Académique Documents

Professionnel Documents

Culture Documents

Thickness Calculation of Pressure Vessel Shell

Transféré par

VishnuGKTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Thickness Calculation of Pressure Vessel Shell

Transféré par

VishnuGKDroits d'auteur :

Formats disponibles

Shell Under Internal Pr/ / Dt.

17/07/2010

Source

Description

MOC

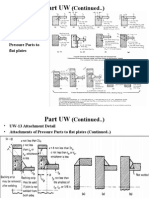

ASME Sec VIII Div 1 UG-27 THICKNESS OF SHELL

ts = (P*R)/((2*S*E)+(0.4*P))

Shell side Design Pressure

Inside Radius of shell

P

R

ts

td

S

S

L

r

Ed

Es

ts

ts

ts

ts

=

=

164

29.92

Psi

In

=

=

0.39

0.39

20015

20015

53.86

10.17

0.85

0.85

0.14

3.65

0.29

7.36

1.50

8.86

In

in

Psi

Psi

In

In

Final Centre Line Radius (Rf)

Original Centre Line Radius (Ro)

Rf

Ro

=

=

% Extreme Fiber Elongation =

( 50*t*(1- Rf/Ro) / Rf)

Ef

= 1.298701

THICKNESS OF DISH TORISPHERICA td = (0.885* P * L ) / ( ( S * E) - ( 0.1 * P ) )

Td

0.46

In

Calculated Thickness of Dish

Add Thinning Allowances

Add Corrosion Allowances

Noiminal Thickness of Dish

Calculated Thickness of Dish

We are using

Increase Thickness of Dish

Final Centre Line Radius (Rf)

Original Centre Line Radius (Ro)

Td

11.67

1.17

0.00

12.84

mm

mm

mm

mm

Rf

Ro

=

=

263.4

Infinity

Ef

= 2.84738

Td

0.29

In

Td

7.33

0.73

1.50

9.56

mm

mm

mm

mm

Rf

Ro

=

=

263.4

Infinity

Ef

= 2.84738

P

Do

ts

td

=

=

=

=

=

Wall Thickness of Shell

Wall Thickness of Dish

Max Allowable stress for Shell Material

ASME Sec.II Part D Table 1A

Max Allowable stress for Dish Material

Crown Radius

Knuckle Radius

Joint Efficiency Dish

Joint Efficiency Shell

Longitudinal Stress

Calculated Thickness of Shell

ts = (P*R)/((2*S*E)+(0.4*P))

Cicumferential Stress

ts = (P*R)/((S*E)-(0.6*P))

Calculated Thickness of Shell

10

10

ASME Sec VIII Div 1 UG-32

% Extreme Fibre Elongation

mm

mm

SS 304 L

SS 304 L

1368

258.4

Add Corrosion Allowance

Thickness of Shell with corrosion allowance

Calculated Thickness is

We are using

Hence Safe

% Extreme Fibre Elongation

11.52279 Kgs/cm2

760

mm

8.86

10

12.84

10

% Extreme Fibre Elongation

THICKNESS OF DISH ELLIPSOIDAL

9.56

10

mm

mm

% Extreme Fiber Elongation =

(75*t*(1- Rf/Ro) / Rf)

Source

Shell Under External Pr// Dt. 17/07/2010

Description

ASME Sec VIII Div 1 UG-28 THICKNESS OF SHELL

Shell External Pressure

Outside Diameter of shell

Shell Thickness

Dish Thickness

Dish SF

Max Allowable stress for Shell Material

ASME Sec.II Part D Table 1A

Max Allowable stress for Dish Material

Crown Radius

Joint Efficiency Dish

Dish Depth

Unsupported Length of Shell

If Do/t >= 10

From Fig G using L/Do and Do/t

From Fig HA-3 for 304L

Maximum Allowable external working

ASME Sec VIII Div 1 UG-28 Pressure

385

Infinity

mm

mm

td = ( P * D ) / ( ( 2* S * E) - ( 0.2 * P ) )

Calculated Thickness of Dish

Add Thinning Allowances

Add Corrosion Allowances

Noiminal Thickness of Dish

Calculated Thickness of Dish

We are using

Hence Safe

Final Centre Line Radius (Rf)

Original Centre Line Radius (Ro)

MOC

4.3

1540

8

16

40

Kgs/cm2

mm

mm

mm

mm

SS 304 L

SS 304 L

1540

388

150

mm

mm

S

S

L

Ed

h

L

L/Do

Do/t

ASME Sec II part D Fig G

=

=

=

=

=

=

61

60.63

0.31

0.63

1.57

15800

15800

60.63

1.00

15.28

5.91

0.10

192.50

A

B

=

0.01

= 8500.00

Pa

58.87

td = (0.885*1.67*P * L ) / ( ( S * E) - ( 0.1 *1.67* P ) ) Td

0.35

Td

8.82

0.88

1.00

10.70

= 0.001299

= 5500

Pa

Pa = 4B/(3*(Do/t))

In

mm

In

mm

mm

mm

% Extreme Fiber Elongation =

(75*t*(1- Rf/Ro) / Rf)

ASME Sec VIII Div 1 UG-32

=

=

=

=

=

=

=

=

4.139297 Kgs/cm2

Psi

In

in

in

in

Psi

Psi

In

in

in

psi

Increase Thickness of Shell

ASME Sec VIII Div 1 UG-32

ASME Sec VIII Div 1 UG-33

THICKNESS OF DISH

Calculated Thickness of Dish

Add Thinning Allowances

Add Corrosion Allowances

Calculated Thickness of Dish

A = 0.125/(Ro/t)

From Fig HA-3 for 304L

Maximum Allowable external working

ASME Sec VIII Div 1 UG-28 Pressure

ASME Sec II part D Fig G

Pa = B/(Ro/t)

4.017553 Kgs/cm2

57.14

In

mm

mm

mm

mm

psi

304L

Vous aimerez peut-être aussi

- Pressure Vessel THCK CalcDocument8 pagesPressure Vessel THCK Calcmkchy12100% (1)

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínPas encore d'évaluation

- Thickness Calculation of Pressure Vessel ShellDocument22 pagesThickness Calculation of Pressure Vessel ShellAkshat Jain88% (26)

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of NozzleChagar HarshpalPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- Section VIII CalDocument21 pagesSection VIII CalRuben Samoel Barros RochaPas encore d'évaluation

- New - Reinforcement of NozzleDocument31 pagesNew - Reinforcement of Nozzlehardik5818Pas encore d'évaluation

- Pressure Vessel Design Excel Sheet Basic Designing Non Critical PDocument1 pagePressure Vessel Design Excel Sheet Basic Designing Non Critical PSana AlzakiPas encore d'évaluation

- Reinf S1Document2 pagesReinf S1tasingenieriaPas encore d'évaluation

- Nozzle Design CalculationDocument1 pageNozzle Design CalculationSachin55860% (1)

- ASME Pressure Vessel Design-ADocument190 pagesASME Pressure Vessel Design-AWidyAdityaPas encore d'évaluation

- WRC For NozzleDocument43 pagesWRC For NozzleSachin55860% (1)

- ThicknessDocument53 pagesThicknessRajul MuraliPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument54 pagesDesign Calculations For Pressure VesselsEdgar A. Arredondo QuirozPas encore d'évaluation

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuPas encore d'évaluation

- Weight Estimation of Vessels AppsDocument26 pagesWeight Estimation of Vessels Appsdhavalesh1Pas encore d'évaluation

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadPas encore d'évaluation

- Dished Ends TypesDocument2 pagesDished Ends Typess.vijayaraghavan50% (4)

- Doshi Ion Exchange & Chemical Ind. LTD.: Material DataDocument7 pagesDoshi Ion Exchange & Chemical Ind. LTD.: Material DataMakrand Sakpal100% (5)

- Ligament Efficiency and Thickness of The Support PlateDocument10 pagesLigament Efficiency and Thickness of The Support PlatePankajDhoblePas encore d'évaluation

- Nozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim GalalaDocument5 pagesNozzle Reinforcing Calculations For A Pressure Vessel Design - by Abdel Halim Galalapaary100% (2)

- Lethal Service - Quick Guide - Pressure Vessel EngineeringDocument4 pagesLethal Service - Quick Guide - Pressure Vessel EngineeringVilas AndhalePas encore d'évaluation

- Excel PV 2016 Demo VersionDocument6 pagesExcel PV 2016 Demo Versionahmadlie0% (1)

- Design of Pressure Vessel NewDocument442 pagesDesign of Pressure Vessel NewkhanfaqihPas encore d'évaluation

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- Sif B31.3Document10 pagesSif B31.3Rob Gillespie100% (1)

- ASME VIII Calc - Shell - HeadsDocument4 pagesASME VIII Calc - Shell - HeadsMuh Safaat100% (1)

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongPas encore d'évaluation

- 2 - 1 Ellipsoidal Head Blank DiameterDocument1 page2 - 1 Ellipsoidal Head Blank Diameterdownloadmonster100% (2)

- Pressure Vessel Design ManualDocument32 pagesPressure Vessel Design ManualAris Purniawan100% (1)

- Calculation of Pipe Reinforcement ASME B31 3Document3 pagesCalculation of Pipe Reinforcement ASME B31 3Brant AkkanPas encore d'évaluation

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- UG 45 Sample CalculationDocument1 pageUG 45 Sample CalculationAris Purniawan100% (1)

- ASME VIII CalculationDocument15 pagesASME VIII CalculationJoao Osmar Correa100% (1)

- Pressure Design Straight Pipe (Run Pipe)Document6 pagesPressure Design Straight Pipe (Run Pipe)gembirasekaliPas encore d'évaluation

- Pressure Vessel Assessment SpreadsheetDocument3 pagesPressure Vessel Assessment SpreadsheetrawirabbatPas encore d'évaluation

- Pressure Vessel FormulaDocument9 pagesPressure Vessel FormulaNasir Khan JadoonPas encore d'évaluation

- Ibr Calc GSRDocument4 pagesIbr Calc GSRAniket GaikwadPas encore d'évaluation

- Boiler Drum Thickness CalculationDocument3 pagesBoiler Drum Thickness Calculationsumang254567% (3)

- Equipment Design As Per Russian Norms - 20090218Document45 pagesEquipment Design As Per Russian Norms - 20090218vikas100% (1)

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjPas encore d'évaluation

- Shell and Tube HE CalculationDocument16 pagesShell and Tube HE CalculationPradip ShindePas encore d'évaluation

- Design Calculations For Pressure ShellDocument33 pagesDesign Calculations For Pressure ShellGeorge GeorgianPas encore d'évaluation

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Weight CalculatorDocument12 pagesWeight CalculatorShafqat AfridiPas encore d'évaluation

- SA 516M GR 485: If Actual Thickness of Head After Forming 9 MMDocument2 pagesSA 516M GR 485: If Actual Thickness of Head After Forming 9 MMMehta MehulPas encore d'évaluation

- Rumus Internal External PressureDocument6 pagesRumus Internal External PressureDidi SudiprayitnaPas encore d'évaluation

- 03 - Lifting Lug - 2nd Stage Separator (New)Document5 pages03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarbonePas encore d'évaluation

- Asme Viii Shell & Se HeadDocument5 pagesAsme Viii Shell & Se HeadSnr George RaczPas encore d'évaluation

- Aspen HX Design ReportDocument78 pagesAspen HX Design ReportberylqzPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsPeña Eepesa100% (2)

- Calculation of PipeReinforcement ASMEB31.1Document3 pagesCalculation of PipeReinforcement ASMEB31.1jayaarnav100% (1)

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiPas encore d'évaluation

- Internal CoilDocument2 pagesInternal CoilwhngomjPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument28 pagesDesign Calculations For Pressure VesselsUmair AwanPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument30 pagesDesign Calculations For Pressure VesselsVinoth Rajendra100% (3)

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuPas encore d'évaluation

- Shell & Dish ThicknessDocument3 pagesShell & Dish Thicknesskirandas_mullasseryPas encore d'évaluation

- 6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3Document8 pages6.1 Design of Main Chs Member: Calculation of Compressive Capacity According To Clause E3abdulPas encore d'évaluation

- ATTAR - Gamma Exposure Calculator and RT CalculationsDocument2 pagesATTAR - Gamma Exposure Calculator and RT CalculationsVishnuGK100% (1)

- Attachment C-Daily Activities and Manpower Report Instructions-REV 3Document2 pagesAttachment C-Daily Activities and Manpower Report Instructions-REV 3VishnuGKPas encore d'évaluation

- 1 WPS 132Document2 pages1 WPS 132VishnuGK100% (1)

- Inspection and Test Plan For Storage TankDocument7 pagesInspection and Test Plan For Storage TankAhmed100% (5)

- Welding Data Sheet 2 BDocument3 pagesWelding Data Sheet 2 BVishnuGKPas encore d'évaluation

- Material-Comparison-List: For Tube or Pipe Tensile Strength Yield Strength Elongation (%) Min Reduction of ADocument2 pagesMaterial-Comparison-List: For Tube or Pipe Tensile Strength Yield Strength Elongation (%) Min Reduction of AVishnuGKPas encore d'évaluation

- SwivelDocument1 pageSwivelVishnuGKPas encore d'évaluation

- Service Agreement: Al Bashaer Mechanical Engineering LLCDocument1 pageService Agreement: Al Bashaer Mechanical Engineering LLCVishnuGKPas encore d'évaluation

- MRB IndexDocument1 pageMRB IndexVishnuGKPas encore d'évaluation

- Al Bashaer Mechanical Engineering LLC: Monthly Production ReportDocument6 pagesAl Bashaer Mechanical Engineering LLC: Monthly Production ReportVishnuGKPas encore d'évaluation

- 1 Smoke Detector With Base (Contex Plus XP95) 10 2 Heat Detector With Base (Contex Plus XP95) 3 3 Manual Call Point (Contex Plus XP95) 5Document2 pages1 Smoke Detector With Base (Contex Plus XP95) 10 2 Heat Detector With Base (Contex Plus XP95) 3 3 Manual Call Point (Contex Plus XP95) 5VishnuGKPas encore d'évaluation

- QC Dossier 1Document1 pageQC Dossier 1VishnuGKPas encore d'évaluation

- Asme 2Document16 pagesAsme 2VishnuGKPas encore d'évaluation

- Manufacturing Technology-I: Introduction To Asme Sec. IxDocument45 pagesManufacturing Technology-I: Introduction To Asme Sec. IxVishnuGKPas encore d'évaluation

- British Thread - Coarse Pitch - BSWDocument6 pagesBritish Thread - Coarse Pitch - BSWVishnuGKPas encore d'évaluation

- Quality Assurance PlanDocument6 pagesQuality Assurance Planvkrishnamoorthy100% (2)

- Demag Cranes BruchureDocument24 pagesDemag Cranes BruchureAnand TornekarPas encore d'évaluation

- Elevation DesignDocument132 pagesElevation DesignpvamshiPas encore d'évaluation

- HDB Elect Sor Jul 2009Document78 pagesHDB Elect Sor Jul 2009kokueiPas encore d'évaluation

- Hot CrackingDocument3 pagesHot CrackingFsPas encore d'évaluation

- C-758 Power Cable Schdule R-0Document2 pagesC-758 Power Cable Schdule R-0HARSHAL KIRITBHAI PATELPas encore d'évaluation

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637Pas encore d'évaluation

- En - 0717 6996 Arq 104 142Document8 pagesEn - 0717 6996 Arq 104 142Khairul ScPas encore d'évaluation

- K EjectionDocument21 pagesK EjectionAmolPagdalPas encore d'évaluation

- 10 IMS - DocumentationDocument4 pages10 IMS - DocumentationantivariPas encore d'évaluation

- V. Project Profile and Analysis 5.1 Historical Background: Commonwealth To Post-Commonwealth EraDocument32 pagesV. Project Profile and Analysis 5.1 Historical Background: Commonwealth To Post-Commonwealth EraMr. ManaloPas encore d'évaluation

- Ccaa Hot Weather ConcretingDocument7 pagesCcaa Hot Weather ConcretingHussain ElarabiPas encore d'évaluation

- Armani Casa Penthouse Floor PlanDocument4 pagesArmani Casa Penthouse Floor PlanSarah Elles BoggsPas encore d'évaluation

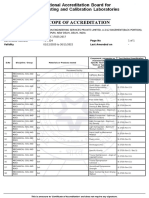

- Scope TC 9124Document1 pageScope TC 9124Esscon Engineering Services Pvt. Ltd.Pas encore d'évaluation

- Fire Resistance of Unprotected Steel Beams - Comparison Between Fire Tests and Calculation ModelsDocument8 pagesFire Resistance of Unprotected Steel Beams - Comparison Between Fire Tests and Calculation Modelspametnica21Pas encore d'évaluation

- Tablas de Esfuerzos PDFDocument729 pagesTablas de Esfuerzos PDFSamuel PohezPas encore d'évaluation

- Bahal - Bahil 15-1140578073Document24 pagesBahal - Bahil 15-1140578073stojshakyas100% (2)

- Codes and Standards: Piping EngineeringDocument23 pagesCodes and Standards: Piping EngineeringAnnieMalikPas encore d'évaluation

- The Alumiguard Sheet Piling Is Used ForDocument2 pagesThe Alumiguard Sheet Piling Is Used ForVitor José RodriguesPas encore d'évaluation

- Catalogo Partes de John DeereDocument633 pagesCatalogo Partes de John DeereJonathan ArgotiPas encore d'évaluation

- 2211 TCP Mechanical Firing Head 130618Document1 page2211 TCP Mechanical Firing Head 130618mahsaPas encore d'évaluation

- 2.4 Ccontract ManagmentDocument27 pages2.4 Ccontract Managmentbereket gPas encore d'évaluation

- Installation Guidelines: 1. Preparing The SubgradeDocument3 pagesInstallation Guidelines: 1. Preparing The SubgradeElard QAPas encore d'évaluation

- Automatic Transmission Overhaul: Group 23BDocument57 pagesAutomatic Transmission Overhaul: Group 23Bahmed meselhyPas encore d'évaluation

- Procedure in Enforcing Administrative Sanctions Procedure For Abatement/Demolition of Dangerous/Ruinous Buildings/StructuresDocument6 pagesProcedure in Enforcing Administrative Sanctions Procedure For Abatement/Demolition of Dangerous/Ruinous Buildings/StructuresJohn Ace CatanghalPas encore d'évaluation

- Permalok Steel Casing Pipe For Microtunneling and Other Jacking ApplicationsDocument36 pagesPermalok Steel Casing Pipe For Microtunneling and Other Jacking Applicationsvmi_dude100% (2)

- Boq Package 4-Mep Rumus1Document413 pagesBoq Package 4-Mep Rumus1Muhammad Iqbal ArdhiansyahPas encore d'évaluation

- Design and Construction of R75 Curve For East West Transmission Cable TunnelDocument15 pagesDesign and Construction of R75 Curve For East West Transmission Cable TunnelfreezefreezePas encore d'évaluation

- Forged Steel Globe Valve 800 15NB To 50NBDocument1 pageForged Steel Globe Valve 800 15NB To 50NBpriyanka GPas encore d'évaluation

- Interior Arch Vs DesignDocument9 pagesInterior Arch Vs DesignAyesha MAhmoodPas encore d'évaluation