Académique Documents

Professionnel Documents

Culture Documents

advantageFYI073 PDF

Transféré par

ShaikhMazharAhmed0 évaluation0% ont trouvé ce document utile (0 vote)

38 vues1 pageTitre original

advantageFYI073.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

38 vues1 pageadvantageFYI073 PDF

Transféré par

ShaikhMazharAhmedDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

SUBJECT: CHILLER AND TOWER SIZING FORMULAS

OPERATION

#3-C-73

10/17/1994

Updated : 03/23/2015

FORMULA

INJECTION MOLDING

30

50

45

40

EXTRUSION

50 pph Polyolefins = 1 ton

75 pph Polystyrene = 1 ton

65 pph P.V.C.

= 1 ton

BLOW MOLDING

40 pph Polyolefins

HYDRAULIC COOLING

= .1 ton/hp

BARREL COOLING

= 1 ton/in. screw diameter

MOLD TEMPERATURE CONTROLLERS

MOLD TEMPERATURE CONTROLLERS

(cooling) see pph table

(heating) 1.2 ton per zone

WATER COOLED CHILLERS

1 ton tower for 1 ton chiller

MOLD ROOM HEATING

NON-MOLD ROOM HEATING

MOLD ROOM AIR CONDITIONING

= 25 BTU/sq.ft (16' ceiling)

= 50 BTU/sq.ft (16' ceiling)

= 80 sq. ft/ton (16' ceiling)

SPOT WELDERS

1/4 ton per tip (chilled water)

PLATING BATHS

Heat removal (BTU/hr) = DC amps x DC volts x 2.56

DIE CASTINGS

Zinc: Heat removal (BTU/hr) = M x 95 BTU/lb

M = throughput rate (lbs/hr)

Pour at 800F

Remove at 300F

pph

pph

pph

pph

Polyolefins

Polystyrene

P.V.C.

P.E.T.

Aluminum:

AIR COMPRESSOR (NO AFTERCOOLER)

=

=

=

=

1

1

1

1

ton

ton

ton

ton

= 1 ton

Heat removal (BTU/hr) = M x 325 BTU/hr

M = throughput rate (lbs/hr)

Pour at 1200F

Remove at 600F

0.1 ton/hp

AIR COMPRESSOR (WITH AFTERCOOLER) 0.2 ton/hr

VACUUM PUMP

0.1 ton/hr

MACHINE TOOLS

0.1 ton/hp

FEED THROATS (UNDER 3" SCREW DIA.)

FEED THROATS (OVER 3" SCREW DIA.)

1 ton/hp

2 tons/hp

ADVANTAGE Engineering, Inc. 525 East Stop 18 Road Greenwood, IN 46142 317-887-0729 fax: 317-881-1277

Web site: www.advantageengineering.com email: sales@advantageengineering.com

Updated 03/23/2015 2015 ADVANTAGE ENGINEERING, INC.

Vous aimerez peut-être aussi

- Je Professional InstituteDocument126 pagesJe Professional InstituterihanPas encore d'évaluation

- Refrigeration BasicsDocument78 pagesRefrigeration BasicsNihal Senanayake100% (1)

- Double Pipe Heat Exchanger - SsDocument72 pagesDouble Pipe Heat Exchanger - SsNathanian100% (2)

- 07-11 Basic HVAC Formulas - Tech TipDocument2 pages07-11 Basic HVAC Formulas - Tech TipAslam100% (1)

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersbashist1969Pas encore d'évaluation

- Hvac Formulas PDFDocument25 pagesHvac Formulas PDFSaraswatapalit0% (1)

- Budgeted Capex (Opr) 2015 Western RegionDocument6 pagesBudgeted Capex (Opr) 2015 Western RegionShaikhMazharAhmedPas encore d'évaluation

- Chiller Cooling Tower AHUDocument9 pagesChiller Cooling Tower AHUAli Hassan RazaPas encore d'évaluation

- Boilers and Steam Systems ..BoeDocument151 pagesBoilers and Steam Systems ..BoeMV AmohanAKarthicK100% (1)

- Basic HVAC Formulas - Tech TipDocument2 pagesBasic HVAC Formulas - Tech Tipgauravgujar24100% (1)

- Once-through supercritical pressure boiler technologyDocument0 pageOnce-through supercritical pressure boiler technologySreenivas100% (1)

- Air Conditioning Design For Conference Hall PDFDocument34 pagesAir Conditioning Design For Conference Hall PDFkalyan1492Pas encore d'évaluation

- "Solutions For The Plastics Industry": Co. IncDocument4 pages"Solutions For The Plastics Industry": Co. IncminiongskyPas encore d'évaluation

- Calculating Chiller and Cooling Tower Refrigeration - in TonsDocument2 pagesCalculating Chiller and Cooling Tower Refrigeration - in TonsjagrutPas encore d'évaluation

- Heating Coil Sizing For Fuel Oil TankDocument2 pagesHeating Coil Sizing For Fuel Oil TankAhmed Mujtaba93% (14)

- Chilled Water PipingDocument6 pagesChilled Water PipingunicornmepPas encore d'évaluation

- Essential design parameters and components of fired heatersDocument38 pagesEssential design parameters and components of fired heatersSong Hoe100% (2)

- Design of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Document42 pagesDesign of Air Pre Heater and Economizer: Submitted by J.Shanmuka Venkata Gopichand (101fa08133) L.SURYA TEJA (101FA08141)Chien NguyenPas encore d'évaluation

- FW HeaterDocument93 pagesFW HeateridigitiPas encore d'évaluation

- Trane Diagnostics Manual PDFDocument88 pagesTrane Diagnostics Manual PDFShaikhMazharAhmed100% (2)

- Guid To Design of EvaporatorDocument40 pagesGuid To Design of Evaporatorscranderi100% (2)

- Sizing of Process ChillerDocument6 pagesSizing of Process ChillerNitinPas encore d'évaluation

- CONDENSATE AND STEAM TRAP IN STEAM LINEDocument16 pagesCONDENSATE AND STEAM TRAP IN STEAM LINEreach_arindomPas encore d'évaluation

- Chiller Design GuidelineDocument1 pageChiller Design GuidelineApiwat DattitPas encore d'évaluation

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersD'EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersPas encore d'évaluation

- Condenser and Circulating Water SystemDocument26 pagesCondenser and Circulating Water SystemKhairun NisaPas encore d'évaluation

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningD'EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningÉvaluation : 5 sur 5 étoiles5/5 (2)

- Chiller Sizing Formulas: Injection Molding ExtrusionDocument3 pagesChiller Sizing Formulas: Injection Molding ExtrusionVarathasankar ArumugamPas encore d'évaluation

- Process Cooling System Chiller and Tower Sizing FormualsDocument2 pagesProcess Cooling System Chiller and Tower Sizing FormualsChuen Hau TanPas encore d'évaluation

- Thermal Tech EquipmentcoDocument5 pagesThermal Tech EquipmentcoSaleem UddinPas encore d'évaluation

- Engineering Formulas: Nominal Design ParametersDocument4 pagesEngineering Formulas: Nominal Design Parametersehtesham314Pas encore d'évaluation

- Formulas: Nominal Design ParametersDocument4 pagesFormulas: Nominal Design Parametersehtesham314Pas encore d'évaluation

- Chiller & Cooling Tower CalcualtionDocument5 pagesChiller & Cooling Tower Calcualtiongnanakumar kPas encore d'évaluation

- Lab Manual - To Study Refrigeration Cycle, Determine of Coefficient of Performance of Cycle & Determine of Tonnage Capacity of Refrigeration UnitDocument4 pagesLab Manual - To Study Refrigeration Cycle, Determine of Coefficient of Performance of Cycle & Determine of Tonnage Capacity of Refrigeration UnitManikanta BoyinaPas encore d'évaluation

- ThermodynamicsDocument2 pagesThermodynamicsmarkalvinbonPas encore d'évaluation

- RAC Lab VIISem-3-6Document4 pagesRAC Lab VIISem-3-6hoddiploma.mePas encore d'évaluation

- Design a vertical tube condenser and subcoolerDocument29 pagesDesign a vertical tube condenser and subcoolert_prithvi0% (1)

- 1.refrigeration Test RigDocument38 pages1.refrigeration Test RigKandavel NatarajPas encore d'évaluation

- Cooling Tower 2020 SPLM1B2 Notes 13 - 14 AugustDocument23 pagesCooling Tower 2020 SPLM1B2 Notes 13 - 14 AugustThabangPas encore d'évaluation

- 4.HVAC and Refrigeration SystemDocument32 pages4.HVAC and Refrigeration SystemPrudhvi RajPas encore d'évaluation

- Engineering Formulas Guide Chillers Cooling TowersDocument4 pagesEngineering Formulas Guide Chillers Cooling TowersSaleem Basha100% (1)

- Chilled Water Design PerametersDocument4 pagesChilled Water Design PerametersSatya N.GPas encore d'évaluation

- Worked Problems Heat ExchangersDocument18 pagesWorked Problems Heat Exchangers521 Balaji OPas encore d'évaluation

- Shell and Tube Condenser DesignDocument4 pagesShell and Tube Condenser DesignAnonymous KsRdWoYtPas encore d'évaluation

- HVAC Rules of Thumb and CalculationsDocument19 pagesHVAC Rules of Thumb and Calculations123john123Pas encore d'évaluation

- Calculating Cooling LoadsDocument2 pagesCalculating Cooling LoadsHerman SubagioPas encore d'évaluation

- Calculating Cooling LoadsDocument2 pagesCalculating Cooling Loadsfatur_vdPas encore d'évaluation

- Swimming Pool DesignDocument4 pagesSwimming Pool DesignIbrahim A. HameedPas encore d'évaluation

- Agitated Vessel PDFDocument9 pagesAgitated Vessel PDFKr AyushPas encore d'évaluation

- 001 VARS Tutor-ManualDocument6 pages001 VARS Tutor-ManualVenkatesh ModiPas encore d'évaluation

- REFRIGERATION & AIR-CONDITIONING SYSTEMSDocument35 pagesREFRIGERATION & AIR-CONDITIONING SYSTEMSlanikhilPas encore d'évaluation

- Ac Test RigDocument7 pagesAc Test Riggopal dasPas encore d'évaluation

- Unit ConversionDocument20 pagesUnit ConversionHimanshu YadavPas encore d'évaluation

- Experiment No #2: ObjectiveDocument5 pagesExperiment No #2: ObjectivemjunaidPas encore d'évaluation

- Lab RepoertDocument11 pagesLab RepoertIhtisham GhazanferPas encore d'évaluation

- Abstract:: Lab ReportDocument11 pagesAbstract:: Lab ReportIhtisham GhazanferPas encore d'évaluation

- Aph PRESENTATIONDocument42 pagesAph PRESENTATIONRajneesh VachaspatiPas encore d'évaluation

- Heat Pipe DemonstratorDocument10 pagesHeat Pipe DemonstratorShoaib PathanPas encore d'évaluation

- Pressureconversion PDFDocument3 pagesPressureconversion PDFShaikhMazharAhmedPas encore d'évaluation

- LG Aircooled Screw Chiller Quotation Batch Plan ProjectDocument1 pageLG Aircooled Screw Chiller Quotation Batch Plan ProjectShaikhMazharAhmedPas encore d'évaluation

- Khalijee AC - 146-12-2-2017Document9 pagesKhalijee AC - 146-12-2-2017ShaikhMazharAhmedPas encore d'évaluation

- PDFDocument8 pagesPDFShaikhMazharAhmedPas encore d'évaluation

- Saudi Roza MainDocument39 pagesSaudi Roza MainShaikhMazharAhmedPas encore d'évaluation

- Technical WordsDocument2 pagesTechnical WordsShaikhMazharAhmedPas encore d'évaluation

- EGVUSE09-07C - A VRV Basic Operation Guide PDFDocument40 pagesEGVUSE09-07C - A VRV Basic Operation Guide PDFShaikhMazharAhmed100% (1)

- Al Muruj ABS Palace134 4-1-2017Document10 pagesAl Muruj ABS Palace134 4-1-2017ShaikhMazharAhmedPas encore d'évaluation

- Business Letters The Writing Center PDFDocument8 pagesBusiness Letters The Writing Center PDFShaikhMazharAhmedPas encore d'évaluation

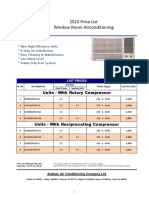

- Carrier Dfs List Price 2015Document6 pagesCarrier Dfs List Price 2015ShaikhMazharAhmedPas encore d'évaluation

- Best Practice Manual Hvac ChillersDocument69 pagesBest Practice Manual Hvac ChillersraajaahPas encore d'évaluation

- Company Profile66Document48 pagesCompany Profile66ShaikhMazharAhmedPas encore d'évaluation

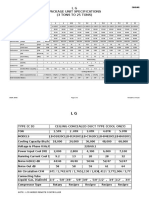

- LG Package Unit Specifications GuideDocument5 pagesLG Package Unit Specifications GuideShaikhMazharAhmed100% (1)

- Cac Page 1-10Document10 pagesCac Page 1-10ShaikhMazharAhmedPas encore d'évaluation

- Taha Al Sabban PricingDocument2 pagesTaha Al Sabban PricingShaikhMazharAhmedPas encore d'évaluation

- ALSTOM Application Form TemplateDocument5 pagesALSTOM Application Form TemplateShaikhMazharAhmedPas encore d'évaluation

- IT CV Mohammed Anwar HussainiDocument3 pagesIT CV Mohammed Anwar HussainiShaikhMazharAhmedPas encore d'évaluation

- June Invoicing 2016Document1 pageJune Invoicing 2016ShaikhMazharAhmedPas encore d'évaluation

- Saudi Roza Gen - Contr. Co - LTD - 9Document1 pageSaudi Roza Gen - Contr. Co - LTD - 9ShaikhMazharAhmedPas encore d'évaluation

- Compliance Centro RiyadhDocument8 pagesCompliance Centro RiyadhShaikhMazharAhmedPas encore d'évaluation

- CAC and RAC Delivery Schedule 2015Document26 pagesCAC and RAC Delivery Schedule 2015ShaikhMazharAhmedPas encore d'évaluation

- Bupa Arabia Claim Form PDFDocument2 pagesBupa Arabia Claim Form PDFlhanx2100% (1)

- Maintenance Form 2015Document4 pagesMaintenance Form 2015ShaikhMazharAhmedPas encore d'évaluation

- Status of AvailabilityDocument2 pagesStatus of AvailabilityShaikhMazharAhmedPas encore d'évaluation

- Conversion Table - SheikhDocument2 pagesConversion Table - SheikhShaikhMazharAhmedPas encore d'évaluation

- Advantage Fyi 073Document1 pageAdvantage Fyi 073ShaikhMazharAhmedPas encore d'évaluation