Académique Documents

Professionnel Documents

Culture Documents

COE 107.04 Cathodic Protection Monitoring Instruments and Procedures

Transféré par

Mo'tasem SerdanehCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

COE 107.04 Cathodic Protection Monitoring Instruments and Procedures

Transféré par

Mo'tasem SerdanehDroits d'auteur :

Formats disponibles

Engineering Encyclopedia

Saudi Aramco Desktop Standards

CATHODIC PROTECTION MONITORING,

INSTRUMENTS & PROCEDURES

Note: The source of the technical material in this volume is the Professional

Engineering Development Program (PEDP) of Engineering Services.

Warning: The material contained in this document was developed for Saudi

Aramco and is intended for the exclusive use of Saudi Aramcos employees.

Any material contained in this document which is not already in the public

domain may not be copied, reproduced, sold, given, or disclosed to third

parties, or otherwise used in whole, or in part, without the written permission

of the Vice President, Engineering Services, Saudi Aramco.

Chapter : Electrical

File Reference: COE 107.04

For additional information on this subject, contact

PEDD Coordinator on 862-1026

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Section

OBJECTIVES

Page

........................................................................................................ 1

TERMINAL OBJECTIVE....................................................................................... 1

ENABLING OBJECTIVES .................................................................................... 1

INFORMATION

........................................................................................................ 3

INTRODUCTION .................................................................................................. 3

LOCATING BURIED PIPELINES ......................................................................... 4

MEASURING STRUCTURE-TO-ELECTROLYTE POTENTIAL........................... 7

MEASURING CATHODIC PROTECTION CURRENT ....................................... 11

Ammeter ............................................................................................................. 11

Shunt Currents ................................................................................................... 12

Clamp-On Ammeter............................................................................................ 14

PERFORMING A WELL CASING SURVEY....................................................... 15

Rectifiers ............................................................................................................ 17

WORK AIDS ...................................................................................................... 19

WORK AID 2: PROCEDURE TO MEASURE STRUCTURE-TOELECTROLYTE POTENTIAL..................................................... 25

WORK AID 3: PROCEDURE TO MEASURE CATHODIC

PROTECTION CURRENT ......................................................... 28

WORK AID 4: PROCEDURE TO PERFORM A WELL CASING CP

SURVEY..................................................................................... 30

Procedure ........................................................................................................... 32

WORK AID 5: PROCEDURE TO INSPECT THE CONDITION AND

OPERATION OF A CATHODIC PROTECTION

RECTIFIER ................................................................................... 34

GLOSSARY ...................................................................................................... 38

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

List of Figures

Figure 1. Conductive Type Pipe Locator ........................................................................ 5

Figure 2. Operation of a Conductive Type Pipe Locator.................................................. 6

Figure 3. Potential Gradient Around a Protected Pipeline ............................................... 8

Figure 4. Technique to Measure Pipe-to-Soil Potential ................................................... 9

Figure 5. Typical Pipeline Potential Survey ................................................................... 10

Figure 6. Multimeter Used as Ammeter......................................................................... 12

Figure 7. Measuring the Voltage Drop Across a Shunt Resistor ................................... 13

Figure 8. Swain Meter with a 1-1/2" Clamp ................................................................... 14

Figure 9. Swain Meter with a 13-inch Clamp................................................................. 16

Figure 10. Typical Cathodic Protection Rectifier Panel ................................................. 17

Figure 11. Nilsson Model 715 Pipe Locator Panel......................................................... 20

Figure 12. Pipe Locator to Pipeline Connections........................................................... 22

Figure 13A. First Null Position ....................................................................................... 23

Figure 13B. Second Null Position.................................................................................. 24

Figure 14. Fluke 77 Multimeter...................................................................................... 25

Figure 15. Multimeter Connection to Shunt Resistor in Junction Box........................... 28

Figure 16. Swain Meter ................................................................................................. 31

Figure 17. Measuring Current with a Swain Meter ....................................................... 33

Figure 18. Rectifier Output Voltage Measurement ........................................................ 34

Figure 19. Rectifier Output Current Measurement ........................................................ 35

List of Tables

Table 1. Saudi Aramco Standards Potential Requirements ............................................ 7

Table 2. Operating Controls and Indicators for Transmitter.......................................... 19

Table 3. Measuring Structure-To-Electrolyte Potential ................................................. 26

Table 4. Current Measuring Shunt mV-to-Amps Conversions....................................... 29

Table 5. Operating Controls and Indicators for Swain Meter........................................ 30

Saudi Aramco Desktop Standards

ii

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

This page intentionally

Saudi Aramco Desktop Standards

iii

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

OBJECTIVES

TERMINAL OBJECTIVE

Upon completion of this module, the participant will be able to

monitor cathodic protection systems, using applicable survey

procedures and equipment.

ENABLING OBJECTIVES

In order to accomplish the Terminal Objective, the participant

will be able to:

Locate buried pipelines.

Measure structure-to-electrolyte potential.

Measure cathodic protection currents.

Perform a well casing survey.

Inspect the condition and operation of a cathodic protection

rectifier.

Note: Definitions of words in italics are contained in the Glossary.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

This Page Intentionally Blank

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

INFORMATION

INTRODUCTION

Cathodic protection (CP) monitoring surveys are conducted

periodically to verify the performance of cathodic protection

systems. Cathodic protection surveys are normally conducted

for a specific structure (e.g., a pipeline, a storage tank, etc.) for

the following reasons:

To determine the need for cathodic protection.

To commission a new cathodic protection system.

To monitor the performance of an existing cathodic

protection system (coating deterioration of the structure and

anode consumption).

To monitor adjustments to the cathodic protection system.

To troubleshoot problems.

This module describes monitoring criteria, techniques, and

equipment for cathodic protection surveys. Information and

procedures are presented to help you operate monitoring

equipment safely and effectively in the field. After the Instructor

discusses monitoring equipment and operating procedures, you

will go to a nearby cathodic protection installation and perform

the following tasks:

Locate buried pipelines.

Measure structure-to-soil potentials.

Measure the current output of impressed current anodes.

Monitor Well Casing Cathodic Protection

Inspect the condition and operation of a rectifier.

Your performance will be evaluated based on your participation

and how well you complete the field data forms.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

LOCATING BURIED PIPELINES

During a cathodic protection survey, it is sometimes necessary

to locate a buried pipeline and other structures that cross the

pipeline. The pipe locator makes this task easier and quicker.

There are basically two types of pipe locators: conductive and

inductive. Both types of pipeline locators contain an alternating

current transmitter that impresses an ac signal on the pipe to be

located. The transmitter signal creates a magnetic field around

the pipe. The pipe is located through the use of a receiver that

detects the magnetic field. In conductive type pipe locators, the

ac signal is conducted to the pipe by a direct wire connection. In

the inductive type pipe locator, the ac signal is induced in the

pipe by an induction coil.

A conductive pipe locator is shown in Figure 1. The transmitter

converts direct current from a 12 V dry cell battery to alternating

current. The receiver is housed in a square phenolic tube that

forms the handle for the flat antenna coil. The receiver contains

input circuitry, an on-off volume control, an amplifier, batteries,

and an output jack. The antenna coil is inserted into a jack at

the volume control end of the receiver. The antenna coil is

molded in an epoxy compound and mounted on a hinged joint

rod. A bubble level is attached to the antenna coil to indicate

both horizontal and 45 degree inclinations. A set of headphones

is plugged into the output jack at the opposite end of the

receiver.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Receiver

Transmitter

FREQUENCY

HI

MED

LO

Headphones

Antenna coil

Figure 1. Conductive Type Pipe Locator

The transmitter contains a circuit that generates a distinctive

electrical signal current. Alternating current is caused to flow

onto the pipeline through a direct wire connection as shown in

Figure 2. This current creates a magnetic field around the pipe.

The magnetic field continuously expands and collapses at a

frequency proportional to the frequency of the transmitted

signal. When the antenna coil is placed in the magnetic field, an

electric current is induced in the receiver. The current is

amplified and produced as an audible tone in the headphones.

The pipe locator contains a device that interrupts the transmitter

output to give a pulsing tone. The pulsing tone allows the

operator to distinguish between the pipe locator tone and tones

that are caused by ac power line interference.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Headphones

Wellhead

Receiver

Transmitter

Wire

connection

Magnetic field

Figure 2. Operation of a Conductive Type Pipe Locator

The relative loudness of the signal, together with the position of

the antenna coil, enables the operator to precisely determine

the path and depth of a pipeline or cable.

There are a number of different types of makes and models of

pipe locators that are used in Saudi Aramco. Refer to the

operating manual of the locator being used to determine the

operating method (conductive or inductive), connections and

interpretation of instrument output (tone/signal strength, display

data, etc.) to determine the buried pipe location and depth.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

MEASURING STRUCTURE-TO-ELECTROLYTE POTENTIAL

Cost-effective corrosion control of onshore and offshore

structures requires that an adequate amount of cathodic

protection current is applied without over-protecting the

structure. The question is, How do we know when an adequate

level of cathodic protection has been reached?

The most widely used criterion for cathodic protection is based

on the potential difference between the structure and its

environment. Table 1 shows Saudi Aramcos design standard

potential requirements for various structures.

Table 1. Saudi Aramco Standards Potential Requirements

Structure

Buried Cross-Country

Pipelines

Buried Plant Piping, Tank

Bottom Externals, Isolated

Buried Casings

Fire Water systems

(hydrants, metal valves &

risers)

Water Tank Interiors

Marine Structures

Saudi Aramco

Engineering

Standard

SAES-X-400

SAES-X-600

SAES-X-600

Minimum Required Potential

-1.2 Volts versus CuSO4 electrode,

current on

-1.0 Volts versus CuSO4 electrode,

current on, -850 mV current off, or

100 mV polarization potential

-1.0 Volts versus CuSO4 electrode,

current on

SAES-X-500

-0.90 volts versus AgAgCl electrode

SAES-X-500

-0.90 volts versus AgAgCl electrode

Operating potential requirements, which are slightly lower than

the ones in the design standards, are given in SAEP-333

Appendix A.

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

The desired potential difference is achieved by making the

structure negative with respect to remote earth. Module 2

described how current from a remote ground bed creates an

area of influence, or potential gradient area, in the earth around

a cathodically protected structure. The potential of the pipeline

becomes increasingly negative as a reference electrode is

moved away from the pipeline to a point where remote earth is

reached.

-0.90V

-0.89V

-0.88V

-0.87V

-0.86V

-0.85V

rrent

t cu

Direc

Protected

pipeline

Figure 3. Potential Gradient Around a Protected Pipeline

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Electrical potentials are measured through the use of a high

input impedance voltmeter and a reference electrode. Ideally,

the potential should be measured with the reference electrode

as close to the pipelines surface as possible; however, it is not

possible to place the reference electrode at the surface of a

buried pipeline.

The best way is to measure the potential between the pipeline

and the earth at the ground surface directly above the pipeline

as shown in 4. The reference electrode is connected to the

positive terminal of the voltmeter. The common (negative)

terminal of the voltmeter is connected to the structure. The

negative terminal can be electrically connected to a buried

structure at a test station or directly to the structure at an above

ground location.

The voltmeter reading is a combination of the potential between

the reference electrode and the soil and the potential between

the pipeline and the soil. The potential between the reference

electrode and the soil is constant. The potential between the

pipeline and the soil can vary. When connected as shown, the

potential reading will normally be positive. By convention,

voltage readings are reported as negative numbers.

Figure 4. Technique to Measure Pipe-to-Soil Potential

Saudi Aramco Desktop Standards

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

To evaluate the degree of cathodic protection that is achieved,

we must determine if enough cathodic protection current has

been applied to protect the entire structure. The technique that

is shown in the previous figure only measures the potential near

the reference electrode; therefore, a potential survey of the

entire pipeline is conducted to determine if a pipeline is

adequately protected. A typical survey consists of the taking of

potential readings at several locations, as shown in Figure 5.

Any readings more negative than -1.20 volts (vs. Cu-CuSO4)

indicate adequate cathodic protection. Any readings more

positive than -1.20 volts indicate possible corrosion zones. A

procedure to measure pipe-to-soil potential of a pipeline is

provided in Work Aid 2.

Figure 5. Typical Pipeline Potential Survey

Saudi Aramco Desktop Standards

10

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

MEASURING CATHODIC PROTECTION CURRENT

Two ways to determine current in a circuit are: (1) measuring

amperes directly with an ammeter, or (2) measuring the voltage

drop across a shunt and calculating the current. Either method

can be used to measure the current output of the following:

Anodes

Cathodic protection rectifiers

Temporary installations for current requirement tests

The following information describes instruments and techniques

that are used to measure cathodic protection current.

Ammeter

Ammeters are instruments that are designed to measure electric

current. An ammeter must be placed within an electric circuit to

measure current. Ammeters have relatively low internal

resistance. They add very little resistance to the circuit so that

there is negligible reduction in the total current that flows

through the circuit. Special combination meters, or multimeters,

have been developed for measuring current, voltage, and

resistance over many orders of magnitude. Figure 6 shows a

typical multimeter that is used by Saudi Aramco. Multimeters

measure both alternating and direct current.

Saudi Aramco Desktop Standards

11

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Figure 6. Multimeter Used as Ammeter

Shunt Currents

Galvanic and impressed current anodes are usually installed

with shunt resistors in the junction box. Shunts allow the current

output of both types of anodes to be measured without

disturbing the system. The current that flows through a shunt

produces a voltage drop, which can be measured with a

multimeter (Figure 7). If the resistance of the shunt is known,

the current output can be calculated through the use of Ohms

Law, I = E/R. For example, if a voltage drop of 3.20 millivolts is

measured across a 0.001 ohm shunt, the amount of current

flowing through the shunt is .0032 millivolts/0.001 ohm, or 3.2

amperes.

Saudi Aramco Desktop Standards

12

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Figure 7. Measuring the Voltage Drop Across a Shunt Resistor

To determine the direction of current flow, it is important to

observe where the positive and negative leads of the multimeter

are attached to the shunt. A positive reading means that current

is flowing from positive to negative through the shunt. A

negative reading means that current is flowing from negative to

positive through the shunt.

Refer to Work Aid 3, for additional details on using this

procedure.

Saudi Aramco Desktop Standards

13

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Clamp-On Ammeter

Electric current produces a small magnetic field as it flows

through a conductor. The strength of the magnetic field is

proportional to the amount of current that flows in the conductor.

A clamp-on ammeter is used to measure the amount and

direction of electric current based on the strength of this

magnetic field. Figure 8. shows a Swain Meter with a 1-1/2"

clamp. The clamp measures the average magnitude of direct or

alternating current that flows in conductors up to 3/4" in

diameter. The advantage of a clamp-on ammeter is that current

can be measured by placing the clamp around an energized

wire without opening the circuit to install a meter.

Figure 8. Swain Meter with a 1-1/2" Clamp

Saudi Aramco Desktop Standards

14

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

PERFORMING A WELL CASING SURVEY

Monitoring Well Casing Cathodic Protection

Monitoring the effectiveness of cathodic protection for well

casings is more difficult than for pipelines.

For well casings, the potential difference along the external

length of the casing cannot be measured without the expense of

a casing potential profile as described in Module 3. A more

practical approach to periodic monitoring to asses the

effectiveness of cathodic protection of well casings is to

measure the CP current pickup by the casing.

A Swain Meter (see Figure 9) is used to measure dc current

that flows on a well casing or flowline. Saudi Aramco normally

uses a 13-inch clamp to measure dc current on a flowline, and a

24-inch clamp to measure current on a well casing. The

procedure to measure the cathodic protection current returned

by a well casing is provided in Work Aid 4.

Engineering Standard SAES-X-700 and Saudi Aramco

Engineering Procedure SAEP-333 detail the minimum design

and operation current requirements, respectively, for well

casings located in the various Saudi Aramco operating areas.

These requirements also differentiate between the various types

of CP power sources and whether the casing being protected is

bare or coated. These current requirements are based on

analysis of data from downhole potential profile logs, and

operating experience for the different types of wells.

Saudi Aramco Desktop Standards

15

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

5 6

7 8 9 10 11 12 13 14 1

5

16

17

4 5 6 7

8

2 3

9

DC AMPERES

18

19

20

10

WM. H. SWAIN CO.

OFF

O N 20

100

10

1.

.2

200

+P O L

2.

DC AMP

TB

ZERO

CLIP

Figure 9. Swain Meter with a 13-inch Clamp

Saudi Aramco Desktop Standards

16

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

INSPECTING THE CONDITION AND OPERATION OF A CATHODIC

PROTECTION RECTIFIER

Saudi Aramco uses two types of dc power sourcesrectifiers

and photovoltaic solar systems. Because of the high current

demand and the high soil resistivity in Saudi Arabia, most of all

cathodic protection systems are powered by rectifiers.

Rectifiers

Figure 10 shows a diagram of a rectifier panel. Note the

locations of the dual meter, meter shunt, meter switch, and dc

output lugs.

Figure 10. Typical Cathodic Protection Rectifier Panel

Saudi Aramco Desktop Standards

17

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

SAEP- 333 requires monthly, quarterly and annual inspection of

rectifiers by Operations or Maintenance personnel. During a

rectifier inspection, the tap settings, voltmeter and ammeter

readings are checked. The output voltage is verified by

measuring the voltage across the dc output terminals of the

rectifier, using a portable voltmeter. The ammeter reading is

verified by measuring the voltage drop across the ammeter

shunt using a portable voltmeter, and calculating the current. All

readings are recorded on a data sheet. The procedure to

inspect a rectifier is provided in Work Aid 5.

Saudi Aramco Desktop Standards

18

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

WORK AIDS

WORK AID 1.

PROCEDURE TO LOCATE BURIED PIPELINES

This Work Aid contains a description of the Nilsson Model 715 pipe locator and a

procedure for its use in locating a buried pipeline. There are other types of makes and

models of pipe locators that are also used in Saudi Aramco. Refer to the operating

manual of the locator being used to determine the operating method (conductive or

inductive), connections and interpretation of instrument output (tone/signal strength,

display data, etc.) to determine the buried pipe location and depth.

Operating controls and indicators for the transmitter and receiver are described in the

following table. The locations of the controls and indicators are shown Figure 11.

Table 2. Operating Controls and Indicators for Transmitter

Index No.

Control/ Indicator

Description

Function

ON-OFF

Flip switch

Turns transmitter on and off.

LOW BATTERY

Indicator

Turns on when the battery light voltage

decreases to 9 - 10 volts.

FREQUENCY

Selector

Selects the proper pitch of the switch

signal.

RATE

Selector

Adjusts the rate at which the switch

signal is interrupted.

IMPEDANCE

Selector

Selects three output impedance switch

ranges to give the best possible signal.

OUTPUT

Binding

Used to connect the transmitter posts

to the pipeline to be located.

ONOFF/VOLUME

Adjustable

Turns receiver on and off and switch

adjusts volume of tone in headphones.

BUBBLE LEVEL

Indicator

Indicates horizontal and 45 inclination

of receiver coil

Saudi Aramco Desktop Standards

19

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

3

FREQUENCY

ON

4

RATE

IMPEDENCE

HI

OUTPUT

MED

Battery

Low

LO

Figure 11. Nilsson Model 715 Pipe Locator Panel

Use the procedure in 1.1, 1.2, or 1.3 below on the basis of the existing conditions in the

field.

Preliminary Starting Procedures

1. Establish a series loop.

1.1 Use the following procedure when two points are

available at some distance apart on the pipeline.

a.

Connect the bare end of an insulated copper wire to

one OUTPUT binding post and tighten the binding

post knob. Attach the opposite end of the wire to a

point on the pipeline.

b.

Locate another point on the pipeline that is at a

considerable distance from the first point. Connect a

second insulated wire from the other OUTPUT

binding post to this point on the pipeline as shown in

Figure 12. Keep the wire about 15 m (50 ft.) from the

probable path of the pipeline to minimize the signal

from the wire.

c.

Set the IMPEDANCE switch to LOW.

1.2 Use the following procedure when one point is available

on the pipeline and there is a nearby metallic structure

that may be used as a grounding structure.

a.

Saudi Aramco Desktop Standards

Connect the bare end of an insulated copper wire to

one OUTPUT binding post and tighten the binding

post knob. Attach the opposite end of the wire to a

point on the pipeline.

20

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

b.

Connect a second insulated wire from the other

OUTPUT binding post to the grounding structure as

shown in Figure 12.

c.

Adjust the IMPEDANCE switch until the best signal is

obtained.

1.3 Use the following procedure when one point is available

on the pipeline and there is no convenient ground

connection nearby.

Saudi Aramco Desktop Standards

a.

Connect the bare end of an insulated copper wire to

one OUTPUT binding post, and tighten the binding

post knob. Attach the opposite end of the wire to a

point on the pipeline.

b.

Drive a 0.5 m (18 in.) metal rod into the ground

approximately 15 m (50 ft.) from the probable path of

the pipeline. Connect a second insulated wire from

the other OUTPUT binding post to the metal rod as

shown in Figure 12.

c.

Adjust the IMPEDANCE switch until the best signal is

obtained.

21

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

A

pipe

About

50 feet

signal in both

pipe

grounded

structure

signal in both

pipe

me tal

rod

Figure 12. Pipe Locator to Pipeline Connections

2. Achieve a distinctive signal.

a.

Assemble the transmitter, receiver, and headphones.

Turn on the transmitter and receiver.

Caution: After the transmitter has been turned on, do

not touch the OUTPUT binding post or wiring. This

contact could cause a shock, which is not dangerous

but may be annoying, especially if the IMPEDANCE

selector is in the HI position.

b.

Saudi Aramco Desktop Standards

Listen to the signal and adjust the FREQUENCY and

RATE controls for the most distinctive tone under the

present conditions. Set the receiver volume to the

lowest level that can be heard comfortably. If a

grounding structure is used, a signal will be heard in

both the pipeline and the grounding structure.

22

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Operating Procedures

3.

Determine the depth and path of the pipeline.

a.

Position the antenna disc close to the ground with the

bottom facing downward. Center the bubble in the level.

b. With the bubble centered, move the antenna disc across

the probable path of the pipeline. When the center of the

disc is directly over the pipeline and parallel to it (Figure

13A), a minimum signal will be heard. This position is

referred to as the null position. Mark the null position on

the ground surface.

Null

position

marker

Pipe

Figure 13A. First Null Position

Saudi Aramco Desktop Standards

23

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

c. After the null position is determined, tip the antenna

disc to a 45 angle (bubble touching the outer edge of

the ring on the level).

d. Move the antenna disc horizontally from the first null

position as shown in Figure 13B until another null

position is obtained. Mark the second null position.

Equal to

depth

45

Depth

Pipe

Figure 13B. Second Null Position

e.

Saudi Aramco Desktop Standards

Record the distance between the two null positions.

This distance is equivalent to the depth of the pipeline

below the first null position.

24

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

WORK AID 2.

PROCEDURE TO MEASURE STRUCTURE-TOELECTROLYTE POTENTIAL

This Work Aid contains a description of the Fluke Model 77 Multimeter and a procedure

to assist the Participant in measuring structure-to-electrolyte potential.

Operating controls and indicators for the Fluke 77 Multimeter

are described in Figure 14.

Figure 14. Fluke 77 Multimeter

Saudi Aramco Desktop Standards

25

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Table 3. Measuring Structure-To-Electrolyte Potential

Ex No.

1

2

3

Control or

Description

Indicator

DIGITAL DISPLAY Indicator

FUNCTION

SELECTOR

V

Rotary Switch

Volts, Ohms Diode

Test

Function

Displays voltage and current

readings.

Selects 7 different functions

or OFF.

Input terminal used with the

volts, mV (ac or dc), ohms,

or diode test position of the

function selector rotary

switch.

V ~ Volts ac

Volts dc

V

Millivolts dc

300 mV

Ohms (resistance, also

conductance (1/) in

nanosiemens (nS)

Continuity or diode

test

COM

Common Terminal

300mA

Milliamperes Input

Terminal

10A

Saudi Aramco Desktop Standards

Amperes Input

Terminal

26

A ~Amps ac

Amps dc

A

Common or return terminal

used for all measurements.

Input terminal used for

current measurements up to

300 mA.

Input terminal used for

current measurements up to

10 A.

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Preliminary Starting Procedures (Before you leave for the field)

1. Check the equipment.

a.

Inspect the copper-sulfate electrode for damage or

undissolved crystals. Make sure the copper rod inside

the electrode assembly is clean and shiny. Clean it if

necessary.

b.

Make sure the electrode works properly. Test the

electrode against another electrode that is kept in the

office and used as a standard.

c.

Turn voltmeter on and check battery. Check test leads

for wear, and replace them if necessary.

Operating Procedures

2.

Saudi Aramco Desktop Standards

Measure the pipeline potential.

a.

Set the FUNCTION SELECTOR to V

b.

Remove the cap from the end of the reference

electrode, and place the plug of the reference

electrode in mud or moist soil over the pipeline and

about 0.6 m (2 ft.) from the test station.

c.

Connect the positive lead of the voltmeter to the

reference electrode.

d.

Connect the negative lead of the voltmeter to the test

station with the hex head nut.

e.

Turn the meter to the lowest input impedance.

f.

Measure the pipe-to-soil potential. (A reading that

varies may indicate a poor connection, dry soil, or soil

soaked with oil.)

g.

Check the connections, and increase the input

impedance until the highest reading is achieved. (The

reading must be the same on two consecutive

settings.)

h.

Record the date, location, and voltage readings on

the Well/Flowline Survey Data Sheet.

i.

Remove the test leads. Remove the reference

electrode from the soil, wipe off the dirt and replace

the cap on the end of the reference electrode probe.

27

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

WORK AID 3.

PROCEDURE TO MEASURE CATHODIC PROTECTION

CURRENT

This Work Aid describes the procedure to measure the current output of impressed

current anodes in a anode junction box.

Operating Procedures

1.

Measure the individual anode current output (at the

junction box).

a. Set the FUNCTION SELECTOR to 300 mV

b. Connect the negative lead from the multimeter to the

left side of the shunt for Anode 1 as shown in Figure 15.

Connect the positive lead from the multimeter to the

right side of the shunt (for the rectifier + output

connection to the bus-bar).

Figure 15. Multimeter Connection to Shunt Resistor in Junction Box

Saudi Aramco Desktop Standards

28

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

c.

Measure the reading (in mV) and record output

current (after conversion from millivolts), on the

Anode Bed Survey form. Refer to Table 5 below for

mV-to-current conversions for common shunt types

and sizes. Be sure to write the reading next to the

proper anode number.

d.

Repeat Steps b. and c. for all of the remaining

anodes.

Table 4. Current Measuring Shunt mV-to-Amps Conversions

0.10 ohms

Equivalent

Current for 1

mV Reading

0.01 A

10 mA/mV

Holloway

Type RS

0.01 ohms

0. 100 A

100 mA/mV

50 mV 50 A

0.001 ohms

1.0 A

1 A/mV

50 mV 40 A

0.00125 ohms

1.25 A

1.25 A/mV

50 mV 30 A

0.00166 ohms

1.66 A

1.66 A/mV

50 mV 25 A

0.002 ohms

2.0 A

2.0A/mV

Shunt Type

or Rating

Ohmic Value

Resistor

Saudi Aramco Desktop Standards

29

Amps/mV

Factor

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

WORK AID 4.

PROCEDURE TO PERFORM A WELL CASING CP

SURVEY

This Work Aid contains a procedure to perform a well casing CP survey using a

multimeter and Cu-CuSO4 reference electrode, and a Swain Meter.

Operating controls and indicators for the Swain Meter are described in the

following table. The locations of the controls and indicators are shown in

Figure 16.

Table 5. Operating Controls and Indicators for Swain Meter

Index

No.

1

Control/ Indicator

Description

Function

ANALOG DISPLAY

Indicator

Displays current readings.

POL

Switch

Sets the meter polarity.

ZERO

Knob

Sets electrical zero.

DC AMP CLIP

Jack

Connects Clamp to meter.

RANGE (not labeled)

Switch

ON-OFF

Flip switch

Selects current ranges from 200 A

to 200 mA. TB setting is for testing

the battery.

Turns transmitter on and off.

Clamp

Encircles wellhead or flowline.

Bridle

Position indicates + or - current.

Saudi Aramco Desktop Standards

30

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

5 6

7 8 9 10 11 12 13 14 1

5

16

17

4 5 6 7

8

2 3

9

DC AMPERES

18

19

20

10

WM. H. SWAIN CO.

OFF

O N 20

100

10

1.

.2

200

+P O L

2.

DC AMP

TB

ZERO

CLIP

Figure 16. Swain Meter

Saudi Aramco Desktop Standards

31

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Procedure

1.

Measure the rectifier operating output

With the rectifier on, record the voltage and current

readings from the rectifier voltmeter and ammeter on

the Well Casing Survey form.

2.

3.

Measure the well casing potential.

a.

Set the FUNCTION SELECTOR on the

.

multimeter to V

b.

Connect the lead from the negative terminal of

the multimeter to the well casing. Connect the

lead from the reference electrode to the positive

terminal of the multimeter.

c.

Remove the cap from the end of the reference

electrode, and place the plug of the reference

electrode in mud or moist soil. If the soil is not

moist, saturate the soil around the electrode with

water. Take readings both inside and outside

the well cellar.

Measure the cathodic protection current returned by

the well casing.

a. Plug the clamp into the CLIP jack of the

Swain Meter. Place the POL switch in the +

position. Turn the RANGE switch to 20 A.

Move the ON/OFF switch to ON to turn on

the meter.

b. Hold the clamp away from the flowline.

Rotate the ZERO knob until the indicator

reads 0.

c. Place the clamp around the flowline with the

bridle pointing to the wellhead as shown in

Figure 17. Adjust the RANGE switch setting

up or down to get the most accurate current

reading. Record the current reading on line

3A of the Well Casing Annual Survey form.

If the current flows from the well to the

flowline, record the current as positive on

Saudi Aramco Desktop Standards

32

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

the form. If the current flows from the

flowline to the well, record the current as

negative on the form.

d.

Turn the rectifier off, and record the current

reading on the form.

e.

Turn the rectifier on, and record the system

output voltage and current on the form.

Positive reading

Sea clamp

Bridle

current

wellhead

Flowline

Bridle toward source of current

Negative reading

Bridle

Flowline

current

wellhead

Bridle away from source of current

Figure 17. Measuring Current with a Swain Meter

Saudi Aramco Desktop Standards

33

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

WORK AID 5.

PROCEDURE TO INSPECT THE CONDITION AND

OPERATION OF A CATHODIC PROTECTION

RECTIFIER

This Work Aid contains the procedure to inspect the condition and operation of a

cathodic protection rectifier.

Procedure

1. Record the rectifier data on the data sheet. This data is

usually found on the manufacturers information plate on

the inside of the rectifier door. Record the voltage and

current readings from the meters on the rectifier panel.

2. Verify the rectifier voltage output.

a. Turn the rectifier off by switching the ac breaker to the

off position.

b. Set the FUNCTION SELECTOR on the multimeter to

. Connect the positive and negative leads from

V

the multimeter to the dc output terminals as shown in

Figure 18.

Figure 18. Rectifier Output Voltage Measurement

Saudi Aramco Desktop Standards

34

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

c.

Turn the rectifier on. Record the multimeter reading

on the data sheet. Compare the multimeter reading to

the rectifiers voltmeter reading.

d.

Turn the rectifier off and remove the leads from the dc

output terminals.

3. Verify the rectifier current output.

a.

Set the FUNCTION SELECTOR on the multimeter to

.

300mV

b. With the rectifier off, connect the positive and negative

leads from the multimeter to the meter shunt as shown

below in Figure 19.

Figure 19. Rectifier Output Current Measurement

Saudi Aramco Desktop Standards

35

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

Saudi Aramco Desktop Standards

c.

Turn the rectifier on and record the multimeter

reading.

d.

Turn the rectifier off and remove the test leads. Turn the

rectifier on.

e.

Multiply the voltage reading (in mV) by the shunt rating

constant (A/mV) to obtain the current output of the rectifier.

Record the calculated current on your data sheet.

f.

Compare the calculated current output with the

rectifiers ammeter reading.

36

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

This Page Intentionally Blank

Saudi Aramco Desktop Standards

37

Engineering Encyclopedia

Corrosion

Cathodic Protection Monitoring Instruments and Procedures

GLOSSARY

Area of Influence

The area in which the potential of a structure exceeds

the minimum potential required for protection.

Current Interrupter

A device that is used to switch a current source off

and on automatically.

Holiday

A discontinuity (pinhole or flaw) in a coated surface

that exposes the metal substrate to the environment.

Impedance

Measured in ohms, impedance is the total opposition

to alternating current in an electric circuit. Impedance

is equal to the square root of the sum of the squares

of the resistance and reactance of the circuit.

IR Drop

The voltage drop across a resistance in accordance

with Ohms Law.

Native Potential

The natural or as found potential of a structure

before the cathodic protection system is energized.

Polarization

The change in potential of a metal surface that results

from the passage of current directly to or from the

electrolyte.

Polarization Potential

The structure-to-earth potential at which corrosion

ceases.

Remote Earth

The area(s) in which the structure-to-electrolyte

potential change is negligible with change in reference

electrode position away from the structure.

Shunt

A low, calibrated, resistance that is connected

between two points in an electrical circuit. A shunt is

used to measure and control current.

Saudi Aramco Desktop Standards

38

Vous aimerez peut-être aussi

- Auditing of Cathodic Protection Systems and Anticorrosion Coating Conservation Status in Oil and Gas Pipelines (CIPS - DCVG Surveys)Document14 pagesAuditing of Cathodic Protection Systems and Anticorrosion Coating Conservation Status in Oil and Gas Pipelines (CIPS - DCVG Surveys)Laith SalmanPas encore d'évaluation

- Cathodic ProtectionDocument40 pagesCathodic Protectionjadav parixeet100% (1)

- Saep 333Document39 pagesSaep 333brecht1980100% (1)

- Corrosion CuoponsDocument70 pagesCorrosion CuoponsWalidbenrhoumaPas encore d'évaluation

- 00 Saip 73Document8 pages00 Saip 73Selvakpm06Pas encore d'évaluation

- Specification For Cathodic Protection System Equipment and MaterialsDocument24 pagesSpecification For Cathodic Protection System Equipment and Materialsg1kumar04100% (1)

- EEX 208.01 Classification of and Protection For Hazardous LocationsDocument33 pagesEEX 208.01 Classification of and Protection For Hazardous LocationsMo'tasem Serdaneh100% (1)

- EEX10401 Industrial Facility SubstationDocument64 pagesEEX10401 Industrial Facility SubstationHonesto Bautista100% (1)

- Sogec - CP Cathodic Protection Training Manual-Module 6Document10 pagesSogec - CP Cathodic Protection Training Manual-Module 6Emre ErdemPas encore d'évaluation

- Intermediate-4-5 - Criteria For Cathodic ProtectionDocument68 pagesIntermediate-4-5 - Criteria For Cathodic Protectionjose yoy100% (1)

- COE 107.03 Designing Cathodic Protection SystemsDocument130 pagesCOE 107.03 Designing Cathodic Protection SystemsMo'tasem SerdanehPas encore d'évaluation

- 15 Saip 51Document5 pages15 Saip 51malika_00Pas encore d'évaluation

- Total Procedure NDT Procedure (Ut For Steel Structure) - 1Document35 pagesTotal Procedure NDT Procedure (Ut For Steel Structure) - 1nanivenkatgauravPas encore d'évaluation

- NDTDocument23 pagesNDTPrabhu Subbiah Ramdoss100% (6)

- Cathodic Protection RectifiersDocument12 pagesCathodic Protection RectifiersCyrix.OnePas encore d'évaluation

- Nace Standard On Cathodic Protection - Google SearchDocument2 pagesNace Standard On Cathodic Protection - Google SearchankiPas encore d'évaluation

- Pipeline Direct AssessmentDocument29 pagesPipeline Direct Assessment김원재100% (1)

- 00 Saip 75Document72 pages00 Saip 75bazresifanniPas encore d'évaluation

- Nondestructive Testing PDFDocument65 pagesNondestructive Testing PDFAnonymous S9qBDVkyPas encore d'évaluation

- Cathodic Protection Design Using ImpressDocument80 pagesCathodic Protection Design Using ImpressAyub Yaakob100% (1)

- 00 Saip 71Document19 pages00 Saip 71balajiPas encore d'évaluation

- Saes-X-700 Sa StandardDocument38 pagesSaes-X-700 Sa StandardMani Raj0% (1)

- BP - GP 32-48-In Service Inspection and Testing of Heat ExchangersDocument16 pagesBP - GP 32-48-In Service Inspection and Testing of Heat ExchangersAmr SolimanPas encore d'évaluation

- SAES X 500 Cathodic ProtectionDocument8 pagesSAES X 500 Cathodic ProtectionAbdul Khader HassanPas encore d'évaluation

- Cathodic Protection DesignDocument23 pagesCathodic Protection DesignYoungtae Kim100% (6)

- 15 Saip 50Document5 pages15 Saip 50malika_00Pas encore d'évaluation

- Pipeline Cathodic Protection Design - Compress PDFDocument20 pagesPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- Pheonwj I PRC 0005 0Document54 pagesPheonwj I PRC 0005 0Iksan Adityo Mulyo100% (1)

- Pipeline Cathodic Protection DesignDocument20 pagesPipeline Cathodic Protection DesignNguyen Thi Thu Huong80% (5)

- Cathodic Protection ReportDocument13 pagesCathodic Protection Reportjeedan75% (8)

- 000-ZA-E-M09405 - B MS For Cathodic Protection SystemsDocument20 pages000-ZA-E-M09405 - B MS For Cathodic Protection Systemssyam prasadPas encore d'évaluation

- CP Training Maual-Module 8-Field Measurement and Testing of CP Sys...Document38 pagesCP Training Maual-Module 8-Field Measurement and Testing of CP Sys...Emre Erdem100% (1)

- Gap Control For Socket Weld Back Welded Threaded FittingsDocument12 pagesGap Control For Socket Weld Back Welded Threaded Fittingslaz_k100% (1)

- Saep 1142Document11 pagesSaep 1142shaban100% (2)

- Saep 1150Document50 pagesSaep 1150Anonymous B7pghhPas encore d'évaluation

- Saes A 007 PDFDocument29 pagesSaes A 007 PDFsindalisindiPas encore d'évaluation

- Sogec - CP Cathodic Protection Training Manual-Module 9Document12 pagesSogec - CP Cathodic Protection Training Manual-Module 9Emre Erdem100% (1)

- Remote Earth Cathodic ProtectionDocument2 pagesRemote Earth Cathodic ProtectionankiPas encore d'évaluation

- Cathodic Protection Report - EKFLRDocument19 pagesCathodic Protection Report - EKFLReke23100% (1)

- Cathodic Protection Part 2Document42 pagesCathodic Protection Part 2tribleprincePas encore d'évaluation

- SAER1972Document9 pagesSAER1972zamil2008Pas encore d'évaluation

- Saep 1143Document30 pagesSaep 1143danielpradeep100% (1)

- 01 Saip 02Document6 pages01 Saip 02malika_00Pas encore d'évaluation

- 00 Saip 08 - 03142016Document9 pages00 Saip 08 - 03142016PandhuPas encore d'évaluation

- Cathodic Protection PrinciplesDocument48 pagesCathodic Protection PrinciplesCoversheet100% (1)

- Model 601 Operating PrinciplesDocument2 pagesModel 601 Operating PrinciplesProfumo San Martin100% (2)

- Cathodic Protection Drawings SP-1136Document4 pagesCathodic Protection Drawings SP-1136anuprajoshPas encore d'évaluation

- 9.19 - P-101 - Positive Material IdentificationDocument13 pages9.19 - P-101 - Positive Material IdentificationRays TioPas encore d'évaluation

- 01 Saip 04Document17 pages01 Saip 04munnaPas encore d'évaluation

- Cathodic Protection 2015Document21 pagesCathodic Protection 2015ainunPas encore d'évaluation

- 17 Samss 006Document13 pages17 Samss 006Ahamedulla KhanPas encore d'évaluation

- COE 107.02 Design Basics For Cathodic Protection SystemsDocument87 pagesCOE 107.02 Design Basics For Cathodic Protection SystemsMo'tasem Serdaneh0% (1)

- Twi Course Name and Description: BGAS/CSWIP CoursesDocument5 pagesTwi Course Name and Description: BGAS/CSWIP Courseskhalidmh100% (1)

- Cathodic ProtectionDocument2 pagesCathodic ProtectionaltamimzPas encore d'évaluation

- Corrosion MonitoringDocument8 pagesCorrosion MonitoringEleonoraPas encore d'évaluation

- Engineering Encyclopedia: Basic Properties of SectionsDocument62 pagesEngineering Encyclopedia: Basic Properties of SectionsVijay KumarPas encore d'évaluation

- CP Training Maual-Module 7-Installation of CP SystemsDocument23 pagesCP Training Maual-Module 7-Installation of CP SystemsEmre ErdemPas encore d'évaluation

- Corrosion Detection Under Pipe Supports Using EMAT PDFDocument10 pagesCorrosion Detection Under Pipe Supports Using EMAT PDFpaeg6512Pas encore d'évaluation

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Samco Saj Saudia AramcoDocument62 pagesSamco Saj Saudia AramcoFaouzi TlemcenPas encore d'évaluation

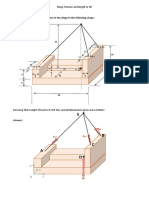

- COG Change and Load ShearingDocument5 pagesCOG Change and Load ShearingMo'tasem SerdanehPas encore d'évaluation

- Sling Length and TensionDocument4 pagesSling Length and TensionMo'tasem SerdanehPas encore d'évaluation

- Apolo Additional Attachments (Slings Tension in 3d)Document4 pagesApolo Additional Attachments (Slings Tension in 3d)Mo'tasem SerdanehPas encore d'évaluation

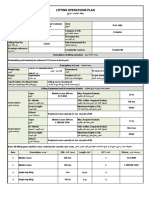

- LP020 - Dismantling and Lowering The Defected STS Boom at Back YardDocument24 pagesLP020 - Dismantling and Lowering The Defected STS Boom at Back YardMo'tasem SerdanehPas encore d'évaluation

- COG 3dDocument2 pagesCOG 3dMo'tasem SerdanehPas encore d'évaluation

- TrignometryDocument4 pagesTrignometryMo'tasem SerdanehPas encore d'évaluation

- COE 107.03 Designing Cathodic Protection SystemsDocument130 pagesCOE 107.03 Designing Cathodic Protection SystemsMo'tasem SerdanehPas encore d'évaluation

- Apolo Additional Attachments (Slings Tension in 3d Part 3)Document6 pagesApolo Additional Attachments (Slings Tension in 3d Part 3)Mo'tasem SerdanehPas encore d'évaluation

- Apolo Additional Attachments (Slings Tension in 3d)Document4 pagesApolo Additional Attachments (Slings Tension in 3d)Mo'tasem SerdanehPas encore d'évaluation

- 144 Pages Basic of Mechanical Engineering PDFDocument144 pages144 Pages Basic of Mechanical Engineering PDFMo'tasem SerdanehPas encore d'évaluation

- CV Mutasem, Crane, Rigger Trainer and Lifting InspectorDocument4 pagesCV Mutasem, Crane, Rigger Trainer and Lifting InspectorMo'tasem SerdanehPas encore d'évaluation

- BV Accedent InvestigationDocument1 pageBV Accedent InvestigationMo'tasem SerdanehPas encore d'évaluation

- 8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaDocument24 pages8 - Lifting Plan For Transfering Engine (z1) Landing Area Then Loading From Ground To Truck and Vice VersaMo'tasem SerdanehPas encore d'évaluation

- EEX 208.01 Classification of and Protection For Hazardous LocationsDocument33 pagesEEX 208.01 Classification of and Protection For Hazardous LocationsMo'tasem Serdaneh100% (1)

- Saes N 120Document13 pagesSaes N 120aamirapi100% (1)

- COE 107.01 Cathodic Protection PrinciplesDocument56 pagesCOE 107.01 Cathodic Protection PrinciplesMo'tasem Serdaneh100% (1)

- COE 107.02 Design Basics For Cathodic Protection SystemsDocument87 pagesCOE 107.02 Design Basics For Cathodic Protection SystemsMo'tasem Serdaneh0% (1)

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDocument79 pagesChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem Serdaneh100% (1)

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDocument79 pagesChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem Serdaneh100% (1)

- Hydrate Inhibition MethodsDocument111 pagesHydrate Inhibition MethodskaitokidH3MPas encore d'évaluation

- Saes N 100Document16 pagesSaes N 100aamirapiPas encore d'évaluation

- Saes N 004Document5 pagesSaes N 004Mo'tasem SerdanehPas encore d'évaluation

- Saes N 140Document10 pagesSaes N 140aamirapiPas encore d'évaluation

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDocument95 pagesChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem SerdanehPas encore d'évaluation

- Basic Rigging Work BookDocument45 pagesBasic Rigging Work BookJohn Henry Sinurat100% (1)

- Rigging BookDocument7 pagesRigging Booksweet0936Pas encore d'évaluation

- Rigging BookDocument7 pagesRigging Booksweet0936Pas encore d'évaluation

- ChE 206.01 Introduction To Hydrate Inhibition and DehydrationDocument79 pagesChE 206.01 Introduction To Hydrate Inhibition and DehydrationMo'tasem Serdaneh100% (1)

- (Rigging) Certex PDFDocument376 pages(Rigging) Certex PDFMo'tasem SerdanehPas encore d'évaluation

- VECU - Manual de Producción 70312913Document33 pagesVECU - Manual de Producción 70312913RainorSS100% (2)

- Ijesrt: Modelling and Simulation of Solar Photovoltaic Array For Battery Charging Application Using Matlab-SimulinkDocument5 pagesIjesrt: Modelling and Simulation of Solar Photovoltaic Array For Battery Charging Application Using Matlab-Simulinksrinureddy2014Pas encore d'évaluation

- Akpark: Cover Sheet - ElectricalDocument10 pagesAkpark: Cover Sheet - ElectricalEngr M.Arshad KhalidPas encore d'évaluation

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KiflePas encore d'évaluation

- Practical Application of Pervious Concrete - Mix Designs That Are WorkableDocument20 pagesPractical Application of Pervious Concrete - Mix Designs That Are WorkablePJ FlexirPas encore d'évaluation

- Lecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFDocument30 pagesLecture 3 Bending and Shear in Beams PHG A8 Oct17 PDFEvi32Pas encore d'évaluation

- Embraco Standard Aftermarket Portfolio PDFDocument2 pagesEmbraco Standard Aftermarket Portfolio PDFJOR4CHPas encore d'évaluation

- Repair of Small Household Appliances and Power ToolsDocument315 pagesRepair of Small Household Appliances and Power ToolsahmadnawazjaswalPas encore d'évaluation

- Technical Specification of Stay InsulatorDocument11 pagesTechnical Specification of Stay Insulatorraj_stuff006Pas encore d'évaluation

- Sir VisvesvarayyaDocument1 pageSir VisvesvarayyaJohn SparrowPas encore d'évaluation

- Boeing Fire AERO - 2011 - Q2 - Article3Document10 pagesBoeing Fire AERO - 2011 - Q2 - Article3Braulio GomesPas encore d'évaluation

- Introduction To Igor Programming PDFDocument33 pagesIntroduction To Igor Programming PDFpaulklyuyevPas encore d'évaluation

- MSC PracticalsDocument13 pagesMSC PracticalslinubinoyPas encore d'évaluation

- Analysis and Design of Gravity Retaining Structures PDFDocument37 pagesAnalysis and Design of Gravity Retaining Structures PDFChin Tiong LeePas encore d'évaluation

- Geopolymer Reinforced With Bamboo For Sustainable Construction MaterialsDocument7 pagesGeopolymer Reinforced With Bamboo For Sustainable Construction MaterialsSamyuktha SridharPas encore d'évaluation

- Melde's MethodDocument2 pagesMelde's MethodDR.P.V.Kanaka Rao0% (1)

- 3D Printing Research Paper - Various Aspects PDFDocument6 pages3D Printing Research Paper - Various Aspects PDFhipovemicPas encore d'évaluation

- Avx 10k Data Sheet Data Sheets enDocument6 pagesAvx 10k Data Sheet Data Sheets enAerotia InternationalPas encore d'évaluation

- CPP ReportDocument5 pagesCPP ReportSujay Hazra100% (1)

- PMAC720Document3 pagesPMAC720felipePas encore d'évaluation

- VAV CablingDocument2 pagesVAV Cablingsripriya01Pas encore d'évaluation

- EC160B/180B/210B/240B/290B/360B/460B: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuDocument31 pagesEC160B/180B/210B/240B/290B/360B/460B: Click The Volvo-Logo in The Lower Right Corner To Return To This Menu Main MenuMACHINERY101GEAR97% (71)

- 7-Strengthening Mechanisms - SlidesDocument74 pages7-Strengthening Mechanisms - SlidesRyan TorresPas encore d'évaluation

- Design and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesDocument26 pagesDesign and Optimization of An XYZ Parallel Micromanipulator With Flexure HingesVijay SakharePas encore d'évaluation

- Schlumberger - Bit Running GuidelinesDocument38 pagesSchlumberger - Bit Running Guidelinesmanuelperdomot100% (1)

- A Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyDocument6 pagesA Biometric Model For Examination Screening and Attendance Monitoring in Yaba College of TechnologyWorld of Computer Science and Information Technology JournalPas encore d'évaluation

- JSA Basket TransferDocument3 pagesJSA Basket TransferCristina Rican100% (1)

- HVAC Maintenance FHDocument22 pagesHVAC Maintenance FHmhussainarabi@gmail.com100% (1)

- MAX32xx, Serial To TTLDocument17 pagesMAX32xx, Serial To TTLDecker JamesPas encore d'évaluation

- 002 Danfoss PICV Energy Valve Ver 090821 r0Document2 pages002 Danfoss PICV Energy Valve Ver 090821 r0Pattana MekkhumPas encore d'évaluation