Académique Documents

Professionnel Documents

Culture Documents

ERRor Code IR3245

Transféré par

JatmokoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ERRor Code IR3245

Transféré par

JatmokoDroits d'auteur :

Formats disponibles

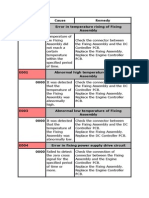

ERR0R CODE COPIER IR 3235

Code

E0000001

E0010000

E0010001

E0010002

E0020000

E0030000

E0040000

E0070000

E0100001

Description

The temperature of the fixing assembly is

abnormally high.

While startup control is under way, the

reading of the main thermistor is less than

30 deg C continuously for 200 msec or

more 1 sec after the start of power supply.

While startup control is under way, the

reading of the main thermistor is less than

70 deg C continuously for 200 msec or

more 2 sec after the start of power supply.

While startup control is under way, the

reading of the main thermistor is less than

120 deg C continuously for 200 msec 6 sec

after the start of power supply. The startup

control does not end 30 sec after the start

of power supply.

The temperature of the fixing assembly is

abnormally high.

The reading of the main thermistor is 250

deg C or more continuously for 200 msec.

The temperature of the fixing assembly is

abnormally high.

The hardware circuit detects overheating of

the main or sub thermistor for 200 msec

The temperature of the fixing assembly is

abnormally high.

The reading of the sub thermistor is 295

deg C or more continuously for 200 msec.

The rise in temperature of the fixing

assembly is faulty.

While startup control is under way, the

reading of the main thermistor is less than

115 deg C continuously for 400 msec 1.3

sec after it has indicated 100 deg C. While

startup control is under way, the reading of

the main thermistor is less than 150 deg C

continuously for 400 msec 1.3 sec after it

has indicated 140 deg C.

The fixing temperature is too low after a

standby state.

While regular temperature control is under

way, the reading of the main thermistor is

less than 140 deg C continuously for 400

msec or more

Failure in main/sub thermistor

When disconnection is detected with

connector of the main/sub thermistor for 30

sec continuously while DC controller is

working.

The rotation of the fixing film is faulty.

While the fixing motor is rotating, the

marker signal is not detected for 6 sec with

the reading of the main thermistor

indicating 100 deg C or more.

The rotation of the main motor is faulty.

Detection is executed every 100 msec after

the start of motor rotation; however, the

drive detection signal is absent for 2 sec.

Remedy

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

main thermistor. Replace the DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

main thermistor. Replace the DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

sub thermistor. Replace the DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

main thermistor. Replace the DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

main thermistor. Replace the DC controller PCB.

Clear the error in Service Mode: COPIER >

FUNCTION > CLEAR > ERR. Replace the main

thermistor (film unit). Replace DC controller PCB.

Reset the condition in service mode:

COPIER>FUNCTION>CLEAR>ERR. Replace the

main thermistor. Replace the DC controller PCB.

Replace the main motor. Replace the DC controller

PCB.

E0100002

E0140001

E0140002

E0190000

E0200000

E0240000

Code

E0240001

E025-

The rotation of the main motor is faulty.

During motor rotation, detection is

executed every 100 msec; however, the

drive signal is absent 5 times in sequence.

The rotation of the fixing motor is faulty.

Detection is executed every 100 msec after

the start of motor rotation; however, the

drive detection signal is absent for 2 sec.

The rotation of the fixing motor is faulty.

During motor rotation, detection is

executed every 100 msec; however, the

drive signal is absent 5 times in sequence.

The waste toner case is full, or the waste

toner case full sensor is faulty.

When the waste toner case is identified as

being full for 2000 prints continuously, an

alert is issued; thereafter, the case is

identified as being full continuously for

100 prints.

The path between the sub hopper and the

developing assembly is clogged with toner

The developing assembly toner sensor

detects the absence of toner, while the sub

hopper toner sensor detects the presence of

toner. With the developing clutch turned

on, the hopper feedscrew motor is rotated

for 1 sec intermittently 194 times; still, the

developing assembly toner sensor does not

detect the presence of toner

The developing assembly connector is

disconnected/Disconnection of Toner

sensor.

The connection detection signal is absent

continuously for 100 msec

Description

The developing assembly connector is

disconnected/Disconnection of Toner

sensor.

Disconnection of the wire used for

detecting the connection of the toner level

sensor is found. When the disconnection of

the wire used for detecting the connection

of the toner level sensor has been detected

for 7.5 min without interruption (12.5 min

in the manual /envelop cassette feeding).

When the disconnection of the wire used

for detecting the connection of the toner

level sensor has been detected for 12.5 min

without interruption.

-iR 3225

When the disconnection of the wire used

for detecting the connection of the toner

level sensor has been detected for 7.5 min

without interruption (12.5 min in the

manual /envelop cassette feeding).

-iR 3245/3235/3230

When the disconnection of the wire used

for detecting the connection of the toner

level sensor has been detected for 12.5 min

without interruption.

The hopper motor or the bottle motor is

Replace the main motor. Replace the DC controller

PCB.

Replace the fixing motor. Replace the DC controller

PCB.

Replace the fixing motor. Replace the DC controller

PCB.

Replace the waste toner sensor. Replace the DC

controller PCB.

Replace the developing assembly toner sensor.

Replace the sub hopper toner sensor. Replace the

DC control PCB

Replace the developing assembly toner sensor.

Connect the connector. Replace the DC controller

PCB.

Remedy

Correct the cable. Replace the sensor.

Replace the sub hopper toner sensor. Connect the

0000

E0250001

E0320001

E0640001

E0640002

E0640003

E0640004

E0640005

E1100001

E1100002

E1100003

faulty.

The sub hopper toner sensor connection

detection signal is absent for 100 msec 10

times in sequence.

The hopper motor or the bottle motor is

faulty.

While the hopper motor is rotating, the

motor error lock signal is detected

continuously 4 times every 56 msec. Or,

while the bottle motor is rotating, the

motor error lock signal is detected 22 times

in sequence every 10 msec.

The NE controller counter malfunctions.

An open circuit is detected for the count

pulse signal.

The voltage of the power supply is faulty

(high-voltage error).

The value read from the EEPORM is

outside a specific range.

The voltage of the power supply is faulty

(high-voltage error).

While output is being generated, the AD

value of the primary DC voltage is 230

(DEC) or more for 100 msec 2 times in

sequence. (However, after output, it is not

detected for 100 msec.)

The voltage of the power supply is faulty

(high-voltage error).

While output is being generated, the AD

value of the developing DC voltage is 224

(DEC) or more for 10 msec 2 times in

sequence. (However, after output, it is not

detected for 100 msec.)

The voltage of the power supply is faulty

(high-voltage error).

While output is being generated, the AD

value of the transfer output current is 205

(DEC) or more for 100 msec 2 times in

sequence. (However, after output, it is not

detected for 100 msec.)

The voltage of the power supply is faulty

(high-voltage error).

While output is being generated, the AD

value of the transfer output voltage is 0

(DEC) for 100 msec 2 times in sequence.

(However, after output, it is not detected

for 100 msec.)

The scanner motor is faulty.

The scanner motor speed lock signal does

not indicate a locked state a specific period

of time after the scanner motor has been

started.

The scanner motor is faulty.

The speed lock signal indicates a deviation

10 times in sequence at intervals of 10

msec after the signal has indicated a locked

state.

With the image clock switched over, the

scanner motor speed lock signal does not

indicate a locked state 6.5 sec after a

switchover is made from low to normal

connector. Replace the detection PCB.

Replace the hopper motor. Replace the bottle motor.

Replace the DC controller PCB.

Turn off the main power, and check the cable for an

open circuit; then, turn the main power back on.

Turn off and then back on the main power. Replace

the EEPROM.

Replace the high-voltage power supply. Replace the

DC controller PCB.

Replace the high-voltage power supply. Replace the

DC controller PCB.

Replace the high-voltage power supply. Replace the

controller PCB.

Replace the high-voltage power supply. Replace the

DC controller PCB.

Replace the laser unit. Replace the DC controller

PCB. Check the wiring.

Replace the laser unit. Replace the DC controller

PCB. Check the wiring.

Replace the laser unit. Replace the DC controller

PCB. Check the wiring.

speed or 8 sec after a switchover is made

from normal to low speed.

There is an error in the communication

with the high-voltage power supply.

The data transmission/reception does not

end normally 500 msec after the most

recent transmission/reception of data ended

normally.

Error in communication of laser driver

PCB

Communication error with IMG1L

(communication data)

Error in communication of laser driver

PCB

Communication error with IMG1L. (Serial

communication ENG)

E1910000

E1970000

E1970001

Replace the high-voltage power supply. Replace the

DC controller PCB.

- Check routing (wiring) - Replace the laser unit Replace DC controller PCBP

- Check routing (wiring) - Replace the laser unit Replace DC controller PCBP

Code

E1970003

Description

Error in communication of laser driver PCB

Disconnection of laser harness

E2020001

E225

There is an error in the detection of the CCD

home position.

The attempt to detect the home position fails

when the CCD is moved forward.

There is an error in the detection of the CCD

home position.

The attempt to detect the home position fails

when the CCD is moved back.

The light intensity of the CCD is faulty.

E2270001

The reader unit power supply (24V) is faulty.

At time of power-on, the 24V port is off.

E2270002

The reader unit power supply (24V) is faulty.

At the start of a job, the 24V port is off.

E2270003

The reader unit power supply (24V) is faulty.

At the end of a job, the 24V port is off.

E2270004

The reader unit power supply (24V) is faulty.

When a load is being driven, the 24V port is

off.

EEPROM error

An error has occurred at power-on.

EEPROM error

An error has occurred during write

operation.

EEPROM error

An error has occurred during read operation

following write operation.

The zero-cross signal is faulty.

When the relay is on, the zero-cross signal

is not detected for 500 msec or more.

E2020002

E2480001

E2480002

E2480003

E2610000

Remedy

- Check routing (wiring) - Replace

the laser unit - Replace DC

controller PCB

Disconnect and then connect the

harness connector. Replace the

optical HP sensor, optical motor,

and reader controller PCB.

Disconnect and then connect the

harness connector. Replace the

optical HP sensor, optical motor,

and reader controller PCB.

Disconnect and then connect the

flexible cable. Replace the flexible

cable, CCD unit, and reader

controller PCB.

Disconnect and then connect the

power supply harness connector.

Replace the power supply.

Disconnect and then connect the

power supply harness connector.

Replace the power supply

Disconnect and then connect the

power supply harness connector.

Replace the power supply.

Disconnect and then connect the

power supply harness connector.

Replace the power supply.

Replace the reader controller

PCB.

Replace the reader controller

PCB.

Replace the reader controller

PCB

Replace the AC driver PCB.

Replace the DC controller PCB.

E2800001

Reading unit communication error

Reception status error

E2800002

Reading unit communication error

Reception interrupt error

E2800003

Reading unit communication error

Insufficient insertion of the reading unit

connector

Description

There is an error in image data.

There is an error in JBIG encoding.

There is an error in image data.

There is an error in JBIG decoding.

There is an error in image data.

Error in decoding of software

There is an error in image data.

Error in ROTU hardware

There is an error in image data.

Error in ROTU timeout

There is an error in image data.

Error in MemFill hardware

There is an error in image data.

Error in MemFill timeout

There is an error in image data.

Error in PrcOverRun

There is an error in image data.

Error in device timeout [location to be

detected] image process module (SCIO)

[Detection timing] when there is no

interruption 2 min after the operation has

been started

There is an error in image data.

Device: abnormal termination error [location

to be detected] image process module

(SCIO) [Detection timing] When abnormal

interruption is detected after the operation

has been started.

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (SCIP)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

(SCIP) [Detection timing] when abnormal

interruption is detected after the operation

has been detected

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (CMIP)

[Detection timing] When there is no

Code

E3150007

E315000d

E315000e

E3150025

E3150027

E3150033

E3150035

E3150100

E3150500

E3150501

E3150510

E3150511

E3150520

Disconnect and then connect the

flexible cable. Replace the flexible

cable

Disconnect and then connect the

flexible cable. Replace the flexible

cable

Disconnect and then connect the

flexible cable. Replace the flexible

cable

Remedy

Turn off and then back on the

power.

Turn off and then back on the

power.

Replace the main controller PCB

Replace SDRAM. Replace HDD.

Replace the main controller PCB

Replace SDRAM. Replace HDD.

Replace the main controller PCB.

Replace the main controller PCB.

Replace the main controller PCB.

Replace the main controller PCB.

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB.

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB.

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB.

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB.

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB.

E3150521

E3150530

Code

E3150531

E3150540

E3150541

E3150550

E3150551

E3150560

E3150561

interruption 2 min after the operation has

been started

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

(CMIP) [Detection timing] when abnormal

interruption is detected after the operation

has been detected

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (JPEN)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

Description

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

(JPEN) [Detection timing] when abnormal

interruption is detected after the operation

has been started.

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (JPDE)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

(JPDE) [Detection timing] when abnormal

interruption is detected after the operation

has been started

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (PRIP)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

(PRIP) [Detection timing] when abnormal

interruption is detected after the operation

has been started.

There is an error in image data.

Device: timeout error [Location to be

detected] image process module (PRIO)

[Detection timing] when there is no

interruption 2 min after the operation has

been started.

There is an error in image data.

Device: abnormal termination error [Location

to be detected] image process module

Check connection with DDI-S

cable(RCON). Replace the main

controller PCB

Turn OFF and then ON the

power. Replace the main

controller PCB if this occurs

frequently.

Remedy

Turn OFF and then ON the

power. Replace the main

controller PCB if this occurs

frequently.

Turn OFF and then ON the

power. Replace the main

controller PCB if this occurs

frequently.

Turn OFF and then ON the

power. Replace the main

controller PCB if this occurs

frequently.

Check connection with DDI-P

cable(DCON). Replace the main

controller PCB.

Check connection with DDI-P

cable(DCON). Replace the main

controller PCB.

Check connection with DDI-P

cable(DCON). Replace the main

controller PCB.

Check connection with DDI-P

cable(DCON). Replace the main

controller PCB.

E4000001

E4000002

(PRIO) [Detection timing] when abnormal

interruption is detected after the operation

has been started.

Fault in communication with the ADF driver

PCB

The checksum values of data from the ADF

driver PCB are inconsistent 14 times

consecutively.

The statuses of data from the ADF driver

PCB are inconsistent 14 times

consecutively.

E4000003

SCI serial communication error interrupt is

detected 14 times consecutively.

E4130001

E4900001

The level of the pressure HP sensor does

not change in a specified period of time.

When the pressure motor is activated, the

level of the pressure HP sensor does not

change in a specified period of time with the

lead roller opened.

The level of the pressure HP sensor does

not change in a specified period of time.

When the pressure motor is activated, the

level of the pressure HP sensor does not

change in a specified period of time with the

lead roller closed.

The ADF installed is not supported.

Error with an incorrect ADF model

E5000001

fault in communication with the finisher

(common among all finishers)

E5030002

fault in communication

fault in communication between finisher and

saddle unit

E4130002

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

Check connection of ADF lattice

cable (cleaning of connecting

point). Replace ADF driver PCB.

Replace the reader controller

PCB.

Replace the pressure motor.

Replace the pressure HP sensor.

Replace the pressure motor.

Replace the pressure HP sensor.

The ADF installed is not

supported. Replace the DC

controller PCB.

Replace the finisher controller

PCB. Replace the DC controller

PCB.

Replace the finisher controller

PCB. Replace the saddle

controller PCB. Check the cable.

Vous aimerez peut-être aussi

- Canon Ir8070 Error Codes List PDFDocument18 pagesCanon Ir8070 Error Codes List PDFGirish KumarPas encore d'évaluation

- Error Code Ir3245 - Series-SmDocument22 pagesError Code Ir3245 - Series-SmvikramPas encore d'évaluation

- Error Codes 7095Document70 pagesError Codes 7095Gerald Aguero PorrasPas encore d'évaluation

- Canon IR2022 Error CodesDocument7 pagesCanon IR2022 Error CodesnafeesPas encore d'évaluation

- Ir3235 Service ManualDocument33 pagesIr3235 Service ManualGirish KumarPas encore d'évaluation

- Canon iR8070 Error Codes ListDocument18 pagesCanon iR8070 Error Codes ListGirish Kumar100% (1)

- Canon IR2020 Trouble Error CodesDocument6 pagesCanon IR2020 Trouble Error Codesnafees100% (1)

- Canon IR2318 Trouble Error CodesDocument7 pagesCanon IR2318 Trouble Error Codesnafees100% (1)

- Canon IR2535 Trouble Error CodesDocument36 pagesCanon IR2535 Trouble Error Codesnafees100% (4)

- Canon IR Advance 500 Trouble Error CodesDocument30 pagesCanon IR Advance 500 Trouble Error CodesnafeesPas encore d'évaluation

- Canon IR3225 Trouble Error CodesDocument30 pagesCanon IR3225 Trouble Error Codesnafees80% (10)

- Canon Ir2525 Trouble Error Codes PDFDocument11 pagesCanon Ir2525 Trouble Error Codes PDFnafees80% (10)

- Canon IR2016 Error CodesDocument7 pagesCanon IR2016 Error CodesnafeesPas encore d'évaluation

- Errorc Ir Advance 6055 6065 6075Document77 pagesErrorc Ir Advance 6055 6065 6075nafeesPas encore d'évaluation

- Konica-Minolta Bizhub 250 Trouble Error CodesDocument11 pagesKonica-Minolta Bizhub 250 Trouble Error Codesnafees100% (1)

- Canon IR105 Trouble Error CodesDocument32 pagesCanon IR105 Trouble Error Codesnafees0% (2)

- IR 400 Error CodesDocument4 pagesIR 400 Error Codeselan20250% (2)

- Canon IR7095 Error CodesDocument21 pagesCanon IR7095 Error CodesnafeesPas encore d'évaluation

- Canon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineDocument94 pagesCanon Ir Advance 4045 Trouble Error Codes List: Downloaded From Manuals Search EngineTengkuPas encore d'évaluation

- Errorc Ir Advance c5051 5045 5035 5030Document109 pagesErrorc Ir Advance c5051 5045 5035 5030koaslosa100% (1)

- Ir4570 Service ManualDocument1 008 pagesIr4570 Service ManualMarco MenaPas encore d'évaluation

- Error Codes Canon Ir3300Document5 pagesError Codes Canon Ir3300Ashraf Ali82% (11)

- Canon Ir7105 Error Code E000197 0000Document2 pagesCanon Ir7105 Error Code E000197 0000ereslomaximo2014100% (4)

- Canon IR2530 Error CodesDocument10 pagesCanon IR2530 Error CodesnafeesPas encore d'évaluation

- Advance Image Runner 6075Document96 pagesAdvance Image Runner 6075vishwajitPas encore d'évaluation

- Canon Copier Service Bulletin DC-Controller Software UpgradeDocument2 pagesCanon Copier Service Bulletin DC-Controller Software Upgradekatem1Pas encore d'évaluation

- Error Code Ir5000Document22 pagesError Code Ir5000Didi ConanPas encore d'évaluation

- Canon Error Codes: Brand Model Error Code Most Likely CauseDocument8 pagesCanon Error Codes: Brand Model Error Code Most Likely CausegigypubsPas encore d'évaluation

- Error Code Details for Canon ImageRunner CopiersDocument70 pagesError Code Details for Canon ImageRunner CopiersPadiparn Sae HousePas encore d'évaluation

- Canon Ir Advance C5030 Trouble Error Codes PDFDocument73 pagesCanon Ir Advance C5030 Trouble Error Codes PDFNafeesAhmad100% (1)

- Ir5000 6000shDocument252 pagesIr5000 6000shgestalb7742100% (1)

- CANON Ir2200 - 2800 - 3300 SHDocument352 pagesCANON Ir2200 - 2800 - 3300 SHjayant_gore100% (1)

- Fixing, Transfer, Developing Errors in Copier CodesDocument9 pagesFixing, Transfer, Developing Errors in Copier CodesJozef0% (1)

- Ir7105 Series SMDocument592 pagesIr7105 Series SMAe Hatyai100% (1)

- Canon Ir5000 Ir6000 Service Repair ManualDocument5 pagesCanon Ir5000 Ir6000 Service Repair ManualAmikFeyzaPas encore d'évaluation

- Xerox Error CodesDocument6 pagesXerox Error Codessaito36Pas encore d'évaluation

- Fixing Assembly Temperature Errors and SolutionsDocument7 pagesFixing Assembly Temperature Errors and SolutionsAnonymous 2WKRBqFlfPas encore d'évaluation

- Err CodeDocument21 pagesErr CodeDidi ConanPas encore d'évaluation

- Canon Copier Error CodesDocument9 pagesCanon Copier Error CodesHaftamu100% (1)

- Ir5000, Ir6000 Series Service BulletinsDocument174 pagesIr5000, Ir6000 Series Service BulletinsAlfonso Sanchez Verduzco100% (1)

- Canon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesDocument37 pagesCanon Copier Error Errors Code Codes Imagerunner Copiers Copy Machine Copy MachinesTariq MajeedPas encore d'évaluation

- Canon Ir3225 Error Codes: Code DescriptionDocument46 pagesCanon Ir3225 Error Codes: Code DescriptionnishaPas encore d'évaluation

- Canon IR3245 Error CodesDocument31 pagesCanon IR3245 Error Codesnafees80% (10)

- Canon IR4570 Trouble Error CodesDocument22 pagesCanon IR4570 Trouble Error Codesnafees100% (3)

- Canon IRC1020 Trouble Error CodesDocument9 pagesCanon IRC1020 Trouble Error CodesnafeesPas encore d'évaluation

- Fix Heater Error Codes IR 5075 SeriesDocument9 pagesFix Heater Error Codes IR 5075 Seriesslavko688% (8)

- Canon IR2420 Trouble Error CodesDocument30 pagesCanon IR2420 Trouble Error Codesnafees86% (7)

- Canon IR2030 Trouble Error CodesDocument7 pagesCanon IR2030 Trouble Error CodesnafeesPas encore d'évaluation

- Error CodeDocument99 pagesError CodeRDN Artha SentosaPas encore d'évaluation

- Error Code ListDocument29 pagesError Code ListBipin SinghPas encore d'évaluation

- Ir7095 Error CodesDocument15 pagesIr7095 Error Codesnag85100% (5)

- DeviceCraftDCmotorController 1015BDocument24 pagesDeviceCraftDCmotorController 1015BbetortitaPas encore d'évaluation

- Imagerunner - 3045 Corona TechnicalDocument23 pagesImagerunner - 3045 Corona TechnicalSilk Karim OussamaPas encore d'évaluation

- Kyocera Service Error Codes SummaryDocument185 pagesKyocera Service Error Codes SummaryBilly Collins100% (2)

- Kode Eror Mesin Canon 5075Document16 pagesKode Eror Mesin Canon 5075donirahmat100% (2)

- Canon Ir1230 Trouble Error Codes PDFDocument4 pagesCanon Ir1230 Trouble Error Codes PDFnafeesPas encore d'évaluation

- Error Code 3030 CanonDocument9 pagesError Code 3030 CanonsubramaniansonyPas encore d'évaluation

- Circuit Breaker Specifications Mentioned On Its NameplateDocument13 pagesCircuit Breaker Specifications Mentioned On Its Nameplatearyo bimo surya putraPas encore d'évaluation

- Speed Control PWM CaterpillarDocument7 pagesSpeed Control PWM CaterpillarJavier Moronta100% (1)

- Manual 1500 / 2500 Va Corona Treater (Regular Model With Power Control Feature) IndexDocument6 pagesManual 1500 / 2500 Va Corona Treater (Regular Model With Power Control Feature) IndexRaja Pathamuthu.GPas encore d'évaluation

- Errorc Ir Advance 6055 6065 6075Document77 pagesErrorc Ir Advance 6055 6065 6075nafeesPas encore d'évaluation

- Casio CE-4000 and CE-4050 operators programming manualDocument4 pagesCasio CE-4000 and CE-4050 operators programming manualJatmokoPas encore d'évaluation

- Canon Imagerunner Ir2200 Ir2800 Ir3300 Image Reader b1 Service Manual DownloadDocument23 pagesCanon Imagerunner Ir2200 Ir2800 Ir3300 Image Reader b1 Service Manual DownloadnishaPas encore d'évaluation

- Electronic Cash Register: User'S ManualDocument98 pagesElectronic Cash Register: User'S ManualJatmokoPas encore d'évaluation

- Canon Imagerunner Ir2200 Ir2800 Ir3300 Image Reader b1 Service Manual DownloadDocument23 pagesCanon Imagerunner Ir2200 Ir2800 Ir3300 Image Reader b1 Service Manual DownloadnishaPas encore d'évaluation

- Errorc Ir Advance 6055 6065 6075Document77 pagesErrorc Ir Advance 6055 6065 6075nafeesPas encore d'évaluation

- Bizhub 501 3Document364 pagesBizhub 501 3JatmokoPas encore d'évaluation

- SC 8206 A 4Document8 pagesSC 8206 A 4Kevin MartPas encore d'évaluation

- Samsung S20 G780F Service ManualDocument111 pagesSamsung S20 G780F Service ManualEdson Ferreira Santos JuniorPas encore d'évaluation

- 2nd Generation LLC Current Resonant Control IC, "FA6A00N Series"Document7 pages2nd Generation LLC Current Resonant Control IC, "FA6A00N Series"Moch Yosef Indra RiznoePas encore d'évaluation

- MEO Orals On Marine Electro Technology Function 5Document2 pagesMEO Orals On Marine Electro Technology Function 5Salih Tuğrul SarıPas encore d'évaluation

- Gensys 2.0 DatasheetDocument4 pagesGensys 2.0 DatasheetSiding BarroPas encore d'évaluation

- En Acs800 107 HW D ScreenDocument128 pagesEn Acs800 107 HW D ScreenElias VelezPas encore d'évaluation

- 4.1 EHW24 Rules&RegulationsDocument58 pages4.1 EHW24 Rules&Regulationsmm22b002Pas encore d'évaluation

- Controlled Rectifier DC Drives GuideDocument25 pagesControlled Rectifier DC Drives GuideshonmlrPas encore d'évaluation

- C15 Generator Set With EMCP 3 - Electrical System - KENR5075-01 - August 2006 - CATERPILLAR PDFDocument2 pagesC15 Generator Set With EMCP 3 - Electrical System - KENR5075-01 - August 2006 - CATERPILLAR PDFpevare100% (2)

- OBE Elecs 1 Midterm Examination - v1 Answer KeyDocument9 pagesOBE Elecs 1 Midterm Examination - v1 Answer KeyRaymond Joseph MeimbanPas encore d'évaluation

- CT Assignment IDocument4 pagesCT Assignment ImosesalvinPas encore d'évaluation

- Moduł Ipm Skiip 20nab12t45 1200v 15a Semikron DatasheetDocument7 pagesModuł Ipm Skiip 20nab12t45 1200v 15a Semikron DatasheetEfra FonsecaPas encore d'évaluation

- Simplified Modeling of A PV Panel by Using PSIM and Its Comparison With Laboratory Test ResultsDocument5 pagesSimplified Modeling of A PV Panel by Using PSIM and Its Comparison With Laboratory Test ResultsMuhammadSaeedTahirPas encore d'évaluation

- Final Boq Elec HotelDocument10 pagesFinal Boq Elec Hoteldamianuskrowin100% (1)

- Service ManualDocument53 pagesService ManualDaniel De PhilippisPas encore d'évaluation

- Indoor Voltage Transformer Fuses, WBP Outdoor Voltage Transformer Fuses, BRTDocument8 pagesIndoor Voltage Transformer Fuses, WBP Outdoor Voltage Transformer Fuses, BRTThi Huyen Trang VuPas encore d'évaluation

- Power Generation From ExhaustDocument41 pagesPower Generation From Exhaustanon_910370414Pas encore d'évaluation

- A20-OlinuXino-Lime2 GPIO layout guideDocument2 pagesA20-OlinuXino-Lime2 GPIO layout guideIlja LebedevPas encore d'évaluation

- How To Measure The Resistance of The SoilDocument13 pagesHow To Measure The Resistance of The Soilmoali moPas encore d'évaluation

- b3800 SDSDocument4 pagesb3800 SDSelmoruPas encore d'évaluation

- (PDF) Text Section 28.3 Kirchhoff's Circuit RulesDocument8 pages(PDF) Text Section 28.3 Kirchhoff's Circuit RulesFernando GandaPas encore d'évaluation

- TOA DA-550F ManualDocument20 pagesTOA DA-550F ManualPaulo SimõesPas encore d'évaluation

- ESPDocument24 pagesESPparag pariharPas encore d'évaluation

- Electromagnetic Clutch System Full SeminarDocument28 pagesElectromagnetic Clutch System Full SeminarPranay Gaddam100% (1)

- McGraw-Edison Concourse Series Brochure 1985Document4 pagesMcGraw-Edison Concourse Series Brochure 1985Alan MastersPas encore d'évaluation

- FusionSolar Utility Smart PV SolutionDocument24 pagesFusionSolar Utility Smart PV Solutionsmrasteg12Pas encore d'évaluation

- Prisma PDocument36 pagesPrisma PNATHANPas encore d'évaluation

- 220kv Line MaterialDocument2 pages220kv Line MaterialVasu BagganPas encore d'évaluation

- TDS - Boiler Vertical Air Break ControlsDocument10 pagesTDS - Boiler Vertical Air Break ControlsB Lal MughalPas encore d'évaluation