Académique Documents

Professionnel Documents

Culture Documents

09 Doosan TIER 4I Engine (120425)

Transféré par

Electromecanica Leon Electromecanica Leon LeonDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

09 Doosan TIER 4I Engine (120425)

Transféré par

Electromecanica Leon Electromecanica Leon LeonDroits d'auteur :

Formats disponibles

Slide 1

Doosan Tier4-i Engine

Sensors & Actuators

Date : 2012-04-25

EMEA Heavy line Training Team

Slide 2

INDEX

1. Development Background

2. Boring Parts & Lubrication

3. FIE system

4. Breather system

5. Cooling system

6. EGR system

7. Regeneration system

8. Forced Regeneration

9. Sensors & Actuators

Doosan Infracore

Slide 3

Contents

Tier4i Engine Specification

Engine system layout

Engine sensors

Engine actuators

ECU Terminal Diagram

ECU connectors

CAN network configuration

CAN Msg. Information

Diagnostic Trouble Code

Basic concept of signal sensing

Engine Torque Derating

Engine Fault Lamp

Example of diagnostic trouble

Doosan Infracore

Slide 4

Tier4i Engine Specification

System improvement from Previous Tier 3 Engine

Higher Combustion Pressure, Turbo System, Cooling Capacity, After treatment (EGR + DPF)

(NOTE: SCR will be added, for Tier4 Final Emission Regulation in the future)

item,

Tier 4 Interim

Tier 4 Final

160

TC or WGT*

WGT* or VGT**

Al-Gallery

Al-Gallery

Material strength

increased

Cyl.Block

Cast Iron

Cyl.Head

Cast Iron

Con-rod

Steel

Strength increased

Crankshaft

Steel

Strength increased

Cooling System

Capacity increment

EGR

I-EGR***

20 ~ 25%

Combustion pressure

(bar)

Turbo System

Piston

Tier 3

DPF

SCR

Yes

No

Yes

* WGT : Waste Gate Turbocharger (Variable waste gate on DL06 Tier 4i)

** VGT

: Variable Geometry Turbo Charger (DL08 Tier 4i)

*** I-EGR : Internal Exhaust Gas Recirculation

Doosan Infracore

Slide 5

Tier4 Engine Specification

Tier4 interim Engine Power

Engine Model

Model

Performance

Max. Power

Kw / rpm

161 /1800

(216 PS / 1800)

216 /1800

(291 PS / 1800)

212 / 1800

(285 PS/ 1800)

Code

(Suffix)

EHPEA

DL08K

DL08-LDE01

DL08-LDE00

Max. Torque

N.m / rpm

970 / 1300

(99 kg.m / 1300)

1274 /1300

(130 kg.m / 1300)

1274 /1300

(130 kg.m / 1300)

Idle RPM

(rpm)

Max. RPM

(rpm)

800

1900

800

1900

800

1900

Doosan Infracore

Slide 6

Tier4 Engine Specification

Tier4 interim Engine Power

Engine Model

Model

DL06K

Performance

Code

(Suffix)

DX255LC-3

(DL06-LDE03)

DX225LC-3

(DL06-LDE00)

DX180LC-3

(DL06-LDE02)

DX140LC-3

(DL06-LDE01)

Max. Power

(Kw / rpm)

140 /1900

(188 PS / 1900)

126 / 1800

(169 PS / 1800)

94 /1800

(127 PS / 1950)

87 /1800

(117.8 PS / 1800)

Max. Torque

(N.m / rpm)

804 / 1400

(82 kg m / 1400)

755 /1400

(77 kg m / 1400)

529 /1950

(54 kg m / 1400)

502 /1400

(51.2 kg m / 1400)

DX190W-3

(DL06-LDE06)

DX170W-3

(DL06-LDE05)

DX140W-3

(DL06-LDE04)

131 / 1900

(176 PS / 1900)

114 / 2000

(154 PS / 2000)

103 / 2000

(139 PS / 2000)

755 /1400

(77 kg m / 1400)

647 /1400

(66 kg m / 1400)

588 / 1400

(60 kg m / 1400)

Idle RPM

(rpm)

Max. RPM

(rpm)

800

2020

800

1920

800

2070

800

1970

800

2020

800

2120

800

2120

Doosan Infracore

Slide 7

Engine System Layout

Tier4 interim Sensor Supplier information

Component

Supplier

Air Mass Sensor with Temperature (HFM)

Delphi

Coolant / Fuel Temperature Sensor

Bosch

Rail Pressure Sensor

Bosch

Boost Pressure and Temperature Sensor

Bosch

Fuel Metering Unit (High Pressure Pump)

Bosch

Metering Unit (DPM)

Bosch

Oil Pressure / Temperature Sensor

Bosch

CAM / Crank Speed Sensor

Continental

Fan Speed Sensor/ Drive

BorgWarne

VGT (Variable Geometry Turbocharger)

BorgWarne

Throttle Valve Actuator

Seohan

EGR (Exhaust Gas Recirculation)

SONCEBOZ

DPF Differental Pressure Sensor

Sensata

Exhaust Gas Temperature Sensor (Before DOC)

NITE

Exhaust Gas Temperature Sensor (Before DPF)

NITE

Exhaust Gas Temperature Sensor (After DPF)

NITE

Doosan Infracore

Slide 8

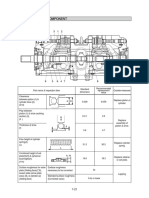

Engine System Layout

Sensor & Actuator positioning concept

Boost Pressure &

Temperature Sensor

Throttle Valve

CAM / CRS

Sensor

Oil Pressure &

Temperature

Sensor

Coolant

Temperature

Sensor

EGR Valve

Injection

Unit

T4,T5,T6 Temperature Sensors

& Differential Pressure Sensor

Turbo

Charger

Air mass flow &

Temperature Sensor

Doosan Infracore

Slide 9

Engine System Layout

After treatment system overview of DOOSAN TIER4i DPF system

TIER4i Engine

DPF Muffler (DOC + DPF)

MU + IU

Temperature Sensor (3 off)

Differential Pressure Sensor (1 off)

Diesel Fuel Return

Fuel Pump

Fuel Filter

Diesel Fuel

Inlet

Fuel Tank

ECU

Metering

Unit (MU)

Diesel Engine

Actuators

Engine CAN

Injection

Unit (IU)

Diagnostic CAN

Temp

Sensor

Differential Pressure

Sensor

Temp

Sensor

Temp

Sensor

Engine

Exhaust Gas

Glossary:

DOC : Diesel Oxidation Catalyst

DPF : Diesel Particulate Filter

MU : Metering Unit

IU

: Injection Unit

ECU : Engine Control Unit

DOC

DPF

Doosan Infracore

Slide 10

Engine System Layout

After treatment system overview of DOOSAN TIER4i DPF system

The MU consists of a housing containing:

One Shutoff Valve (SV)

Two Pressure Sensors (PS)

One Dosing Valve (DV)

Cooling adapter

Doosan Infracore

Slide 11

Engine Sensors (DL08)

1

7

3

6

4

5

2

1.

2.

3.

4.

5.

6.

7.

Boost Pressure & Temperature Sensor

Coolant Temperature Sensor

Crankshaft Speed Sensor

Rail Pressure Sensor

CP Pump Metering Unit

Camshaft Speed Sensor

Fuel Temperature Sensor

Doosan Infracore

10

Slide 12

Engine Sensors

Boost Pressure & Temperature Sensor.

Harness connector

4

3

2

1

No.

1

2

3

4

Sensor Value:

Low (unit)

Sensor Value: Failure

High (unit)

Detection

Failure

Indication

ECU Pin

290

237

207

286

Sensor Name

Sensed Parameter Range:

Low / High (Units)

Default Mode

Threshold value

Boost

Temperature

Cold < 20 C

20 C <= Normal <= 50 C

Hot > 50 C

215.2 mV

4921.8 mV

By ECM

Replacement value = Frozen value

(Last valid value: just before error was

detected during current operating cycle)

Check lamp =On

Failure Code stored.

Next operating cycle it will take the

default value of 40 deg C

Boost

Pressure

100kPa < Normal < 340kPa

202.8 mV

4873 mV

By ECM

Check lamp = Blink

Failure Code stored.

Replacement value = 220 kPa

PIN description

Ground

Boost temperature signal

+ 5 V supply

Boost pressure signal

Failure

Consequence

Impacts on Emissions

N/A

N/A

* Torque limit

10%

VGT actuator is controlled

by boost air pressure.

Doosan Infracore

11

Slide 13

Engine Sensors

Coolant / Fuel Temperature Sensor.

Harness connector

2

1

No.

1

2

Sensed Parameter Range:

High / Low (Units)

Sensor Name

Coolant temperature

ECU Pin

PIN description

239

Coolant Temperature Signal

Ground

259

Sensor Value: Sensor Value: Failure

Low (unit)

High (unit)

Detection

Failure

Indication

Fuel temperature

ECU Pin

PIN description

212

Fuel Temperature Signal

259

Ground

No.

1

2

Default Mode

Threshold value

Failure

Consequence

(Sensor Operating)

Threshold temp = 105 C

Cold < 60 C

60 C <= Normal <= 100 C

Hot > 100 C

Coolant

Temperature

Fuel

Temperature

-30 C <= Normal <= 40 C

188.2 mV

188.2 mV

4929 mV

By ECM

4929 mV

By ECM

Check lamp =Blink

and Failure Code

stored.

Check lamp =On

Failure Code stored.

Impacts on Emissions

105 C: Max. fuel rate 2% limit

Power derated for engine

protection .

110 C: Max. fuel rate 20% limit

105 deg C: Torque 2% limit

Threshold temp = 110 C

115 C: Max. fuel rate 50% limit

Threshold temp = 115 C

107 C : Engine check lamp On

107 C : Engine check lamp On

EGR Valve 0%, VGT 0%

(Sensor Failure)

Replacement value

engine is running = 85 C

engine is not running = - 25 C

Torque limit 10%

EGR valve 0% / VGT 0%

Power derated for engine

protection only.

Replacement value = 48 C

N/A

N/A

110 deg C: Torque 20% limit

115 deg C: Torque 50% limit

Doosan Infracore

12

Slide 14

Engine Sensors

Camshaft Speed Sensor (DL08,DL06) Crankshaft Speed Sensor (DL06)

Harness connector

Crankshaft Speed Sensor (DL06)

No.

ECU Pin

PIN description

1

266

CRS POS

2

265

CRS NEG

3

269

Shield

Sensor Name

Sensed Parameter Range:

High / Low (Units)

No.

1

2

3

Camshaft Speed Sensor (DL06)

ECU Pin

PIN description

268

CAS POS

CAS NEG

267

269

Shield

Sensor Signal

Failure

Detection

Failure

Indication

No.

1

2

3

Default Mode

Threshold value

Camshaft Sensor (DL08)

ECU Pin

PIN description

267

CAS NEG

268

CAS POS

269

Shield

Failure

Consequence

Crankshaft

Speed Sensor

650 rpm < normal < 2200

rpm

Pulse signal

By ECM

Check lamp =on

and Failure Code

stored.

If the camshaft rotation counter

crosses the threshold "threshold

=4"and if the camshaft signal is tested

and plausible the error is set

Torque limit 10%

CAM shaft sensor back

up mode

CAM

Position Sensor

20 Hz < Normal < 95 Hz

Pulse signal

By ECM

Check lamp =on

and Failure Code

stored.

In between of several crankshaft

revolutions there is not any camshaft

edge present. (Threshold = 4)

Starting delay during

engine cranking.

After cranking, no effect

Impacts on Emissions

Vehicle safety

engine protection

Vehicle safety

engine protection

Doosan Infracore

13

Slide 15

Engine Sensors

Crankshaft Speed Sensor (DL08)

Harness connector

2

1

No.

1

2

Sensor Name

Crankshaft

Speed Sensor

Sensed Parameter Range:

High / Low (Units)

Sensor Signal

Failure

Detection

Failure

Indication

Pulse signal

By ECM

Check lamp =on

and Failure Code

stored.

650 rpm < normal < 2200

rpm

Crankshaft Speed Sensor (DL08)

ECU Pin

PIN description

266

CRS POS

265

CRS NEG

Default Mode

Threshold value

Failure

Consequence

If the camshaft rotation counter

crosses the threshold "threshold

=4"and if the camshaft signal is tested

and plausible the error is set

Impacts on Emissions

Torque limit 10%

CAM shaft sensor back

up mode

vehicle safety

engine protection

Doosan Infracore

14

Slide 16

Engine Sensors

Rail Pressure Sensor.

Harness connector

No.

1

2

3

Sensor Name

Sensed Parameter Range:

Low / High (Units)

Fuel Pressure

(High Pressure)

50MPa < Normal < 180MPa

Sensor Value: Sensor Value:

Low (unit)

High (unit)

ECU Pin

260

236

211

Failure

Detection

Failure

Indication

Default Mode

Threshold value

By ECM

Check lamp = Blink

Failure Code stored.

Replacement value is

varied according to CP

pump metering unit.

PIN description

Ground

Rail pressure signal

+ 5 V supply

Failure

Consequence

Impacts on Emissions

Torque limit 50%

268 mV

4868 mV

Rail pressure for

opened PRV

Changes with speed /

load conditions.

Doosan Infracore

15

Slide 17

Engine Sensors

Air Mass Flow Sensor.

Harness connector

A

No.

A

B

C

D

E

Sensor Name

Mass Air Flow

(HFM) Sensor

Air Flow Temperature

Sensed Parameter Range:

Low / High (Units)

Sensor Value: Sensor Value:

Low (unit)

High (unit)

Failure

Detection

Failure

Indication

100kg/hr < Normal < 1000kg/hr

70 us

7000 us

By ECM

Check lamp =Blink

Failure Code stored.

Cold < 20 C

20 C <= Normal <= 30 C

Hot > 30 C

400mV

4900mV

By ECM

Check lamp =on

Failure Code stored.

ECU Pin

230

238

230

284

254

PIN description

Ground

Air temperature signal

Ground

+ 12 V

Frequency output

Failure

Consequence

Default Mode

Threshold value

Replacement value = Model value by Boost

pressure and Boost temperature

When Boost sensor is failed, engine

chooses mapping value by engine rpm.

Replacement value = Frozen value (Last

valid value: just before error was detected)

at detect operating cycle

Torque limit 10%

EGR valve = 0 %

VGT = 0%

EGR Valve = 0%

VGT = 0%

Next operating cycle will take default value

( 30 C)

Doosan Infracore

16

Slide 18

Sensors & Actuators (DL08)

1

2

1.

2.

3.

4.

EGR Valve (Exhaust Gas Recirculation)

Throttle Valve

VGT (Variable Geometry Turbo)

Oil Pressure & Temperature Sensor

Doosan Infracore

17

Slide 19

Engine Actuator

Smart Actuator. (EGR)

Harness connector

- The *SRA controls the position using an internal closed-loop system.

- CAN Communication is used to input / output information to the SRA.

- If the EGR does not receive a valid CAN signal. It goes to its Default position

of 0%. (Fully Closed, no EGR)

Smart Remote Actuator

Supply Voltage

24V

Operating Voltage

9V ~ 32V

Typical Operating Voltage

13.8V ~ 28V

Max. Operating Temp. Range

140 ambient (with water cooling, max. 110)

Max. Storage Temp. Range

-40 ambient

CAN communication Baud rate

250k bits/s

Min. Operating Temp. Range

Sensor or

Actuator Name

EGR Flow Control

Sensed Parameter

Range: Low /High

(Units)

0 < Normal < 100%

-50 ~ 150

No.

1

2

3

4

ECU Pin

Vbat

GND

218

217

EGR Valve

PIN description

+24 Volt supply

Ground

CAN 2 Low

CAN 2 High

Sensor Actuator control

Failure Detection

Failure Indication

Default Mode /

threshold value

Failure

Consequence

Controls itself

(Smart Control)

By itself

(Sends message

to ECM)

Engine Check lamp =On

Failure Code stored.

0 ~ 100%

N/A

Impacts on Emissions

If EGR is deactivated, NOx

emissions increase.

* SRA: Smart Remote Actuator

Doosan Infracore

18

Slide 20

Engine Actuator

Smart Actuator. (EGR)

To minimize formation of NOx, recirculation of some of the exhaust gas into combustion chamber along with the fresh air is used (lowers oxide

concentration and decreases combustion temperature)

EGR Valve

Inter-cooler

Turbocharger

Fresh Air

EGR

Cooler

DPF

Exhaust Gas

Cooled EGR (Exhaust Gas Recirculation)

Uses a water cooled heat exchanger (EGR Cooler) to cool down the exhaust gas being used for recirculation,

to minimize its volume.

Doosan Infracore

19

Slide 21

Engine Actuator

Smart Actuator. (EGR)

Current Air Mass

(AFS_mAirPercyl)

Coolant Temp.

HFM Air Temp.

Desired Value

Calculation

AirCtl_mDesVal

Desired air mass set point (mg/hub)

PI- Controller

Adjusting the Measured air

mass to match the desired

set point air mass

AirCtl_rCtlVal

Engine RPM

AirCtl_rGovEGR

EGRVlv_r

Working ranges

Sys. error Mon

Transient detection

Air Ctl _Gov Closed-Loop

Control

EGR open-loop control value (%)

Monitoring

and Shut-off

Injection Quantity

EGR

Engine Stop (IGN On)

Engine Running (Idle 800rpm)

Engine Running (900rpm)

EGR Valve Closed (0%)

0%

20% ~ 23 %

The function processes and transmits the message every 10ms cycle time of the CAN interface according to SAE J1939, with update rate of 10ms.

The first two bytes of CAN Frame is used to transmit EGR valve position value

Tx / Rx

Name

Transmission Repetition

ECU EGR

ComTx_EDC2EGRVLV

10ms

ECU EGR

ComRx_EGRVlv2EDC

20ms

ComRx_EGRErrSt

100ms

Realized Byte

Byte 1,2[1..8] : EGR Actuator Position Request

Byte 3[1..8] : EGR Actuator Command State

Byte 0 : Actuator state

Byte 1,2 : Actuator actual shaft position

Byte 3 : Actuator Internal temperature

Byte 4 : Actuator fault code

Byte 5,6 : Actuator target shaft position

Byte 7 : Actuator Motor Effort

Byte 0 ~ Byte 7 : Actuator Fault Code

Doosan Infracore

20

Slide 22

Engine Actuator

Throttle Valve Actuator.

Harness connector

6

2

1

Characteristic

Position Angle

Mechanical Stop

Min. Electrical closed position

Max. Electrical open position

DC-Motor unpowered

Actuator Name

Throttle Feed

back sensor

0

1.8

84

89

Sensor Output(%Vdd)

(Based On 5V Voltage Supply)

901% (4.5V)

88.5% (4.425V)

18.51%(0.926V)

14.253.5% (0.713V)

No.

1

2

3

5

6

ECU Pin

234

229

240

215

205

PIN description

5 Volt supply

DC motor Ground

Feedback sensor signal

DC motor +

Sensed Parameter

Range:

High / Low (Units)

Sensor - Actuator

Value: Low (unit)

Sensor / Actuator

Value: High (unit)

Failure Detection

Failure Indication

Default Mode / threshold

value

Failure Consequence

0 < Normal < 100

NOTE:

(Activated only when

DOC upstream

temperature is < 230 C,

else 0% full open.)

400mV

4800mV

By ECM

Check lamp =On

Failure Code stored.

When throttle value

feedback failed

Default value = 0%

Torque limit 25%

EGR valve = 0%

OC = Oxydation Catalyst

Doosan Infracore

21

Slide 23

Engine Actuator

Smart Remote Actuator. (VGT Only On DL08 Engines)

- The SRA controls its position by use of an internal closed-loop system.

Harness connector

- CAN Communication is used to input / output information to the SRA.

- If the VGT does not receive a valid CAN signal for 1sec. Default position 15%.

- Once the VGT receives a valid CAN signal for 4 sec. resumes normal operation.

Smart Remote Actuator

24V

Reduced Function

18V ~ 22V and 32V ~ 36V

Full Function

22V ~ 32V

Max. Operating Temp. Range

Max. Storage Temp. Range

-40 ~ 130 (140 for 100 hours)

CAN communication Baud rate

250k bits/s

VGT

VGT Control and

Position Sensor

0 < Normal < 100%

No.

1

2

3

4

-40 ~ 150

Sensed Parameter

Range: Low / High Sensor - Actuator control

(Units)

Sensor or

Actuator Name

3

4

Supply Voltage

Failure Detection

By itself

(Sends message

to ECM)

Controls itself

(Smart Control)

Failure Indication

Check lamp =on

and Failure Code

stored.

ECU Pin

Vbat

GND

218

217

Default Mode

threshold value

Failure Consequence

0~100%

N/A

PIN description

+24 Volt supply

Ground

CAN 2 Low

CAN 2 High

Impacts on Emissions

VGT pressure controls boost and

EGR pressures so that

proportionality is maintained and

EGR can be driven into the intake air

supply. Also manages power control

via the Speed/Load (Boost) tables

* SRA: Smart Remote Actuator

Doosan Infracore

22

Slide 24

Engine Actuator

Smart Actuator. (VGT Only DL08)

Boost pressure sensor value

PCR_pDesVal

boost-pressure set point (hPa)

PID- Controller

PCR_rGov

PCR_rCtlVal

VGT open-loop control value (%)

Engine RPM

Minimize the deviation between

pressure set point and boost

pressure sensor

Monitoring

and Shut-off

TrbCh_r

Working ranges

Sys. error Mon

Transient detection

PCR _Gov Closed-Loop Control

Injection Quantity

VGT

Engine Stop (IGN Off)

Engine Stop (IGN On)

Engine Running (Idle 800rpm)

0%

34%

34% ~ 43%

The message TrbCh_rPosVGT gives the demanded position of VGT actuator which is the output duty cycle to power stage .The duty cycle is updated into position

demand message Com_rPosEDC2VGTB. Com_rPosEDC2VGTB takes a value 0 for 0% open and 1000 for 100% open.

Tx / Rx

Name

Transmission Repetition

ECU VGT

ComTx_EDC2VGTB

10ms

ECU VGT

ComRx_VGTB2EDC

30ms

Realized Byte

Byte 0,1 : Position demand for actuator in terms of duty cycle

Byte 2[0] : Switch status for motor

Byte 2[1] : Switch status for learn permission

Byte 0,1 : Actual shaft position of actuator

Byte 2 : Internal temperature of the actuator

Byte 3,4 : Span percent of end of line

Byte 5 : Power applied to the motor

Byte 6 : Fault and warning messages

Byte 7[1] : Actuator learn status

Doosan Infracore

23

Slide 25

Engine Sensors

Oil Pressure & Temperature Sensor.

Harness connector

4

3

2

1

No.

1

2

3

4

Sensor Name

Sensed Parameter Range:

Low / High (Units)

Sensor Value:

Low (unit)

Sensor Value:

High (unit)

Failure

Detection

Failure

Indication

Oil Temperature

-30 C <= Normal <= 115 C

232.2 mV

4924.4 mV

By ECM

Failure Code stored.

Oil Pressure

400kPa < Normal < 600kPa

202.8 mV

4924.2 mV

By ECM

Check lamp =Blink

Failure Code stored.

ECU Pin

206

213

231

235

Default Mode

Threshold value

Replacement value

= Coolant temperature

MIN Threshold pressure

800 rpm : 220 kPa

900 rpm : 240 kPa

1000 rpm : 260 kPa

1200 rpm : 280 kPa

1600 rpm : 300 kPa

3200 rpm : 320 k=hPa

PIN description

Ground

Oil temperature signal

+ 5 V supply

Oil pressure signal

Failure

Consequence

Impacts on Emissions

N/A

N/A

Torque limit 50%

Only for Engine

protection

Check lamp only.

Replacement value

= 450 kPa

N/A

Doosan Infracore

24

Slide 26

Metering Unit & Exhaust System Sensors (DL08)

5

6

7

8

1.

2.

3.

4.

5.

6.

7.

8.

Shut Off Valve

Upstream Pressure & Temperature Sensor

Dosing Valve

Downstream Pressure Sensor

DOC Upstream Temperature Sensor

DPF Upstream Temperature Sensor

DPF Downstream Temperature Sensor

DPF Differential Pressure Sensor

Doosan Infracore

25

Slide 27

Metering Unit

Metering Unit (Shut Off Vale & Dosing Valve)

Harness connector

Dosing Valve

No.

1

2

Shutoff Valve

ECU Pin

PIN description

120

Shutoff valve high side

145

Shutoff valve low side

No.

1

2

Dosing Valve

ECU Pin

PIN description

122

Dosing valve high side

124

Dosing valve low side

Dosing Valve

Feature

Normal value

Coil resistance

15.95

Shutoff Valve

Feature

Normal value

Coil resistance

3.3

Shut Off Valve

Cooling adapter

Doosan Infracore

26

Slide 28

Metering Unit

Metering Unit (Upstream Pressure & Temperature Sensor)

Harness connector

Upstream P_T

4

3

2

1

No.

1

2

3

4

Sensor Name

HCI Upstream

Pressure

HCI Upstream

Temperature

Sensed Parameter Range:

Low / High (Units)

0 kpa < Normal < 1200 kpa

-40 C < Normal < 130 C

Sensor Value: Sensor Value:

Low (unit)

High (unit)

250 mV

250 mV

4850 mV

4750 mV

Failure

Detection

Failure Indication

ECU Pin

133

142

191

130

Default Mode

threshold value

PIN description

Ground

Temperature signal

+5 V supply

Pressure signal

Failure Consequence

Impacts on Emissions

By ECM

Check lamp = Blink Replacement value

Failure Code stored

= 300 kpa

Inhibit the HC dosing

Torque limit 25%

Exhaust Gas temperature

control for DPF regeneration.

By ECM

Check lamp = On Replacement value

Failure Code stored

= 48 C

Inhibit the HC dosing

Exhaust Gas temperature

control for DPF regeneration.

Doosan Infracore

27

Slide 29

Metering Unit

Metering Unit (Downstream Pressure.)

Harness connector

No.

1

2

3

Downstream

Pressure Sensor

Sensor Name

Downstream

Pressure

Sensor

Sensed Parameter Range:

Low / High (Units)

ECU Pin

167

133

156

Sensor Value:

Low (unit)

Sensor Value:

High (unit)

Failure

Detection

Failure Indication

Default Mode

threshold value

250 mV

4750 mV

By ECM

Check lamp =Blink

Failure Code stored.

Replacement value

= 200 kpa

0 kpa < Normal < 1200 kpa

PIN description

+5 V supply

Ground

Pressure signal

Failure Consequence

Impacts on Emissions

Active Regeneration is Exhaust Gas temperature

prevented

control for DPF

Torque limit 25%

regeneration.

Doosan Infracore

28

Slide 30

Exhaust System Sensors

Exhaust Gas Temperature Sensors

Harness connector

2

1

No.

1

2

T4 DOC upstream

ECU Pin

PIN description

116

Temperature signal

118

Ground

Sensor Name

Sensed Parameter Range:

Low / High (Units)

No.

1

2

T5 DPF upstream

ECU Pin

PIN description

117

Temperature signal

118

Ground

Sensor Value: Sensor Value: Failure

Low (unit)

High (unit) Detection

Failure Indication

Default Mode

threshold value

No.

1

2

T6 DPF downstream

ECU Pin

PIN description

140

Temperature signal

143

Ground

Failure Consequence

Exhaust Gas

Temperature Sensor

(T4 Upstream of

DOC)

-40 C <= Normal <= 500 C

Exhaust Gas

Temperature Sensor

(T5 Between

DOC and DPF)

-40 C <= Normal <= 500 C

200 C <= DPF RGN <= 800 C

Exhaust Gas

Temperature Sensor

(T6 Downstream of

DPF)

-40 C <= Normal <= 500 C

200 C <= DPF RGN <= 800 C

200 mV

200 mV

500 mV

3000 mV

4900 mV

1800 mV

By ECM

Check lamp =Blink

Failure Code stored.

Check lamp =on

Failure Code stored.

By ECM

By ECM

Check lamp =Blink

Failure Code stored.

Check lamp =Blink

Failure Code stored.

Replacement value

= 200 C

Threshold temp

= 700 C

Replacement value

= 200 C

Replacement value

= 200 C

Impacts on Emissions

Torque limit 25%

EGR valve = 0 %

HC dosing module can start

dosing by upstream DOC

temperature sensor.

Regeneration is not allowed at

idle but may be allowed at light

load conditions where upstream

temperature is above 200C.

Inhibit the HC dosing

system

Torque limit 25%

EGR valve = 0 %

Inhibit HC dosing

HC dosing module is controlled

by temperature sensor between

DOC and DPF

Threshold temp

= 600 C

N/A

N/A

Note: HC means Hydro Carbon (ie. Diesel Fuel)

Doosan Infracore

29

Slide 31

Exhaust System Sensors

DPF Differential Pressure Sensor.

Harness connector

Supply Voltage

(Vcc)

1 2 3

Ground

1

Output Signal

Sensor Name

DPF

Differential Pressure

Sensed Parameter Range:

Low / High (Units)

No.

1

2

3

Sensor Value: Sensor Value: Failure

Low (unit)

High (unit)

Detection

0 kPa <= Normal or RGN <= 9 kPa

DPF Cleaning at >12 kPa

85 mV

4085 mV

ECU Pin

190

143

155

Failure Indication

Default Mode

threshold value

Red Stop lamp =

On

Failure Code stored

Threshold

= 20 kPa

By ECM

PIN description

+ 5 V supply

Ground

Diff pressure signal

Failure

Consequence

Impacts on Emissions

DPF plugging and

cracking can be found

by DPF differential

pressure sensor.

Torque limit 10%

Check lamp = On

Replacement value

Failure Code stored.

= 3 kPa

Monitors DPF soot / ash

loading to establish

service / maintenance

intervals.

Note: A reading of >2 kPa at idle with no load indicates a blocked DPF

Doosan Infracore

30

Doosan Infracore

31

Slide 32

ECU Terminal Diagram

Slide 33

ECU Terminal Diagram

Doosan Infracore

32

Doosan Infracore

33

Slide 34

ECU Terminal Diagram

Engine ECU

Injector

Solenoids

Engine

Connector

Vehicle

Connector

Injector 1, Bank 1

Injector 2, Bank 1

Injector 3, Bank 1

Injector 1, Bank 2

Injector 2, Bank 2

Injector 3, Bank 2

Fuel Metering

Unit (ZME)

Rail Pressure

Control Valve (DRV)

Rail Pressure

Sensor

Slide 35

ECU Terminal Diagram

Air Flow

Meter

Shield

Oil Pressure &

Temperature

Sensor

Can H0

Boost

Pressure &

Temperature

Sensor

Can L0

Shield

Can H1

Can L1

Variable Turbo

Geometry

(VGT)

Actuator 1 /

Waste Gate1

Shield

Doosan Infracore

34

Slide 36

ECU Terminal Diagram

(Preheat Symbol)

HCI Pressure

Sensor

Downstream

HCI Pressure

&

Temperature

Sensor

Upstream

Throttle Plate

Actuator

Throttle Plate

Actuator

HCI Metering

Valve

Engine Brake Actuator 1

Internal Engine

Decompression Valve

HCI Shut-Off

Valve

DPF

Differential

Pressure

Sensor

Turbine Wheel

Speed Sensor A

Controller Area

Network 2

EGR Differential

Pressure Sensor

Shield

DPF Exhaust

Temperature

Sensor (T6)

DPF Exhaust

Temperature

Sensor (T5)

DPF Exhaust

Temperature

Sensor (T4)

Doosan Infracore

35

Slide 37

ECU Terminal Diagram

Camshaft Speed Sensor

Output Signal

Crankshaft Speed Sensor

Output Signal

Inhibit

Regenerate

DPF

Regeneration

Switch

Fuel

Temperature

Sensor

Coolant

Temperature

Sensor

Crankshaft

Speed Sensor

Shield

Engine

Emergency

Stop Switch

Camshaft

Speed Sensor

Shield

Fuse 14 of Fuse Box 1

Pre Heat Relay Terminal C

Pre Heat Relay Terminal D

Starter Switch Terminal R2

Fuse 11 of Fuse Box 1

Note:

Fuse 11 of Fuse Box 1 is Key Controlled

Fuse 14 of Fuse Box 1 is Constant 24vSupply

Doosan Infracore

36

Doosan Infracore

37

Slide 38

ECU Terminal Diagram

Slide 39

Engine Harness Layout

* ECU mounted on machine

Note: With the ECU not mounted on the

engine, it is no longer cooled by fuel.

Doosan Infracore

38

Slide 40

ECU Connector

Connector (96-way module)

Vehicle side

Locking Slide

Engine side

73

96

24

73

Locking lever

96

24

Doosan Infracore

39

Slide 41

CAN Network Configuration

CAN 0 High : Pin No. 146

Machine

controller

(EPOS)

Vehicle side

CAN 0

120

120

CAN 0 Low : Pin No. 147

CAN 1 Low : Pin No. 195

Communication

with computer

CAN 1

(use only for Dev. Engineer)

CAN 1 High : Pin No. 171

EDC17

ECU

Engine side

CAN 2 Low : Pin No. 218

CAN 2

120

120

CAN 2 High : Pin No. 217

EGR

VGT

Doosan Infracore

40

Slide 42

CAN Massage Information (ECU EPOS)

New ID

Sub Title

DEC1_V

0x0CFF0117

EBC1

0x18F00100

Period

50ms

100ms

Data

Byte

Bit

Byte0

Byte1

Bit0~1

Byte0~2

Bit4~5

Request PGN

0x18EA0017

1000ms

Byte0

Byte1

Byte2

Receive Frame to control fan speed : DL06 Fan Clutch

0x18FF2800

1000ms

Byte0

Bit0~1

Bit0~1

Byte1

Byte2

Bit0~1

Name

Accelerator pedal position

Accelerator pedal position

Unused

Auxiliary Engine Shutdown Switch

New ID

Period

Sub Title

EEC2 : Electronic Engine Controller 2

0x0CF00300

50ms

EEC1 : Electronic Engine Controller 1

0x0CF00400

10ms

PGN number low byte

PGN number mid byte

PGN number high byte

ET1 : Engine Temperature 1

0x18FEEE00

1000ms

status message to reduce fan speed by 0%

EFL / P1 :Engine Fluid Level/Pressure 1

0x18FEEF00

500ms

status message to reduce fan speed by 30%

status message to reduce fan speed by 70%

Byte3

Bit0~1

status message to reduce fan speed by 80%

Byte4

Bit0~1

status message to reduce fan speed by 100%

0x18FEF200

100ms

IC1 : Inlet/Exhaust Conditions 1

0x18FEF600

500ms

Unused

Bit2~3

Data

Name

Byte0~1

Byte2

Unused

Percent Load at current Speed

Byte0~1

Byte2

Byte3~4

Unused

Actual Engine - Percent Torque

Engine Speed

Byte0

Byte1

Byte2~3

Engine Collant Temperature

Fuel Temperature

Engine Oil Temperature

Byte0

Byte3

Byte0~1

Byte6

Hydraulic Oil Temperature

Bit

Engine Fuel Delivery Pressure

Engine Oil Pressure

LFE : Fuel Economy

AAI : Auxiliary Analog Information : Hyd.Oil Temp

0x18FE8C17

1000ms

Byte0

AUXIO1 : Auxiliary Input/Output Status 1

0x18FDCB1

100ms

Byte0

7

Byte

Pilot Cutoff Status

FD : Fan Drive

0x18FEBD00

1000ms

LFC : Fuel Consumption

0x18FEE900 receiving a PGN request

Fuel Rate

Engine Throttle Position

Byte0

Byte1

Boost Pressure

Byte2

Intake Manifold temperature

Byte0

Byte2~3

Byte0~3

Byte4~7

Fan Speed

Total Fuel Consumption

PTC1

1000ms

DM1-Single

DM2-Multi Packet and BAM

Diesel Particulate Filter Regeneration

Byte0

Bit 1..3 status Lamp Command

Byte3

Bit 3..4 Status Lamp command

Byte7

Bit 3..5 Lamp Command

DPF Active Regeneration Inhibited

Exhaust System High Temperature

Doosan Infracore

41

Slide 43

Diagnostic Trouble Shooting Codes

DTC List

No.

DTC

C028

Bus Off error CAN A

C046

Bus Off error CAN C

C10A

EGR valve actuator communication loss error

C10C

Timeout error of CAN receive from VGT

C121

Timeout error of CAN receive from TCU

C122

Timeout Error of CAN-Receive-From DEC1V

C123

Accel pedal CAN max error

C124

Timeout error of CAN receive from Vehicle cut off switch

C125

Vehicle cutoff switch error

10

C141

Timeout Error of CAN-Receive-From Hydraulic oil temperature

11

C40B

EGR valve actuator error

12

C40D

VGT actuator error

13

D100

Engine shut off request from EPOS

14

P0087

Monitoring for minimum rail pressure

15

P0088

Monitoring f or maximum rail pressure

16

P0089

pressure relief valve is out of range : increase, pressure shock

17

P0096

Physical Signal Range high on the air mass flow sensor temperature

18

P0100

Battery voltage error of HFM sensor

19

P0101

Sensitivity drift out of range error for HFM sensor

20

P0102

SRC low error for raw value in HFM sensor

21

P0103

SCB of hardware signal or SRC high error for raw value of HFM sensor

22

P0112

SRC Low for boost temperature

23

P0113

SRC High for boost temperature

24

P0116

Physical out of range check high for coolant temperature

Description

Doosan Infracore

42

Slide 44

Basic Concept Of Signal Sensing

Raw

value

ADC

Signal

Range

Check

Raw

value

Sensed

value

[mV]

[deg C]

Physical

Range

Check

Signal used in

Application

Software

[deg C]

< Transfer curve >

SRC MAX

<The sensor raw signal voltage is above the threshold.>

SRC MIN

<The sensor raw signal voltage is below the threshold.>

Physical range MAX

<The sensed sensor signal is greater than the threshold.>

Physical range MIN

<The sensed sensor signal is less than the threshold.>

Doosan Infracore

43

Slide 45

Engine Torque Derating

Torque Derating

Doosan Infracore

44

Slide 46

Engine Fault Lamp

Error Code Class & Lamp Information

Failure

OK

Display Action

Display

No Lamp

Level 1

SVS Lamp On

Level 2

SVS Lamp Blinking

Level 3

MIL On

Fault Lamp On: It is necessary to take a service when the engine has a system error.

Service Lamp On : Sensor/ Actuator electronic error or mechanical system error

Service Lamp Blinking : Sensor/ Actuator electronic error or mechanical system error with Engine Torque Derating

Maintenance Indicator Lamp On : DPF related error with DPF protection (ex. Soot max error, DPF differential pressure error)

Engine stop and take a service immediately when the error is occurred.

Doosan Infracore

45

Slide 47

Example Of Diagnostic Trouble

Trouble Shooting

DTC

C122

Description

Timeout Error of CAN-Receive-Frame DEC1V

Model: DX340LC-3

Symptom

- SVS Lamp Blinking (only active error)

- 1200 RPM shift down and fixed

Check Result

-Only history error was stored

in EEPROM

- Check the msg. missing using

the measuring tool

Doosan Infracore

Slide 48

- EOD -

Doosan Infracore

46

Vous aimerez peut-être aussi

- Doosan Engine DX Serie NON DPF TrainingDocument136 pagesDoosan Engine DX Serie NON DPF Trainingmnowaq100% (21)

- 3 Engine DX Serie SCR TrainingDocument63 pages3 Engine DX Serie SCR TrainingJose Rafael Ramos Chiquillo67% (3)

- Monitoramento DoosanDocument35 pagesMonitoramento DoosanMauricio Simon75% (4)

- Doosan Engine DX Serie NON DPF TrainingDocument136 pagesDoosan Engine DX Serie NON DPF TrainingEslam Mansour100% (5)

- 08 Doosan TIER 4I Engine (120425)Document13 pages08 Doosan TIER 4I Engine (120425)Jose Rafael Ramos ChiquilloPas encore d'évaluation

- Fault Code PDFDocument33 pagesFault Code PDFJORGE DAVID APAZA HURTADO100% (3)

- Doosan Common Rail Engine (Euro-III) : Overseas Service TeamDocument144 pagesDoosan Common Rail Engine (Euro-III) : Overseas Service TeamQuốc Phú Đinh100% (1)

- Doosan Basic EngineDocument67 pagesDoosan Basic EngineJuan Guzmán100% (4)

- KVMG270 Parts Location: - Applied Model: DX300LC, DX340LCDocument30 pagesKVMG270 Parts Location: - Applied Model: DX300LC, DX340LCJacques Van Niekerk100% (8)

- Test & Adjust Doosan ExDocument43 pagesTest & Adjust Doosan ExJacques Van Niekerk100% (9)

- Doosan Products Overview (HEX)Document122 pagesDoosan Products Overview (HEX)Juan Guzmán100% (1)

- Euro III BH117L Engine DL08 Operation Maintenance ManualDocument221 pagesEuro III BH117L Engine DL08 Operation Maintenance ManualLeticia Naranjo100% (5)

- Foreword: DL08 Diesel EngineDocument180 pagesForeword: DL08 Diesel Enginevarthot100% (8)

- Doosan Dx140Document114 pagesDoosan Dx140Trọng100% (3)

- Doosan Esquema EletricoDocument129 pagesDoosan Esquema EletricoAnderson Salzano95% (22)

- Doosan DL Hydraulic TrainingDocument24 pagesDoosan DL Hydraulic TrainingVentsislav Venev100% (7)

- Modulo 4 DX Excavator (K3 - K5 - T5 Main Pump)Document32 pagesModulo 4 DX Excavator (K3 - K5 - T5 Main Pump)Omar Diaz Segura100% (6)

- Manual Doosan DX300LC PDFDocument818 pagesManual Doosan DX300LC PDFJimmyJavierTorresSalas100% (4)

- Electrical SystemDocument24 pagesElectrical SystemPutra Jawa100% (1)

- Doosan Daewoo Dx225lcDocument4 pagesDoosan Daewoo Dx225lcrayendra100% (3)

- sm-K1010635E (DL400) LowResDocument876 pagessm-K1010635E (DL400) LowResElectromecanica Leon Electromecanica Leon Leon100% (4)

- Doosan Eschemtic PDFDocument318 pagesDoosan Eschemtic PDFThomas Hansen100% (3)

- 01 Doosan TIER 4I Engine (120425)Document6 pages01 Doosan TIER 4I Engine (120425)Soufiane KadarPas encore d'évaluation

- Doosan Diesel Engine DL06Document211 pagesDoosan Diesel Engine DL06mnowaq98% (42)

- DX140 DX255 913Document32 pagesDX140 DX255 913juan100% (2)

- Dx210w - Shop ManualDocument1 186 pagesDx210w - Shop ManualPhan Văn Định94% (18)

- Doosan D34 PDFDocument4 pagesDoosan D34 PDFDaniel Delgado100% (1)

- ENG0010 DL DV TroubleshootingDocument33 pagesENG0010 DL DV Troubleshootingmike100% (1)

- Euro III BH117L Engine DL08 Operation Maintenance ManualDocument221 pagesEuro III BH117L Engine DL08 Operation Maintenance ManualBambang Setyo Utomo88% (17)

- #01. DL08 Engine IntroductionDocument48 pages#01. DL08 Engine IntroductionAugusto Nuñez100% (1)

- HYD0003 Solar Main Pump K3V, K5VDocument31 pagesHYD0003 Solar Main Pump K3V, K5VSergey100% (2)

- Motor Doosan DV11Document220 pagesMotor Doosan DV11David Catari100% (4)

- Daewoo Doosan Excavator DX Series Electrical Hydraulic Schematic Manual - CollectionDocument20 pagesDaewoo Doosan Excavator DX Series Electrical Hydraulic Schematic Manual - Collectionsen til80% (5)

- DX140W-5 Usa PDFDocument1 610 pagesDX140W-5 Usa PDFthang100% (9)

- Doosan dl06 Exc 420 PDFDocument206 pagesDoosan dl06 Exc 420 PDFVictor Maestre100% (2)

- Dx140w - Shop ManualDocument1 180 pagesDx140w - Shop ManualPhan Văn Định100% (18)

- Dx300lc Shop ManualDocument50 pagesDx300lc Shop ManualSaid Gedeon100% (3)

- Doosan DX340LCDocument133 pagesDoosan DX340LCHarlinton descalzi100% (7)

- SM K1015439E (DX225LC)Document856 pagesSM K1015439E (DX225LC)Keron Trotz94% (18)

- Om K1024898e (dx140w)Document309 pagesOm K1024898e (dx140w)Diego Mauricio Zapata Garcia50% (2)

- DX225LCA DX340LCA Sales MaterialDocument46 pagesDX225LCA DX340LCA Sales MaterialAntonio Carrion100% (9)

- Doosan DX700LC Shop Manual 950106 00013E - 2Document1 190 pagesDoosan DX700LC Shop Manual 950106 00013E - 2Wa Toke100% (4)

- DOOSAN Reserves The Right To Improve Our Products in A Continuing Process To Provide The BestDocument1 176 pagesDOOSAN Reserves The Right To Improve Our Products in A Continuing Process To Provide The BestTeknik Makina100% (5)

- Doosan DX225LC PDFDocument856 pagesDoosan DX225LC PDFHarlinton descalzi94% (16)

- DX480LC 520LCDocument866 pagesDX480LC 520LCmike100% (3)

- DOOSAN Diagnostic ToolsDocument6 pagesDOOSAN Diagnostic ToolsE BECK100% (1)

- DOOSAN DL420 Wheeled Loader Service Repair ManualDocument29 pagesDOOSAN DL420 Wheeled Loader Service Repair Manualcvt100% (1)

- Service HandbookDocument123 pagesService HandbookArbey Gonzalez100% (7)

- Doosan Fault Codes DTCDocument26 pagesDoosan Fault Codes DTCleonardo_199488% (17)

- DOOSANDocument832 pagesDOOSANsegundo100% (5)

- Doosan Fault Codes ListDocument1 pageDoosan Fault Codes ListKeron Trotz100% (6)

- DTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) DTC P0430 Catalyst System Efficiency Below Threshold (Bank 2)Document6 pagesDTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) DTC P0430 Catalyst System Efficiency Below Threshold (Bank 2)dion132Pas encore d'évaluation

- 039 - Displays and GaugesDocument81 pages039 - Displays and GaugesGedas Gvildys100% (1)

- Genset - 2MVA-5Document6 pagesGenset - 2MVA-5Shawn ZadehPas encore d'évaluation

- FlaDocument553 pagesFlaObrocea Nelu100% (5)

- Genset - 2MVA-2Document6 pagesGenset - 2MVA-2Shawn ZadehPas encore d'évaluation

- Catalogo Generador Cat 3512Document6 pagesCatalogo Generador Cat 3512pamg50% (1)

- Cek Electric ME STBD Valiant - PSRPT - 2021-06-23 - 16.39.43Document7 pagesCek Electric ME STBD Valiant - PSRPT - 2021-06-23 - 16.39.43Muhammad RamadhanPas encore d'évaluation

- p0420 Catalyst ErrorDocument7 pagesp0420 Catalyst Errordion132100% (2)

- JM at - 20040129Document11 pagesJM at - 20040129wreckedweaselPas encore d'évaluation

- 1-1 SHPDocument9 pages1-1 SHPElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 2-1 Structure and FunctionDocument107 pages2-1 Structure and FunctionElectromecanica Leon Electromecanica Leon Leon100% (1)

- 6-4 Has.Document24 pages6-4 Has.Electromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 2-2 TechDocument25 pages2-2 TechElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 2 SpecificationsDocument27 pagesGroup 2 SpecificationsElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 5 Travel Speed Control SystemDocument1 pageGroup 5 Travel Speed Control SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 9 5 PDFDocument1 page9 5 PDFElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 5 Swing Device Group 5 Swing Device: 1. Removal and Install of MotorDocument21 pagesGroup 5 Swing Device Group 5 Swing Device: 1. Removal and Install of MotorElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 4 Power Boost SystemDocument1 pageGroup 4 Power Boost SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 1 - Power Mode Selection SystemDocument3 pages1 - Power Mode Selection SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 9 2 PDFDocument2 pages9 2 PDFElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 6 StructureDocument4 pagesGroup 6 StructureElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 3 Electric SystemDocument2 pagesGroup 3 Electric SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 5 UndercarriageDocument1 pageGroup 5 UndercarriageElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- 5 5 PDFDocument1 page5 5 PDFElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 2 Major ComponentDocument11 pagesGroup 2 Major ComponentElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 2 Engine SystemDocument2 pagesGroup 2 Engine SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 4 Hydraulic SystemDocument3 pagesGroup 4 Hydraulic SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Group 4 Connectors: 1. Connector DestinationDocument21 pagesGroup 4 Connectors: 1. Connector DestinationElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Section 5 Mechatronics SystemDocument3 pagesSection 5 Mechatronics SystemElectromecanica Leon Electromecanica Leon LeonPas encore d'évaluation

- Engine Especifications G3520BDocument4 pagesEngine Especifications G3520BYaneth100% (1)

- STP39780S IndexDocument3 pagesSTP39780S IndexAnonymous OFKjccHOPas encore d'évaluation

- WRC 525 (Fabrication and Repair of Low Alloy Steels)Document103 pagesWRC 525 (Fabrication and Repair of Low Alloy Steels)Anonymous lIxDbX1Pas encore d'évaluation

- Wellsite GeologyDocument6 pagesWellsite GeologyLeonardo CarrilloPas encore d'évaluation

- To Study Optimum Parameters in The Soap Production Derived From Palm Kernel Oil and Palm Oil by SaponificationDocument24 pagesTo Study Optimum Parameters in The Soap Production Derived From Palm Kernel Oil and Palm Oil by SaponificationEdgardo Ed RamirezPas encore d'évaluation

- Smokehouse Owner'S Manual Section I Installation InstructionsDocument12 pagesSmokehouse Owner'S Manual Section I Installation Instructionsronal552Pas encore d'évaluation

- Lt. Governor Patrick Earns Support From Texas Food & Fuel Association PACDocument1 pageLt. Governor Patrick Earns Support From Texas Food & Fuel Association PACallen.blakemorePas encore d'évaluation

- 250kva Tech SpecsDocument3 pages250kva Tech Specscrawn06Pas encore d'évaluation

- New Microsoft Office Word DocumentDocument60 pagesNew Microsoft Office Word DocumenthhhPas encore d'évaluation

- Case Study Summary For The Exxon Valdez Spill (Li Li) - Crisis Management and StrategiesDocument3 pagesCase Study Summary For The Exxon Valdez Spill (Li Li) - Crisis Management and StrategiesViral_gohelPas encore d'évaluation

- Valve and PumpDocument32 pagesValve and Pumpwan muhdPas encore d'évaluation

- Tabla Settings Crusher .. Incluido Datos de PruebaDocument30 pagesTabla Settings Crusher .. Incluido Datos de PruebaAndrés Mancilla BustamantePas encore d'évaluation

- Petrochemical Industry - Production ProcessDocument40 pagesPetrochemical Industry - Production ProcessAyie Arie AyitPas encore d'évaluation

- Testing & Commissioning Checklist For Fire PumpDocument2 pagesTesting & Commissioning Checklist For Fire PumpOanh Nguyen86% (7)

- DNGF PR 200 Dbs 1009-2-1 3 Fire Protection System Design Basis and PhilosophyDocument21 pagesDNGF PR 200 Dbs 1009-2-1 3 Fire Protection System Design Basis and Philosophychy_id100% (2)

- EngineDocument2 pagesEngineHaikal Rivaldy PrimayogaPas encore d'évaluation

- Ipr RegDocument34 pagesIpr RegNicolae PopPas encore d'évaluation

- United Nations Warns World To Quit 'Coal Addiction' (5th November, 2019)Document3 pagesUnited Nations Warns World To Quit 'Coal Addiction' (5th November, 2019)Fack FackPas encore d'évaluation

- Manual Generador QAS 30Document74 pagesManual Generador QAS 30wilasn1Pas encore d'évaluation

- Topic # 11 Application of Fluid MachineriesDocument31 pagesTopic # 11 Application of Fluid MachineriesALL THE GOOD STUFF0% (1)

- 16 Fire Fighting Appliance and Preventive Measures Onboard ShipsDocument2 pages16 Fire Fighting Appliance and Preventive Measures Onboard ShipsMicro Boy Veera100% (1)

- 06 I C EnginesDocument60 pages06 I C Engines1234Pas encore d'évaluation

- Isobutylene by MTBE Decomposition-CD TECHDocument2 pagesIsobutylene by MTBE Decomposition-CD TECHDrVedprakash Mishra100% (1)

- Jobs Safety Plan - TemplateDocument16 pagesJobs Safety Plan - TemplateFairus Md Yusof100% (1)

- 100732Document8 pages100732213eknoPas encore d'évaluation

- Valori Tipici Coefficiente Di DiffusioneDocument1 pageValori Tipici Coefficiente Di Diffusioneziojoe2Pas encore d'évaluation

- Volkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolDocument128 pagesVolkswagen Fox 2003-2010 Motor BNM Manual Reparacion EspañolAndres Jauregui Garcia100% (2)

- APPENDIX B - DATA SETS FOR EXERCISES - Introduction To Linear Regression Analysis, 5th EditionDocument14 pagesAPPENDIX B - DATA SETS FOR EXERCISES - Introduction To Linear Regression Analysis, 5th EditionvasubatraPas encore d'évaluation

- Anti FoulingDocument2 pagesAnti FoulingTun Naing WinPas encore d'évaluation