Académique Documents

Professionnel Documents

Culture Documents

WML 213

Transféré par

08088338Description originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

WML 213

Transféré par

08088338Droits d'auteur :

Formats disponibles

1793-00

1. SPECIFICATION

Item

Motor

E-EGR valve

Valve

E-EGR cooler

E-EGR bypass valve

Solenoid valve

Specification

EGR response time

50 ms

Driven by

DC motor

EGR gas flow rate

120 kg/h

Cooling capacity

8.3 kW or more

Cooling fin type

Wavy fin

Cooler type

U-shaped

Drivien by

Vacuum

(Solenoid valve)

13-3

13-4

1. SYSTEM DESCRIPTION

1) Overview

The EGR (Electric-Exhaust Gas Recirculation) valve reduces the NOx emission level by recirculating

some of the exhaust gas to the intake system.

To meet Euro-V regulation, the capacity and response rate of E-EGR valve in D20DTR engine have been

greatly improved. The EGR cooler with high capacity reduces the Nox, and the bypass valve reduces the

CO and HC due to EGR gas before warming up.

Also, the engine ECU adjusts the E-EGR opening by using the air mass signal through HFM sensor. If

the exhaust gas gets into the intake manifold when the EGR valve is open, the amount of fresh air

through HFM sensor should be decresed.

Benefits of E-EGR valve

-

Improved accuracy and response through electric control

Feedback function (Potentiometer)

Preventing chattering of EGR valve and improved durability

Self-cleaning function

1793-00

13-5

2) Location and Components

HFM sensor

E-EGR cooler and bypass valve

EGR cooler

Used as a main map value to control the EGR.

The coolant temperature, engine rpm, engine

load, intake air temperature (HFM: decreased at

60C or more), atmospheric pressure

(atmospheric pressure sensor: altitude

compensation) are used as auxiliary map values.

E-EGR valve

Receives the electric signal from the ECU to

control the valve.

* For details, see the section "Engine control".

EGR bypass

See the section "Engine control" for E-EGR

valve control logic.

The cooler lowers the high temperature of the

exhaust gas and the bypass valve directly

supplies the exhaust gas to the intake duct

without passing through the EGR cooler to

reduce the emission of exhaust gas before

warming up the engine.

EGR pipe

Transports the exhaust gas from the EGR cooler

and EGR bypass valve to the intake duct.

13-6

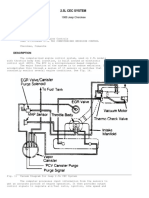

2. OPERATING PROCESS

1) Schematic Diagram

1793-00

2) Input/Output Devices

13-7

13-8

3) Control Logic

The EGR system controls the EGR amount based on the map values shown below:

Main map value: Intake air volume

Auxiliary map value:

- Compensation by the coolant temperature

- Compensation by the atmospheric pressure: Altitude compensation

- Compensation by the boost pressure deviation (the difference between the requested value and the

measured value of boost pressure)

- Compensation by the engine load: During sudden acceleration

- Compensation by the intake air temperature

The engine ECU calculates the EGR amount by adding main map value (intake air volume) and auxiliary

map value and directly drives the solenoid valve in the E-EGR to regulate the opening extent of the EGR

valve and sends the feedback to the potentiometer.

(1) Operating conditions

-

Intake air temperature: between -10 and 50

Atmospheric pressure: 0.92 bar or more

Engine coolant temperature: between 0 and 100C

When there is no fault code related to EGR

(2) Shut off conditions

-

Abrupt acceleration: with engine speed of 2600 rpm or more

When the engine is idling for more than 1 minute

Vehicle speed: 100 km/h or more

Engine torque: 380 Nm or more

Vous aimerez peut-être aussi

- Bosch Vp37 PumpsDocument32 pagesBosch Vp37 PumpsLuís Fidalgo92% (13)

- Ford BTR Transmission Repair Manual PDFDocument100 pagesFord BTR Transmission Repair Manual PDF08088338100% (2)

- BP (Public) 1Document204 pagesBP (Public) 1Kai Esperon93% (46)

- Manual Motor Action+d20dtDocument182 pagesManual Motor Action+d20dtPamela MontesPas encore d'évaluation

- SsangYong Korando / New Actyon - Engine Control SystemDocument172 pagesSsangYong Korando / New Actyon - Engine Control Systemtroublezaur80% (5)

- Operation Stages HDI SIEMENSDocument9 pagesOperation Stages HDI SIEMENSSergio SambuelliPas encore d'évaluation

- SSP 296 1.4 & 1.6 FSi EngineDocument24 pagesSSP 296 1.4 & 1.6 FSi Engineภูเก็ต เป็นเกาะ100% (3)

- 3grfse 1Document42 pages3grfse 1Zoli Borbely100% (3)

- MODULE 14 Instrument System PDFDocument5 pagesMODULE 14 Instrument System PDFastikPas encore d'évaluation

- MCS120 220 Error Ref - GAA30082DAC - RefDocument21 pagesMCS120 220 Error Ref - GAA30082DAC - RefCoil98Pas encore d'évaluation

- C200 - E-Egr SystemDocument9 pagesC200 - E-Egr SystemKada Ben youcefPas encore d'évaluation

- E-Erg SystemDocument20 pagesE-Erg SystemRiver OzPas encore d'évaluation

- El Sistema Egr en Common RailDocument4 pagesEl Sistema Egr en Common RailpepeladazoPas encore d'évaluation

- Exhaust Gas RecirculationDocument15 pagesExhaust Gas RecirculationJesus FloresPas encore d'évaluation

- Toyota Avensis DPFDocument22 pagesToyota Avensis DPFCarl Anthony Chamberlain100% (3)

- Phases of Operation - Injection System Magneti Marelli 6LPDocument16 pagesPhases of Operation - Injection System Magneti Marelli 6LPGrizono MassimoPas encore d'évaluation

- 02 K Exhaust Gas RecirculationDocument4 pages02 K Exhaust Gas RecirculationJUAN MANUEL RUIZ BERMEJOPas encore d'évaluation

- Star MazdaDocument40 pagesStar MazdastvnscottPas encore d'évaluation

- On Board DiagnosticsDocument52 pagesOn Board Diagnosticsjayasundar100% (1)

- Weber Injection-Ignition SystemDocument27 pagesWeber Injection-Ignition SystemjohnvandurenPas encore d'évaluation

- Tata Bs IV Final CircularDocument19 pagesTata Bs IV Final CircularD. Nanda KishorePas encore d'évaluation

- FF EcuDocument9 pagesFF EcuEduardo J CondePas encore d'évaluation

- Engine Electronic Governor PurposeDocument2 pagesEngine Electronic Governor PurposeAli AkbarPas encore d'évaluation

- GDIDocument7 pagesGDIlinhda561Pas encore d'évaluation

- DENSO SystemsDocument34 pagesDENSO Systemsthailan100% (3)

- Fuel Injection System Bosch AfcDocument28 pagesFuel Injection System Bosch AfcShivam TandonPas encore d'évaluation

- Detroit 60 Datos BásicosDocument16 pagesDetroit 60 Datos Básicosvictorhernandezrega100% (1)

- 2.5l Cec SystemDocument37 pages2.5l Cec Systemdaniel lacerdaPas encore d'évaluation

- Sfi SystemDocument96 pagesSfi SystemWawan SatiawanPas encore d'évaluation

- Automotive Electronics - Vol 2Document40 pagesAutomotive Electronics - Vol 2Victor Balas100% (14)

- Technical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisDocument13 pagesTechnical Service Bulletin: Exhaust Gas Recirculation (Egr) System DiagnosisWilliam J. BurnorePas encore d'évaluation

- Engine Managment System PDFDocument9 pagesEngine Managment System PDFDilanWijerathnaPas encore d'évaluation

- Need of Variable Valve ActuationDocument5 pagesNeed of Variable Valve Actuationjayendrakashyap01Pas encore d'évaluation

- Em MissionsDocument3 pagesEm Missionsภูเก็ต เป็นเกาะPas encore d'évaluation

- 300 KW Electric Power Station Components: Commercial OfferDocument5 pages300 KW Electric Power Station Components: Commercial OfferLong Leo100% (1)

- Топливная Система Siemens Sid 201Document105 pagesТопливная Система Siemens Sid 201Vytautas Mackonis67% (3)

- AC DescriptionDocument7 pagesAC DescriptionrxhughesPas encore d'évaluation

- Modern Automotive Technologies: UNIT-1 Advanced Engine ControlDocument9 pagesModern Automotive Technologies: UNIT-1 Advanced Engine ControlMd zakirPas encore d'évaluation

- Isuzu EngineDocument53 pagesIsuzu EngineSmaileRun78% (18)

- Engine Data Display Table: Parameter Unit ValueDocument45 pagesEngine Data Display Table: Parameter Unit ValuedavidPas encore d'évaluation

- Engine PADocument49 pagesEngine PAlartsim115Pas encore d'évaluation

- 4.0L Cec System: 1988 Jeep CherokeeDocument17 pages4.0L Cec System: 1988 Jeep CherokeefredericdiPas encore d'évaluation

- Crdi BoshDocument61 pagesCrdi BoshIsmahan Ochi Noro100% (1)

- Knjiga596 617Document22 pagesKnjiga596 617jovopavlovicPas encore d'évaluation

- AssignmentDocument5 pagesAssignmentSai DivakarPas encore d'évaluation

- Lecture 06Document16 pagesLecture 06Ekoms GamingPas encore d'évaluation

- Public (Step1)Document207 pagesPublic (Step1)gerallazo29Pas encore d'évaluation

- Ec240 Volvo 1 102Document102 pagesEc240 Volvo 1 102Muriel Remberto100% (23)

- Group 17 Emission ControlDocument33 pagesGroup 17 Emission ControlClaudio Rene Silva HernandezPas encore d'évaluation

- Libro InstructorDocument62 pagesLibro InstructorTHOMAS NGPas encore d'évaluation

- Electronic Fuel Injection System: Contributions and Challenges For Light VehiclesDocument22 pagesElectronic Fuel Injection System: Contributions and Challenges For Light VehiclesRoba FikaduPas encore d'évaluation

- Lect 1-Efi Petrol 3HRSDocument50 pagesLect 1-Efi Petrol 3HRSHodge LornePas encore d'évaluation

- Module 14 Propulsion Notes-3 PDFDocument5 pagesModule 14 Propulsion Notes-3 PDFastikPas encore d'évaluation

- Egine Control System: GeneralDocument18 pagesEgine Control System: GeneralAdrianoTHEPas encore d'évaluation

- Sensors and ActuatorsDocument25 pagesSensors and Actuatorsyk_maddy100% (4)

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SD'EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SPas encore d'évaluation

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGD'EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGPas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitD'EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitPas encore d'évaluation

- V6 Auto TransDocument9 pagesV6 Auto Trans08088338Pas encore d'évaluation

- g3 Air System AbaDocument15 pagesg3 Air System Aba08088338Pas encore d'évaluation

- Technical Service Bulletin: Sorento Digital Clock Losing TimeDocument4 pagesTechnical Service Bulletin: Sorento Digital Clock Losing Time08088338Pas encore d'évaluation

- Kia Sorento 2.4 ChargerDocument1 pageKia Sorento 2.4 Charger08088338Pas encore d'évaluation

- Technical Service Bulletin: - DescriptionDocument4 pagesTechnical Service Bulletin: - Description08088338Pas encore d'évaluation

- Water Pump Cleaning and InspectionDocument1 pageWater Pump Cleaning and Inspection08088338Pas encore d'évaluation

- General Body Construction Unibody DescriptionDocument3 pagesGeneral Body Construction Unibody Description08088338Pas encore d'évaluation

- Data Link Communications Description and OperationDocument1 pageData Link Communications Description and Operation08088338Pas encore d'évaluation

- Engine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l LmuDocument1 pageEngine Coolant Fan Replacement 1 0l LMT 1 19l Lc5 and 1 2l Lmu08088338Pas encore d'évaluation

- Subaru WRX 97 To 98 Full PinoutsDocument1 pageSubaru WRX 97 To 98 Full Pinouts08088338Pas encore d'évaluation

- Evaporative Emission Control System DescriptionDocument1 pageEvaporative Emission Control System Description08088338Pas encore d'évaluation

- 2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: FuelDocument1 page2005 Audi A6 / Quattro (4F) : Submodel: Engine Type: Liters: Fuel Delivery: Fuel08088338Pas encore d'évaluation

- S53 Manual TransaxleDocument2 pagesS53 Manual Transaxle08088338Pas encore d'évaluation

- 231Document4 pages23108088338Pas encore d'évaluation

- 13 ToyotaDocument105 pages13 Toyota0808833867% (3)

- Ford 30 V600Document7 pagesFord 30 V60008088338Pas encore d'évaluation

- 307-01 - Digital Transmission Range (TR) SensorDocument6 pages307-01 - Digital Transmission Range (TR) Sensor08088338Pas encore d'évaluation

- Circuit Diagram: Luggage Compartment Light Ceiling LampDocument1 pageCircuit Diagram: Luggage Compartment Light Ceiling Lamp08088338Pas encore d'évaluation

- Circult DiagramDocument1 pageCircult Diagram08088338Pas encore d'évaluation

- Xtunter-E3 User Manual v8.4Document62 pagesXtunter-E3 User Manual v8.408088338Pas encore d'évaluation

- DTC P1602 Deterioration of Battery: DescriptionDocument5 pagesDTC P1602 Deterioration of Battery: DescriptionEdy SudarsonoPas encore d'évaluation

- Celitron ISS 25L - Product Spec Sheet V 2.1 enDocument9 pagesCelitron ISS 25L - Product Spec Sheet V 2.1 enyogadwiprasetyo8_161Pas encore d'évaluation

- Chemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDocument1 pageChemical Analysis and Mechancial Test Certificate: Yield Strength Tensile Strength ElongationDigna Bettin CuelloPas encore d'évaluation

- Lesson Plan in Advanced Chemistry AlcohoDocument17 pagesLesson Plan in Advanced Chemistry AlcohoGlaiza Mapute CaringalPas encore d'évaluation

- The Human Body: An Orientation: Part ADocument10 pagesThe Human Body: An Orientation: Part ARoi Christoffer Jocson PeraltaPas encore d'évaluation

- Ne XT ProtDocument2 pagesNe XT Protwilliam919Pas encore d'évaluation

- Intraocular Pressure and Aqueous Humor DynamicsDocument36 pagesIntraocular Pressure and Aqueous Humor DynamicsIntan EkarulitaPas encore d'évaluation

- 351 UN 1824 Sodium Hydroxide SolutionDocument8 pages351 UN 1824 Sodium Hydroxide SolutionCharls DeimoyPas encore d'évaluation

- TCM Reach TrucksDocument5 pagesTCM Reach TrucksMuhammad SohailPas encore d'évaluation

- Epoxy Data - AF35LVE TDS - ED4 - 11.17Document8 pagesEpoxy Data - AF35LVE TDS - ED4 - 11.17HARESH REDDYPas encore d'évaluation

- The Development of Attachment in Separated and Divorced FamiliesDocument33 pagesThe Development of Attachment in Separated and Divorced FamiliesInigo BorromeoPas encore d'évaluation

- Mon AnhDocument7 pagesMon AnhDavid NguyenPas encore d'évaluation

- Main CatalogueDocument12 pagesMain Catalogueferpa_ferPas encore d'évaluation

- Margarita ForesDocument20 pagesMargarita ForesKlarisse YoungPas encore d'évaluation

- Installation Manual: 1.2 External Dimensions and Part NamesDocument2 pagesInstallation Manual: 1.2 External Dimensions and Part NamesSameh MohamedPas encore d'évaluation

- Usp 1078 Good Manufacturing Practices For Bulk Pharmaceutical Excipients PDFDocument13 pagesUsp 1078 Good Manufacturing Practices For Bulk Pharmaceutical Excipients PDFMayson BaliPas encore d'évaluation

- Research Activity #2Document2 pagesResearch Activity #2Shania GualbertoPas encore d'évaluation

- Class 7 Work Book Answers Acid Bases and SaltsDocument2 pagesClass 7 Work Book Answers Acid Bases and SaltsGaurav SethiPas encore d'évaluation

- 2013 Audi A5 Cabriolet s5 Cabriolet 8Document16 pages2013 Audi A5 Cabriolet s5 Cabriolet 8Adrio BianchiPas encore d'évaluation

- Evidence-Based Strength & HypertrophyDocument6 pagesEvidence-Based Strength & HypertrophyAnže BenkoPas encore d'évaluation

- The Coca-Cola Company - Wikipedia, The Free EncyclopediaDocument11 pagesThe Coca-Cola Company - Wikipedia, The Free EncyclopediaAbhishek ThakurPas encore d'évaluation

- WCC PSV PDFDocument40 pagesWCC PSV PDFAlejandro RamelaPas encore d'évaluation

- Broucher Design - 02Document8 pagesBroucher Design - 02ಉಮೇಶ ಸಿ. ಹುಕ್ಕೇರಿ ಹುಕ್ಕೇರಿPas encore d'évaluation

- City of Atlanta - Structural Checklist: All Items Listed Herein Shall Be Complied With If Applicable To The ProjectDocument16 pagesCity of Atlanta - Structural Checklist: All Items Listed Herein Shall Be Complied With If Applicable To The ProjectSandip SurPas encore d'évaluation

- AACO 7th Aviation Fuel Forum: AttendanceDocument3 pagesAACO 7th Aviation Fuel Forum: AttendanceJigisha Vasa0% (1)

- Teleperformance Global Services Private Limited: Full and Final Settlement - December 2023Document3 pagesTeleperformance Global Services Private Limited: Full and Final Settlement - December 2023vishal.upadhyay9279Pas encore d'évaluation

- Transmission Lines SMART EDGE VILLARUEL For April 2024 v1Document89 pagesTransmission Lines SMART EDGE VILLARUEL For April 2024 v1mayandichoso24Pas encore d'évaluation

- Sithpat006ccc019 A - 2021.1Document34 pagesSithpat006ccc019 A - 2021.1Mark Andrew Clarete100% (2)

- Rrs PresentationDocument69 pagesRrs PresentationPriyamvada Biju100% (1)