Académique Documents

Professionnel Documents

Culture Documents

Exhaust Aftertreatment System Fault Tracing

Transféré par

JhonnyVillarroelMendietaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Exhaust Aftertreatment System Fault Tracing

Transféré par

JhonnyVillarroelMendietaDroits d'auteur :

Formats disponibles

Volvo Trucks North America

Greensboro, NC USA

Service Bulletin

Trucks

Date

Group

No.

Page

3.2008

258

45

1(5)

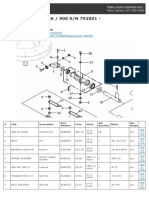

Exhaust Aftertreatment System

Fault Tracing

D11F, D13F and D16F

Exhaust Aftertreatment System Fault Tracing

W2005786

This bulletin provides information regarding the catalyzed exhaust aftertreatment system

fault tracing on a vehicle with a Volvo D11F, D13F or D16F engine.

Contents

Exhaust After-Treatment System, (EATS), Fault Tracing page 2

Note: Information is subject to change without notice.

Illustrations are used for reference only and can differ slightly from the actual vehicle

being serviced. However, key components addressed in this information are

represented as accurately as possible.

PV776-20143790

USA29508.ihval

Volvo Trucks North America

Service Bulletin

D

Date

Group

No.

Page

3.2008

258

45

2(5)

Troubleshooting

Exhaust After-Treatment System, (EATS), Fault Tracing

Introduction

It is important to use a systematic approach to diagnosis.

Depending on the vehicle configuration, a problem

may be caused, or influenced, by malfunctions in other

vehicle components. Diagnostic help can be found in

the Premium Tech Tool (PTT). PTT provides access to

vehicle and parameter programming, service information

and diagnostics. To obtain PTT, contact your local Volvo

Truck dealer.

Regeneration

Vehicles equipped with a 2007 emission compliant engine

have an exhaust aftertreatment system which includes a

Diesel Particulate Filter (DPF). During normal operation,

the DPF collects soot and other particulate matter which

is eventually oxidized using a regeneration process. The

filter insert in the exhaust aftertreatment system must be

cleaned or replaced with a remanufactured filter insert if

any of the following conditions exist:

The filter insert has been in service for 400 000 km

(250,000 miles) or 4,500 hours

There is a significant amount of black coating on the

surfaces behind the DPF

The soot level is above 200%, the DPF inlet looks very

dirty, and the differential pressure is above 15 kPa (2.2

psi) when checked with VCADS.

Severe black coating on the surfaces behind the DPF

indicates that the DPF is cracked or partially melted. The

DPF failure is unrecoverable and it must be replaced.

The exhaust aftertreatment system also includes two

components designed to increase exhaust system

temperature for DPF regeneration. The Aftertreatment

Fuel Injector (AFI), mounted on the turbocharger diffuser,

injects diesel fuel into the exhaust stream during a

regeneration cycle. The fuel contacts the Diesel Oxidation

Catalyst (DOC), a chemical reaction occurs, and the

exhaust system temperature increases to a level that

oxidizes the soot in the filter.

W2005917

Aftertreatment Fuel Injector (AFI)

The Discharge Recirculation Valve (DRV), mounted

on the charge air cooler inlet pipe, increases exhaust

system temperature by recirculating air back into the

turbocharger.

W2006056

Discharge Recirculation Valve (DRV)

Volvo Trucks North America

Service Bulletin

Automatic Regeneration

When the soot level in the DPF reaches 100%, the system

attempts to regenerate automatically, if the vehicle speed

is above 40 kph (25 mph) and load or throttle position

is higher than 40%. An automatic regeneration attempt

will fail if:

The system has been disabled by the operator

There are active component fault codes

Exhaust system temperature is too low

Engine operates in low-load duty-cycle conditions

(stop-and-go traffic or similar)

Date

Group

No.

Page

3.2008

258

45

3(5)

An automatic regeneration will start if the soot level

exceeds 100% and the engine operating conditions

are correct. Short interruptions are allowed, but the

regeneration must be completed within 45 minutes. If

the regeneration does not complete, it will start again

after 30 minutes. The system will attempt to initiate an

automatic regeneration a predetermined number of times

(depending on the software version) before a regeneration

fault code is set. The regeneration fault code is reset

once a regeneration is completed. Also, the soot level

is reduced every time the DPF is at a sufficiently high

temperature for a period of time.

Parked Regeneration

Once the soot level reaches 110%, the operator can

initiate a parked regeneration. A parked regeneration is

allowed up to a 170% soot level. However, the engine will

start to de-rate slightly at 140% and de-rate will increase

as the soot level increases. During parked regeneration

the engine will run at 1050-1200 rpm, depending on

ambient conditions. A parked generation attempt will fail

if:

There are active component fault codes

The transmission is not in neutral

The parking brake is not on

The accelerator and clutch pedal are not released

The coolant temperature is not above 35 C (95 F)

There is a heat mode related problem

The battery voltage is not above 10 volts

Service Regeneration

Once the soot level reaches 170%, the engine is in full

de-rate. The DPF requires a service regeneration by a

Volvo Truck dealer using the VCADS tool in PTT. VCADS

can be used to perform a service regeneration up to a

soot level of 200%.

If a parked regeneration is completed successfully, the

system is operational. However, automatic regenerations

may still fail due to low exhaust temperatures, or

due to degraded AFI or DOC performance. Low

exhaust temperature can be caused by cold ambient

temperature, periods of low load, periods of idle, periods

of coasting/engine brake, stop-and-go traffic, or any

combination of these conditions. Degraded AFI or DOC

performance can be caused by full or partial AFI clogging,

DOC face plugging, or DOC sulfur poisoning due to not

using Ultra Low Sulfur Diesel (ULSD) fuel. Therefore, the

AFI tip should be cleaned and the DOC inlet should be

inspected before replacing the AFI. Follow the procedures

in Guided Diagnostics to inspect and clean the DOC.

Volvo Trucks North America

Service Bulletin

Diagnostics

Find out how the vehicle is driven. What is the typical

duty-cycle? Determine how the aftertreatment system

operated before it failed. Ask about the maintenance

schedule and the fuel, coolant and lubricant used.

Begin by attempting to determine whether anything

has happened recently that could point to the electrical

system, but which is not related to the electronic control

system.

If possible, recreate the problem in an environment similar

to that described by the vehicle operator. Run the engine

at the temperature at which the symptom occurred. Check

if there is soot in the exhaust pipes behind the DPF.

Guided Diagnostics

Guided Diagnostics is an application in PTT that presents

step-by-step instructions for fault code and symptom

fault tracing that pinpoints the cause of the fault. Guided

Diagnostics is organized into a series of tabs outlining

a diagnostic process.

Connect PTT to the vehicle and use Guided Diagnostics

to check for active fault codes. Active fault codes must

be corrected.

W2006448

D

Date

Group

No.

Page

3.2008

258

45

4(5)

Volvo Trucks North America

Service Bulletin

If there are no active fault codes, proceed to the

Symptoms tab in Guided Diagnostics. Click on Engine,

Exhaust Aftertreatment and Service regeneration

failure. Open the Diagnostic folder and follow the

instructions.

W2006447

If the results are inconclusive, the message No fault

found is displayed, rerun the diagnostic procedure.

W2006446

Date

Group

No.

Page

3.2008

258

45

5(5)

Vous aimerez peut-être aussi

- Obd VNL VolvoDocument23 pagesObd VNL Volvosalvatore702100% (2)

- Climate SystemDocument25 pagesClimate Systeminformer techPas encore d'évaluation

- Valves and Unit Injectors, AdjustingDocument9 pagesValves and Unit Injectors, Adjustingcarlos maradiagaPas encore d'évaluation

- Aftertreatment Shutoff Valve ReplacementDocument5 pagesAftertreatment Shutoff Valve ReplacementIsmar Edgardo100% (1)

- Engine, Lubrication: CautionDocument26 pagesEngine, Lubrication: CautionBenPas encore d'évaluation

- Actuator Variable Geometry Turbocharger ReplacementDocument11 pagesActuator Variable Geometry Turbocharger ReplacementZoltán Szecsődi100% (1)

- I-Shift Spec Sheet ATO2612DDocument2 pagesI-Shift Spec Sheet ATO2612DmartinezsoriaPas encore d'évaluation

- 221-42 Oil Pressure Fault-TracingDocument8 pages221-42 Oil Pressure Fault-TracingElio Custodio HuachacaPas encore d'évaluation

- Data Link, Fault Tracing V2Document22 pagesData Link, Fault Tracing V2Minn Thet NaingPas encore d'évaluation

- Volvo D13A Engine SensorsDocument1 pageVolvo D13A Engine Sensorsram_thriveni100% (1)

- Volvo EngineDocument36 pagesVolvo EngineDEEPAK GOYAL100% (1)

- FM PDFDocument660 pagesFM PDFEngkus KuswayaPas encore d'évaluation

- Bleeding Fuel SystemDocument2 pagesBleeding Fuel SystemSherzad Chem100% (1)

- Exhaust Pressure GovernorDocument25 pagesExhaust Pressure GovernorHamilton Miranda100% (1)

- 431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFDocument7 pages431-168 Input Shaft, Overhaul FM9, FM12, FH12, FH16, FH, FM PDFautoeletricamalaquiaPas encore d'évaluation

- Ivtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionDocument48 pagesIvtm - Tire Pressure Monitoring For Commercial Vehicles: System DescriptionElmin SkuljPas encore d'évaluation

- D13F Viscoso Fan ChekDocument2 pagesD13F Viscoso Fan ChekHamilton mirandaPas encore d'évaluation

- ABS Manual 3Document102 pagesABS Manual 3musah ayubaPas encore d'évaluation

- Diesel d13Document8 pagesDiesel d13gustavoPas encore d'évaluation

- Volvo D16-500V - 2050-Xe PDFDocument2 pagesVolvo D16-500V - 2050-Xe PDFDIONYBLINK100% (1)

- Zf-Freedomline Transmission: Maintenance and Diagnostics Manual Mm-0150Document192 pagesZf-Freedomline Transmission: Maintenance and Diagnostics Manual Mm-0150Rob & Nicole RobardsPas encore d'évaluation

- CamshaftDocument16 pagesCamshaftIzz BaharPas encore d'évaluation

- Mack: Volvo Air in The Fuel System, Check (Basic)Document8 pagesMack: Volvo Air in The Fuel System, Check (Basic)Hamish SchnurigerPas encore d'évaluation

- Engine BrakeDocument8 pagesEngine BrakeIzz Bahar100% (1)

- Volvo Gear Actuator: Design - Function - RepairDocument76 pagesVolvo Gear Actuator: Design - Function - RepairNadeem Mohd100% (2)

- Cylinder Balancing, Fault TracingDocument8 pagesCylinder Balancing, Fault TracingIzz BaharPas encore d'évaluation

- PDFDocument9 pagesPDFkrarPas encore d'évaluation

- Service Bulletin Trucks: Timing Gears, Replacement (All)Document7 pagesService Bulletin Trucks: Timing Gears, Replacement (All)Miller Andres ArocaPas encore d'évaluation

- Priming Fuel SystemDocument4 pagesPriming Fuel SystemIzz BaharPas encore d'évaluation

- Tech Tool Adapters and CablesDocument15 pagesTech Tool Adapters and Cablesmetanirvana100% (5)

- Retarder - Oil Change - pdf2Document3 pagesRetarder - Oil Change - pdf2Hariyanto oknesPas encore d'évaluation

- Feul Feed Pressure CheckingDocument20 pagesFeul Feed Pressure Checkingzoe zetPas encore d'évaluation

- Catalogo Abs Meritor WabcoDocument12 pagesCatalogo Abs Meritor Wabcosifuentes18100% (3)

- Transmission Oil Cooler Recommendations - ESA - 04 - 877724 PDFDocument6 pagesTransmission Oil Cooler Recommendations - ESA - 04 - 877724 PDFApdel Rahman RazzoukPas encore d'évaluation

- Tech Tool FAQs v1.45 March 2017Document20 pagesTech Tool FAQs v1.45 March 2017Harlinton descalzi100% (1)

- Volvo June 2016 New Monthly Releases PV776-K-D16H Engine TOCDocument5 pagesVolvo June 2016 New Monthly Releases PV776-K-D16H Engine TOCGurpartap Singh100% (2)

- Wabco Wall Chart For Trailer and Truck AbsDocument1 pageWabco Wall Chart For Trailer and Truck AbsJay RitschardPas encore d'évaluation

- D13 SCR 375-1450Document2 pagesD13 SCR 375-1450ddi11Pas encore d'évaluation

- Clutch PDFDocument12 pagesClutch PDFIzz BaharPas encore d'évaluation

- Service Bulletin Trucks: Control Housing, ReplacementDocument18 pagesService Bulletin Trucks: Control Housing, ReplacementAndrey GaivoronskyPas encore d'évaluation

- Wiring Diagram Link J1939 For Volvo D13ADocument17 pagesWiring Diagram Link J1939 For Volvo D13AThan MinZaw100% (2)

- Lubrication and Oil SystemDocument6 pagesLubrication and Oil SystemIzz BaharPas encore d'évaluation

- Service Bulletin Trucks: Immobilizer FeatureDocument7 pagesService Bulletin Trucks: Immobilizer FeatureRegistr RegistrPas encore d'évaluation

- Pnumatic BrakeDocument19 pagesPnumatic BrakeClovis100% (1)

- PTT ManualDocument40 pagesPTT ManualRoni SocompiPas encore d'évaluation

- Vdocuments - MX Service Manual Trucks General Manual Trucks Group 72 Volvo Air SuspensionDocument58 pagesVdocuments - MX Service Manual Trucks General Manual Trucks Group 72 Volvo Air SuspensionGabrielPas encore d'évaluation

- Volvo VebDocument60 pagesVolvo Vebjuan100% (4)

- Service Bulletin Trucks: Special Tools, Group 2Document46 pagesService Bulletin Trucks: Special Tools, Group 2mattkidoPas encore d'évaluation

- Gearbox, Mechanical - I Shift Generation DDocument55 pagesGearbox, Mechanical - I Shift Generation DMurniansyah AnsyahPas encore d'évaluation

- Volvo Section 3 Electrical Control UnitDocument170 pagesVolvo Section 3 Electrical Control UnitDžejLan Čakrama100% (4)

- Wabco SlabsDocument7 pagesWabco SlabsJonathan GridleyPas encore d'évaluation

- Volvo Tech Tool User Manual PDFDocument83 pagesVolvo Tech Tool User Manual PDFСаиф Аббас100% (1)

- VOLVO VCADS User ManualDocument62 pagesVOLVO VCADS User ManualRolando Mancilla Flores100% (5)

- Service Bulletin: Exhaust Aftertreatment System Fault Tracing - Catalyzed DPFDocument6 pagesService Bulletin: Exhaust Aftertreatment System Fault Tracing - Catalyzed DPFZeckPas encore d'évaluation

- Vag Disesel Particulate FiltersDocument5 pagesVag Disesel Particulate FiltersvondrPas encore d'évaluation

- Delphi DieselMax and Turbocharger Extra Modules PDFDocument3 pagesDelphi DieselMax and Turbocharger Extra Modules PDFSherita Thomas100% (1)

- Install 6l80Document4 pagesInstall 6l80oliver lealPas encore d'évaluation

- Delphi DieselMax and Turbocharger Extra ModulesDocument3 pagesDelphi DieselMax and Turbocharger Extra ModulesVovkaPas encore d'évaluation

- The New (Or The First?) Build System For Android: GradleDocument45 pagesThe New (Or The First?) Build System For Android: GradleJhonnyVillarroelMendietaPas encore d'évaluation

- Saej 1587 V 003Document225 pagesSaej 1587 V 003JhonnyVillarroelMendietaPas encore d'évaluation

- PTT Devtool Parameter DescriptionDocument1 383 pagesPTT Devtool Parameter DescriptionJhonnyVillarroelMendieta75% (4)

- Project: Food For Homeless StoryboardDocument1 pageProject: Food For Homeless StoryboardJhonnyVillarroelMendietaPas encore d'évaluation

- English in Common 4 43-54 PDFDocument7 pagesEnglish in Common 4 43-54 PDFJhonnyVillarroelMendietaPas encore d'évaluation

- System Components RequiredDocument3 pagesSystem Components RequiredJhonnyVillarroelMendietaPas encore d'évaluation

- Emission Label Clean IdleDocument4 pagesEmission Label Clean IdleJhonnyVillarroelMendietaPas encore d'évaluation

- General RTOS Concepts-PresentationDocument17 pagesGeneral RTOS Concepts-PresentationJhonnyVillarroelMendietaPas encore d'évaluation

- JC-364-TSKS IOM EN Final HiRes NoCropsDocument12 pagesJC-364-TSKS IOM EN Final HiRes NoCropsFabio StuiPas encore d'évaluation

- 1 LZ60 CylinderDocument14 pages1 LZ60 CylinderaPas encore d'évaluation

- Global Diesel EngineDocument13 pagesGlobal Diesel Enginefromgod83Pas encore d'évaluation

- FME OP BrochureDocument2 pagesFME OP BrochureMartin KratkyPas encore d'évaluation

- 4110001262驱动桥 后桥 看图王 Hoid MostDocument24 pages4110001262驱动桥 后桥 看图王 Hoid Mostenhbat batsuhPas encore d'évaluation

- Tecumseh TEC-632795A Parts Diagram For CarburetorDocument3 pagesTecumseh TEC-632795A Parts Diagram For CarburetorovertopPas encore d'évaluation

- L30-L75 Fixed Speed Rotary Screw Compressor BrochureDocument2 pagesL30-L75 Fixed Speed Rotary Screw Compressor BrochureSpark ElectricPas encore d'évaluation

- Watt's GovernorDocument3 pagesWatt's GovernorwesamPas encore d'évaluation

- Volvo Penta Cylinder HeadsDocument1 pageVolvo Penta Cylinder HeadsMarine Parts ChinaPas encore d'évaluation

- Pump VLR-16Document2 pagesPump VLR-16Nguyễn Hoàng PhúcPas encore d'évaluation

- TestDocument3 pagesTestNSS GBPECPas encore d'évaluation

- 489 Fanuc M 10ia Robot AdatlapDocument4 pages489 Fanuc M 10ia Robot AdatlapassPas encore d'évaluation

- KR 96068 237899 569585Document4 pagesKR 96068 237899 569585Ronald BosPas encore d'évaluation

- Mercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 EcuDocument5 pagesMercedes W 124 - Instrument Cluster - Engines 104 HFM-SFI 602 606 Ecuadisby7Pas encore d'évaluation

- ATPL Inst 3.1 PDFDocument10 pagesATPL Inst 3.1 PDFKoustubh VadalkarPas encore d'évaluation

- Zenoah Owner Service ManualDocument20 pagesZenoah Owner Service ManualMochtar SusantoPas encore d'évaluation

- A TNN DCS25 149a 1 2006 04 031 PDFDocument31 pagesA TNN DCS25 149a 1 2006 04 031 PDFGoran RistićPas encore d'évaluation

- Challenge 20 Manual PDFDocument65 pagesChallenge 20 Manual PDFAlfonso Sanchez VerduzcoPas encore d'évaluation

- TA30T3 A8941011 To A8941753Document528 pagesTA30T3 A8941011 To A8941753Khaled Naseem Abu-Sabha100% (5)

- Periodical Service Tadano ATF110: Adaro SIS Mia4Document4 pagesPeriodical Service Tadano ATF110: Adaro SIS Mia4ainul arifPas encore d'évaluation

- SP Brochure 60HzDocument4 pagesSP Brochure 60HzDerahamaniPas encore d'évaluation

- Autotransformer StarterDocument22 pagesAutotransformer StarterSiswoyo SuwidjiPas encore d'évaluation

- Parking Brake Shoes Removal and Installation PDFDocument4 pagesParking Brake Shoes Removal and Installation PDFMichael Hernandez100% (1)

- Xunke CNC Machine CO., LTDDocument9 pagesXunke CNC Machine CO., LTDSALISU ABDULWAHEED KOLAWOLEPas encore d'évaluation

- Towercrane 111115091832 Phpapp01Document26 pagesTowercrane 111115091832 Phpapp01Ar Dheeraj MauryaPas encore d'évaluation

- Chrysler Neon - Turn Signal - Hazzard Warning SystemsDocument6 pagesChrysler Neon - Turn Signal - Hazzard Warning SystemseephantomPas encore d'évaluation

- Brushless DC MotorDocument19 pagesBrushless DC MotorAnonymous M8PzfJmPas encore d'évaluation

- Ta 19 V10Document6 pagesTa 19 V10Edgar Rojas EspejoPas encore d'évaluation

- Dom Notes Flywheel Unit 4Document36 pagesDom Notes Flywheel Unit 4Mohammed FarhanPas encore d'évaluation

- Manitowoc 2250Document108 pagesManitowoc 2250Michael SerraPas encore d'évaluation