Académique Documents

Professionnel Documents

Culture Documents

8205 2 PDF

Transféré par

Yang WuTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

8205 2 PDF

Transféré par

Yang WuDroits d'auteur :

Formats disponibles

Standing pipe support, side movable, for pipes with heat

insulation, surrounding pipe support, slide bearing and

fixed point, ferritic steel

temperature 20 C to 300 C; nominal diameter 25 to 200

Werknorm

8205-2

August 2001

Replaces Standard 8205

version 08.00

Dimensions in mm

Contents

Page

Layout, pipe configuration.......................................................................................................... 1

Pipe supports, dimensions, weights and drawing number ........................................................ 2

Mounting the pipe support ......................................................................................................... 7

Mounting system types A, B and C............................................................................................ 7

Mounting system types D1 and D2 ............................................................................................ 9

Pipeline thermal expansion...................................................................................................... 11

1

2

3

3.1

3.2

4

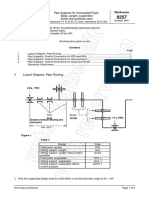

Layout, pipe configuration

Pos. U

FPSL

FPS

Pos. V

Pos. U

SBS

SBSL

FPS

Distance bearing to fixed point

max. 30 m

Fig. 1.

Table 1.

Designation

SBS

Dim. standard

CS 8202-2

SBSL, U, V

CS 8205-2

Fixed point, standing

FPS

CS 8202-2

Fixed point, standing, side movable

FPSL

CS 8205-2

Slide bearing, standing

Slide bearing, standing, side movable

Standards Leverkusen

Code

Page 1 of 12

Werknorm 8205-2 August 2001

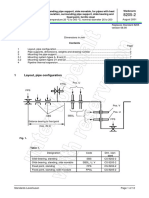

Pipe supports are selected on the basis of Company Standard 8202-1 according to:

-

outside pipe diameter

temperature (inside pipe temperature)

insulation thickness

For longer distances, slide bearing length l1 must be checked and corrected as needed. The diagram in Fig.

8 on page 11 showing thermal expansion, fixed-point distances and temperature differences is intended as

an aid.

The specific pipe support type is determined with reference to the required insulation thickness s1 and the

base dimension h1.

Pipe support type 6 as shown in the standard drawings is specified for pipe supports conforming to this standard in which criteria (e.g. space problems, access) other than insulation thickness s1 (inside pipe temperature) must be taken into account in determining h1.

Pipe supports, dimensions, weights and drawing number

h2

h1

h3

d1

s1

SBSL-type pipe supports for mountings system types A, B and C

T 80

l1

SBSL: Inside pipe temperature

20 C to 200 C

l1 = 200 mm

over 200 C to 300 C

l1 = 300 mm

Insulation thickness s1 is selected with reference to inside pipe diameter in accordance with CS 8101-1.

Fig. 2. SBSL-type supports for mounting system types A, B and C

SBSL pipe supports for mounting system types D1 and D2 correspond to FPS as specified in CS 8202-2

Standards Leverkusen

Page 2 of 12

Werknorm 8205-2 August 2001

s1

FPSL for mounting system types A, B and C, l1 = 200 mm

h3

d1

h2

h1

A

5

l1

A-A

Nocken

L- Stahl DIN 102

Cam, angle steel

DN 25 bis DN 50 L20x3x30

DN 65 bis DN 200 L30x4x50

ND 25 to ND 50 L20x3x30

ND 65 to ND 200 L30x4x50

Fig. 3. FPSL-type supports for mounting system types A, B and C

FPSL pipe supports for mounting system types D1 and D2 correspond to FPS as specified in CS 8202-1

FPSL pipe supports for mounting system types A, B and C must have drilled holes measuring 18. The position of the holes depends upon the mounting system, which is shown in the diagram in Section 3.1. Additional parts (flat steel bar 25x8x15) are also welded to FPSL-type pipe supports for mounting system types

D1 and D2. See Section 3.2 for positioning

Table 2. Dimension h1 for SBSL and FPSL pipe supports

Pipe

h1

Nominal

diameter

d1

40

Insulation thickness s1

60

80

100

25

33.7

102

122

142

162

32

42.4

106

126

146

166

40

48.3

109

129

149

169

189

50

60.3

116

136

156

176

196

65

76.1

124

144

164

184

204

80

88.9

130

150

170

190

210

100

114.3

145

165

185

205

225

125

139.7

158

178

198

218

238

150

168.3

172

192

212

232

252

200

219.1

198

218

238

258

278

Pipe support type

120

Nomenclature for a pipe support for a ND 50 pipe, Slide bearing, standing, side movable,

Temperature to 200 C, insulation thickness s1 = 60 mm, prepared for mounting system type A1,

anti-corrosion treatment as specified in CS 8110-F:

Pipe support 8205-2-50 SBSL 200-60 A1-F

Standards Leverkusen

Page 3 of 12

Werknorm 8205-2 August 2001

Nomenclature for a pipe support for a ND 50 pipe, Fixed point, standing, side movable, temperature up to

200 C, insulation thickness s1 = 60 mm, prepared for mounting system type A1,

anti-corrosion treatment as specified in CS 8110-F:

Pipe support CS 8205-2-50 FPSL 200-60 A1-F

Table 3. Dimensions h2 and h3 for pipe supports made of T steel in accordance with DIN

1024 for SBSL pipe supports and mounting system types A, B and C

Pipe

h2+h3 or. h2-h3

Insulation thickness s1

Nominal

diameter

d1

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

40

60

80

100

80+20

80+0

100+40

100+20

120+0

1

120-20 )

1

120-40 )

140-40 )

120+40

120+20

100+0

100-20 )

120

140+20

140+0

2

140-20 )

140 )

160 )

1) The bridge of the T profile must be reduced by the value of h3.

2) These pipe supports are made of flat iron. For details see drawings based on Tables 7 and 8.

Table 4. Dimensions h2 and h3 for pipe supports made of T steel in accordance with DIN

1024 for FPSL pipe supports and mounting system types A, B and C

Pipe

h2+h3 or h2-h3

Insulation thickness s1

Nominal

diameter

25

33.7

32

42.4

40

48.3

50

60.3

65

76.1

80

88.9

100

114.3

125

139.7

150

168.3

200

219.1

d1

40

60

80

100

80+20

80+0

100+40

100+20

120+0

120-20 )

1

120-40 )

140-40 )

120+40

120+20

100+0

100-20 )

120

140+20

140+0

2

140-20 )

140 )

160 )

1) The bridge of the T profile must be shortened by the value h3 for pipe supports.

2) The pipe supports are made of flat iron. For details see the drawings based on Tables 7 and 8.

Standards Leverkusen

Page 4 of 12

Werknorm 8205-2 August 2001

Table 5. Dimension b for SBSL pipe supports and mounting system types A, B and C

Pipe support base width b

Nominal

diameter

Insulation thickness s1

25

40

80

60

80

80

100

100

100

120

120

32

80

80

100

100

120

40

80

80

100

100

120

50

80

80

100

100

120

65

80

100

100

120

120

80

80

100

100

120

120

100

100

100

120

120

140

125

100

100

120

140

140

150

100

120

120

140

150

200

120

140

140

150

150

Table 6. Dimensions b for FPSL pipe supports and mounting system types A, B and C

Pipe support base width b

Nominal

diameter

Insulation thickness s1

25

40

100

60

100

80

100

100

100

120

120

32

100

100

100

100

120

40

100

100

100

100

120

50

100

100

100

100

120

65

100

100

100

120

120

80

100

100

100

120

120

100

100

100

120

120

140

125

100

100

120

140

140

150

100

120

120

140

150

200

120

140

140

150

150

Standards Leverkusen

Page 5 of 12

Werknorm 8205-2 August 2001

Table 7. Weights for SBSL pipe supports and mounting system types A, B and C, l1 = 200 or 300 mm

3

Nominal

diameter

Weight in kg =7.85 kg/dm

Pipe support base width b

Insulation thickness s1

40

60

80

100

120

Inside pipe temperature 20 C to 200 C and l1 = 200

mm

Pipe support

drawing no.

25

2.87

3.00

4.18

4.30

5.69

LE 994 737-2N

32

2.94

3.06

4.24

4.36

5.75

LE 994 738-2N

40

2.99

3.11

4.29

4.41

5.80

LE 994 739-2N

50

3.47

3.59

4.74

4.86

6.22

LE 994 740-2N

65

3.63

4.77

4.90

6.25

6.38

LE 994 741-2N

80

3.81

4.95

5.08

6.44

6.55

LE 994 742-2N

100

6.48

6.75

8.09

8.22

9.80

LE 994 743-2N

125

6.87

7.14

8.48

10.07

10.19

LE 994 744-2N

150

7.37

8.63

8.98

10.57

8.99

LE 994 745-2N

200

9.42

10.95

11.32

9.84

10.12

LE 994 746-2N

Inside pipe temperature over 200 C to 300 C and

l1 = 300 mm

25

3.94

4.07

5.82

5.94

8.01

32

4.00

4.13

5.88

6.01

8.07

40

4.06

4.18

5.93

6.05

8.12

50

4.54

4.66

6.50

6.63

8.66

65

4.70

6.42

6.54

8.58

8.70

80

4.88

6.59

6.72

8.76

8.88

100

7.95

8.39

10.41

10.53

12.93

125

8.35

8.79

10.80

13.20

13.32

150

8.85

10.77

11.30

13.67

11.35

200

11.36

13.66

14.24

12.03

12.48

Drawing no.

same as for inside pipe temperature

20 C to

200 C

Table 8. Weights for FPSL pipe supports and mounting system types A, B and C, l1 = 200 mm

3

Nominal

diameter

40

Weight in kg =7.85 kg/dm

Pipe support base width b

Insulation thickness s1

60

80

100

120

25

3.70

4.05

4.18

4.30

5.70

LE 994 747-2N

32

3.77

4.11

4.24

4.36

5.76

LE 994 748-2N

40

3.82

4.16

4.29

4.41

5.81

LE 994 749-2N

50

4.30

4.61

4.74

4.86

6.23

LE 994 750-2N

65

4.46

4.77

4.90

6.26

6.39

LE 994 751-2N

80

4.64

4.95

5.08

6.45

6.56

LE 994 752-2N

100

6.48

6.75

8.08

8.21

9.80

LE 994 753-2N

125

6.87

7.14

8.47

10.07

10.19

LE 994 754-2N

150

7.37

8.63

8.97

10.57

8.99

LE 994 755-1N

200

9.42

10.95

11.32

9.84

10.12

LE 994 756-1N

Standards Leverkusen

Page 6 of 12

Werknorm 8205-2 August 2001

Mounting the pipe support

3.1

Mounting system types A, B and C

SBSL

Fig. 4. Mounting system, slide bearing, standing, side movable

Table 9. Parts list for mounting system, slide bearing, standing, side movable, as shown in Fig. 4

Quantity

for

mounting

A

B

C

1

1

1

Pipe support

Pos.

no.

DIN no.

CS no.

Part no.

Remarks

Hex bolt M 16 x 40 Mu

USt 37-2

RSt 37-2

5.6/5-2

galvanized

Hex bolt M 16 x 90 Mu

5.6/5-2

Washer 16

St

DIN EN ISO 4018

DIN EN ISO 4034

DIN EN ISO 4016

DIN EN ISO 4034

DIN EN ISO 7091

1 345 035

Lock washer C 18-F

St 37 - 2

Washer 17,5

St

Slide plate B )

1.4510

CS 8399

1 290 752

DIN 436

1 345 115

CS 8226

Nomenclature

Material

galvanized

2

2

2

) See Table 7 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other anti-corrosion treatment requirements must be indicated in the order.

) Slide plate sizes for Pos. U are listed in Table 10; sizes for Pos. V are listed in Table 11.

Table 10. Pos. U hole-centre distance t2 and slide plate size

Pipe support base width

b

80

100

120

140

150

Standards Leverkusen

Slide plate size

t2

B 225

195

B 265

235

Page 7 of 12

Werknorm 8205-2 August 2001

Table 11. Pos. V hole-centre distance t2 and slide plate size

Inside pipe

temperature C

Slide plate size

t2

20 to 200

B 300

270

over 200 to 300

B 355

325

FPSL

Mounting

Dimension t3 is to be found in Table 13

Fig. 5. Mounting system, fixed point, standing, side movable

Table 12. Parts list for mounting system, fixed point, standing, side movable, as shown in Fig. 5

A1

1

Quantity

for

mounting

A2

B

1

1

Nomenclature

C

1

Pipe support

Material

Pos.

no.

DIN no.

CS no.

Part no.

Remarks

CS 8226

1 292 002

CS 8226

1 292 003

CS 8226

1 292 004

CS 8226

DIN EN ISO 7091

1 345 035

CS 8227/

1 304 506

Slide plate A 100

USt 37-2

RSt 37-2

1.4510

Slide plate A 120

1.4510

Slide plate A 140

1.4510

Separator plate C )

1.4510

Washer 16

St

Hook bolt

M 16 x 32 K

4.6/5

galvanized

) See Table 10 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other anti-corrosion treatment requirements

must be indicated in the order.

3

) Separator plates sizes are listed in Table 13.

2

Table 13. Dimension t3 and separator plates size for mounting system type C

Pipe support base width

b

Slide plate size

t3

100

C 100

60

120

140

150

Standards Leverkusen

70

C 140

80

80

Page 8 of 12

Werknorm 8205-2 August 2001

3.2

Mounting system types D1 and D2

SBSL

Mounting system D

Fig. 6. Mounting system, slide bearing, standing, side movable, with guide bearing

Table 14. Parts list for mounting system, slide bearing, standing, side movable, with guide bearing as shown

in Fig. 6

Quantity

for

mounting

D1

D2

Nomenclature

Material

Pos.

no.

Pipe support

USt 37-2

RSt 37-2

Guide bearing

GTW 40

DIN no.

Drawing no.

Part no.

Remarks

Hesterberg Co.

)

)

GTW 40

Hesterberg Co.

Hex bolt M 12 x 150 Mu

5.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Hex bolt M 12 x 170 Mu

5.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Guide bearing

) See Table 10 for individual part drawings.

) Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other anti-corrosion treatment requirements

must be indicated in the order.

Standards Leverkusen

Page 9 of 12

Werknorm 8205-2 August 2001

FPSL

Mounting system D

Pos. 4 for

mounting

system D1

Pos. 4 for

mounting

system D2

Fig. 7. Mounting system, fixed point, standing, side movable, with guide bearings

Table 15. Parts list for mounting system, standing, side movable, as shown in Fig. 7

Quantity

for

mounting

D1

D2

Material

Pos.

no.

Pipe support

USt 37-2

RSt 37-2

Nomenclature

DIN no.

Drawing no.

Part , no.

Remarks

Guide bearing

GTW 40

Hesterberg Co.

Guide bearing

GTW 40

Hesterberg Co.

Hex bolt M 12 x 150 Mu

5.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Hex bolt M 12 x 170 Mu

5.6/5-2

DIN EN ISO 4016

DIN EN ISO 4034

galvanized

Flat steel bar 25 x 8 x 15

USt 37-2

DIN 1017-1

)

)

1)

See Table 5 for individual part drawings, l1 = 200 mm.

2)

Anti-corrosion treatment as specified in CS 8110-F, hot-galvanized. Other anti-corrosion treatment requirements must be indicated in the order.

Standards Leverkusen

Page 10 of 12

Werknorm 8205-2 August 2001

Pipeline thermal expansion

Dist. from fixed point

Fig. 8. Thermal expansion: ferritic steel

Standards Leverkusen

Page 11 of 12

Werknorm 8205-2 August 2001

List of standards cited

DIN 436

Square washers for use in timber constructions

DIN 1014-1

Steel bars; Hot rolled squares for general purpose; Dimensions, permissible deviations

on dimension and form

DIN 1017-1

Steel bars; Hot rolled flat steel for general purpose; Dimensions, weights, permissible

variations

DIN 1025-2

Hot-rolled I-beams; Part 2: Wide flange I-beams, IPB series; Dimensions, masses,

sectional properties

DIN EN 10 056-1

Structural steel equal and unequal leg angles; Part 1: Dimensions; German version

EN 10056-1:1998

DIN EN 10 278

Dimensions and tolerances of bright steel products; German version

EN 10 278 :1999

DIN EN ISO 4016

Hexagon head bolts; Product grade C (ISO 4016:1999); German version

EN ISO 4016:2000

DIN EN ISO 4018

Hexagon head screws; Product grade C (ISO 4018:1999); German version

EN ISO 4018:2000

DIN EN ISO 4034

Hexagon nuts; Product grade C (ISO 4034:1999); German version EN ISO 4034:2000

DIN EN ISO 7091

Plain washers; Normal series; Product grade C (ISO 7091:2000); German version

EN ISO 7091:2000

CS 8101-1

Heat insulation; insulation layer thickness, definitions, terms

CS 8110

Pipe supports; anti-corrosion treatment; specifications

CS 8202-2

Pipe supports, standing, for pipes with heat insulation, surrounding pipe support, slide

bearing and fixed point; ferritic steel, temperature 20 C to 300 C; nominal diameter

25 to 200

CS 8226

Pipe supports; slide plates and separator plates for piping, ND 25 to

ND 200

CS 8227

Pipe supports; hook bolts

CS 8250

Pipe supports; pipe clamps for nominal diameters 15 to 1000

CS 8252

Pipe supports; pipe clamps for nominal diameters 25 to 500

CS 8399

Pipe supports; lock washer for double-angle bridges

Previous versions

CS 8205: 1970-12; 1974-05; 1976-05; 1980-11; 1982-04; 1988-09; 1998-10; 2000-08

Changes

The following changes were made to the version of August 2000:

a) Company standard 8205 was revised and issued separately CS 8205-2 for ferritic steel.

b) DIN standards updated.

Standards Leverkusen

Page 12 of 12

Vous aimerez peut-être aussi

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- 8202 2Document10 pages8202 2Yang WuPas encore d'évaluation

- 8217 2Document7 pages8217 2Yang WuPas encore d'évaluation

- Werknorm: Layout Diagram, Pipe RoutingDocument6 pagesWerknorm: Layout Diagram, Pipe RoutingYang WuPas encore d'évaluation

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Bayer: Pipes With Low-Temperature Insulation, SuspendedDocument5 pagesBayer: Pipes With Low-Temperature Insulation, SuspendedYang WuPas encore d'évaluation

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- PL 008748Document10 pagesPL 008748ronaldxmenPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Catalog Tevi Pag FDocument12 pagesCatalog Tevi Pag FGPPas encore d'évaluation

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosPas encore d'évaluation

- Boq (110912)Document144 pagesBoq (110912)Ali AlaliPas encore d'évaluation

- Pocket Guide to Flanges, Fittings, and Piping DataD'EverandPocket Guide to Flanges, Fittings, and Piping DataÉvaluation : 3.5 sur 5 étoiles3.5/5 (22)

- La Royal LaborDocument7 pagesLa Royal LaborDEVSHILPI ARCHITECTSPas encore d'évaluation

- 16620YDocument17 pages16620YbalajivangaruPas encore d'évaluation

- Arcing DevicesDocument10 pagesArcing DevicessalvandyPas encore d'évaluation

- 12/1/2021 /conversion/tmp/activity - Task - Scratch/561025520Document10 pages12/1/2021 /conversion/tmp/activity - Task - Scratch/561025520htanhPas encore d'évaluation

- PipingDocument7 pagesPipingAshar HassanPas encore d'évaluation

- Boq Msgq-Burkina Faso-V & AcDocument4 pagesBoq Msgq-Burkina Faso-V & AcFadi AbdelnourPas encore d'évaluation

- Victaulic Cs Spec To 24 In.Document10 pagesVictaulic Cs Spec To 24 In.Luis HernandezPas encore d'évaluation

- 23 21 00 - Hydronic PipingDocument8 pages23 21 00 - Hydronic PipingLoraine AnnPas encore d'évaluation

- Datasheet Capacitor YAGEODocument10 pagesDatasheet Capacitor YAGEOrafaelfernandes183Pas encore d'évaluation

- Flexible Metal HosesDocument16 pagesFlexible Metal Hosesyoonchankim0911Pas encore d'évaluation

- Rev DDocument21 pagesRev Dpsn1234567890Pas encore d'évaluation

- Sonda Temperatura Wika DS TE6010 GB 2032Document6 pagesSonda Temperatura Wika DS TE6010 GB 2032Emilio AlmedaPas encore d'évaluation

- Duplex Stainless Steels by ArcelorMittal - 930koDocument11 pagesDuplex Stainless Steels by ArcelorMittal - 930koSampath Kumar YerraPas encore d'évaluation

- Valvula Mariposa 705 VictaulicDocument7 pagesValvula Mariposa 705 Victaulicrvalentino2012Pas encore d'évaluation

- SECTION 22 05 29 Hangers and Supports For Plumbing Piping and EquipmentDocument6 pagesSECTION 22 05 29 Hangers and Supports For Plumbing Piping and Equipmentmichael_george291616Pas encore d'évaluation

- ALPEMA Standards Rev1Document8 pagesALPEMA Standards Rev1nattusharanPas encore d'évaluation

- Hydraulic Tubes and PipesDocument18 pagesHydraulic Tubes and Pipeshp_vijaykPas encore d'évaluation

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongPas encore d'évaluation

- Steel Supply Sub-Grades To EC3Document22 pagesSteel Supply Sub-Grades To EC3Anonymous iS33V5Pas encore d'évaluation

- HTC.netDocument4 pagesHTC.netVinod KumarPas encore d'évaluation

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDocument32 pagesI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- rc61180 b09Document9 pagesrc61180 b09eww08Pas encore d'évaluation

- La Royal SupplyDocument7 pagesLa Royal SupplyDEVSHILPI ARCHITECTSPas encore d'évaluation

- Bimetal Thermometers Model 52, Industrial Series: ApplicationsDocument4 pagesBimetal Thermometers Model 52, Industrial Series: ApplicationsAhrian BenaPas encore d'évaluation

- Steam and Condensate Piping Design BasicsDocument21 pagesSteam and Condensate Piping Design BasicsVIVEKZI0Pas encore d'évaluation

- 04 - Buttweldfitt Ellbows Din2605 PDFDocument8 pages04 - Buttweldfitt Ellbows Din2605 PDFJacob HarrisPas encore d'évaluation

- Din 8074 Pehd PipesDocument20 pagesDin 8074 Pehd PipesAli MkawarPas encore d'évaluation

- Pipe and TubesDocument12 pagesPipe and TubesTn MuralidharaPas encore d'évaluation

- 1/27/2019 /conversion/tmp/scratch/407716113Document10 pages1/27/2019 /conversion/tmp/scratch/407716113Maki DizonPas encore d'évaluation

- Materials and Cold Work of Forming: 2.1 Steel StandardsDocument23 pagesMaterials and Cold Work of Forming: 2.1 Steel Standardshunter8080Pas encore d'évaluation

- 159 Pul-Si: Vishay BccomponentsDocument8 pages159 Pul-Si: Vishay BccomponentsteomondoPas encore d'évaluation

- Tubos Huecos Seccion Cuadrada - PROTUBSADocument56 pagesTubos Huecos Seccion Cuadrada - PROTUBSACarlos Di Perna AriniPas encore d'évaluation

- 61502YDocument9 pages61502YbalajivangaruPas encore d'évaluation

- CS PipingDocument15 pagesCS PipingJavierSeimanPas encore d'évaluation

- 8249Document13 pages8249Yang WuPas encore d'évaluation

- Typical Solar BQDocument7 pagesTypical Solar BQngarinyagaPas encore d'évaluation

- DW144 Smacna 2005Document32 pagesDW144 Smacna 2005Angel Daniel GarciajoyaPas encore d'évaluation

- Thyssenkrupp Materials International: Material Data SheetDocument4 pagesThyssenkrupp Materials International: Material Data SheetjaseerkannothPas encore d'évaluation

- Boq For RSP Ccas PipingDocument3 pagesBoq For RSP Ccas Pipingkoushikdey_2011Pas encore d'évaluation

- Stainless Steel Needle Tubing: Standard Specification ForDocument2 pagesStainless Steel Needle Tubing: Standard Specification Formalika_00Pas encore d'évaluation

- Seamless Copper Water Tube (Metric) : Standard Specification ForDocument7 pagesSeamless Copper Water Tube (Metric) : Standard Specification ForCarlos VegaPas encore d'évaluation

- Rectangular Duct AtteDocument4 pagesRectangular Duct AtteShahrukh AnsariPas encore d'évaluation

- 3051CDocument5 pages3051CAntonio FloresPas encore d'évaluation

- NHC NHU NH60Hz IA144-CDocument9 pagesNHC NHU NH60Hz IA144-CYang WuPas encore d'évaluation

- Astm, Ks-Jis-Din Material Comparison Tables (Part 1)Document5 pagesAstm, Ks-Jis-Din Material Comparison Tables (Part 1)Yang WuPas encore d'évaluation

- B 45-75kW IA102-BDocument7 pagesB 45-75kW IA102-BYang WuPas encore d'évaluation

- B Ia110-LDocument9 pagesB Ia110-LYang WuPas encore d'évaluation

- B 45-75kW IA102-BDocument7 pagesB 45-75kW IA102-BYang WuPas encore d'évaluation

- Equivalent ASTM MaterialDocument34 pagesEquivalent ASTM Materialgolf0910251891% (45)

- Astm Mto ListDocument4 pagesAstm Mto ListYang WuPas encore d'évaluation

- Wns Type Energy-Saving BoilerDocument14 pagesWns Type Energy-Saving BoilerYang WuPas encore d'évaluation

- NHC NHU NH60Hz IA144-CDocument9 pagesNHC NHU NH60Hz IA144-CYang WuPas encore d'évaluation

- Bechtek Piping Material ClassDocument34 pagesBechtek Piping Material ClassBari Ipung GunturPas encore d'évaluation

- Wns Type Energy-Saving BoilerDocument14 pagesWns Type Energy-Saving BoilerYang WuPas encore d'évaluation

- Bayer AGDocument5 pagesBayer AGYang WuPas encore d'évaluation

- 60hz Cast Iron Pump ChineseDocument2 pages60hz Cast Iron Pump ChineseYang WuPas encore d'évaluation

- Bechtek Piping Material ClassDocument34 pagesBechtek Piping Material ClassBari Ipung GunturPas encore d'évaluation

- Explant-I User GuideDocument28 pagesExplant-I User GuideXinggrage NihPas encore d'évaluation

- HsaDocument11 pagesHsaYang WuPas encore d'évaluation

- ch29 733 744Document12 pagesch29 733 744Yang WuPas encore d'évaluation

- Betco ScaffoldDocument52 pagesBetco ScaffoldezzularabPas encore d'évaluation

- Catalogue Dorpa enDocument12 pagesCatalogue Dorpa enYang WuPas encore d'évaluation

- Getting Started With Final DesignerDocument50 pagesGetting Started With Final DesignerManny MendozaPas encore d'évaluation

- Explant-A User GuideDocument14 pagesExplant-A User GuideFaizal SattuPas encore d'évaluation

- 1 Layout, Pipe ConfigurationDocument12 pages1 Layout, Pipe ConfigurationYang WuPas encore d'évaluation

- Bayer AGDocument5 pagesBayer AGYang WuPas encore d'évaluation

- 8249Document13 pages8249Yang WuPas encore d'évaluation

- 8214 2Document11 pages8214 2Yang WuPas encore d'évaluation