Académique Documents

Professionnel Documents

Culture Documents

CHE 414 Principles of Plant Design I Part 5B

Transféré par

ifiokCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CHE 414 Principles of Plant Design I Part 5B

Transféré par

ifiokDroits d'auteur :

Formats disponibles

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Course Outline

WEEK

TOPIC

Process Design Principles

Flow-sheeting,

Piping and instrumentation.

Chemical Engineering Design of Mass and

Heat Transfer Equipment (Plate columns,

absorption towers, distillation columns, heat

exchangers, evaporators etc).

Mechanical Design of Equipments Pressure vessels, columns, storage tanks,

heat exchanger, etc.

Costing and Project Evaluation

1 2 3 4 5 6 7 8 9 10 11 12 13 1

4

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers

Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

GENERAL DESIGN CONSIDERATIONS: PRESSURE VESSELS

A vessel must be designed to

withstand the maximum pressure to

which it is likely to be subjected in

operation.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

For vessels under internal pressure, the

design

pressure

(sometimes

called

maximum allowable working pressure or

MAWP) is taken as the pressure at which

the relief device is set. This will normally be

5 to 10% above the normal working

pressure, to avoid spurious operation during

minor process upsets.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Vessels likely to be subjected to vacuum

should be designed for a full negative

pressure of 1 bar, unless fitted with an

effective, and reliable, vacuum breaker

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The maximum design temperature at

which the maximum allowable stress is

evaluated should be taken as the maximum

working temperature of the material, with

due allowance for any uncertainty involved

in predicting vessel wall temperatures.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Pressure vessels are constructed from

plain carbon steels, low and high alloy

steels, other alloys, clad plate, and

reinforced plastics.

Selection of a suitable material must take

into account the suitability of the material

for fabrication (particularly welding), as

well as the compatibility of the material

with the process environment.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The maximum allowable stress is the lowest of

1. The specified minimum tensile strength at

room temperature divided by 3.5;

2. The tensile strength at temperature divided by

3.5;

3. The specified minimum yield strength at room

temperature divided by 1.5;

4. The yield strength at temperature divided by

1.5.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

At temperatures where creep and stress

rupture strength govern, the maximum

allowable stress is the lowest of

1. The average stress to produce a creep

rate of 0.01%/1000 h;

2. F times the average stress to cause

rupture at the end of 100,000 h, where

F=0.67 for temperatures below 8150C

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Refer to Table 13.2. of Text for Typical

Maximum Allowable Stresses for Plates

Under ASME BPV Code Sec. VIII D.1

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The ASME BPV Code Sec. VIII D.1 defines four categories of weld

(PartUW-3):

A Longitudinal or spiral welds in the main shell, necks or

nozzles, or circumferential welds connecting hemispherical heads

to the main shell, necks, or nozzles;

B Circumferential welds in the main shell, necks, or nozzles or

connecting a formed head other than hemispherical;

C Welds connecting flanges, tube sheets, or flat heads to the

main shell, a formed head, neck, or nozzle;

D Welds connecting communicating chambers or nozzles to

the main shell, to heads, or to necks.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The possible lower strength of a welded joint

compared with the virgin plate is usually

allowed for in design by multiplying the

allowable design stress for the material by a

joint efficiency E.

The value of the joint efficiency used in design

will depend on the type of joint and amount

of radiography required by the design code

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The corrosion allowance is the additional thickness of

metal added to allow for material lost by corrosion and

erosion, or scaling. Corrosion is a complex phenomenon,

and it is not possible to give specific rules for the

estimation of the corrosion allowance required for all

circumstances. The allowance should be based on

experience with the material of construction under similar

service conditions to those for the proposed design.

For carbon and low-alloy steels, where severe corrosion is

not expected, a minimum allowance of 2.0mm should be

used; where more severe conditions are anticipated, this

should be increased to 4.0 mm. Most design codes and

standards specify a minimum allowance of 1.0 mm.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

The loads to which a process vessel will be subject in

service can be classified as major loads, which must

always be considered in vessel design, and subsidiary

loads.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Major Loads

1. Design pressure: including any significant static head of liquid.

2. Maximum weight of the vessel and contents, under operating conditions.

3. Maximum weight of the vessel and contents under the hydraulic test

conditions.

4. Wind loads.

5. Earthquake (seismic) loads.

6. Loads supported by, or reacting on, the vessel.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Subsidiary Loads

1. Local stresses caused by supports, internal

structures, and connecting pipes.

2. Shock loads caused by water hammer or by surging

of the vessel contents.

3. Bending moments caused by eccentricity of the

center of the working pressure

relative to the neutral axis of the vessel.

4. Stresses due to temperature differences and

differences in the coefficient of expansion of materials.

5. Loads caused by fluctuations in temperature and

pressure.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Minimum Practical Wall Thickness

As a general guide the wall thickness of any vessel should not be

less than the following values ; the values include a corrosion

allowance of 2 mm:

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

THE DESIGN OF THIN-WALLED VESSELS UNDER

INTERNAL PRESSURE

Cylinders Shells, The ASME BPV Code specifies that the minimum

thickness is the lower of :

S is the maximum allowable stress and Pi is the internal pressure. E is

welding Efficiency

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

THE DESIGN OF THIN-WALLED VESSELS UNDER

INTERNAL PRESSURE

Spherical Shells The ASME BPV Code specifies that the minimum thickness

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Heads and Closures

The ends of a cylindrical vessel are closed by

heads of various shapes. The principal types

used are

1. Flat plates and formed flat heads

2. Hemispherical heads

3. Ellipsoidal heads

4. Torispherical heads

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Choice of Closure

Flat plates are used as covers for manways and as the

channel covers of heat exchangers.

Standard torispherical heads (dished ends) are the most

commonly used end closure for vessels up to operating

pressures of 15 bar.

Above 15 bar an ellipsoidal head will usually prove to be the

most economical closure to use.

Hemispherical heads are used for high pressure but the cost

of forming is higher than for a shallow torispherical head.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Design of Flat Ends

The ASME BPV Code specifies the minimum thickness

as:

C = a design constant, dependent on the edge constraint (obtained from literaure)

De = nominal plate diameter;

S = maximum allowable stress;

E = joint efficiency.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Hemispherical Heads

In the ASME BPV Code, the equation specified is the same as

for a spherical shell:

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Ellipsoidal Heads

In the ASME BPV Code, the equation specified is:

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Torispherical Heads

In the ASME BPV Code the equation specified is:

where Rc = crown radius

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Conical Closure

In the ASME BPV Code the equation specified is:

used to make a gradual reduction in diameter from

one cylindrical section to another of smaller diameter.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Conical Closure

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Example 13.1

Estimate the thickness required for the component parts

of the vessel shown in the diagram. The vessel is to

operate at a pressure of 14 bar (absolute) and

temperature of 2600C. The material of construction will be

plain carbon steel. Welds will be fully radiographed. A

corrosion allowance of 2mm should be used.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Covenant University Department of Chemical Engineering . CHE 414: Principles of Plant Design - Daniel Ayo, PhD.

Mechanical Design of Pressure Vessels and Heat Exchangers Part B

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- ProtaStructure QSG enDocument64 pagesProtaStructure QSG enHenry67% (3)

- Quality Assurance of Bored Pile FoundationsDocument6 pagesQuality Assurance of Bored Pile Foundationshugojameswood0% (1)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- HDPE Pipeline Installation and DesignDocument19 pagesHDPE Pipeline Installation and Designcrys suryo prayogo100% (1)

- Structural Design of Single Cell Box CulvertDocument14 pagesStructural Design of Single Cell Box CulvertafiqPas encore d'évaluation

- Vryhoff Anchor Manual 2005 PDFDocument187 pagesVryhoff Anchor Manual 2005 PDFAmit R. Ghule100% (2)

- Trussteel Design Manual 2012Document78 pagesTrussteel Design Manual 2012Daniel Kane50% (2)

- LRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFDocument61 pagesLRFD Steel Girder SuperStructure Design Example - LRFD - Design - Bridge - Structures PDFSomi Khan100% (1)

- 7 3814 AX SG 000002 IS05 Structural Steel SpecificationDocument34 pages7 3814 AX SG 000002 IS05 Structural Steel Specificationgchaves504Pas encore d'évaluation

- 5100 1-2004 (+a1)Document81 pages5100 1-2004 (+a1)kevin_au18100% (1)

- Bleaching Effect On Palm OilDocument239 pagesBleaching Effect On Palm Oilde eagle100% (6)

- BS 5385-4Document44 pagesBS 5385-4mohammad82% (11)

- Prediction of end-bearing capacity of rock-socketed shafts considering RQDDocument14 pagesPrediction of end-bearing capacity of rock-socketed shafts considering RQDN.D.Jiji100% (1)

- KAIT Workshop Case StudyDocument40 pagesKAIT Workshop Case StudyRaluca Gîlcă100% (1)

- BS en 81.43.2009Document64 pagesBS en 81.43.2009Garuda GarudaPas encore d'évaluation

- Anon 2Document18 pagesAnon 2ifiokPas encore d'évaluation

- Chapter One 1.0 1.1. Background of The StudyDocument3 pagesChapter One 1.0 1.1. Background of The StudyifiokPas encore d'évaluation

- AnonDocument26 pagesAnonifiokPas encore d'évaluation

- ZeoliDocument11 pagesZeoliifiokPas encore d'évaluation

- Effects of Refining On Chemical and Physical Properties of Palm Oil ProductsDocument4 pagesEffects of Refining On Chemical and Physical Properties of Palm Oil ProductsifiokPas encore d'évaluation

- Auwal Paint2 Power PointDocument24 pagesAuwal Paint2 Power PointifiokPas encore d'évaluation

- 2multicomponent Distillation CalculationsDocument1 page2multicomponent Distillation CalculationsifiokPas encore d'évaluation

- Biodiesel Production From Palm Kernel Oil Using CalciumDocument28 pagesBiodiesel Production From Palm Kernel Oil Using CalciumifiokPas encore d'évaluation

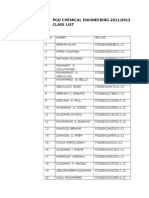

- PGD Chemical Engineering 2011/2012 Class ListDocument2 pagesPGD Chemical Engineering 2011/2012 Class ListifiokPas encore d'évaluation

- Engine Oil and Oil in General Can Be Made From Several MaterialsDocument5 pagesEngine Oil and Oil in General Can Be Made From Several MaterialsifiokPas encore d'évaluation

- Template For Research ProjectDocument18 pagesTemplate For Research ProjectifiokPas encore d'évaluation

- CHE518 Introduction To Polymer Engineering and ProcessingDocument3 pagesCHE518 Introduction To Polymer Engineering and ProcessingifiokPas encore d'évaluation

- EarningsDocument18 pagesEarningsArun KumarPas encore d'évaluation

- Stocks PDFDocument4 pagesStocks PDFifiokPas encore d'évaluation

- Lecture - 3 - Heat and The First Law Example ProblemsDocument22 pagesLecture - 3 - Heat and The First Law Example ProblemsifiokPas encore d'évaluation

- CHE 414 Part 1Document87 pagesCHE 414 Part 1ifiokPas encore d'évaluation

- Investing in BondsDocument6 pagesInvesting in BondsNicolloPas encore d'évaluation

- Corrosion Class Coating SlideDocument27 pagesCorrosion Class Coating SlideIwuoha Maxrofuzo ChibuezePas encore d'évaluation

- Alkenes and Alkynes I. Addition Reactions: Chapter EightDocument68 pagesAlkenes and Alkynes I. Addition Reactions: Chapter EightifiokPas encore d'évaluation

- Schematic Diagram: Water WaterDocument5 pagesSchematic Diagram: Water WaterifiokPas encore d'évaluation

- CHE 414 Principles of Plant Design I Part 2Document30 pagesCHE 414 Principles of Plant Design I Part 2ifiokPas encore d'évaluation

- CHE 414 Principles of Plant Design I Part 4ADocument58 pagesCHE 414 Principles of Plant Design I Part 4AifiokPas encore d'évaluation

- CHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTDocument4 pagesCHEMICAL ENGINEERING PROCESS ANALYSIS COURSE COMPACTCharles BaileyPas encore d'évaluation

- Self Evaluation Skills: Dayo OdukoyaDocument17 pagesSelf Evaluation Skills: Dayo OdukoyaifiokPas encore d'évaluation

- EDS411 - Entrepreneurial Marketing777777777777777Document26 pagesEDS411 - Entrepreneurial Marketing777777777777777ifiokPas encore d'évaluation

- Time Management by Owoeye S.TDocument10 pagesTime Management by Owoeye S.TifiokPas encore d'évaluation

- Che 414 Process Design e NoteDocument114 pagesChe 414 Process Design e Noteifiok100% (1)

- Week 4Document45 pagesWeek 4Iwuoha Maxrofuzo ChibuezePas encore d'évaluation

- Radial Gate ReviewDocument7 pagesRadial Gate Reviewsuranga dadallagePas encore d'évaluation

- F1440Document6 pagesF1440Gustavo SuarezPas encore d'évaluation

- Bracken Engineering Establishing and Investigating Foundation Zones of InfluenceDocument11 pagesBracken Engineering Establishing and Investigating Foundation Zones of InfluencescegtsPas encore d'évaluation

- Load Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil EngineerDocument11 pagesLoad Testing of Bridges - Global State-Of-Practice - India's Top Construction, Infrastructure & Civil Engineercristina_romanescuPas encore d'évaluation

- New Heangjy Bridge Collapse 1992Document9 pagesNew Heangjy Bridge Collapse 1992Erkan ŞamhalPas encore d'évaluation

- 1 Project Description: Hospital - DBRDocument19 pages1 Project Description: Hospital - DBRkiran raghukiranPas encore d'évaluation

- DSTO-TR-1842 Part 2 PressDocument126 pagesDSTO-TR-1842 Part 2 PressArunkumarPas encore d'évaluation

- Frame Supported Membrane StructureDocument11 pagesFrame Supported Membrane StructureSushil DhunganaPas encore d'évaluation

- Design Basis Report - HNBS - R0-13-12-2023Document20 pagesDesign Basis Report - HNBS - R0-13-12-2023samir bendrePas encore d'évaluation

- Arc Length Method For Passing Limit PointsDocument17 pagesArc Length Method For Passing Limit PointsozkanhasanPas encore d'évaluation

- Chapter 3 - 3 OSH Mechanical SafetyDocument24 pagesChapter 3 - 3 OSH Mechanical SafetyMahes War100% (1)

- 1.2. General Design Provisions For National Structural Code of The Philippines - CE 013-CE31S7 - Building Systems DesignDocument2 pages1.2. General Design Provisions For National Structural Code of The Philippines - CE 013-CE31S7 - Building Systems DesignAlexis DulayPas encore d'évaluation

- Aerospace & Defense Isolator Catalog: Vibration, Shock & Motion Control ProductsDocument148 pagesAerospace & Defense Isolator Catalog: Vibration, Shock & Motion Control ProductsCharyPas encore d'évaluation

- Practical Structural Examination of Container Handling Cranes in Ports and TerminalsDocument17 pagesPractical Structural Examination of Container Handling Cranes in Ports and TerminalsStella SofiaPas encore d'évaluation

- Crossarm Design 3071/1 3071/2 Crossarm Applications 3072: Description DWG Description DWGDocument4 pagesCrossarm Design 3071/1 3071/2 Crossarm Applications 3072: Description DWG Description DWGiobtecPas encore d'évaluation

- Eurocode 8 - Part 2. Seismic Design of Bridges: 1. Introduction - SummaryDocument20 pagesEurocode 8 - Part 2. Seismic Design of Bridges: 1. Introduction - SummarykstayroskPas encore d'évaluation

- Astm E894Document8 pagesAstm E894yuvaraj0% (2)