Académique Documents

Professionnel Documents

Culture Documents

210479820563440B840B297C6C79B23C

Transféré par

yashvantDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

210479820563440B840B297C6C79B23C

Transféré par

yashvantDroits d'auteur :

Formats disponibles

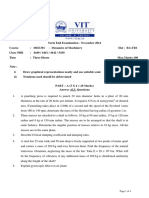

Inter Session Examination - December 2013

Course

: MEE304

Class NBR

: 1265

Time

: Three Hours

- Turbomachines

Slot: A1+A2

Max.Marks:100

(Steam and gas tables will be permitted)

Answer any TEN Questions

(10 X 10 = 100 Marks)

1.

Define total-to-total and total-to-static efficiencies for gas turbines. Give the situations

where these efficiencies are used. State the reasons.

2.

a) A low pressure air compressor develops a pressure of 1500 mm W.G. If the initial

and final states of air are P1 = 1.02 bar, T1 = 300 K and T2 = 315 K, determine the

compressor and the infinitesimal stage efficiencies.

b) Another compressor changes the state of air from P1 = 1.02 bar, T1 = 300 K and

P2 = 2.5 bar with an efficiency of 75%. Determine the infinitesimal efficiency of this

compressor.

Explain the large deviation in the efficiency of this compressor from that of the L.P

compressor in (a)

3.

Define the following terms:

(a) Stagnation temperature

(b) Stagnation velocity of sound

(c) Stagnation density

(d) Adiabatic flow through nozzle

4.

A centrifugal blower with a radial impeller produces a pressure equivalent to 100 cm

column of water. The pressure and temperature at its entry are 0.98 bar and 310 K. The

electric motor driving the blower runs at 3000 rpm. The efficiencies of the fan and drive

are 82% and 88% respectively. The radial velocity remains constant and has a value of

0.2u2. The velocity at the inner eye is 0.4u2. If the blower handles 200 m3/min of air at

the entry conditions, determine:

(a) Power required by the electric motor,

(b) Impeller diameter,

Page 1 of 3

(c) Air angle at entry,

(d) Inner diameter of the blade ring,

(e) Impeller width at entry and exit,

(f) Specific speed.

5.

Sketch an axial fan stage with an inlet nozzle, UGVs, DGVs and outlet diffuser. Show

the variation of static pressure through such a stage. Draw the velocity triangles at the

entry and exit of the impeller.

6.

Air enters the inducer section of a centrifugal compressor at P01 = 1.02 bar, T01 = 335K.

The hub and tip diameters of the impeller eye are 10 cm and 25 cm respectively. If the

compressor runs at 7200 rpm and delivers 5.0 kg/s of air, determine the air angle at the

inducer blade entry and the relative Mach number. If IGVs are used to obtain a straight

inducer section, determine the air angles at the IGVs exit and the new value of the

relative Mach number.

7.

Explain with neat sketch the enthalpy-entropy diagram for flow through a centrifugal

compressor stage.

8.

A ninety degree IFR turbine stage has the following data:

Total-to-static pressure ratio

P01/P3 = 3.5

Exit pressure

1 bar

Stagnation pressure at entry

650C

Blade-to isentropic speed ratio

= 0.66

Rotor diameter ratio

d1/d2 =0.45

Rotor speed

N = 16000 rpm

Nozzle exit air angle

2 =20

Nozzle efficiency

N =0.95

Rotor width at entry

b2 =5 cm

Assuming constant meridional velocity, axial exit and that the properties of the working

fluid are the same as those of air, determine the following quantities:

(a) The rotor diameter, (b) the rotor blade exit air angle, (c) the mass-flow rate, (d) the

hub and tip diametersat the rotor exit (e) the power developed and (f) the total-to-static

efficiency of the stage.

9.

Draw the sketch of a ninety degree inward-flow radial turbine stage with an exit diffuser

showing its main components. What are the main advantages of this type over the other

types of inward-flow gas turbines.

Page 2 of 3

10.

A centrifugal pump delivers water against a net head of 14.5 meters and a design speed

of 1000 rpm. The vanes are curved back to an angle of 30 with the periphery. The

impeller diameter is 300 mm and outlet width 50 mm. Determine the discharge of the

pump if manometric efficiency is 95%.

11.

Obtain an expression for the work done by the centrifugal pump on water.

12.

A pelton wheel has a mean bucket speed of 10 metres per second with a jet of water

flowing at the rate of 0.70 m3/s under a head of 30 metres. The bucket deflects the jet

through an angle of 160. Calculate the power given by the water to the runner and the

hydraulic efficiency of the turbine. Assume co-efficient of velocity as 0.98.

13.

A Francis turbine with an overall efficiency of 75% is required to produce 148.25 kW

power. It is working under a head of 7.62 m. The peripheral velocity =0.26 2

. The

wheel runs at 150 rpm and the hydraulic losses in the turbine are 22% of the available

energy. Assuming radial discharge, determine :

(a) The guide blade angle, (b) The vane angle at inlet,

(c) Diameter of the wheel at inlet, and (d) Width of the wheel at inlet.

Page 3 of 3

Vous aimerez peut-être aussi

- Steam Engines Machinery's Reference Series, Number 70D'EverandSteam Engines Machinery's Reference Series, Number 70Pas encore d'évaluation

- 7ADC8292A41A4EB196A3FFDEE99589FDDocument4 pages7ADC8292A41A4EB196A3FFDEE99589FDyashvantPas encore d'évaluation

- Turbomachines Jan 2014Document2 pagesTurbomachines Jan 2014Prasad C M100% (1)

- Page 1 of 3Document3 pagesPage 1 of 3yashvantPas encore d'évaluation

- Propulsion 1 Unit-V Question Bank (Compressors)Document4 pagesPropulsion 1 Unit-V Question Bank (Compressors)kevintsubasa0% (2)

- Turbo MachinesDocument2 pagesTurbo MachinesDarani PriyaPas encore d'évaluation

- 5TH UnitDocument2 pages5TH UnitHarsha Vardhan GuptaPas encore d'évaluation

- 4 Performance of A Centrifugal FanDocument7 pages4 Performance of A Centrifugal Fanfinix33Pas encore d'évaluation

- Class: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2Document2 pagesClass: B.E. 4/4 Mech-1 Sub: TTM: MVSR Engineering College, Nadergul Department of Mechanical Engineering Assignment-2santhosh bandariPas encore d'évaluation

- Internal-II Question Paper TE - SET-IIDocument2 pagesInternal-II Question Paper TE - SET-IItagoreboopathyPas encore d'évaluation

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsMital PatelPas encore d'évaluation

- 3-QUESTION PAPER TEE 2020 Model PaperDocument2 pages3-QUESTION PAPER TEE 2020 Model PapermvzhvschdbsKPas encore d'évaluation

- 9A03402 Thermal Engineering - IDocument4 pages9A03402 Thermal Engineering - IsivabharathamurthyPas encore d'évaluation

- TurbomachinesDocument2 pagesTurbomachinesThesinghPas encore d'évaluation

- PSet03 TurboB2020Document2 pagesPSet03 TurboB2020Kyillos SaaidPas encore d'évaluation

- ATD - I B.techDocument4 pagesATD - I B.techKarthiKeyanPas encore d'évaluation

- Assignment 6Document3 pagesAssignment 6Muhammad Jawad IsmaeelPas encore d'évaluation

- Centrifugal CompressorDocument2 pagesCentrifugal CompressorAyman EsaPas encore d'évaluation

- Fluid Power EngineeringDocument2 pagesFluid Power EngineeringNilesh Mistry (Nilesh Sharma)Pas encore d'évaluation

- Axial Flow Compressors and Fans - DixDocument4 pagesAxial Flow Compressors and Fans - DixYanganani SindeloPas encore d'évaluation

- Assignment 1 ATDDocument4 pagesAssignment 1 ATDPrashant Singh0% (1)

- Tutorial 4 Turbomachinery v2Document4 pagesTutorial 4 Turbomachinery v2Nik JaffPas encore d'évaluation

- TM 7me4a Question Bank Mid Term IDocument1 pageTM 7me4a Question Bank Mid Term IVijay SharmaPas encore d'évaluation

- Air Compressor System Compressor Fundamentals: IntercoolingDocument56 pagesAir Compressor System Compressor Fundamentals: IntercoolingAmarendra Mani TiwariPas encore d'évaluation

- Sub. Name: Thermal Engineering Sub. Code: ME6404 PART A (5x2 10) (Answer All The Questions)Document2 pagesSub. Name: Thermal Engineering Sub. Code: ME6404 PART A (5x2 10) (Answer All The Questions)Prakash RamakrishnanPas encore d'évaluation

- Assignment I 3rd RegularDocument2 pagesAssignment I 3rd RegularRoha EngineeringPas encore d'évaluation

- Late Submission Is Strictly Not PermittedDocument2 pagesLate Submission Is Strictly Not PermittedChandru APas encore d'évaluation

- According To Bernoulli Equation:: Discharge, Q (M 3/s) Head (M) Pump Power (KW)Document4 pagesAccording To Bernoulli Equation:: Discharge, Q (M 3/s) Head (M) Pump Power (KW)dffd34354Pas encore d'évaluation

- Paper 4A3 2015Document5 pagesPaper 4A3 2015feutseuPas encore d'évaluation

- AE321-Tutorial 7Document3 pagesAE321-Tutorial 7Hritik singh parmarPas encore d'évaluation

- Channabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)Document2 pagesChannabasaveshwara Institute of Technology: (NAAC Accredited & An ISO 9001:2015 Certified Institution)cenu 1999Pas encore d'évaluation

- 08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Document3 pages08cmre44 Thermodynamics-Iii Maximum Hours 3 Hours Total Marks 75 Section - A Answer All The Questions (10x2 20)Senthil AnnaunivPas encore d'évaluation

- ATD Question Bank-Mid 2-V6Document3 pagesATD Question Bank-Mid 2-V6vijayavijju1047Pas encore d'évaluation

- Propulsion Ii Question BankDocument13 pagesPropulsion Ii Question BankSathya NarayananPas encore d'évaluation

- Taller 5 FluidosDocument5 pagesTaller 5 FluidosManuel OlayaPas encore d'évaluation

- Fluid Machinery II Seme2 2006Document2 pagesFluid Machinery II Seme2 2006Arindam MisraPas encore d'évaluation

- Part A and B QB PropulsionDocument3 pagesPart A and B QB Propulsionsrinithims78Pas encore d'évaluation

- Review Problems: Module 1 - CompressorsDocument5 pagesReview Problems: Module 1 - CompressorsJustine Somentac0% (1)

- Applied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetDocument4 pagesApplied Thermal Engineering - II (MEC 316) Unit - 2 Gas Turbines Tutorial SheetShashi Kant KhalkhoPas encore d'évaluation

- Midterm ExaminationDocument2 pagesMidterm ExaminationKristine Joy BagaporoPas encore d'évaluation

- FA B.E. 3/4 (Prod.) II Semi: Part-ADocument2 pagesFA B.E. 3/4 (Prod.) II Semi: Part-ApalreddyPas encore d'évaluation

- Turbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineDocument4 pagesTurbomachinery Problem Sheet 1: General Electric J85-GE-17A Turbojet EngineEchebiri Collins100% (1)

- 01 Model QP - ATD-IDocument2 pages01 Model QP - ATD-ICk DhiyanPas encore d'évaluation

- Mechanical Power Department 4 Year Turbo-Machinery II Centrifugal CompressorDocument5 pagesMechanical Power Department 4 Year Turbo-Machinery II Centrifugal Compressorاحمد تاشهاويPas encore d'évaluation

- Propulsion !Document3 pagesPropulsion !dickandballsPas encore d'évaluation

- Me2301 QBDocument7 pagesMe2301 QBbalajigandhirajanPas encore d'évaluation

- Fluid Power EngineeringDocument4 pagesFluid Power EngineeringrameshsagapariyaPas encore d'évaluation

- Fluid Machine ExamDocument2 pagesFluid Machine ExamHagosMebrahtuPas encore d'évaluation

- Assignment FD Compressors and BlowersDocument2 pagesAssignment FD Compressors and BlowersXheikhKaleemPas encore d'évaluation

- Exercise Single Stage Reciprocating Air CompressorDocument3 pagesExercise Single Stage Reciprocating Air CompressorAbhishek ShrikhandkarPas encore d'évaluation

- Jitorres - Ejercicios TH - VentiladoresDocument3 pagesJitorres - Ejercicios TH - VentiladoresJuanDiegoReyesSanchezPas encore d'évaluation

- skmm2323 Turbomc Tutorial PDFDocument3 pagesskmm2323 Turbomc Tutorial PDFLove StrikePas encore d'évaluation

- QP 2010Document25 pagesQP 2010samy_175Pas encore d'évaluation

- Gujarat Technological University: InstructionsDocument2 pagesGujarat Technological University: InstructionsNilesh Mistry (Nilesh Sharma)Pas encore d'évaluation

- Assignment 4 Reciprocating Air CompressorsDocument8 pagesAssignment 4 Reciprocating Air CompressorsAkshay A KumarPas encore d'évaluation

- Te MJ07Document4 pagesTe MJ07Anonymous ijGnA6CWEaPas encore d'évaluation

- Numericals On Centrifugal and Axial CompressorsDocument2 pagesNumericals On Centrifugal and Axial CompressorsMoiz Tinwala33% (3)

- Fluid Machinery May-June 2009Document2 pagesFluid Machinery May-June 2009Pavan HkPas encore d'évaluation

- Zoho Sofware Developer RequiremtsDocument1 pageZoho Sofware Developer RequiremtsyashvantPas encore d'évaluation

- To Whomsoever It May Concern: Declaration of The EmployeeDocument1 pageTo Whomsoever It May Concern: Declaration of The EmployeeyashvantPas encore d'évaluation

- Analyticsvidhya ComDocument38 pagesAnalyticsvidhya ComyashvantPas encore d'évaluation

- To Whomsoever It May Concern: Declaration of The EmployeeDocument1 pageTo Whomsoever It May Concern: Declaration of The EmployeeyashvantPas encore d'évaluation

- Zs AssociatesDocument52 pagesZs AssociatesyashvantPas encore d'évaluation

- Multi-Party Privacy Risks in Social MediaDocument39 pagesMulti-Party Privacy Risks in Social MediayashvantPas encore d'évaluation

- Android Tools - Device.: - All Android Devices Are Debug-Able Via USB "Out of The Box" (No Root Is Needed) - To EnableDocument35 pagesAndroid Tools - Device.: - All Android Devices Are Debug-Able Via USB "Out of The Box" (No Root Is Needed) - To EnableyashvantPas encore d'évaluation

- Mee301 Dynamics-Of-machinery Eth 1.10 Ac26Document2 pagesMee301 Dynamics-Of-machinery Eth 1.10 Ac26yashvantPas encore d'évaluation

- Multi-Party Privacy Risks in Social Networks: AbstractDocument36 pagesMulti-Party Privacy Risks in Social Networks: AbstractyashvantPas encore d'évaluation

- Frame RelayDocument14 pagesFrame RelayyashvantPas encore d'évaluation

- Unit-I: Demand Forecasting AND Elements of CostDocument50 pagesUnit-I: Demand Forecasting AND Elements of CostyashvantPas encore d'évaluation

- Circuit Switching and Packet SwitchingDocument22 pagesCircuit Switching and Packet SwitchingyashvantPas encore d'évaluation

- Mee305-Design Project: Design and Analysis of A Rotor of A Disc BrakeDocument1 pageMee305-Design Project: Design and Analysis of A Rotor of A Disc BrakeyashvantPas encore d'évaluation

- Indian RulesDocument30 pagesIndian RulesyashvantPas encore d'évaluation

- D04FA48908744891B70ED91613E5E5ABDocument4 pagesD04FA48908744891B70ED91613E5E5AByashvantPas encore d'évaluation

- 081B52EFAC704D5AB58072B74C443C48Document3 pages081B52EFAC704D5AB58072B74C443C48yashvantPas encore d'évaluation

- Application of Physical Vapour Deposition and Chemical Vapour Deposition For Industrial ComponentsDocument6 pagesApplication of Physical Vapour Deposition and Chemical Vapour Deposition For Industrial ComponentsyashvantPas encore d'évaluation

- Copenhagen Energy Vision 2050Document126 pagesCopenhagen Energy Vision 2050Paula EscobarPas encore d'évaluation

- Museam of Built Enviroment Saudi ArabiaDocument2 pagesMuseam of Built Enviroment Saudi ArabiaGautam SethPas encore d'évaluation

- Basic of BoilerDocument107 pagesBasic of Boilerjohn_kadier651Pas encore d'évaluation

- 14 Bus ReferenceDocument6 pages14 Bus ReferenceArifah HamidunPas encore d'évaluation

- Tutorial 4 CT VTDocument3 pagesTutorial 4 CT VTEyad A. FeilatPas encore d'évaluation

- TEN100: Test 02 - Study GuideDocument4 pagesTEN100: Test 02 - Study GuidenhstechnologyPas encore d'évaluation

- 365 - Single Channel ChillerDocument2 pages365 - Single Channel Chillerঅর্ণব কোলেPas encore d'évaluation

- Onshore Offshore Oil Field DevelopmentDocument10 pagesOnshore Offshore Oil Field DevelopmentAnre Thanh HungPas encore d'évaluation

- Bill of QuantitiesDocument26 pagesBill of QuantitiesFeroz HakkimPas encore d'évaluation

- Lifan Breez 1.3 HBDocument323 pagesLifan Breez 1.3 HBDenis_1969Pas encore d'évaluation

- ET Solar 245 WP PDFDocument2 pagesET Solar 245 WP PDFΑλοϊσιοςΔαεληςPas encore d'évaluation

- EcoGrid - DK - WP4 Report Measures PDFDocument279 pagesEcoGrid - DK - WP4 Report Measures PDFstevenblomPas encore d'évaluation

- Review Paper On Power Generation by FootstepsDocument3 pagesReview Paper On Power Generation by FootstepsIJSTEPas encore d'évaluation

- ECOCEMDocument24 pagesECOCEMoneakshayPas encore d'évaluation

- Leviton Datasheet Wireless-Occupancy-Sensors WSCXXDocument2 pagesLeviton Datasheet Wireless-Occupancy-Sensors WSCXXred petalsPas encore d'évaluation

- CHAPTER 1 Solar Powered Power BankDocument9 pagesCHAPTER 1 Solar Powered Power BankDiane LogroñoPas encore d'évaluation

- SubstationDocument18 pagesSubstationrakib100% (1)

- Aeronautika RječnikDocument6 pagesAeronautika RječnikIvona IvkovicPas encore d'évaluation

- A Comprehensive Study of The Impact of Green Roofs On Building Energy PerformanceDocument8 pagesA Comprehensive Study of The Impact of Green Roofs On Building Energy PerformanceViet TruongPas encore d'évaluation

- BME - FuelDocument54 pagesBME - FuelRavichandran GPas encore d'évaluation

- 04 - Operational Boundaries - FinalDocument39 pages04 - Operational Boundaries - FinalzillsmkPas encore d'évaluation

- Adjustable Tilt CMP Mounting KitDocument2 pagesAdjustable Tilt CMP Mounting KitBharat KaushikPas encore d'évaluation

- Set3080 Summary of All LecturesDocument67 pagesSet3080 Summary of All LecturesRishabh PalPas encore d'évaluation

- Data Sheet (500w VAWT)Document3 pagesData Sheet (500w VAWT)invic7usPas encore d'évaluation

- A Guide To The Development of A Biomass ProjectDocument16 pagesA Guide To The Development of A Biomass ProjectHeb RuPas encore d'évaluation

- Heliarc 281i/283i/353i AC/DCDocument6 pagesHeliarc 281i/283i/353i AC/DCnetineersPas encore d'évaluation

- Visco MeterDocument1 pageVisco MetercellPas encore d'évaluation

- Step-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferDocument7 pagesStep-By-Step Self-Assembled Hybrids That Feature Control Over Energy and Charge TransferLuciano PereiraPas encore d'évaluation

- CCC 2023 Final CaseDocument23 pagesCCC 2023 Final CaseAbdeljalil OuiPas encore d'évaluation

- Start-Up Costs of Thermal Power Plants in Markets With Increasing Shares of Variable Renewable GenerationDocument6 pagesStart-Up Costs of Thermal Power Plants in Markets With Increasing Shares of Variable Renewable GenerationIkenna OnyegbaduePas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemD'EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemPas encore d'évaluation

- Electric Motor Control: DC, AC, and BLDC MotorsD'EverandElectric Motor Control: DC, AC, and BLDC MotorsÉvaluation : 4.5 sur 5 étoiles4.5/5 (19)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Well Control for Completions and InterventionsD'EverandWell Control for Completions and InterventionsÉvaluation : 4 sur 5 étoiles4/5 (10)

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialD'EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialPas encore d'évaluation

- Building Energy Management Systems and Techniques: Principles, Methods, and ModellingD'EverandBuilding Energy Management Systems and Techniques: Principles, Methods, and ModellingPas encore d'évaluation

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisD'EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisÉvaluation : 5 sur 5 étoiles5/5 (1)

- Solar Energy: Survive Easily on Solar Power Off the GridD'EverandSolar Energy: Survive Easily on Solar Power Off the GridPas encore d'évaluation

- The Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidenceD'EverandThe Journeyman Electrician Exam Study Guide: Proven Methods for Successfully Passing the Journeyman Electrician Exam with ConfidencePas encore d'évaluation

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AD'EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&APas encore d'évaluation

- Renewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningD'EverandRenewable Energy: Physics, Engineering, Environmental Impacts, Economics and PlanningÉvaluation : 5 sur 5 étoiles5/5 (4)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ED'EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EÉvaluation : 3 sur 5 étoiles3/5 (6)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsD'EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsÉvaluation : 4 sur 5 étoiles4/5 (11)

- Electric Motors and Drives: Fundamentals, Types and ApplicationsD'EverandElectric Motors and Drives: Fundamentals, Types and ApplicationsÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Handbook on Battery Energy Storage SystemD'EverandHandbook on Battery Energy Storage SystemÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Fire Protection Engineering in Building DesignD'EverandFire Protection Engineering in Building DesignÉvaluation : 4.5 sur 5 étoiles4.5/5 (5)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- The Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadD'EverandThe Truth About Solar Panels The Book That Solar Manufacturers, Vendors, Installers And DIY Scammers Don't Want You To ReadÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Global Landscape of Renewable Energy FinanceD'EverandGlobal Landscape of Renewable Energy FinancePas encore d'évaluation

- Thermal Power Plant: Design and OperationD'EverandThermal Power Plant: Design and OperationÉvaluation : 4.5 sur 5 étoiles4.5/5 (23)