvement in the

quality and stability of the product can be achieved by the

introduction of a hydrogen donor gas and/or steam.

According to the method described herein, the

to the electron treatment Zone (22). Heating may occur at the

pre-heater (20) or both at a pre-heater and pre-conditioning

stage prior to the treatment Zone (22). When heating, parts

of the How having a boiling point loWer than the prescribed

treatment temperature Will be volatiZed, but according to the

present invention these volatiZed parts may be arranged to

be present in the continuous ?oW prior to the electron

treatment Zone. This is accomplished either by maintaining

the volatiles under pressure in the How or by returning the

volatiles to the How just prior to the electron treatment Zone.

These hydrocarbons of loWer molecular Weight encourage a

greater number of reactions and a greater degree of cracking

of heavier oil molecules in the How.

Dec. 13, 2007

US 2007/0284285 A1

[0064] When it is desirable to vary the composition of

molecules in the end product at the distillation unit (26), the

amount of volatiles from the pre-heater or the electron

treatment Zone Which are returned back into the How prior

to further electron beam treatment can be varied in a

controllable manner to, in turn, vary the types of reactions

taking place in the treatment Zone.

[0065] As described herein, the method according to the

present invention generally comprises the following steps:

[0066]

l) A heavy oil feedstock is introduced to the

process through Line #1. The How rate is a function of the

accelerator poWer and the capacity of the electron treatment

Zone. For an electron dose of 10 kGy supplied to the

feedstock, throughput is up to 1.70 barrels per hour for every

kilowatt of installed electron poWer.

[0067] 2) The feedstock may be conditioned With air

containing oZone produced by the electron/x-ray treatment

of the cooling air stream. OZone may also be added from

other oZone-generating technologies. Any parts of the feed

stock Which are volatiZed during this preconditioning may

be retained in the feedstock ?oW or may be vented off and

returned to the feedstock ?oW just prior to subsequent

electron treatment at Line #3.

[0068] 3) The conditioned feedstock is pumped through

Line #1 to the continuous ?oW preheater, Where the feed

stock is raised in temperature, up to a maximum of 4250 C.

Steam and preheated hydrogen donor gas, such as methane,

may be injected into the feedstock either prior to the

preheater or just prior to electron/x-ray treatment to control

speci?c reactions. The light fractions released during pre

heating are pumped through Line #3 to either the Distillation

Unit or recirculated back to the feedstock via Line #4 to

enhance the effects of the cracking process.

[0069]

4) The feedstock exits the preheater through Line

#2 and enters the electron treatment Zone. As the tempera

ture is maintained, the feedstock is treated With electrons or

X-rays to a dose of up to 50 kGy. The treatment Zone is

operated at or near atmospheric pressure. The treatment Zone

is designed to insure that the feedstock depth during treat

ment is optimiZed for the electron or x-ray energy used. The

How rate, dictated by the required electron/x-ray dose, Will

be suf?cient to minimiZe fouling Within the apparatus. The

process may include mixing the feedstock stream during

Unit. In the Distillation Unit, light fractions are volatiliZed

and exit. The less volatile fraction of the feedstock stream

exits the Distillation Unit and continues through the tradi

tional heavy oil processing stages.

[0073] Since various modi?cations can be made in the

invention as herein above described, and many apparently

Widely different embodiments of same made Within the spirit

and scope of the claims Without department from such spirit

and scope, it is intended that all matter contained in the

accompanying speci?cation shall be interpreted as illustra

tive only and not in a limiting sense.

1. A method of upgrading a heavy oil feedstock, the

method comprising:

forming a continuous How of the heavy oil feedstock;

heating the continuous How to a prescribed temperature;

cracking the heavy oil feedstock in the continuous ?oW by

directing either electrons or x-rays at the continuous

How.

2. The method according to claim 1 including recycling a

separated portion comprising volatiZed parts of the continu

ous ?oW back into the continuous ?oW prior to electron

cracking.

3. The method according to claim 1 including varying

constituents of the continuous ?oW subsequent to cracking

by varying an amount of the separated portion recycled back

into the continuous How.

4. The method according to claim 1 including recycling

back into the How a separated portion comprising a part of

the continuous ?oW Which is volatiZed When heating the

How to said prescribed temperature.

5. The method according to claim 1 including precondi

tioning the continuous ?oW prior to heating to said pre

scribed temperature by adding to the How a selected one or

more of oZone, steam or a hydrogen donor gas and recycling

back into the How a separated portion comprising parts of

the continuous ?oW Which are volatiZed When precondition

ing.

6. The method according to claim 1 including reducing a

cross sectional dimension of the continuous How in one

electron treatment, either With ba?les or blades in the How

direction prior to electron cracking.

7. The method according to claim 1 including recycling

path. The light fractions released during electron/x-ray treat

back into the How a separated portion of the continuous ?oW

ment may be pumped through Line #5 to either the Distil

comprising hydrocarbon molecules.

lation Unit or recirculated back to the feedstock stream prior

to electron/x-ray treatment to further enhance the effects of

8. The method according to claim 1 including electron or

x-ray cracking at conditions near atmospheric pressure.

the cracking process.

9. The method according to claim 1 including mixing the

continuous ?oW during electron or x-ray cracking.

10. The method according to claim 1 including directing

[0070] 5) The accelerator produces either a pulsed or a

continuous electron beam. The air stream from the electron/

x-ray treatment Zone With oZone produced during the elec

tron/x-ray treatment, may be pumped to the inlet line for the

feedstock (Line 7) to enhance the effects of the cracking

process.

[0071] 6) The accelerator facility may generate multiple

beams, either With multiple accelerators or the use of beam

splitters to alloW the feedstock to be treated from multiple

sides in the electron treatment Zone. Standard shielding

designs for accelerator facilities may be used for this facility.

[0072] 7) The cracked feedstock is noW appropriately

conditioned and fed through Line #6 into the Distillation

electrons at the continuous ?oW from more than one direc

tion.

11. A method according to claim 1 including arranging a

portion of the continuous How to comprise hydrocarbons

having a boiling point loWer than said prescribed tempera

ture prior to electron or x-ray cracking by maintaining under

pressure in the continuous ?oW at least a portion of hydro

carbons volatiZed during heating.

*

Vous aimerez peut-être aussi

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsD'EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerPas encore d'évaluation

- Mohammad 2008Document11 pagesMohammad 2008wsanchez_soteloPas encore d'évaluation

- The Reactivity and Kinetics of Yanzhou Coal Chars From Elevated Pyrolysis Temperatures During Gasification in Steam at 900 - 120088888CDocument9 pagesThe Reactivity and Kinetics of Yanzhou Coal Chars From Elevated Pyrolysis Temperatures During Gasification in Steam at 900 - 120088888CAlfiDahliaArofaniPas encore d'évaluation

- Kinetic modeling of high-severity fluidizing catalytic crackingDocument6 pagesKinetic modeling of high-severity fluidizing catalytic crackingignacio7pazPas encore d'évaluation

- New Approach of Retorting of Huadian Oil Shale in Order To Reduce CO and CO EmissionsDocument8 pagesNew Approach of Retorting of Huadian Oil Shale in Order To Reduce CO and CO EmissionsIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- 3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - LiDocument1 page3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - Liamerico molinaPas encore d'évaluation

- One-Pot Solvent-Free Synthesis ofDocument14 pagesOne-Pot Solvent-Free Synthesis ofJulieta StassiPas encore d'évaluation

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0015405 A1Document27 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0015405 A1edwinPas encore d'évaluation

- Down-Hole Heavy Crude Oil Upgrading by CAPRI Effect of HydrogenDocument10 pagesDown-Hole Heavy Crude Oil Upgrading by CAPRI Effect of HydrogenAli ShahPas encore d'évaluation

- Us4342699 PDFDocument18 pagesUs4342699 PDFKhabib FirmansyahPas encore d'évaluation

- Chemical Dechlorination of PCBs From Dielectric OilsDocument6 pagesChemical Dechlorination of PCBs From Dielectric Oilsgerodot2falconPas encore d'évaluation

- Maximizing Rhodium Recovery in the Methyl Acetate Carbonylation ProcessDocument19 pagesMaximizing Rhodium Recovery in the Methyl Acetate Carbonylation ProcessJohn Patrick DaglePas encore d'évaluation

- Catalytic Deoxygenation of Waste Soybean Oil Over Hybrid Catalyst For Production of Bio-Jet Fuel - in Situ Supply of Hydrogen by Aqueous-Phase Reforming (APR) of GlycerolDocument10 pagesCatalytic Deoxygenation of Waste Soybean Oil Over Hybrid Catalyst For Production of Bio-Jet Fuel - in Situ Supply of Hydrogen by Aqueous-Phase Reforming (APR) of GlycerolThiago de Santana SouzaPas encore d'évaluation

- Three-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionDocument5 pagesThree-Way Regeneration of Spent V2O5 Catalyst From Sulfuric Acid ProductionInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- 1 s2.0 S0255270104001461 MainDocument8 pages1 s2.0 S0255270104001461 MainIlireaPas encore d'évaluation

- Study of The Thermal Cracking During The Vacuum Distillation of Atmospheric Residue of Crude OilDocument11 pagesStudy of The Thermal Cracking During The Vacuum Distillation of Atmospheric Residue of Crude OilPhạm QuânPas encore d'évaluation

- 2010 Energy Paper XYZDocument7 pages2010 Energy Paper XYZAgung Dedy Pramana PutraPas encore d'évaluation

- Energy Production from biomass gasification by molten carbonate fuel cells: process simulation and optimizationDocument6 pagesEnergy Production from biomass gasification by molten carbonate fuel cells: process simulation and optimizationNaason VelascoPas encore d'évaluation

- J Fuel 2021 120469Document10 pagesJ Fuel 2021 120469Roni GustiwaPas encore d'évaluation

- Evaporation of Biomass Fast Pyrolysis Oil: Evaluation of Char FormationDocument8 pagesEvaporation of Biomass Fast Pyrolysis Oil: Evaluation of Char FormationyemresimsekPas encore d'évaluation

- Dissolved Gas Analysis-1Document31 pagesDissolved Gas Analysis-1Karan Tripathi100% (2)

- CatalystDocument4 pagesCatalystDussadeePas encore d'évaluation

- A Comprehensive Kinetic Theory To Model Thermolysis, Aquathermolysis, Gasification, Combustion, and Oxidation of Athabasca BitumenDocument31 pagesA Comprehensive Kinetic Theory To Model Thermolysis, Aquathermolysis, Gasification, Combustion, and Oxidation of Athabasca BitumenMejbahul SarkerPas encore d'évaluation

- Vacuum Residue Upgrading in Supercritical WaterDocument46 pagesVacuum Residue Upgrading in Supercritical WaterRamesh DasariPas encore d'évaluation

- Patent Application Publication (10) Pub. No.: US 2009/0206007 A1Document13 pagesPatent Application Publication (10) Pub. No.: US 2009/0206007 A1Tree SilviaPas encore d'évaluation

- Preparation of KF/CaO nanocatalyst for biodiesel from Chinese tallowDocument5 pagesPreparation of KF/CaO nanocatalyst for biodiesel from Chinese tallowArief SetyoPas encore d'évaluation

- Maschio 1994Document8 pagesMaschio 1994khanzm818Pas encore d'évaluation

- Diesel HydrotreatingDocument21 pagesDiesel HydrotreatingIzack Silva S100% (1)

- Experimental and Theoretical Investigation of Biomass Gasification Using Circulating Fluidised Bed GasifierDocument5 pagesExperimental and Theoretical Investigation of Biomass Gasification Using Circulating Fluidised Bed GasifiertheijesPas encore d'évaluation

- Production of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno CatalystDocument6 pagesProduction of Hydrogen by Steam Reforming of Ethanol Over A Ni/Zno Catalystpetro121Pas encore d'évaluation

- Air Injection Into Light and Medium Heavy Oil Reservoirs: Combustion Tube Studies On West of Shetlands Clair Oil and Light Australian OilDocument10 pagesAir Injection Into Light and Medium Heavy Oil Reservoirs: Combustion Tube Studies On West of Shetlands Clair Oil and Light Australian OilAlejandro Duvan Lopez RojasPas encore d'évaluation

- Olefin Thermal CrackingDocument13 pagesOlefin Thermal CrackingMarinda RahimPas encore d'évaluation

- Patente 10Document26 pagesPatente 10Laura GarciaPas encore d'évaluation

- Lecture2 (Petrochemical)Document12 pagesLecture2 (Petrochemical)ToniAndiwijaya100% (1)

- Bambang Veriansyah, Jae Young Han, Seok Ki Kim, Seung-Ah Hong, Young Jun Kim, Jong Sung Lim, Young-Wong Shu, Seong-Geun Oh, Jaehoon KimDocument8 pagesBambang Veriansyah, Jae Young Han, Seok Ki Kim, Seung-Ah Hong, Young Jun Kim, Jong Sung Lim, Young-Wong Shu, Seong-Geun Oh, Jaehoon Kimscorpion2001glaPas encore d'évaluation

- Simulation of Fluid Catalytic CrackerDocument62 pagesSimulation of Fluid Catalytic CrackerAhmed Ali100% (1)

- CHPT 1 - Petroleum RefiningDocument2 pagesCHPT 1 - Petroleum RefiningMABUKE NDINAINWI INNOCENTIAPas encore d'évaluation

- Microscale Organic Laboratory TechniquesDocument162 pagesMicroscale Organic Laboratory TechniquesAndréRochaPas encore d'évaluation

- Submitted by Department of Chemistry, Imam Hossein University, Tehran, IRANDocument4 pagesSubmitted by Department of Chemistry, Imam Hossein University, Tehran, IRANsinaPas encore d'évaluation

- Modernization of Unit For Elimination of Vocs by Catalytic OxidationDocument6 pagesModernization of Unit For Elimination of Vocs by Catalytic Oxidationoverlord5555Pas encore d'évaluation

- Obtention of Tio Rutile at Room Temperature Through Direct Oxidation of TiclDocument4 pagesObtention of Tio Rutile at Room Temperature Through Direct Oxidation of TiclWilliam Soracà OspinoPas encore d'évaluation

- Aceite de FrituraDocument8 pagesAceite de FrituraNestor Andres Urbina SuarezPas encore d'évaluation

- SPE 122028 Potential For Hydrogen Generation During in Situ Combustion of BitumenDocument14 pagesSPE 122028 Potential For Hydrogen Generation During in Situ Combustion of BitumenRoobinRZamirPas encore d'évaluation

- Catalytic Cracking of Used Palm Oils: Dhundiraj P.Deshpande, S.V.Aneker and N.G.KanseDocument5 pagesCatalytic Cracking of Used Palm Oils: Dhundiraj P.Deshpande, S.V.Aneker and N.G.KanseFillipe DragoPas encore d'évaluation

- Kinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasDocument8 pagesKinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasLina ArevaloPas encore d'évaluation

- SPE 8907 PA FassigiDocument9 pagesSPE 8907 PA FassigiCaRlosTorresPas encore d'évaluation

- 1 s2.0 S0016236100001010 MainDocument8 pages1 s2.0 S0016236100001010 MainlunarPas encore d'évaluation

- 1 s2.0 S0140670199982565 MainDocument1 page1 s2.0 S0140670199982565 MainAtiqah AuliaPas encore d'évaluation

- Asetaldehid (Recovered)Document15 pagesAsetaldehid (Recovered)Mario VensfiseCrewPas encore d'évaluation

- Yeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Document8 pagesYeo Il Yoon, Il Hyun Baek, and Sang Do Park: To Whom All Correspondence Should Be Addressed. (E-Mail: Ihbaek@kier - Re.kr)Mohammed AsherPas encore d'évaluation

- Hydroprocessing of Maya Heavy Crude Oil in Two Reaction StagesDocument12 pagesHydroprocessing of Maya Heavy Crude Oil in Two Reaction StagesFredy Akenaton ArroyoPas encore d'évaluation

- Fluid Catalytic Cracking of Heavy (Residual) Oil Fractions A Review PDFDocument21 pagesFluid Catalytic Cracking of Heavy (Residual) Oil Fractions A Review PDFMmediong UdofiaPas encore d'évaluation

- Electrocatalysis For The Direct Alcohol Fuel Cell: 1022-5528/06/1100-0111/0 2006 Springer Science+Business Media, IncDocument11 pagesElectrocatalysis For The Direct Alcohol Fuel Cell: 1022-5528/06/1100-0111/0 2006 Springer Science+Business Media, InchoangPDAPas encore d'évaluation

- Modeling and Simulation of Fluidized Catalytic Cracking Riser Reactor Using Pseudo Reaction Kinetics: A ReviewDocument15 pagesModeling and Simulation of Fluidized Catalytic Cracking Riser Reactor Using Pseudo Reaction Kinetics: A Reviewsalim salimPas encore d'évaluation

- United States Patent (19) : Hu Et AlDocument4 pagesUnited States Patent (19) : Hu Et AlSepti WidyaPas encore d'évaluation

- The Heat of Hydrosulfurization Reaction of Heavy OilDocument7 pagesThe Heat of Hydrosulfurization Reaction of Heavy OilmoeraeleizhajPas encore d'évaluation

- Pyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilDocument7 pagesPyrolysis Using Microwave Heating: A Sustainable Process For Recycling Used Car Engine OilSalman Raza NaqviPas encore d'évaluation

- 071 - 88 Ing.3Document18 pages071 - 88 Ing.3Leonardo SaggiomoPas encore d'évaluation

- Pyrolysis of Polystyrene Waste in A Fluidized-Bed Reactor To Obtain Styrene Monomer and Gasoline FractionDocument11 pagesPyrolysis of Polystyrene Waste in A Fluidized-Bed Reactor To Obtain Styrene Monomer and Gasoline FractionMubshir MughalPas encore d'évaluation

- Molecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaDocument5 pagesMolecules: Liquid-Phase Synthesis of Cyanuric Acid From UreaSrujana BudhePas encore d'évaluation

- Industry-5 RAS8090 PDFDocument8 pagesIndustry-5 RAS8090 PDFdeni.sttnPas encore d'évaluation

- Invitation PDFDocument19 pagesInvitation PDFdeni.sttnPas encore d'évaluation

- High Temperature Stable Separator For Lithium Batteries Based On SiO2 and Hydroxypropyl Guar GumDocument14 pagesHigh Temperature Stable Separator For Lithium Batteries Based On SiO2 and Hydroxypropyl Guar GumFamiloni LayoPas encore d'évaluation

- Landry Monitoring EC in Soils and MediaDocument5 pagesLandry Monitoring EC in Soils and Mediadeni.sttnPas encore d'évaluation

- Molecules: Structural Characterization of Calcium Alginate Matrices by Means of Mechanical and Release TestsDocument15 pagesMolecules: Structural Characterization of Calcium Alginate Matrices by Means of Mechanical and Release Testsdeni.sttnPas encore d'évaluation

- Parametric Study For Hydrogel With Medium SwellingDocument14 pagesParametric Study For Hydrogel With Medium Swellingdeni.sttnPas encore d'évaluation

- Using Eggshell Membrane As A Separator in Supercapacitor: Journal of Power SourcesDocument6 pagesUsing Eggshell Membrane As A Separator in Supercapacitor: Journal of Power Sourcesdeni.sttnPas encore d'évaluation

- Nuclear researchers exchange program detailsDocument19 pagesNuclear researchers exchange program detailsdeni.sttnPas encore d'évaluation

- 2 PBDocument5 pages2 PBdeni.sttnPas encore d'évaluation

- Using Eggshell Membrane As A Separator in Supercapacitor: Journal of Power SourcesDocument6 pagesUsing Eggshell Membrane As A Separator in Supercapacitor: Journal of Power Sourcesdeni.sttnPas encore d'évaluation

- RBIP81Document1 pageRBIP81deni.sttnPas encore d'évaluation

- Ten Teb 2009 0639Document14 pagesTen Teb 2009 0639deni.sttnPas encore d'évaluation

- 1 s2.0 S0360319911020039 MainDocument9 pages1 s2.0 S0360319911020039 Maindeni.sttnPas encore d'évaluation

- Evangel Los B Our BosDocument7 pagesEvangel Los B Our Bosdeni.sttnPas encore d'évaluation

- Chemical Engineering Science: Nurettin Sahiner, Sultan Butun, Tugce TurhanDocument7 pagesChemical Engineering Science: Nurettin Sahiner, Sultan Butun, Tugce Turhandeni.sttnPas encore d'évaluation

- 1 s2.0 S036031991101007X MainDocument8 pages1 s2.0 S036031991101007X Maindeni.sttnPas encore d'évaluation

- 1 s2.0 S0969806X13001503 MainDocument4 pages1 s2.0 S0969806X13001503 Maindeni.sttnPas encore d'évaluation

- 1 s2.0 S092633731000425X MainDocument7 pages1 s2.0 S092633731000425X Maindeni.sttnPas encore d'évaluation

- Effect of Gamma-Irradiation On Surface and Catalytic Properties of Cuo-Zno/Al203 SystemDocument6 pagesEffect of Gamma-Irradiation On Surface and Catalytic Properties of Cuo-Zno/Al203 Systemdeni.sttnPas encore d'évaluation

- Art - 10.1007 - s10967 007 7079 1 1Document9 pagesArt - 10.1007 - s10967 007 7079 1 1deni.sttnPas encore d'évaluation

- How Does - Irradiation in Uence The Phase Transition of - Nimoo ?Document5 pagesHow Does - Irradiation in Uence The Phase Transition of - Nimoo ?deni.sttnPas encore d'évaluation

- Art 10.1023 A 1020814219592Document8 pagesArt 10.1023 A 1020814219592deni.sttnPas encore d'évaluation

- Effect of Electron Beam Irradiation On CO Reformingof Methane Over Ni/Al O CatalystsDocument7 pagesEffect of Electron Beam Irradiation On CO Reformingof Methane Over Ni/Al O Catalystsdeni.sttnPas encore d'évaluation

- Ijct 11 (3) 326-330 PDFDocument5 pagesIjct 11 (3) 326-330 PDFdeni.sttnPas encore d'évaluation

- 1 s2.0 S0969806X13001503 MainDocument4 pages1 s2.0 S0969806X13001503 Maindeni.sttnPas encore d'évaluation

- Probing The Degree of Crosslinking of A Cellulose Based Superabsorbing Hydrogel Through Traditional and NMR TechniquesDocument12 pagesProbing The Degree of Crosslinking of A Cellulose Based Superabsorbing Hydrogel Through Traditional and NMR Techniquesdeni.sttnPas encore d'évaluation

- Jan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958Document5 pagesJan. 22, 1963 L.. Domash Etal 3,074,380: Improvement 1N Hydrodesulfurization With Filed Dec. 30, 1958deni.sttnPas encore d'évaluation

- Hydrocracking of Cumene Over Ni/Al O As in Uenced by Ceo Doping and G-IrradiationDocument7 pagesHydrocracking of Cumene Over Ni/Al O As in Uenced by Ceo Doping and G-Irradiationdeni.sttnPas encore d'évaluation

- Ip Je 94030205Document5 pagesIp Je 94030205deni.sttnPas encore d'évaluation

- Introduction To Animal Science For Plant ScienceDocument63 pagesIntroduction To Animal Science For Plant ScienceJack OlanoPas encore d'évaluation

- MLS 321 Aubf M6u2 Other Metabolic Diseases V2122Document7 pagesMLS 321 Aubf M6u2 Other Metabolic Diseases V2122proximusPas encore d'évaluation

- Antenna LecDocument31 pagesAntenna Lecjosesag518Pas encore d'évaluation

- 2024 - Chung 2024 Flexible Working and Gender Equality R2 CleanDocument123 pages2024 - Chung 2024 Flexible Working and Gender Equality R2 CleanmariaPas encore d'évaluation

- Assessment Formal AssessmentDocument7 pagesAssessment Formal Assessmentashish33% (3)

- Proper restraint techniques for dogs and catsDocument153 pagesProper restraint techniques for dogs and catsjademattican75% (4)

- TS4-F - Fire SafetyDocument2 pagesTS4-F - Fire SafetyDominic SantiagoPas encore d'évaluation

- Retail Management PPT1Document14 pagesRetail Management PPT1Srilekha GubbalaPas encore d'évaluation

- Spec BoilerDocument9 pagesSpec BoilerAchmad MakmuriPas encore d'évaluation

- CHAPTER3 Foundations of Individual BehaviorDocument32 pagesCHAPTER3 Foundations of Individual BehaviorLynoj AbangPas encore d'évaluation

- GTT Module 5Document156 pagesGTT Module 5ABDULRAHIMAN RAJEKHANPas encore d'évaluation

- Alternate Mekton Zeta Weapon CreationDocument7 pagesAlternate Mekton Zeta Weapon CreationJavi BuenoPas encore d'évaluation

- Acc101Q7CE 5 3pp187 188 1Document3 pagesAcc101Q7CE 5 3pp187 188 1Haries Vi Traboc MicolobPas encore d'évaluation

- Rudraksha - Scientific FactsDocument20 pagesRudraksha - Scientific FactsAkash Agarwal100% (3)

- Vturn-NP16 NP20Document12 pagesVturn-NP16 NP20José Adalberto Caraballo Lorenzo0% (1)

- COVID 19 Impacts On The Construction IndustryDocument46 pagesCOVID 19 Impacts On The Construction IndustryAlemayehu DargePas encore d'évaluation

- Chennai's 9 sewage treatment plants process 486 MLDDocument5 pagesChennai's 9 sewage treatment plants process 486 MLDmoni_john_1Pas encore d'évaluation

- English III Module 2 Simple Present Job and Job VerbsDocument4 pagesEnglish III Module 2 Simple Present Job and Job VerbsAdrian CortesPas encore d'évaluation

- Pet - WikipediaDocument12 pagesPet - Wikipediabdalcin5512Pas encore d'évaluation

- Abortion and UtilitarianismDocument4 pagesAbortion and UtilitarianismBrent Harvey Soriano JimenezPas encore d'évaluation

- RUKUS March 2010Document32 pagesRUKUS March 2010RUKUS Magazine29% (14)

- Auditor General Insurance Regulation Dec 2011Document23 pagesAuditor General Insurance Regulation Dec 2011Omar Ha-RedeyePas encore d'évaluation

- AZ ATTR Concept Test Clean SCREENERDocument9 pagesAZ ATTR Concept Test Clean SCREENEREdwin BennyPas encore d'évaluation

- QRF HD785-7Document2 pagesQRF HD785-7Ralf MaurerPas encore d'évaluation

- EO On Ban of Fireworks (Integrated)Document2 pagesEO On Ban of Fireworks (Integrated)Mario Roldan Jr.Pas encore d'évaluation

- New Microsoft Excel WorksheetDocument4 pagesNew Microsoft Excel WorksheetRaheel Neo AhmadPas encore d'évaluation

- Growth Developt Pearl MilletDocument17 pagesGrowth Developt Pearl MilletdarmaPas encore d'évaluation

- Quality ImprovementDocument3 pagesQuality ImprovementViky SinghPas encore d'évaluation

- Soal Upk B Inggris PKBM WinaDocument11 pagesSoal Upk B Inggris PKBM WinaCuman MitosPas encore d'évaluation

- VIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhDocument3 pagesVIDEO 2 - Thì hiện tại tiếp diễn và hiện tại hoàn thànhÝ Nguyễn NhưPas encore d'évaluation

- Asset Integrity Management for Offshore and Onshore StructuresD'EverandAsset Integrity Management for Offshore and Onshore StructuresPas encore d'évaluation

- Industrial Piping and Equipment Estimating ManualD'EverandIndustrial Piping and Equipment Estimating ManualÉvaluation : 5 sur 5 étoiles5/5 (7)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesD'EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertÉvaluation : 3 sur 5 étoiles3/5 (2)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisD'EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisPas encore d'évaluation

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideD'EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideÉvaluation : 2 sur 5 étoiles2/5 (1)

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- Flow Analysis for Hydrocarbon Pipeline EngineeringD'EverandFlow Analysis for Hydrocarbon Pipeline EngineeringPas encore d'évaluation

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionD'EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionÉvaluation : 4.5 sur 5 étoiles4.5/5 (16)

- Pipeline Integrity: Management and Risk EvaluationD'EverandPipeline Integrity: Management and Risk EvaluationÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Biostratigraphic and Geological Significance of Planktonic ForaminiferaD'EverandBiostratigraphic and Geological Significance of Planktonic ForaminiferaÉvaluation : 4 sur 5 étoiles4/5 (5)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Practical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsD'EverandPractical Wellbore Hydraulics and Hole Cleaning: Unlock Faster, more Efficient, and Trouble-Free Drilling OperationsÉvaluation : 5 sur 5 étoiles5/5 (1)

- Experimental Design in Petroleum Reservoir StudiesD'EverandExperimental Design in Petroleum Reservoir StudiesPas encore d'évaluation

- Black Gold Stranglehold: The Myth of Scarcity and the Politics of OilD'EverandBlack Gold Stranglehold: The Myth of Scarcity and the Politics of OilPas encore d'évaluation

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationD'EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesD'EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesÉvaluation : 4 sur 5 étoiles4/5 (2)

- Oil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsD'EverandOil & Gas Design Engineering Guide Book: Useful Practices and Equipment & SystemsPas encore d'évaluation

- Fire in the Night: The Piper Alpha DisasterD'EverandFire in the Night: The Piper Alpha DisasterÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Asphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsD'EverandAsphaltene Deposition Control by Chemical Inhibitors: Theoretical and Practical ProspectsPas encore d'évaluation

- Risk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesD'EverandRisk Management in the Oil and Gas Industry: Offshore and Onshore Concepts and Case StudiesPas encore d'évaluation

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryD'EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryPas encore d'évaluation