Académique Documents

Professionnel Documents

Culture Documents

Talc Filler Datasheet

Transféré par

mashanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Talc Filler Datasheet

Transféré par

mashanDroits d'auteur :

Formats disponibles

Fibre Glast Developments Corporation

800.214.8579

www.fibreglast.com

Product Data Sheet

Talc

Part # - 1131

Talc is the major component of anybody filler. #1131 is a sandable filler added for

fairing and smoothing the finish of fiberglass laminations. The recommended filler

ratio is 2 parts #1131 to 1 part resin to result in a smooth, creamy semi-paste. The

exact filler portion will vary by application depending on the desired consistency.

Allow to stand one hour before adding hardener and using.

Description

Typical Properties

#1131 is a highly lamellar talc/carbonate mineral pigment

that provides a unique balance of prime pigment spacing

Brightness, Y

77

(opacity), film reinforcement, anti-cracking and barrier

100 Mesh, % retained

trace

properties to architectural and decorative coatings.

325 Mesh, % passing

99.7

Oil Absorption, g oil/100g talc

30

Specific Gravity

2.8

polyester resin for fairing and smoothing the finish of

Average Moisture, wt%

<0.5

fiberglass laminations. The recommended filler ratio is one

pH, 10% Slurry

9.5

cup #1131 to one-half cup resin to result in smooth, creamy

Loose Bulk Density, lbs/ft

30

Mixing Directions:

#1131 is a sandable talc filler to be added to epoxy or

semi-paste. The exact filler portion will vary by application

depending on the desired consistency. Allow to stand one

hour before adding hardener and using.

Mineral Analysis (by X-Ray Diffraction)

Safety & Handling:

Talc, %

55 - 65

#1131 contains ingredients which could be harmful if

Carbonates, %

35 - 40

mishandled. Contact with skin and eyes should be avoided

Chlorite, %

1-4

and necessary protective equipment and clothing should be

worn. Individuals should wash with soap and water before

eating, drinking, or using toilet facilities. Individuals should

observe conditions of good industrial hygiene and safe

working practice. For more detailed instructions on handling

please see the MSDS

Information present herein has been compiled from sources considered to be dependable and is accurate and

reliable to the best of our knowledge and belief but is not guaranteed to be so. Nothing herein is to be construed as

recommending any practice or any product violation of any patent or in violation of any law or regulation. It is the

users responsibility to determine for himself the suitability of any material for a specific purpose and to adopt such

safety precautions as may be necessary. We make no warranty as to the results to be obtained in using any material

and, since conditions of use are not under our control, we must necessarily disclaim all liability with respect to the

use of any material supplied by us.

Copyright 2011 Fibre Glast Developments Corporation

Fibre Glast Developments Corporation

385 Carr Drive

Brookville, Ohio 45309

Phone 800.214.8579

Fax 937.833.6555

www.fibreglast.com

PDCT-PDS-00365-A-05/11-DA

Page 1 of 1

Vous aimerez peut-être aussi

- ST Epan: Product BulletinDocument2 pagesST Epan: Product Bulletinsriatul2006Pas encore d'évaluation

- TDS - Encor 2750 - 01-12Document2 pagesTDS - Encor 2750 - 01-12APEX SONPas encore d'évaluation

- Alk-774 TDSDocument2 pagesAlk-774 TDSManuel Antonio Oñate CarvajalPas encore d'évaluation

- 1581 enDocument2 pages1581 enyasafyPas encore d'évaluation

- SC2032 PDFDocument4 pagesSC2032 PDFA MahmoodPas encore d'évaluation

- Elastomeric Polyurethane Desmocoll 540 Product InformationDocument2 pagesElastomeric Polyurethane Desmocoll 540 Product Informationlobocerna100% (3)

- Gallagher Polyurethane GuideDocument34 pagesGallagher Polyurethane Guidefeltofsnake100% (4)

- XR 1300 English - Ed April - 2020Document2 pagesXR 1300 English - Ed April - 2020Chamakhi AmeurPas encore d'évaluation

- Carpenter Co.: Carpol® MX-425Document1 pageCarpenter Co.: Carpol® MX-425A MahmoodPas encore d'évaluation

- Orotan 1124Document3 pagesOrotan 1124nsastoquepPas encore d'évaluation

- Encor: Pure Acrylic Latex For Interior and Exterior PaintsDocument2 pagesEncor: Pure Acrylic Latex For Interior and Exterior PaintsAPEX SONPas encore d'évaluation

- Tds of Loctite 41411Document1 pageTds of Loctite 41411ken philipsPas encore d'évaluation

- Product Description Sheet Hysol® Product 9460F: Industrial Products, August 2001Document2 pagesProduct Description Sheet Hysol® Product 9460F: Industrial Products, August 2001engpontelliPas encore d'évaluation

- Orotan - 1124 Msds PDFDocument3 pagesOrotan - 1124 Msds PDFRenato Diaz FrigerioPas encore d'évaluation

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaPas encore d'évaluation

- Adcote76P1 38TDS PDFDocument3 pagesAdcote76P1 38TDS PDFLaury Suarez BayonaPas encore d'évaluation

- ADCOTE™ 76P1-38: Laminating AdhesiveDocument3 pagesADCOTE™ 76P1-38: Laminating AdhesiveLaury Suarez BayonaPas encore d'évaluation

- RF-9801 Lamination Adhesive For Soft PackageDocument4 pagesRF-9801 Lamination Adhesive For Soft PackageWasif AzimPas encore d'évaluation

- SC2053Document4 pagesSC2053A MahmoodPas encore d'évaluation

- DA-1100 VAE Redispersible Powder Technical Data SheetDocument2 pagesDA-1100 VAE Redispersible Powder Technical Data Sheetminhhuan0101Pas encore d'évaluation

- ELASTENE 1500 DCM-APR TDS en Final - 1501Document2 pagesELASTENE 1500 DCM-APR TDS en Final - 1501rogerkid17Pas encore d'évaluation

- Food Grade Anti-Seize Product SheetDocument1 pageFood Grade Anti-Seize Product SheetFabio ParceroPas encore d'évaluation

- Wellboost 13967Document2 pagesWellboost 13967Bassem BalghouthiPas encore d'évaluation

- XIAMETER™ MEM-1111 Emulsion: Features & BenefitsDocument3 pagesXIAMETER™ MEM-1111 Emulsion: Features & Benefitszaryab khanPas encore d'évaluation

- Hoja Técnica Lanco 1890 CDocument2 pagesHoja Técnica Lanco 1890 CBryan GavilanezPas encore d'évaluation

- Celocor: Opaque PolymerDocument2 pagesCelocor: Opaque PolymerCHIRE SARAYASI MANUELPas encore d'évaluation

- LM Pe 6550 (CC10036550BG) - TDSDocument2 pagesLM Pe 6550 (CC10036550BG) - TDSBogdan ShevchenkoPas encore d'évaluation

- Tai County Silicones Co., Ltd. E-814L Emulsifier: Description ApplicationsDocument1 pageTai County Silicones Co., Ltd. E-814L Emulsifier: Description ApplicationsMark WuPas encore d'évaluation

- A-173 Orotan-731a-Dispersant-TdsDocument2 pagesA-173 Orotan-731a-Dispersant-Tdswiwat dussadinPas encore d'évaluation

- Pi Recon Acryl-Eze 93A3Document3 pagesPi Recon Acryl-Eze 93A3mykiend2002Pas encore d'évaluation

- SC1933 PDFDocument4 pagesSC1933 PDFA MahmoodPas encore d'évaluation

- ElasTechs 413 Technical BulletinDocument1 pageElasTechs 413 Technical BulletinMansoor KhanaliPas encore d'évaluation

- Deh 545Document2 pagesDeh 545Fredy de Jesus Baez MartinezPas encore d'évaluation

- XIAMETER® OFX-8803 Silicone Fluid PDFDocument3 pagesXIAMETER® OFX-8803 Silicone Fluid PDFPablo Manu Gomez VPas encore d'évaluation

- 1049D CERABOND 2000 Rev (1409)Document2 pages1049D CERABOND 2000 Rev (1409)Trịnh Minh KhoaPas encore d'évaluation

- Molykote HP 300Document2 pagesMolykote HP 30013AngelesPas encore d'évaluation

- ACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionDocument3 pagesACOUSTICRYL™ AV-1331 Copolymer Emulsion: Regional Product Availability DescriptionJaved ShaikhPas encore d'évaluation

- PRIMAL™ P-308M: Acrylic Emulsion PolymerDocument2 pagesPRIMAL™ P-308M: Acrylic Emulsion PolymermelsabaePas encore d'évaluation

- 95 935 Dowsil Acp 3990 Antifoam CompDocument2 pages95 935 Dowsil Acp 3990 Antifoam CompZhan FangPas encore d'évaluation

- SC1931 PDFDocument4 pagesSC1931 PDFA MahmoodPas encore d'évaluation

- Arcol PPG 2000Document2 pagesArcol PPG 2000Onesany TecnologiasPas encore d'évaluation

- Primal Ac 261Document2 pagesPrimal Ac 261hongducxxx50% (2)

- Acronal 4120 AdhesivesDocument2 pagesAcronal 4120 AdhesivesVenu KavetiPas encore d'évaluation

- CT-4130 PDSDocument2 pagesCT-4130 PDSMark WuPas encore d'évaluation

- SC1936 PDFDocument3 pagesSC1936 PDFA MahmoodPas encore d'évaluation

- SL 332 English - Ed April - 2020Document2 pagesSL 332 English - Ed April - 2020Chamakhi AmeurPas encore d'évaluation

- PRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionDocument3 pagesPRIMAL™ AC-365 Acrylic Emulsion: Regional Product Availability DescriptionLong An ĐỗPas encore d'évaluation

- Chemicals Zetag DATA Inverse Emulsions - 1009Document2 pagesChemicals Zetag DATA Inverse Emulsions - 1009PromagEnviro.com100% (1)

- 324 00582 01 Aculyn 88 Rheology ModifierDocument3 pages324 00582 01 Aculyn 88 Rheology ModifierAbdulrahman HamdanPas encore d'évaluation

- Afe 2017 Xiameter-Afe-3168-Antifoam-EmulsDocument2 pagesAfe 2017 Xiameter-Afe-3168-Antifoam-EmulsZhan FangPas encore d'évaluation

- Henk Loctite Gasket Seal 2 TdsDocument1 pageHenk Loctite Gasket Seal 2 TdsGabo TellezPas encore d'évaluation

- Carbocoat 8215 PDS 6-10Document2 pagesCarbocoat 8215 PDS 6-10Mayur PatelPas encore d'évaluation

- DOW Primal-As-8000-Acrylic-EmulsionDocument2 pagesDOW Primal-As-8000-Acrylic-EmulsionAzhar Abdul RazakPas encore d'évaluation

- Tai County Silicones Co., Ltd. F-505 Softffin: Description ApplicationsDocument1 pageTai County Silicones Co., Ltd. F-505 Softffin: Description ApplicationsMark WuPas encore d'évaluation

- E 135Document2 pagesE 135Parashuram ChauhanPas encore d'évaluation

- Syloid Al-1 FP: Pharmaceutical ExcipientDocument2 pagesSyloid Al-1 FP: Pharmaceutical ExcipientMechaheb Massinissa50% (2)

- Carpenter Co.: Carpol GSP-280Document1 pageCarpenter Co.: Carpol GSP-280A MahmoodPas encore d'évaluation

- Creative Resin: Easy techniques for contemporary resin artD'EverandCreative Resin: Easy techniques for contemporary resin artPas encore d'évaluation

- VL2019201000534 DaDocument2 pagesVL2019201000534 DaEnjoy LifePas encore d'évaluation

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDocument61 pagesBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriPas encore d'évaluation

- The Botanical AtlasDocument74 pagesThe Botanical Atlasjamey_mork1100% (3)

- Rheology of Polymer BlendsDocument10 pagesRheology of Polymer Blendsalireza198Pas encore d'évaluation

- Lady Allen On Froebel Training School, Emdrup, CopenhagenDocument5 pagesLady Allen On Froebel Training School, Emdrup, CopenhagenLifeinthemix_FroebelPas encore d'évaluation

- Put The Items From Exercise 1 in The Correct ColumnDocument8 pagesPut The Items From Exercise 1 in The Correct ColumnDylan Alejandro Guzman Gomez100% (1)

- Factsheet B2B PunchOut en 140623Document2 pagesFactsheet B2B PunchOut en 140623Curtis GibsonPas encore d'évaluation

- sl2018 667 PDFDocument8 pagessl2018 667 PDFGaurav MaithilPas encore d'évaluation

- Philips DVD Player SpecificationsDocument2 pagesPhilips DVD Player Specificationsbhau_20Pas encore d'évaluation

- All Associates Warning Against ChangesDocument67 pagesAll Associates Warning Against Changesramesh0% (1)

- NGPDU For BS SelectDocument14 pagesNGPDU For BS SelectMario RamosPas encore d'évaluation

- IMT Ghaziabad PGDM Timetable Term II 2020Document22 pagesIMT Ghaziabad PGDM Timetable Term II 2020Ved JhingranPas encore d'évaluation

- Standard Deviation IntroductionDocument3 pagesStandard Deviation IntroductionShyam ShresthaPas encore d'évaluation

- The Sound Collector - The Prepared Piano of John CageDocument12 pagesThe Sound Collector - The Prepared Piano of John CageLuigie VazquezPas encore d'évaluation

- Course: Citizenship Education and Community Engagement: (8604) Assignment # 1Document16 pagesCourse: Citizenship Education and Community Engagement: (8604) Assignment # 1Amyna Rafy AwanPas encore d'évaluation

- The Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToDocument21 pagesThe Learners Demonstrate An Understanding Of: The Learners Should Be Able To: The Learners Should Be Able ToBik Bok50% (2)

- Post Marketing SurveillanceDocument19 pagesPost Marketing SurveillanceRamanjeet SinghPas encore d'évaluation

- Active and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Document5 pagesActive and Passive Voice of Future Continuous Tense - Passive Voice Tips-1Kamal deep singh SinghPas encore d'évaluation

- Domingo V People (Estafa)Document16 pagesDomingo V People (Estafa)Kim EscosiaPas encore d'évaluation

- Amana PLE8317W2 Service ManualDocument113 pagesAmana PLE8317W2 Service ManualSchneksPas encore d'évaluation

- Sekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Document11 pagesSekolah Menengah Kebangsaan Ss17 JALAN SS17/1, Subang Jaya English Scheme of Work Form 3Rohana YahyaPas encore d'évaluation

- 10 Slides For A Perfect Startup Pitch DeckDocument6 pages10 Slides For A Perfect Startup Pitch DeckZakky AzhariPas encore d'évaluation

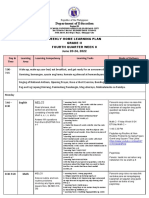

- Department of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Document8 pagesDepartment of Education: Weekly Home Learning Plan Grade Ii Fourth Quarter Week 8Evelyn DEL ROSARIOPas encore d'évaluation

- PREMIUM BINS, CARDS & STUFFDocument4 pagesPREMIUM BINS, CARDS & STUFFSubodh Ghule100% (1)

- Covey - Moral CompassingDocument5 pagesCovey - Moral CompassingAsimPas encore d'évaluation

- Investigatory Project Pesticide From RadishDocument4 pagesInvestigatory Project Pesticide From Radishmax314100% (1)

- 2.4 Avogadro's Hypothesis+ Equivalent MassesDocument12 pages2.4 Avogadro's Hypothesis+ Equivalent MassesSantosh MandalPas encore d'évaluation

- 2019-10 Best Practices For Ovirt Backup and Recovery PDFDocument33 pages2019-10 Best Practices For Ovirt Backup and Recovery PDFAntonius SonyPas encore d'évaluation

- How To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)Document19 pagesHow To Check PC Full Specs Windows 10 in 5 Ways (Minitool News)hiwot kebedePas encore d'évaluation

- Installation Instruction XALM IndoorDocument37 pagesInstallation Instruction XALM IndoorVanek505Pas encore d'évaluation