Académique Documents

Professionnel Documents

Culture Documents

Constant Volume Combustion Cycle For IC Engines: Jovan Dorić

Transféré par

HortodoxocsTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Constant Volume Combustion Cycle For IC Engines: Jovan Dorić

Transféré par

HortodoxocsDroits d'auteur :

Formats disponibles

Jovan Dori

Assistant

University of Novi Sad

Faculty of Technical Sciences

Ivan Klinar

Full Professor

University of Novi Sad

Faculty of Technical Sciences

Marko Dori

PhD student

University of Novi Sad

Faculty of Agriculture

Constant Volume Combustion Cycle

for IC Engines

This paper presents an analysis of the internal combustion engine cycle in

cases when the new unconventional piston motion law is used. The main

goal of the presented unconventional piston motion law is to make a

realization of combustion during constant volume in an engines cylinder.

The obtained results are shown in PV (pressure-volume) diagrams of

standard and new engine cycles. The emphasis is placed on the

shortcomings of the real cycle in IC engines as well as policies that would

contribute to reducing these disadvantages. For this paper, volumetric

efficiency, pressure and temperature curves for standard and new piston

motion law have been calculated. Also, the results of improved efficiency

and power are presented.

Keywords: constant volume combustion, IC engine, kinematics.

1. INTRODUCTION

Internal combustion engine simulation modelling has

long been established as an effective tool for studying

engine performance and contributing to evaluation and

new developments. Thermodynamic models of the real

engine cycle have served as effective tools for complete

analysis of engine performance and sensitivity to

various operating factors [1-4]. During its 135 years

long history, a reciprocating four stroke piston internal

combustion engine has evolved in a very mature thermal

machine which has excluded all the alternatives offered

for motor vehicles drive. The main goal of its further

development is to harmonize the growing traffic with

environmental and energy consumption. The four stroke

SI engine is a widely applied power source in

transportation and other power generation units. In some

areas IC engines are so dominant without concurrence

of other types of engines. However, the construction of

conventional internal combustion engines is based on

inefficient thermodynamic and mechanical concept.

Only 12.6 % of original energy from the fuel conversion

to the wheels provides acceleration, overcomes

aerodynamic drag and rolling resistance [5]. The rest is

lost, therefore because of this the potential to improve

fuel economy with advanced technologies is enormous.

Even modern internal combustion engines convert only

one third of the energy in fuel into useful work. The rest

of the energy is lost to waste heat, the friction of moving

engine parts or to pumping air into and out of the

engine. One of the main causes for such low efficiency

of these engines is related to process and way of heat

addition in IC engines. A study of gas cycles as the

models of internal combustion engines is useful for

illustrating some of the important parameters

influencing engine performance. As is well known, the

constant volume heat addition cycle, which is often

referred to as the Otto cycle, considers one special case

Received: April 2011, Accepted: July 2011

Correspondence to: Jovan Dori M.Sc.

Faculty of Technical Sciences,

Trg Dositeja Obradovia 6, 21000 Novi Sad, Serbia

E-mail: jovan_d@uns.ac.rs

Faculty of Mechanical Engineering, Belgrade. All rights reserved

of an internal combustion engine, whose combustion is

so rapid that the piston does not move during the

combustion process, and thus combustion is assumed to

take place at constant volume [6]. Although in

theoretical terms heat addition takes place at constant

volume, in real engine cycle heat addition at constant

volume can not be performed. The main reason for this

is relatively simple kinematics of IC engines, which

provides continuously piston movement during the

rotation of the crankshaft. So in the real engine heat

addition occurs during a variable volume, and this

results in reduced efficiency.

In this paper, an unconventional piston motion law

which provides smooth stop, dwell and go movement of

the piston has been simulated. In this way, heat addition

can occur during constant volume in a real engine

process.

2. OTTO CYCLE

2.1 Air standard Otto cycle

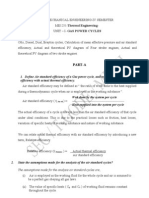

An air standard Otto cycle model is shown in Figure 1.

The compression process is an isentropic process 1-2;

the heat addition is an isohoric process 2-3; the

expansion process is an isentropic process 3-4; and the

heat rejection is an isochoric process 4-1. As is usual in

finite time thermodynamic heat engine cycle models we

suppose two instantaneous adiabatic processes 1-2 and

3-4.

Figure 1. TS diagram for the air standard Otto cycle

FME Transactions (2011) 39, 97-104

97

Also, the same cycle can be shown in another more

appropriate diagram, where changes in volume and

pressure in relation to heat addition and heat rejection

can be easily seen. A PV diagram of the air standard

Otto cycle is shown in Figure 2.

Typical valve events such as intake valve open

(IVO), intake valve close (IVC), exhaust valve open

(EVO) and exhaust valve close (EVC) are shown in the

diagram along with the direction indicators to clarify the

process. The area under the curve is the indicated work

per cycle as given by the (2) where p is the cylinder

pressure and V is the cylinder volume.

W

= pdV .

cycle

Figure 2. PV diagram for the air standard Otto cycle

The constant-volume process is thermodynamically

efficient and, in principle, a feasible cycle. In contrast to

the Carnot process, it avoids isothermal expansion and

compression and the unrealistically high pressure ratio. It

consists of two isentropes and two isohores. It is called a

constant-volume process because the heat supply (instead

of combustion) ensues in constant space, i.e. under

constant volume. Because the piston moves continuously,

the heat supply would have to occur infinitely fast, i.e.

abruptly. However, that is not realistically feasible. For

the thermal efficiency of this process follows:

T4

1

qremoved

Cv (T4 T1 )

T1 T1

= 1

= 1

t = 1

. (1)

qsupplied

Cv (T3 T2 )

T2 T3

1

T2

2.2 Real engine cycle

(2)

From Figure 3 it can be seen that there are three

distinctive areas known as Area A, Area B and Area C.

The integral over the exhaust and intake strokes (Area B

+ Area C) is the indicated work done on the gas by the

piston. This is known as pumping indicated work. On

the other hand, the integral over the compression and

power strokes (Area A + Area C) is the indicated work

done onto the piston by the gas. This is known as gross

indicated work. The work generated throughout the

entire cycle is then known as the net indicated work.

Note that work out of the system is negative and work

into the system is positive. It is evident from Figures 2

and 3 that there are drastic differences between ideal

and theoretical cycles. One of the reasons for these

differences is related to the kinematics of the piston

mechanism. The differences between the conventional

and unconventional kinematics will be described in the

sections below.

3. KINEMATICS OF CONVENTIONAL IC ENGINE

Movement of the piston in conventional IC engines is

based on relatively simple kinematics [7,8]. Figure 4

shows the kinematics of a crankshaft drive with

crossing, in which the longitudinal crankshaft axis does

not intersect with the longitudinal cylinder axis, but

rather is displaced by the length e.

The real engine cycle of an SI four stroke engine can be

illustrated by mapping the pressure-volume (PV) data

extracted from a pressure trace. As the cylinder volume

is a function of the crank angle, it is possible to relate

the cylinder pressure to cylinder volume and thus

construct a PV diagram as seen in Figure 3.

Figure 4. Kinematics of the crankshaft drive

For the piston path s (), it follows from Figure 4.

s ( ) = c3 c2 r cos( )

Figure 3. PV diagram for a four stroke SI engine

98 VOL. 39, No 3, 2011

(3)

from which with

FME Transactions

sin =

e

e

and = arcsin

,

r +l

r +l

(4)

respectively

c1 = e r sin( )

c2 = l 2 c12

c3 =

( r + l )2 e2

(5)

finally

s ( ) =

( r + l )2 e 2

l 2 [ e + r sin( ) ]

2

r cos( ) .

(6)

The derivative provides for the piston speed the

relation:

r [ e + r sin( ) ] cos( )

ds

= r sin( ) +

. (7)

d

2

2

l e + r sin( )

From the definition of the cylinder volume:

V ( ) = VC + D 2

s ( )

4

(8)

the alteration of cylinder volume follows in (9):

dV

ds

.

= D2

d

4 d

(9)

With the eccentric ratio of crank radius and

connecting rod length = r/l, it follows for the limiting

case when e = 0.

1

1 1 k2 sin 2 ( ) . (10)

s ( ) = r [1 cos( ) ] +

Through this kinematics, the movement of the piston

is very limited, refer to (10), the piston is not able to

make a dwell, but only changes the direction of the

movement. It can be seen that dwell exists only for an

infinitesimal moment.

4. UNCONVENTIONAL PISTON MOVEMENT

In this section, the new unconventional piston motion

law will be presented. With this movement, the piston is

able to make such motion where heat addition can be

done during piston dwell. The IC engine mechanism

that can allow such unconventional motion will not be

presented in this paper, since it is not the authors

intention to propose a new internal combustion engine

design.

The design geometry creates a pause or dwell in the

pistons movement at the TDC (top dead center) and the

BDC (bottom dead center), while the output shaft

continues to rotate for up to 20 degrees. Adding these

constant volume dwell cycles improves fuel burn,

maximizes pressure, and increases cylinder charge. Fuel

burn can be precisely controlled by maintaining a

minimum volume (TDC piston dwell) throughout the

burn process. Containment maximizes pressure and burn

FME Transactions

efficiency. Furthermore, holding the piston at maximum

volume (BDC piston dwell) provides additional time for

the cylinder to fully charge before closing the intake

valves. The design creates unconventional four stroke

cycle process. This unconventional cycle consists of the

following strokes and processes:

The first stroke consists of forced and free intake.

During the forced intake, piston travels from TDC to

BDC, which draws fresh mixture into the cylinder. This

part of the stroke is the same as the intake stroke in the

ordinary IC engines. The second part is the free intake.

After the piston comes into BDC, it stops there for a

while. This dwell time depends on the optimization of

the intake process and it will not be explained in detail

in this paper. However, it is very important that the

piston dwell does not last longer or shorter than the

optimal calculated value. After the piston comes into

BDC, the column of fresh gases continues to flow into

the cylinder by inertia, until the intake valve closes. In

this way the intake volumetric efficiency is increased.

The second stroke consists of the compression

process and a combustion during constant volume. In the

first part of this second stroke, the piston travels from

BDC to TDC. The ignition occurs at TDC without any

spark advance, thus saving the accumulated energy of

the flywheel. Ignition begins when the piston is stopped

at the TDC, while the piston stop lasts for the time

calculated by optimisation to complete combustion and

prevent any back-pressure caused by the spark advance.

Consequently, the use of energy obtained from the fuel is

maximized and the fuel consumption is decreased.

The third stroke is an expansion stroke, during

which the piston comes from TDC to BDC like in a

standard mechanism but with the exception that piston

again makes a dwell in BDC. In this new

unconventional four stroke cycle, the entire expansion

stroke occurs between TDC and BDC. Compared to

standard IC engine, in the new piston motion movement

there is no exhaust valve opening advance, which

determines loss of possibly resulting work. In the

second part of this third stroke, the piston comes on

BDC and stays in the same position for a while. During

this time high-pressure gases are spontaneously

evacuated, while the piston is stopped at the BDC.

The last stroke is exhaust stroke, during which the

exhaust gas is actually a low pressure gas, so the piston

will not require a big pumping effort going up towards

TDC. In the last phase of exhaust stroke, exhaust gases

can freely leave compression volume. At the same time

intake valves slowly open and fresh charge comes into

the cylinder, while the piston is still in the dwell mode

at TDC. Previously described unconventional four

stroke cycle can be illustrated by Figure 5.

The similarity with the standard piston path is

evident. The piston dwells can be seen in the Figure 5.

In this case, 20 degree dwells were chosen for both

TDC and BDC. This value improves combustion and

cylinder charging, respectively.

Figure 6 shows standard piston movement for the

next selected parameters:

r = 60 mm;

l = 200 mm;

e = 0 mm.

VOL. 39, No 3, 2011 99

120

difference form for each of these elementary volumes.

A staggered mesh system is used, with equations of

mass and energy solved for each volume and the

momentum equation solved for each boundary between

volumes. The equations are written in an explicitly

conservative form as:

Equation (11): mass countinuity equation

100

s [mm]

80

60

40

dm

= mflux .

dt boundaries

20

0

0

90

180

270

360

450

540

630

720

Equation (12): Conservation of momentum equation

angle of crankshaft [deg]

d(mflux )

=

dt

Figure 5. Piston path for new four stroke cycle

120

100

s [mm]

80

60

4C f

dpA +

(mflux u )

boundaries

dx

u 2 dxA

2D

C p u2 A

2

.

dx

(12)

Equation (13): Conservation of energy equation

40

d(men )

dV

=p

+ mflux H hg A(Tgas Twall ) . (13)

dt

dt bound.

20

0

0

90

180

270

360

450

540

630

720

angle of crankshaft [deg]

Figure 6. Piston path in conventional IC engine

The following figure (Fig. 7) presents a comparison

of both piston motion laws, showing all the differences

and similarities of two different approaches to solving

the piston movement problems, i.e. volume changing in

IC engine cylinder.

piston dwell at TDC and BDC

convetional piston movement

120

If the engine cylinder element has one zone, the

entire cylinder is treated as one region. In the latter, the

cylinder is divided into two regions (unburned and

burned), which share a common pressure. The two-zone

model is used to capture the chemical processes taking

place during the combustion period in more detail.

Combustion models may be used either with a single or

two-zone engine cylinders, but for this research two

zone models were used. For the single zone model there

is the energy equation, refer to (14), as below:

(mu ) =

n valves

i =1

100

mi hi Q PV .

(14)

60

During combustion, the only term of enthalpy flow

is mihi due to propagation of the flame front to the

unburned zone. For the two-zone, refer to model (14), in

the unburned zone we have:

40

mu1uu1 mu0uu0 + P (Vu1 Vu0 ) +

20

+Qu mui hui = 0 .

80

s [mm]

(11)

(15)

Using the equation of the state, it becomes:

0

0

90

180 270 360 450 540

angle of crankshaft [deg]

630

720

Figure 7. Comparison of standard and new four stroke

cycles

5. CYCLE MODEL

The details of the flow (as calculated in the flow

network of both engine models) are obtained as a

solution of quasi-one-dimensional compressible flow

equations governing the conservation of mass,

momentum and energy. The flow network of both

conventional and unconventional piston movement is

discretized into a series of small volumes and the

governing equations are then written in a finite

100 VOL. 39, No 3, 2011

mu1uu1 mu0uu0 + mu1Ru1Tu1 PVu0 +

+Qu mui hui = 0 .

(16)

Similarly, for the burned zone we have:

mb1ub1 mb0 ub0 + mb1 Rb1Tb1 PVb0 +

+Qb mbi hbi = 0 .

(17)

As a constraint, the volumes of the unburned and

burned zones are summed up to the total cylinder

volume:

mu1Ru1Tu1 + mb1Rb1Tb1 PVc = 0 .

(18)

The last three equations are a complete set and are

solved by using the Newton iteration method.

FME Transactions

W = 1 exp( AWI ( / BDUR )(WEXP +1) )

(19)

normalised fule mass burned

where: AWI is internally calculated parameter to allow

BDUR to cover the range of 10 90 %, is degrees past

start of combustion, BDUR is combustion duration (10

90 %), and WEXP is exponent in Viebe function.

For the both cases was chosen law of fuel

combustion refer to Figure 8.

1

0,9

0,8

0,7

0,6

0,5

0,4

0,3

0,2

0,1

0

0

10

20

30

40

50

angle [deg]

Figure 8. Normalised fuel mass burned

FME Transactions

60

70

80

6. RESULTS

The following parameters from Table 1 have been

selected for this analysis.

Table 1. Main engine data

Swept volume [l]

2.71

Bore/stroke [mm/mm]

120/120

Compression ratio [-]

10

Number of valves per cylinder

4 (2 inlet and 2 exhaust)

with dwell

without dwell

10

IVDUR inlet valves open

duration [deg]

230

240

Inlet valves diameter [mm]

44

44

EVO exhaust valve opens

[CA before BDC]

48.5

41

EVDUR exhaust valves open

duration [deg]

235

232

Exhaust valves diameter [mm]

40

40

IVO inlet valves opens [CA

before TDC]

It is observed from Table 1 that some parameters are

different for these two approaches for realisation of the

IC engine cycle. One of the main reasons for different

values is in relation to different piston movement, i.e.

different length of compression and expansion cycles.

Also, the start of combustion for these two cases is

different; because of the piston dwell in TDC with the

proper ignition time it is possible to avoid negative work.

PV diagram of conventional IC engine was shown in

Figure 9.

60

50

40

P [bar]

Within the automotive industry the most widely

adopted technique for gas exchange studies is to solve the

one-dimensional coupled set of non-linear equations

using the finite volume or finite difference method. This

technique is used in several commercial softwares e.g.,

Ricardo/WAVE, GT-Power and AVL/BOOST. In this

paper, Ricardo/WAVE software was used, which

provides a fully integrated treatment of time-dependent

fluid dynamics and thermodynamics by means of onedimensional formulation. Since this article investigates

the unconventional piston motion, classical approach to

solving the problems of volume changes cannot be

applied. When the piston position differs from standard

crank piston motion, the imposed piston motion submodel can be used for modelling the engine. The

formulation to calculate the instantaneous cylinder

volume is identical to the one used in the standard

WAVE model, with the exception that the piston

position, s, is linearly interpolated between points in the

user-entered profile. Smooth piston motion depends on

the fine spacing of the crank angle array. In this case

arrays large enough were used to enable one-degree

spacing. As far as the high-pressure part of the cycle is

considered, the most important process is the combustion.

In this program, the Ricardo Wave model of combustion

can be selected between several options, ranging from

theoretical models with constant volume or constant

pressure heat release, over Viebe-function based heat

release models, to quasidimensional two-zone model of

turbulent flame propagation. The SI Viebe function is

widely used to describe the rate of fuel mass burned in

thermodynamic calculations [9]. This relationship allows

the independent input of function shape parameters and

of burn duration. The experimentally observed trends of

premixed SI combustion are represented quite well. In

this paper, the Viebe one-stage model of heat release has

been chosen. The parameters of Viebe function were

selected to achieve good agreement between modelled

and experimentally recorded pressure. The selected

parameters have been successfully applied in the research

[10-12]. The cumulative mass fraction burned as a

function of crank angle is given by the following

equation:

30

20

10

0

0

10

12

Normalised Volume

Figure 9. PV diagram of conventional IC engine

Now, it is interesting to see how this unconventional

motion with piston dwell in BDC and TDC has an

impact on pressure changes in relation to cylinder

volume. Such PV diagram is shown in the next figure

(Fig. 10), where is obvious that this new piston motion

allows different changes of the working fluid. First, it

can be concluded that in this case adding heat has been

done by increasing the constant volume portion of

combustion, i.e. more constant volume combustion.

Also, there is no rising of pressure due to combustion

before TDC, and negative work has been eliminated in

this new concept. This feature is a consequence of

piston dwell in TDC. Both PV diagrams were solved for

the cases when engine operates at 2000 rpm at full

throttle.

VOL. 39, No 3, 2011 101

70

temperatures of products of combustion at the end of the

expansion stroke.

60

P [bar]

50

40

30

20

10

0

0

10

12

Normalised Volume

Figure 10. PV diagram due piston dwell in TDC and BDC

Besides this very important fact about a new

concept, there are some other advantages over the

standard PV diagram. If we look at the end of the

expansion stroke, it is evident that expansion occurs

between TDC and BDC, where the exhaust valve opens

when the piston stops in TDC. In this way, the area of

PV diagram is increased, and for the same heat input it

means more efficiency. Also, the pressure at the

beginning of the exhaust stroke is smaller than in

conventional engines, so with this new four stroke

movement pumping work is lower.

Now, we can compare these two approaches. This

comparison is shown through the graph in Figure 11.

70

conventional piston motion

50

P [bar]

Figure 14. Comparison of temperature during working

process

piston dwell in TDC and BDC

60

Figure 13. Comparison of power

Efficiency curves for the full throttle conditions have

also been performed for this analysis. These results can

be seen in graph from Figure 15.

40

30

10

0

0

10

12

Normalised Volume

Figure 11. Comparison of standard and new four stroke

cycles in PV diagram

The impact of unconventional piston motion on

volumetric efficiency and power of engine was

presented through Figures 12 and 13.

efficiency [%]

20

40

piston dwell

35

without piston dwell

30

25

20

15

0

2000

4000

n [rpm]

6000

8000

Figure 15. Comparison of efficiency curves

It can be concluded that with this new kinematics of

IC engine there is an efficiency improvement of about

11 % at full throttle.

7. CONCLUSION

Figure 12. Comparison of volumetric efficiency

One of the important aspects of each heat engine is

the temperature of exhaust gases. As can be seen from

Figure 14 unconventional kinematics allows lower

102 VOL. 39, No 3, 2011

In this paper, a new four stroke cycle for internal

combustion engines was analyzed. The main purpose of

this new cycle is to increase the engine efficiency. The

essential challenges in developing this procedure are the

control of the start of combustion, and proper selection of

IVDUR, EVDUR, IVO and EVO. Improvement in the

efficiency is achieved through unconventional kinematics

of piston movement, as a result of more favourable heat

input and lower pumping work. The goal of new motion is

to achieve smooth stop, dwell and go movement in real

engine cycle. Simulation on the basis of quasi onedimensional modelling was performed to obtain PV

FME Transactions

diagrams, temperatures and efficiency curves under full

throttle for standard and new piston motion. From the

results described in Figures 13 and 15 it can be concluded

that piston dwells in TDC and BDC have significant

impact on engine performances. The volumetric efficiency

is a measure of the ability of an engine to induct air into its

cylinders. Maximizing the volumetric efficiency is always

a high priority. With piston dwell in BDC, high pressure

of fresh gases in the beginning of compression stroke can

be achieved. Also, with piston dwell in TDC it is possible

to realize more constant volume combustion.

The automobile industry is under large pressure to

keep developing automobiles with IC engines, to reduce

fuel consumption and exhaust gas emissions, as well as

to seek better alternatives for vehicle drive. In this

article, one of the possible alternatives for conventional

internal combustion engine cycle which contributes to

increasing efficiency has been presented.

ACKNOWLEDGMENT

This work was supported by Projects TR35041 and

TR31046 of the Serbian Ministry of Science.

REFERENCES

[1] Heywood, J.B.: Internal Combustion Engine

Fundamentals, McGraw-Hill, New York, 1988.

[2] Horlock, J.H. and Winterbone, D.E.: The

Thermodynamics and Gas Dynamics of Internal

Combustion Engines, Vol. II, Oxford University

Press, New York, 1986.

[3] Moran, M.J. and Shapiro, H.N.: Fundamentals of

Engineering Thermodynamics, Wiley, New York,

2000.

[4] Rakopoulos, C.D. and Giakoumis, E.G.: Secondlaw analyses applied to internal combustion engines

operation, Progress in Energy and Combustion

Science, Vol. 32, No. 1, pp. 2-47, 2006.

[5] Mahlia, T.M.I., Saidur, R., Memon, L.A., Zulkifli,

N.W.M. and Masjuki, H.H.: A review on fuel

economy standard for motor vehicles with the

implementation

possibilities

in

Malaysia,

Renewable and Sustainable Energy Reviews, Vol.

14, No. 9, pp. 3092-3099, 2010.

[6] Zhaoa, Y. and Chen, J.: An irreversible heat engine

model including three typical thermodynamic

cycles and their optimum performance analysis,

International Journal of Thermal Sciences, Vol. 46,

No. 6, pp. 605-613, 2007.

[7] Merker, G.P., Schwarz, C., Stiesch, G. and Otto, F.:

Simulating Combustion, Springer-Verlag, Berlin,

2006.

[8] Dori, J. and Klinar, I.: Kinematic analysis of

piston mechanism in valveless internal combustion

engine with more complete expansion, in:

Proceedings of the International Congress Motor

Vehicles & Motors 2010, 07-09.10.2010,

Kragujevac, Serbia, pp. 397-405.

[9] Tomi, M. and Petrovi, S.: Spark ignition engine

part load fuel economy improvement: Numerical

consideration, FME Transactions, Vol. 31 No. 1,

pp. 21-26, 2003.

FME Transactions

[10] Schaerlaeckens, W.P.M. and Deckers, R.J.H.: The

application of WAVE in the early stages of engine

design, NedCar Technology, Helmond, Holland,

available at: http://www.ricardo.com/Documents/

Downloads/pdf/wave_early_stages.pdf

[11] Golubev, P.A., Mironychev, M.A. and Nesterenkov,

A.M.: Application of the WAVE system at the initial

stages of engine design, OJSC ZMZ, Russia,

available at: http://www.ricardo.com/Documents/

Downloads/pdf/wave_initial_stage_design.pdf

[12] McCollum, D.L., Thornton, M.J. and Taylor, J.D.:

Application of WAVE 1-D engine models with

vehicle simulation tools to investigate efficiency,

performance, and emission impacts of advanced

engine operation, Presented at the Ricardo Software

9th Annual International Users Conference,

13.03.2004, Southfield, USA, available at:

http://www.ricardo.com/Documents/Downloads/pdf/

wave_1d_engine_models.pdf

NOMECLATURE

CV

D

e

en

H

h

hg

l

m

n

P

Q

R

r

s

t

u

V

x

specific heat under constant volume

cylinder diameter

eccentricity

energy

enthalpy

specific enthalpy

heat transfer coefficient

connecting rod length

mass

number of revolution per minute

pressure

heat

universal gas constant

crankshaft radius

piston path

time

specific internal energy

volume

coordinate

Abbreviations

AWI

BDUR

EVDUR

EVO

IVDUR

IVO

WEXP

internally calculated parameter to allow

BDUR to cover the range of 10 90 %

combustion duration

exhaust valves open duration

exhaust valve opens

inlet valves open duration

inlet valves opens

exponent in Viebe function

Greek symbols

angle

difference

compression ratio

thermal efficiency

degrees past start of combustion

rod relation

number ( 3.1415)

density

VOL. 39, No 3, 2011 103

angle of crankshaft

Subscripts

1

2

3

4

b

c

u

gas state at the beginning of compression

gas state at the end of compression

gas state at the beginning of expansion

gas state at the end of expansion

burnt gas

chamber

unburnt gas

104 VOL. 39, No 3, 2011

, ,

.

.

PV () .

.

,

,

.

FME Transactions

Vous aimerez peut-être aussi

- Otto and Diesel CyclesDocument16 pagesOtto and Diesel CyclesYogaisan RamasawmyPas encore d'évaluation

- Air-Standard Cycles and Their AnalysisDocument40 pagesAir-Standard Cycles and Their AnalysisSrimanthula Srikanth100% (1)

- Unit 2 IC Engine CyclesDocument12 pagesUnit 2 IC Engine CyclesFrezer BelayPas encore d'évaluation

- Technical Objectives:: MECH 337 Thermodynamics Class Notes - Page: 1 Gas Power Systems Text Reading: Ch. 9Document18 pagesTechnical Objectives:: MECH 337 Thermodynamics Class Notes - Page: 1 Gas Power Systems Text Reading: Ch. 9RAJAPas encore d'évaluation

- Radial Curtis StageDocument8 pagesRadial Curtis StageProAkademiaPas encore d'évaluation

- Modeling of Variable Intake Valve Timing in SI EngineDocument15 pagesModeling of Variable Intake Valve Timing in SI EngineHuneza AtaPas encore d'évaluation

- Energy: James C. Conklin, James P. SzybistDocument7 pagesEnergy: James C. Conklin, James P. SzybistAneesh KumarPas encore d'évaluation

- Aissa Thermo1 Chapter 009Document132 pagesAissa Thermo1 Chapter 009ParmeshwarPaulPas encore d'évaluation

- Chapter6 - Reciprocating Internal Combustion EnginesDocument38 pagesChapter6 - Reciprocating Internal Combustion EnginesErwin Paulian SihombingPas encore d'évaluation

- Chapter 2Document14 pagesChapter 2Abdullah OmerPas encore d'évaluation

- 144 0067Document4 pages144 0067Antony BanderasPas encore d'évaluation

- MEEG 346 Thermal Laboratory: Experiment #4: The Four-Stroke Combustion EngineDocument9 pagesMEEG 346 Thermal Laboratory: Experiment #4: The Four-Stroke Combustion EnginepsunmoorthyPas encore d'évaluation

- Otto Cycle: Internal Combustion EnginesDocument18 pagesOtto Cycle: Internal Combustion EnginesNajrul IslamPas encore d'évaluation

- BMM2523_Chapter 2 thermodynamics9-13 An air-standard cycle executed in a piston-cylinder system is composed of three specified processes. The cycle is to besketcehed on the P - v and T - s diagrams and the back work ratio are to be determined. Assumptions 1 The air-standard assumptions are applicable. 2 Kinetic and potential energy changes are negligible. 3 Air isan ideal gas with constant specific heats. Properties The properties of air are given as R = 0.287 kPa·m 3 /kg·K, c p = 1.005 kJ/kg·K, c v = 0.718 kJ/kg·K, and k =1.4. Analysis (a) The P - v and T - s diagrams of the cycle are shown in the figures.(b) Process 1-2: Isentropic compression )( 12,21 T T mcw in −= − v s T 321 v P 321 11212 =⎟⎟ ⎠⎜⎜⎝ = r T T T v 11 −− ⎞⎛ k k v rocess 2-3: Constant pressure heat addition T T mRP −=−= V V v he back wrk ratio isP 2,32 Pd w out = ∫ − )()( 232323 To )()( 2312,32,21 T T mRT TDocument11 pagesBMM2523_Chapter 2 thermodynamics9-13 An air-standard cycle executed in a piston-cylinder system is composed of three specified processes. The cycle is to besketcehed on the P - v and T - s diagrams and the back work ratio are to be determined. Assumptions 1 The air-standard assumptions are applicable. 2 Kinetic and potential energy changes are negligible. 3 Air isan ideal gas with constant specific heats. Properties The properties of air are given as R = 0.287 kPa·m 3 /kg·K, c p = 1.005 kJ/kg·K, c v = 0.718 kJ/kg·K, and k =1.4. Analysis (a) The P - v and T - s diagrams of the cycle are shown in the figures.(b) Process 1-2: Isentropic compression )( 12,21 T T mcw in −= − v s T 321 v P 321 11212 =⎟⎟ ⎠⎜⎜⎝ = r T T T v 11 −− ⎞⎛ k k v rocess 2-3: Constant pressure heat addition T T mRP −=−= V V v he back wrk ratio isP 2,32 Pd w out = ∫ − )()( 232323 To )()( 2312,32,21 T T mRT Tmh13001Pas encore d'évaluation

- Illustration of The Use of An Instructional Version of A Thermodynamic Cycle Simulation For A Commercial Automotive Spark-Ignition EngineDocument15 pagesIllustration of The Use of An Instructional Version of A Thermodynamic Cycle Simulation For A Commercial Automotive Spark-Ignition EngineJose Luis RattiaPas encore d'évaluation

- Noxe MillerDocument11 pagesNoxe Millercezar_iasiPas encore d'évaluation

- Lab Session 4Document8 pagesLab Session 4Shahid FarooqPas encore d'évaluation

- 7 MCE 211-The Carnot CycleDocument8 pages7 MCE 211-The Carnot CycleAhmed Al-ayatPas encore d'évaluation

- Handbook Ch13 SIDocument26 pagesHandbook Ch13 SIIsanga ronaldPas encore d'évaluation

- Mechanical Engineering Thermodynamics II - Lecture 03 - 27 SepDocument25 pagesMechanical Engineering Thermodynamics II - Lecture 03 - 27 SepThineshraaj Naidu Jaya RamanPas encore d'évaluation

- Brayton Cycle Experiment - Jet EngineDocument10 pagesBrayton Cycle Experiment - Jet EngineAsif MohammedPas encore d'évaluation

- Me8493-Thermal Engineering - I-993512870-Te QB Part A &BDocument20 pagesMe8493-Thermal Engineering - I-993512870-Te QB Part A &BMarites TuyogonPas encore d'évaluation

- Ice CyclDocument13 pagesIce CyclYousif OthmanPas encore d'évaluation

- Introduction To IC EnginesDocument10 pagesIntroduction To IC Enginesabhiy91Pas encore d'évaluation

- Thermal Univ QBDocument15 pagesThermal Univ QBrajapratyPas encore d'évaluation

- Thermal Engineering Unit I For BE StudentsDocument44 pagesThermal Engineering Unit I For BE Studentsba27100% (8)

- Combustion Part IIB LT 2005: Dr. Clemens KaminskiDocument38 pagesCombustion Part IIB LT 2005: Dr. Clemens KaminskiHotib PerwiraPas encore d'évaluation

- QQQQQQQQQQQQQQQQQQQQDocument8 pagesQQQQQQQQQQQQQQQQQQQQreal_paladinePas encore d'évaluation

- Ciclos AtkinsonDocument8 pagesCiclos AtkinsontumadreestupadrePas encore d'évaluation

- Thermodynamics of Prime MoversDocument8 pagesThermodynamics of Prime MoversSelva KumarPas encore d'évaluation

- En601 Foundation For Energy EngineeringDocument10 pagesEn601 Foundation For Energy EngineeringJAMI PRUDHVI RAJPas encore d'évaluation

- Te QbwaDocument50 pagesTe Qbwasrinithims78Pas encore d'évaluation

- ME6404 Thermal EngineeringDocument21 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfPas encore d'évaluation

- Cranfield University: Piston Engines Module Lecture NotesDocument242 pagesCranfield University: Piston Engines Module Lecture NotesIzzadAfif1990Pas encore d'évaluation

- Simulation and Modelling of Injection System in Diesel Engine PDFDocument5 pagesSimulation and Modelling of Injection System in Diesel Engine PDFmechveenaPas encore d'évaluation

- Gas Cycles - Part IDocument22 pagesGas Cycles - Part ImohsinsafiPas encore d'évaluation

- Gas Power Cycles Study Guide in Powerpoint: To AccompanyDocument68 pagesGas Power Cycles Study Guide in Powerpoint: To AccompanyAbraham HutomoPas encore d'évaluation

- Thermal EngineeringDocument118 pagesThermal EngineeringMukesh Kumar67% (6)

- Basic Stirling Engine ModalDocument59 pagesBasic Stirling Engine ModalRohan Goralkar0% (1)

- Efficiency of A New Ic Engine Concept With Variable Piston MotionDocument17 pagesEfficiency of A New Ic Engine Concept With Variable Piston MotionaadhanPas encore d'évaluation

- Thermal Univ PDFDocument8 pagesThermal Univ PDFNithin Mathew EyyalilPas encore d'évaluation

- Simulation of The Dynamics of A Marine Diesel EngineDocument16 pagesSimulation of The Dynamics of A Marine Diesel EngineFlorian DraguPas encore d'évaluation

- L 1 Gas Power Cycle 1Document77 pagesL 1 Gas Power Cycle 1De Jose Niño VonPas encore d'évaluation

- ME12B1044 Lab 1 ReportDocument9 pagesME12B1044 Lab 1 ReportVivek D S VickyPas encore d'évaluation

- Gas Power Cycles Sivakumar.E VITDocument47 pagesGas Power Cycles Sivakumar.E VITmohan govindasamyPas encore d'évaluation

- Chapter 9 LectureDocument29 pagesChapter 9 Lectureinam vf100% (6)

- Hybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignD'EverandHybrid Systems Based on Solid Oxide Fuel Cells: Modelling and DesignPas encore d'évaluation

- Southern Marine Engineering Desk Reference: Second Edition Volume IiD'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiPas encore d'évaluation

- Case Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferD'EverandCase Studies in Mechanical Engineering: Decision Making, Thermodynamics, Fluid Mechanics and Heat TransferÉvaluation : 5 sur 5 étoiles5/5 (2)

- Control of DC Motor Using Different Control StrategiesD'EverandControl of DC Motor Using Different Control StrategiesPas encore d'évaluation

- The Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EngineD'EverandThe Petrol Engine: A Text-book dealing with the Principles of Design and Construction, with a Special Chapter on the Two-stroke EnginePas encore d'évaluation

- Steam Engines Machinery's Reference Series, Number 70D'EverandSteam Engines Machinery's Reference Series, Number 70Pas encore d'évaluation

- Thermo-hydrodynamic Lubrication in Hydrodynamic BearingsD'EverandThermo-hydrodynamic Lubrication in Hydrodynamic BearingsPas encore d'évaluation

- Design Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationD'EverandDesign Optimization of Fluid Machinery: Applying Computational Fluid Dynamics and Numerical OptimizationPas encore d'évaluation

- Toyota NR Series EnginesDocument18 pagesToyota NR Series EnginesHortodoxocs50% (2)

- Comparison of A Turbocharger Model Based On Isentropic e Ciency Maps With A Parametric Approach Based On Euler's Turbo-Machinery EquationDocument6 pagesComparison of A Turbocharger Model Based On Isentropic e Ciency Maps With A Parametric Approach Based On Euler's Turbo-Machinery EquationHortodoxocsPas encore d'évaluation

- M.F. Harrison and P.T. Stanev: Journal of Sound and Vibration, Volume 269, Issues 1-2, 6 January 2004, Pages 361-387Document46 pagesM.F. Harrison and P.T. Stanev: Journal of Sound and Vibration, Volume 269, Issues 1-2, 6 January 2004, Pages 361-387HortodoxocsPas encore d'évaluation

- CHP GuideDocument173 pagesCHP GuidemanolojethroPas encore d'évaluation

- ICE BibliographyDocument5 pagesICE BibliographyMOHANBALAJIECEPas encore d'évaluation

- Summary Water Injection PressDocument1 pageSummary Water Injection PressHortodoxocsPas encore d'évaluation

- U-Boat Archive - Type VII C ManualDocument173 pagesU-Boat Archive - Type VII C ManualHortodoxocs100% (2)

- U-Boat Archive - Type VII C ManualDocument173 pagesU-Boat Archive - Type VII C ManualHortodoxocs100% (2)

- Objective Mapping and Kriging: 5.1 Contouring and Gridding ConceptsDocument24 pagesObjective Mapping and Kriging: 5.1 Contouring and Gridding Conceptsforscribd1981Pas encore d'évaluation

- Gas Absorption - Lecture 3Document37 pagesGas Absorption - Lecture 3aminsubriPas encore d'évaluation

- Noelle Combs Inquiry LessonDocument6 pagesNoelle Combs Inquiry LessonBrandi Hughes CaldwellPas encore d'évaluation

- Exam Review - 2012Document3 pagesExam Review - 2012Clement HoangPas encore d'évaluation

- Concept of StrategyDocument3 pagesConcept of StrategyvikasmishraelexPas encore d'évaluation

- Optimization of Machining Parameters For Surface Roughness in Milling OperationDocument5 pagesOptimization of Machining Parameters For Surface Roughness in Milling OperationArmando Rosas GonzalitosPas encore d'évaluation

- CaissonDocument12 pagesCaissonjohnnyoliveiraPas encore d'évaluation

- C DacDocument3 pagesC DacAnsh Sharma0% (1)

- Namma Kalvi 12th Accountancy Unit 4 Sura English Medium Guide PDFDocument10 pagesNamma Kalvi 12th Accountancy Unit 4 Sura English Medium Guide PDFAakaash C.K.Pas encore d'évaluation

- Oops Level 1 Oops ElabDocument59 pagesOops Level 1 Oops ElabChellamuthu HaripriyaPas encore d'évaluation

- Instruction. Shade The Letter of Your Answer On The Answer Sheet Provided. Use Dark Pencil OnlyDocument4 pagesInstruction. Shade The Letter of Your Answer On The Answer Sheet Provided. Use Dark Pencil OnlyJay NastorPas encore d'évaluation

- UntitledDocument8 pagesUntitledapi-233604231Pas encore d'évaluation

- FY 65 - MathematicsDocument12 pagesFY 65 - MathematicsAstrology StudyPas encore d'évaluation

- Lesson 9Document7 pagesLesson 9Mitzi. SumaderoPas encore d'évaluation

- A Levels Physics Formula RelationshipDocument8 pagesA Levels Physics Formula Relationships ramanPas encore d'évaluation

- Reviewed Risk Theory NotesDocument112 pagesReviewed Risk Theory Notesajami malalaPas encore d'évaluation

- Engineering Mechanics PPT 1Document48 pagesEngineering Mechanics PPT 1muralikrishna1917100% (3)

- Gaussian & Gaussview: Shubin Liu, Ph.D. Research Computing Center, Its University of North Carolina at Chapel HillDocument86 pagesGaussian & Gaussview: Shubin Liu, Ph.D. Research Computing Center, Its University of North Carolina at Chapel HillRAMKUMARPas encore d'évaluation

- Fundamentals in ALGEBRADocument8 pagesFundamentals in ALGEBRACarlo BiongPas encore d'évaluation

- Aula PulpDocument64 pagesAula PulpFelipe Rech BrunettaPas encore d'évaluation

- OS-Kings College Unit WiseDocument8 pagesOS-Kings College Unit WisePradeep KumarPas encore d'évaluation

- Mathematics: Circle and Its PartsDocument30 pagesMathematics: Circle and Its PartsDom Martinez100% (2)

- Mroz ReplicationDocument9 pagesMroz ReplicationMateo RiveraPas encore d'évaluation

- Solving Even-Parity Problems Using Traceless Genetic ProgrammingDocument7 pagesSolving Even-Parity Problems Using Traceless Genetic ProgrammingMihai OlteanPas encore d'évaluation

- HSC Extension II Mathematics: Chapter 1. Miscellaneous Polynomials ProblemsDocument8 pagesHSC Extension II Mathematics: Chapter 1. Miscellaneous Polynomials ProblemsSyed Hasan100% (1)

- Ckfëtf Epsf Jolqmx? SF) CLWSF/ DJGWL DXF +WL PJ+:J) Lr5S K - F) 6F) SN @) )Document14 pagesCkfëtf Epsf Jolqmx? SF) CLWSF/ DJGWL DXF +WL PJ+:J) Lr5S K - F) 6F) SN @) )Krishna ThapaPas encore d'évaluation

- Spe 199716 MSDocument43 pagesSpe 199716 MSJamesPas encore d'évaluation

- Sample Solution Midterm 2Document9 pagesSample Solution Midterm 2Ferdinand MangaoangPas encore d'évaluation

- Error DetectionDocument4 pagesError DetectionJsie HFPas encore d'évaluation

- Q1 4TH Assessment Test MATHDocument2 pagesQ1 4TH Assessment Test MATHManila Hankuk AcademyPas encore d'évaluation