Académique Documents

Professionnel Documents

Culture Documents

Solar Mount Tech Data Sheet

Transféré par

royvindasCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Solar Mount Tech Data Sheet

Transféré par

royvindasDroits d'auteur :

Formats disponibles

R

Technical Datasheets

A HILTI GROUP COMPANY

SolarMount Technical Datasheet

Pub 110818-1td V1.0 August 2011

SolarMount Module Connection Hardware................................................................... 1

Bottom Up Module Clip.................................................................................................1

Mid Clamp.....................................................................................................................2

End Clamp.....................................................................................................................2

SolarMount Beam Connection Hardware.......................................................................3

L-Foot............................................................................................................................3

SolarMount Beams...........................................................................................................4

SolarMount Module Connection Hardware

SolarMount Bottom Up Module Clip

Part No. 302000C

Bottom

Up Clip

Nut

Washer

(hidden..see

note*)

Bolt

Beam

Bottom Up Clip material: One of the following extruded aluminum

alloys: 6005-T5, 6105-T5, 6061-T6

Ultimate tensile: 38ksi, Yield: 35 ksi

Finish: Clear Anodized

Bottom Up Clip weight: ~0.031 lbs (14g)

Allowable and design loads are valid when components are

assembled with SolarMount series beams according to authorized

UNIRAC documents

Assemble with one -20 ASTM F593 bolt, one -20 ASTM F594

serrated flange nut, and one flat washer

Use anti-seize and tighten to 10 ft-lbs of torque

Resistance factors and safety factors are determined according to

part 1 section 9 of the 2005 Aluminum Design Manual and thirdparty test results from an IAS accredited laboratory

Module edge must be fully supported by the beam

NOTE ON WASHER: Install washer on bolt head side of assembly.

DO NOT install washer under serrated flange nut

Applied Load

Direction

Y

X

Average

Ultimate

lbs (N)

Allowable

Load

lbs (N)

Safety

Factor,

FS

Design

Load

lbs (N)

Resistance

Factor,

Tension, Y+

1566 (6967)

686 (3052)

2.28

1038 (4615)

0.662

Transverse, X

1128 (5019)

329 (1463)

3.43

497 (2213)

0.441

66 (292)

27 (119)

2.44

41 (181)

0.619

Sliding, Z

Dimensions specified in inches unless noted

Technical Datasheets

A HILTI GROUP COMPANY

SolarMount Mid Clamp

Part No. 302101C, 302101D, 302103C, 302104D,

302105D, 302106D

Mid

Clamp

Serrated

Flange Nut

Bolt

Beam

Mid clamp material: One of the following extruded aluminum

alloys: 6005-T5, 6105-T5, 6061-T6

Ultimate tensile: 38ksi, Yield: 35 ksi

Finish: Clear or Dark Anodized

Mid clamp weight: 0.050 lbs (23g)

Allowable and design loads are valid when components are

assembled according to authorized UNIRAC documents

Values represent the allowable and design load capacity of a single

mid clamp assembly when used with a SolarMount series beam to

retain a module in the direction indicated

Assemble mid clamp with one Unirac -20 T-bolt and one -20

ASTM F594 serrated flange nut

Use anti-seize and tighten to 10 ft-lbs of torque

Resistance factors and safety factors are determined according to

part 1 section 9 of the 2005 Aluminum Design Manual and thirdparty test results from an IAS accredited laboratory

Applied Load

Direction

Average

Ultimate

lbs (N)

Allowable

Load

lbs (N)

Safety

Factor,

FS

Design

Load

lbs (N)

Resistance

Factor,

Tension, Y+

2020 (8987)

891 (3963)

2.27

1348 (5994)

0.667

Transverse, Z

520 (2313)

229 (1017)

2.27

346 (1539)

0.665

Sliding, X

1194 (5312)

490 (2179)

2.44

741 (3295)

0.620

X

Dimensions specified in inches unless noted

SolarMount End Clamp

Part No. 302001C, 302002C, 302002D, 302003C,

302003D, 302004C, 302004D, 302005C, 302005D,

302006C, 302006D, 302007D, 302008C, 302008D,

302009C, 302009D, 302010C, 302011C, 302012C

Bolt

Serrated

Flange Nut

End Clamp

Beam

Applied Load

Direction

Tension, Y+

Dimensions specified in inches unless noted

End clamp material: One of the following extruded aluminum

alloys: 6005-T5, 6105-T5, 6061-T6

Ultimate tensile: 38ksi, Yield: 35 ksi

Finish: Clear or Dark Anodized

End clamp weight: varies based on height: ~0.058 lbs (26g)

Allowable and design loads are valid when components are

assembled according to authorized UNIRAC documents

Values represent the allowable and design load capacity of a single

end clamp assembly when used with a SolarMount series beam to

retain a module in the direction indicated

Assemble with one Unirac -20 T-bolt and one -20 ASTM F594

serrated flange nut

Use anti-seize and tighten to 10 ft-lbs of torque

Resistance factors and safety factors are determined according to

part 1 section 9 of the 2005 Aluminum Design Manual and thirdparty test results from an IAS accredited laboratory

Modules must be installed at least 1.5 in from either end of a beam

Average

Ultimate

lbs (N)

Allowable

Load

lbs (N)

Safety

Factor,

FS

Design

Loads

lbs (N)

Resistance

Factor,

1321 (5876)

529 (2352)

2.50

800 (3557)

0.605

Transverse, Z

63 (279)

14 (61)

4.58

21 (92)

0.330

Sliding, X

142 (630)

52 (231)

2.72

79 (349)

0.555

Technical Datasheets

A HILTI GROUP COMPANY

SolarMount Beam Connection Hardware

SolarMount L-Foot

Part No. 304000C, 304000D

Beam

Bolt

L-Foot

Serrated

Flange Nut

NOTE: Loads are given for the L-Foot to beam connection only; be

sure to check load limits for standoff, lag screw, or other

attachment method

Applied Load

Direction

Dimensions specified in inches unless noted

L-Foot material: One of the following extruded aluminum alloys: 6005T5, 6105-T5, 6061-T6

Ultimate tensile: 38ksi, Yield: 35 ksi

Finish: Clear or Dark Anodized

L-Foot weight: varies based on height: ~0.215 lbs (98g)

Allowable and design loads are valid when components are

assembled with SolarMount series beams according to authorized

UNIRAC documents

For the beam to L-Foot connection:

Assemble with one ASTM F593 -16 hex head screw and one

ASTM F594 serrated flange nut

Use anti-seize and tighten to 30 ft-lbs of torque

Resistance factors and safety factors are determined according to part

1 section 9 of the 2005 Aluminum Design Manual and third-party test

results from an IAS accredited laboratory

Average

Ultimate

lbs (N)

Allowable Load

lbs (N)

Safety

Factor,

FS

Design

Load

lbs (N)

Resistance

Factor,

Sliding, Z

1766 (7856)

755 (3356)

2.34

1141 (5077)

0.646

Tension, Y+

1859 (8269)

707 (3144)

2.63

1069 (4755)

0.575

Compression, Y- 3258 (14492)

1325 (5893)

2.46

2004 (8913)

0.615

213 (949)

2.28

323 (1436)

0.664

Traverse, X

486 (2162)

Technical Datasheets

A HILTI GROUP COMPANY

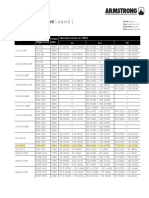

SolarMount Beams

Part No. 310132C, 310132C-B, 310168C, 310168C-B, 310168D

310208C, 310208C-B, 310240C, 310240C-B, 310240D,

410144M, 410168M, 410204M, 410240M

Properties

Units

SolarMount

SolarMount HD

Beam Height

in

2.5

3.0

Approximate Weight (per linear ft)

plf

0.811

1.271

Total Cross Sectional Area

in

0.676

1.059

Section Modulus (X-Axis)

in3

0.353

0.898

Section Modulus (Y-Axis)

in3

0.113

0.221

Moment of Inertia (X-Axis)

in4

0.464

1.450

Moment of Inertia (Y-Axis)

in4

0.044

0.267

Radius of Gyration (X-Axis)

in

0.289

1.170

Radius of Gyration (Y-Axis)

in

0.254

0.502

SLOT FOR T-BOLT OR

1

4"

1.728

SLOT FOR T-BOLT OR

HEX HEAD SCREW

2X SLOT FOR

BOTTOM CLIP

4"

HEX HEAD SCREW

SLOT FOR

BOTTOM CLIP

2.500

3.000

1.316

SLOT FOR

3

8"

1.385

SLOT FOR

HEX BOLT

8"

HEX BOLT

.387

.750

1.207

1.875

Y

X

SolarMount Beam

SolarMount HD Beam

Dimensions specified in inches unless noted

Vous aimerez peut-être aussi

- Analysis Oil Hand Book For Motor PDFDocument106 pagesAnalysis Oil Hand Book For Motor PDFDonald VasquezPas encore d'évaluation

- Oil AnalysisDocument41 pagesOil AnalysisMuhammad TahaPas encore d'évaluation

- Emergency and Standby Power Systems Design and Code RequirementsDocument14 pagesEmergency and Standby Power Systems Design and Code RequirementsSteffanie Jorj EspirituPas encore d'évaluation

- Nfpa 110Document2 pagesNfpa 110royvindasPas encore d'évaluation

- ASHRAE Seminar - Isolation Room HVAC DesignDocument29 pagesASHRAE Seminar - Isolation Room HVAC Designvalentinlupascu33100% (3)

- Standard For Time Start DGDocument4 pagesStandard For Time Start DGRebekah PowellPas encore d'évaluation

- Oil-Less Scroll Air Compressor System With Desiccant Air TreatmentDocument2 pagesOil-Less Scroll Air Compressor System With Desiccant Air TreatmentroyvindasPas encore d'évaluation

- Oil AnalysisDocument41 pagesOil AnalysisMuhammad TahaPas encore d'évaluation

- EMERGENCY Generators PDFDocument94 pagesEMERGENCY Generators PDFroyvindasPas encore d'évaluation

- NFPA110 WhitepaperDocument8 pagesNFPA110 WhitepaperroyvindasPas encore d'évaluation

- Carbon Monoxide DM-100-CO PDSDocument2 pagesCarbon Monoxide DM-100-CO PDSroyvindasPas encore d'évaluation

- 75LC 10Document12 pages75LC 10royvindasPas encore d'évaluation

- EMERGENCY Generators PDFDocument94 pagesEMERGENCY Generators PDFroyvindasPas encore d'évaluation

- HVAC Cooling Load Procedure Guideline Lo0Document62 pagesHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- Standard For Time Start DGDocument4 pagesStandard For Time Start DGRebekah PowellPas encore d'évaluation

- BHD-H BHDP-H Owners ManualDocument16 pagesBHD-H BHDP-H Owners ManualroyvindasPas encore d'évaluation

- Baldor EstandarDocument358 pagesBaldor EstandarroyvindasPas encore d'évaluation

- Vialox Nav LampsDocument7 pagesVialox Nav LampsroyvindasPas encore d'évaluation

- BAT02FXA Oct08Document2 pagesBAT02FXA Oct08royvindasPas encore d'évaluation

- F43 167 Fire Vertical InLine Typical ArrangementsDocument1 pageF43 167 Fire Vertical InLine Typical ArrangementsroyvindasPas encore d'évaluation

- F43 10 VIL FireSet FirePakDocument2 pagesF43 10 VIL FireSet FirePakroyvindasPas encore d'évaluation

- F43 160 PDFDocument16 pagesF43 160 PDFroyvindasPas encore d'évaluation

- HVAC Cooling Load Procedure Guideline Lo0Document62 pagesHVAC Cooling Load Procedure Guideline Lo0api-385802594% (36)

- F43 102e FirePak F4516 SubmittalDocument2 pagesF43 102e FirePak F4516 SubmittalroyvindasPas encore d'évaluation

- Arc Flash Calculation MethodsDocument34 pagesArc Flash Calculation MethodsroyvindasPas encore d'évaluation

- Arc Flash Calculations - What Does It All Mean - Rev 1 PDFDocument59 pagesArc Flash Calculations - What Does It All Mean - Rev 1 PDFroyvindasPas encore d'évaluation

- F43 167 Fire Vertical InLine Typical ArrangementsDocument1 pageF43 167 Fire Vertical InLine Typical ArrangementsroyvindasPas encore d'évaluation

- F43 102e FirePak F4516 SubmittalDocument2 pagesF43 102e FirePak F4516 SubmittalroyvindasPas encore d'évaluation

- Wire Terminations 0110DB9901R2-02Document6 pagesWire Terminations 0110DB9901R2-02M Usman RiazPas encore d'évaluation

- Arc Flash Calculation MethodsDocument34 pagesArc Flash Calculation MethodsroyvindasPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Verilog HDL Lab ManualDocument68 pagesVerilog HDL Lab ManualParag Parandkar80% (25)

- RLE Journal CoverDocument2 pagesRLE Journal Coverrchellee689Pas encore d'évaluation

- 102XM PartesDocument109 pages102XM PartesGuillermo García GarcíaPas encore d'évaluation

- DO 178B DetailedDocument25 pagesDO 178B DetailedSenthil KumarPas encore d'évaluation

- 3 Human Resource ManagementDocument10 pages3 Human Resource ManagementRonaldPas encore d'évaluation

- Zkihel Ilaye Efera: EducationDocument3 pagesZkihel Ilaye Efera: EducationezkihelPas encore d'évaluation

- 2 - SM Watches Father's Day Promotion - June 2023Document11 pages2 - SM Watches Father's Day Promotion - June 2023Shekhar NillPas encore d'évaluation

- E Studio 167Document26 pagesE Studio 167GabiPas encore d'évaluation

- Training MatrixDocument4 pagesTraining MatrixJennyfer Banez Nipales100% (1)

- IIM Kozhikode Senior Management ProgrammeDocument14 pagesIIM Kozhikode Senior Management ProgrammeGupta KanPas encore d'évaluation

- Political Science Class 12TH Project Work 2022-23Document2 pagesPolitical Science Class 12TH Project Work 2022-23Hariom Yadav100% (1)

- Actividad 3-Semana2-DécimoDocument7 pagesActividad 3-Semana2-DécimoAmaury VillalbaPas encore d'évaluation

- Approved Local Government Taxes and Levies in Lagos StateDocument5 pagesApproved Local Government Taxes and Levies in Lagos StateAbū Bakr Aṣ-Ṣiddīq50% (2)

- StompIO-1 User ManualDocument92 pagesStompIO-1 User ManualFederico Maccarone50% (2)

- CMC Internship ReportDocument62 pagesCMC Internship ReportDipendra Singh50% (2)

- Nice - Folder - Bar - System - en Mbar HighlightedDocument16 pagesNice - Folder - Bar - System - en Mbar HighlightedSamastha Nair SamajamPas encore d'évaluation

- Political Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationDocument9 pagesPolitical Internet Memes On Corruption Issue Surrounding The Philippine Health Insurance CorporationFeline Joy SarinopiaPas encore d'évaluation

- 21 B 53679 Cdae 251 D 88 AeDocument2 pages21 B 53679 Cdae 251 D 88 Aeapi-439429931Pas encore d'évaluation

- Domestic Ro Price List 2021Document6 pagesDomestic Ro Price List 2021den onePas encore d'évaluation

- Terms and conditions for FLAC 3D licensingDocument2 pagesTerms and conditions for FLAC 3D licensingseif17Pas encore d'évaluation

- New Form 2550 M Monthly VAT Return P 1 2 1Document3 pagesNew Form 2550 M Monthly VAT Return P 1 2 1The ApprenticePas encore d'évaluation

- Parliamentary Procedure in The Conduct of Business MeetingDocument14 pagesParliamentary Procedure in The Conduct of Business MeetingEstephanie SalvadorPas encore d'évaluation

- LGDocument5 pagesLGPreetham Kiran RodriguesPas encore d'évaluation

- Work-Experience-Sheet CSC Form 212Document5 pagesWork-Experience-Sheet CSC Form 212Marc AbadPas encore d'évaluation

- Drinking Water StandardDocument2 pagesDrinking Water StandardNoorul Mufas Mn100% (1)

- ERP ImplementationDocument47 pagesERP Implementationattarjaved100% (1)

- About 1,61,00,00,000 Results (0.20 Seconds) : All Books Shopping Videos More Settings ToolsDocument2 pagesAbout 1,61,00,00,000 Results (0.20 Seconds) : All Books Shopping Videos More Settings Toolsupen097Pas encore d'évaluation

- Page 34-45 BLK PicDocument12 pagesPage 34-45 BLK PicMihir MehraPas encore d'évaluation

- III International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaDocument8 pagesIII International Congress on Teaching Cases Related to Public and Nonprofit Marketing: Nestlé's CSR in Moga District, IndiaIshita KotakPas encore d'évaluation