Académique Documents

Professionnel Documents

Culture Documents

FR48-003-D03-0047 2D MDS Water Accumulator

Transféré par

pragatheeskDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FR48-003-D03-0047 2D MDS Water Accumulator

Transféré par

pragatheeskDroits d'auteur :

Formats disponibles

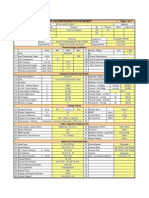

CONTRACTOR :

FR48 SHALAPA - LPG UNDERGROUND STORAGE IN SHALAPA,

IXHUATLAN DEL SURESTE, MEXICO

SUPPLY OF PP-03 DEHYDRATION UNIT

VENDOR :

MECHANICAL DATA SHEET

FOR

WATER ACCUMULATOR (TA-601)

TABULATION OF REVISED PAGES

SHEET

REVISION

SHEET

1D

2D

51

52

53

54

55

56

57

58

59

10

60

11

61

12

62

13

63

14

64

15

65

16

66

17

67

18

68

19

69

20

70

21

71

22

72

23

73

24

74

25

75

26

76

27

77

28

78

29

79

30

80

31

81

32

82

33

83

34

84

35

85

36

86

37

87

38

88

39

89

40

90

41

91

42

92

43

93

44

94

45

95

46

96

47

97

48

98

49

99

50

100

REVISION

Contractor Document Number :

Vendor Document Number :

Sheet Number :

FR48-003-D03-0047

225-M-DS-005

2 OF 5

CONTRACTOR :

VENDOR :

FR48 SHALAPA - LPG UNDERGROUND STORAGE IN SHALAPA,

IXHUATLAN DEL SURESTE, MEXICO

SUPPLY OF PP-03 DEHYDRATION UNIT

MECHANICAL DATA SHEET

FOR

WATER ACCUMULATOR (TA-601)

Sheet :

Doc. No.

225-M-DS-005

Unit

DEHYDRATION

Service

WATER ACCUMULATOR

Tag No.

TA-601

No. of units

3 OF 5

General Characteristics

1

Unit

Parameter

2

3

Service

Fluid

Parameter

WATER ACCUMULATOR

Unit

mm

Corrosion Allowance

LPG (Liquid)

3

1/1

Joint Efficiency ( shell / head)

Design Code

ASME SECT. VIII Div. 1 2013 Edition

Orientation

Horizontal

Vessel Inside Diameter

mm

Length (T/T)

Boot Size (Dia.OD x H)

10

No

Sour Service

3

Design / Operating Gas Flowrate

m /h

N/A

2000

Design / Operating Liquid Flowrate

m3/h

mm

6000

Operating gas viscosity

mm

STA (Note 2 )

See Process Data Sheet

(225-P-DS-005)

See Process Data Sheet

(225-P-DS-005)

See Process Data Sheet

(225-P-DS-005)

Design Pressure

kg/cm2g

31.60

11

Operating Pressure

kg/cm2g

28.60

km/hr

160

12

Test pressure

kg/cm2g

As per code

Seismic Factor ( c )

13

Design Temperature

-46 / 65

Period of Vibration

14

Operating Temperature

50

15

Shell Thickness (Nom)

mm

16

Head Thickness (Min)

mm

Operating liquid viscosity

2D

Wind Velocity

0.4

s

0.3

Insulation

mm

No

STA (Note 2 )

Fire Proofing

mm

No

STA (Note 2 )

Capacity

STA

17

18

19

Material Specification

Material

Description

Description

Material

20

Shell

SA 516 Gr. 60

Internal

21

Head

SA 516 Gr.60

Internal Attachment (fix)

22

Reinforcing Pads

SA 516 Gr.60

Manhole Davit

23

Vessel Supports

SA 36

Platform

A 36

24

Base Plate

SA 36

Ladder

SA 36

25

Nozzle

SA 350 Gr. LF2

- Flange

26

- Neck

27

- Forging

316L SS

SA 516 Gr.60

SA 36

SA 516 Gr.60

Clips

SA 333 Gr. 6

SA 516 Gr. 60 (Note 6 )

Lifting Lugs

SA 350 Gr. LF2

304 SS

Earthing bosses

28

29

Gasket

30

Bolt/Nut (ext)

31

Bolt/Nut (int)

Spiral Wound 316L SS

Name plate

SA320 Gr.L7 / SA194 Gr.4 (Fluorocarbon Coated)

2D

316 SS

- Data

SA 516 Gr.60

- Bracket

316 SS

32

Construction

33

2:1 Ellipsoidal

34

Head

35

Vessel Support

Saddles

36

Manhole davit

37

38

Yes

Internal Support

Ladder clips

Yes

Yes

Insulation clips

N/A

Earthing bosses

Yes

Piping clips

TBA

Lifting Lug

Yes

39

Platform

Yes

Name Plate + Bracket

Yes

40

Ladder

Yes

41

Platform clips

Yes

Fabrication and Inspection Requirements

42

43

Regulating Authority

Hydrotest Pressure

44

Inspection Authority

Pneumatic Test

45

Radiography

46

Ultrasonic Testing

As per code

PWHT

47

Magnetic Particle

As per code

Stress Relief

48

Dye Penetrant

As per code

49

ASME Stamp Required

50

Painting

51

100%

No

- External

Yes (Note 8 )

- Internal

Yes, as per code

Yes (reinforce pad only)

Yes

Impact Test

As per code

As per code

(Shell / Head)

Estimated Weight

Empty

Operating

16440 (VTA) Kg

(VTA) Kg

Testing

37730 (VTA) Kg

52

225-M-DS-005 - WATER ACCUMULATOR (TA-601)_Rev.2D

CONTRACTOR :

VENDOR :

FR48 SHALAPA - LPG UNDERGROUND STORAGE IN SHALAPA,

IXHUATLAN DEL SURESTE, MEXICO

SUPPLY OF PP-03 DEHYDRATION UNIT

MECHANICAL DATA SHEET

FOR

WATER ACCUMULATOR (TA-601)

Sheet :

Doc. No.

225-M-DS-005

Unit

DEHYDRATION

Service

WATER ACCUMULATOR

Tag No.

TA-601

4 OF 5

No. of units

NOZZLE LIST

1

2

3

4

ITEM

QTY.

SIZE (DN)

SCH

CLASS

TYPE

DESCRIPTION

REMARKS

N1

6"

300#

RF

INLET

Note 3

N2

2"

300#

RF

OUTLET HEAVY LIQUID

N3

3"

300#

RF

PSV

N4

6"

300#

RF

OUTLET LIGHT LIQUID

Note 3

N5

2"

300#

RF

DRAIN

Note 3

2D

Note 3

2D

Note 3

N6 A/B

2"

300#

RF

LG/LT

Note 3

N7

2"

300#

RF

VENT

Note 3

12

N8 A/B

2"

300#

RF

LSLL

Note 3

13

N9

3"

300#

RF

INLET DEPRESSURING

Note 3

N10

2"

300#

RF

TG

Note 3

N11

3"

300#

RF

BLOWDOWN

Note 3

MH

24"

300#

RF

MANHOLE

c /w

/ Bli

Blind

d Flange

Fl

+ Davit

D it Arm

A

10

2D

11

2D

14

15

16

17

18

19

2D

20

21

22

23

24

25

26

27

6000 mm(T/T)

28

29

30

31

32

33

34

N1

N9

N11

N3

N7

2D

N4

INLETDEFLECTOR

DEEP

PIPE

35

36

37

N6A

38

(ID)

39

MH

COALESCER

41

42

2000

40

N10

43

44

45

N8B

46

STA

47

48

49

N-5

WEIR

PLATE

N6B

50

51

52

53

54

55

N-2

N8A

STA

STA

STA

225-M-DS-005 - WATER ACCUMULATOR (TA-601)_Rev.2D

FR48 SHALAPA - LPG UNDERGROUND STORAGE IN SHALAPA,

IXHUATLAN DEL SURESTE, MEXICO

SUPPLY OF PP-03 DEHYDRATION UNIT

CONTRACTOR:

MECHANICAL DATA SHEET

FOR

WATER ACCUMULATOR (TA-601)

Doc. No.

Service

:

:

225-M-DS-005

WATER ACCUMULATOR

Unit

Tag No.

:

:

DEHYDRATION

TA-601

VENDOR:

Sheet :

5 of 5

No. of units

Notes

1

2

3

4

1.

5

6

2.

2D

Supplier / Sub Vendor to design and construct as per No. 225-M-SP-001 " Specification for Pressure Vessel ".

And No. 225-Q-PR-003 " General Welding Procedure ".

Supplier / Sub Vendor shall advise and finalize thickness during detail engineering and shall be responsible for vessel

design to meet process design requirements.

Minimum thickness shall be calculated as per code. Supplier / Sub Vendor shall confirm the suitability of the material

and may propose alternative.

8

9

10

11

3.

Nozzle schedule, reinforce pad, etc. To be determined during detail engineering.

Instrument nozzle elevation shall comply with process elevation.

4.

The bolt holes of the nozzle and manhole flanges shall always straddle the principal centerlines of the pressure vessel or

their parallel lines.

5.

The Supplier / Sub Vendor shall design the removable internal parts to enable installation through the flange body.

6.

The lifting lugs / trunnions and the attachment points to the pressure vessel shall be designed to a minimum load

factors equal to 1.5 x lifted weight and shall be attached by full penetration welds.

7.

Where blind flanges are specified, they shall be completed with bolts/nuts, gaskets and spares :

- Gasket

:

100% spares each blind flange nozzle

- Bolt / Nut

:

10% spare or min 2 whichever is higher for each blinded flange nozzle

8.

Application of painting shall be in accordance with No. 225-L-SP-004 " Specification for Sand blasting and Painting ".

9.

Process Design & warranty should be vendor scope.

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

2D

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

225-M-DS-005 - WATER ACCUMULATOR (TA-601)_Rev.2D

Vous aimerez peut-être aussi

- Household Electricity End-Use ConsumptionDocument22 pagesHousehold Electricity End-Use ConsumptionEva ViskadourakiPas encore d'évaluation

- Thermocouples Specification and Data SheetsDocument8 pagesThermocouples Specification and Data SheetsRakesh NayakPas encore d'évaluation

- Chapter 7 - Transient Heat Conduction PDFDocument64 pagesChapter 7 - Transient Heat Conduction PDFhaqjmiPas encore d'évaluation

- SAIC-D-2022 Rev 2Document5 pagesSAIC-D-2022 Rev 2ரமேஷ் பாலக்காடுPas encore d'évaluation

- Datasheet Phe OnwjDocument1 pageDatasheet Phe OnwjMamank Ira Sudrajat100% (1)

- Receiving Inspection of Pressure VesselsDocument5 pagesReceiving Inspection of Pressure Vesselsரமேஷ் பாலக்காடுPas encore d'évaluation

- Ms Megachem A2740 8e 3Document23 pagesMs Megachem A2740 8e 3nata siagianPas encore d'évaluation

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988Pas encore d'évaluation

- Scrubber DatasheetDocument3 pagesScrubber DatasheetShima Ash100% (2)

- 310-1512715 Bilge System H01Document11 pages310-1512715 Bilge System H01buturca sorinPas encore d'évaluation

- GCI Storage Tank Data SheetDocument4 pagesGCI Storage Tank Data SheetAlvin Smith60% (5)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1D'EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Évaluation : 3.5 sur 5 étoiles3.5/5 (3)

- Corrosion Types and Prevention Methods in 40 CharactersDocument75 pagesCorrosion Types and Prevention Methods in 40 CharactersCipri Croitor0% (1)

- SEO-Optimized Title for Pig Receiver Datasheet DocumentDocument6 pagesSEO-Optimized Title for Pig Receiver Datasheet Documenthai_solincvnPas encore d'évaluation

- Air Dryer Atlas Copco CD 12 (01-Technical - 1154207 - 1 - 00)Document43 pagesAir Dryer Atlas Copco CD 12 (01-Technical - 1154207 - 1 - 00)Leon Strantzias86% (7)

- ZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Document6 pagesZAU 256 MS 2105 00003 0001 A01 Datasheet For Produced Water Storage Vessel (V 8421)Vijayaraj KumarPas encore d'évaluation

- Comparision Sheet-Ccoling TowersDocument16 pagesComparision Sheet-Ccoling TowersKenny RuizPas encore d'évaluation

- BLOCK B - O MON PIPELINE GAS HEATER DATADocument9 pagesBLOCK B - O MON PIPELINE GAS HEATER DATALuong AnhPas encore d'évaluation

- Tell Tale HoleDocument45 pagesTell Tale HoleSingarao Katta33% (3)

- TBDP A M DS 0007 2Document7 pagesTBDP A M DS 0007 2Bùi Văn HợpPas encore d'évaluation

- Product Leaflet Seawater Electrochlorination PDFDocument4 pagesProduct Leaflet Seawater Electrochlorination PDFgkdora574Pas encore d'évaluation

- FO14-104 Vacuum Deaerator Datasheet - Rev ADocument3 pagesFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- Aqap2120 Ed 1 PDFDocument18 pagesAqap2120 Ed 1 PDFmaccione4311Pas encore d'évaluation

- Data Sheet: DescriptionDocument6 pagesData Sheet: DescriptionEDUARDOPas encore d'évaluation

- Umm Lulu Phase II Amine ContactorDocument7 pagesUmm Lulu Phase II Amine ContactorchetanmalePas encore d'évaluation

- Technical Bid Evaluation Heat ExchangerDocument211 pagesTechnical Bid Evaluation Heat ExchangerpragatheeskPas encore d'évaluation

- Accessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsDocument32 pagesAccessories: More of What You Need To Work Smarter, Faster, and Better. Visit The-Minute Accessory SelectionsPartsGopher.comPas encore d'évaluation

- P&ID Check ListDocument2 pagesP&ID Check ListHadi ShahsavanPas encore d'évaluation

- B 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerDocument11 pagesB 84567 SB Mm2 DSR ST 60 0020 - 1 - Aoc - GTG Fuel Gas Filter CoalescerpragatheeskPas encore d'évaluation

- DS-21-J-0026 - 2 TPCDR Approved PDFDocument40 pagesDS-21-J-0026 - 2 TPCDR Approved PDFsumant.c.singh1694Pas encore d'évaluation

- Hotpoint Service Manual Fridge FreezerDocument36 pagesHotpoint Service Manual Fridge FreezerMANUEL RODRIGUEZ HERRERA100% (1)

- TopCorbelco - WPS FCAW Sa 516 GR 70Document6 pagesTopCorbelco - WPS FCAW Sa 516 GR 70miltonangulomorrisPas encore d'évaluation

- MIS-M-DS-04045 Closed Drain Drum Data Sheet-BDocument3 pagesMIS-M-DS-04045 Closed Drain Drum Data Sheet-Bhappale2002Pas encore d'évaluation

- MM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With InternalDocument9 pagesMM ZTK 1B WPX MEC DTS 0013 Rev.C1 Diesel Oil Filter With Internalpragatheesk100% (1)

- Residual Life Assessment and Failure of The BoilerDocument21 pagesResidual Life Assessment and Failure of The BoilernagasureshPas encore d'évaluation

- MM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1Document10 pagesMM-ZTK-1A-ZPQ-PIP-DTS-0125 Rev A1gracemanotocPas encore d'évaluation

- TCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression VesselsDocument59 pagesTCE Consulting Engineers Process Data Sheet for Ammonia Storage and Compression Vesselsrotatic_engineerPas encore d'évaluation

- Rev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFDocument15 pagesRev A. Magnetic Level Gauge With Level Transmitter Datasheet PDFNguyễnQuíTrọngPas encore d'évaluation

- Tank Calculation Kasikan Gs Rev BDocument20 pagesTank Calculation Kasikan Gs Rev BTrian Desta Rizal80% (5)

- PE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - BDocument7 pagesPE-D-A06124222143-01-ME-DAS-015-01-E - Net Oil Storage Tanks - TFRJ-33-TK-1101A - B7radu7Pas encore d'évaluation

- SVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage TankDocument4 pagesSVSW 004110 G8 0001 Rev.a Datasheet For Chemical Storage Tanknguyenquoc1988100% (1)

- Evaporator Data Sheet - SKO0501049 Rev0Document10 pagesEvaporator Data Sheet - SKO0501049 Rev0chublackPas encore d'évaluation

- Kubota-Mbr Technical PDFDocument13 pagesKubota-Mbr Technical PDFpragatheeskPas encore d'évaluation

- TBE For UG Knock Out Drum - Draft For Rev.C1Document22 pagesTBE For UG Knock Out Drum - Draft For Rev.C1pragatheeskPas encore d'évaluation

- Design of Oxidation DitchDocument23 pagesDesign of Oxidation Ditchartiraha100% (1)

- Base Station Antennas1Document66 pagesBase Station Antennas1redha_rebaiPas encore d'évaluation

- Mechanical Data Sheet for Water AccumulatorDocument5 pagesMechanical Data Sheet for Water AccumulatorpragatheeskPas encore d'évaluation

- Owner GuideDocument741 pagesOwner Guidealfatih1407497100% (1)

- Ejemplo de Cálculo de Equipo A Presión Con CompressDocument67 pagesEjemplo de Cálculo de Equipo A Presión Con Compresskdt3Pas encore d'évaluation

- PMO-GENERAL SANTOS SUPPLEMENTAL APP as of December 2013Document16 pagesPMO-GENERAL SANTOS SUPPLEMENTAL APP as of December 2013Marigold CalendulaPas encore d'évaluation

- CKD INSTALLATION MANUAL FOR 39G AIR HANDLING UNITSDocument42 pagesCKD INSTALLATION MANUAL FOR 39G AIR HANDLING UNITSthanh_79Pas encore d'évaluation

- ETA Freyssinet enDocument90 pagesETA Freyssinet enbulbucataPas encore d'évaluation

- ARI-Strainer technical specificationsDocument6 pagesARI-Strainer technical specificationsEmnPas encore d'évaluation

- Spraymaster Duo dimensions and ratingsDocument4 pagesSpraymaster Duo dimensions and ratingsAgustin Montiel GonzalezPas encore d'évaluation

- Model-7 (1-4)Document23 pagesModel-7 (1-4)Sayyed FaqruddinPas encore d'évaluation

- 2 Well Design ProcessDocument38 pages2 Well Design ProcessJoseMi Vacaflor IllanesPas encore d'évaluation

- Re92105 2003-11Document32 pagesRe92105 2003-11Madhu RajagopalanPas encore d'évaluation

- Pressure Pipe Fittings PDFDocument64 pagesPressure Pipe Fittings PDFmonkeyDivanPas encore d'évaluation

- Api C23 1CW-FL E1Document19 pagesApi C23 1CW-FL E1kevin_lim90Pas encore d'évaluation

- BK16-M-DS-003 - A - Data Sheet For Manual ValvesDocument3 pagesBK16-M-DS-003 - A - Data Sheet For Manual ValvesHiếu NguyênPas encore d'évaluation

- LauncherDocument29 pagesLauncherMecha AuahPas encore d'évaluation

- Tinita: Engineering Private LimitedDocument2 pagesTinita: Engineering Private LimitedalokbdasPas encore d'évaluation

- ACUMULADORESDocument18 pagesACUMULADORESJuan GuillermoPas encore d'évaluation

- G-90-041-VAG-10 - ENGINEERING - Vers.01.00Document47 pagesG-90-041-VAG-10 - ENGINEERING - Vers.01.00Tudor MarcusPas encore d'évaluation

- B 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerDocument11 pagesB 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerpragatheeskPas encore d'évaluation

- Lennox CX34 CX33 Coils Installation ManualDocument20 pagesLennox CX34 CX33 Coils Installation Manualfogdart100% (1)

- Specification For Lube Oil and Dry Gas Seal SystemDocument17 pagesSpecification For Lube Oil and Dry Gas Seal Systemjahosolaris5512Pas encore d'évaluation

- 8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFDocument90 pages8559 Finalresponsetoprebidqueriesftp114720.04.2016 PDFAbhijeet SahuPas encore d'évaluation

- HD - Planta de PVCDocument7 pagesHD - Planta de PVCDavid LapacaPas encore d'évaluation

- Viking Extended Coverage Quick Respons SidewallDocument6 pagesViking Extended Coverage Quick Respons SidewallguspriyPas encore d'évaluation

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskPas encore d'évaluation

- SBR StudyDocument4 pagesSBR StudypragatheeskPas encore d'évaluation

- LabDocument12 pagesLabpragatheeskPas encore d'évaluation

- SBR 1Document20 pagesSBR 1pragatheeskPas encore d'évaluation

- RFQ For Pumps-UpdatedDocument3 pagesRFQ For Pumps-UpdatedpragatheeskPas encore d'évaluation

- List of Preferred BrandDocument8 pagesList of Preferred BrandpragatheeskPas encore d'évaluation

- AreaDocument6 pagesAreapragatheeskPas encore d'évaluation

- ComparisonDocument10 pagesComparisonpragatheeskPas encore d'évaluation

- Work Activity List For Lockdown Scenario - 2nd MonthDocument1 pageWork Activity List For Lockdown Scenario - 2nd MonthpragatheeskPas encore d'évaluation

- Tax Clearance Calculator Check ScenariosDocument1 pageTax Clearance Calculator Check ScenariospragatheeskPas encore d'évaluation

- MBR FibracastDocument83 pagesMBR FibracastCu AgPas encore d'évaluation

- Equipment: Respond To This Bidding DocumentDocument1 pageEquipment: Respond To This Bidding DocumentpragatheeskPas encore d'évaluation

- Appendix A7 2Document2 pagesAppendix A7 2pragatheeskPas encore d'évaluation

- MSIG Jilid V 02 Table of ContentDocument4 pagesMSIG Jilid V 02 Table of ContentnaqiePas encore d'évaluation

- Table of Chapters and AbbreviationsDocument84 pagesTable of Chapters and AbbreviationspragatheeskPas encore d'évaluation

- MBR System Comparison GuideDocument9 pagesMBR System Comparison GuidepragatheeskPas encore d'évaluation

- MSIG Jilid V 01 Title Page & ForewordDocument4 pagesMSIG Jilid V 01 Title Page & Forewordnaqie100% (1)

- Centrifuge Appendix 2CDocument6 pagesCentrifuge Appendix 2Csachinsuvarna1987Pas encore d'évaluation

- Appendices O&MDocument115 pagesAppendices O&MpragatheeskPas encore d'évaluation

- Chapter 2Document42 pagesChapter 2Manoj SinghPas encore d'évaluation

- SeparatorDocument1 pageSeparatorpragatheeskPas encore d'évaluation

- Centrifuge Appendix 2CDocument6 pagesCentrifuge Appendix 2Csachinsuvarna1987Pas encore d'évaluation

- Coverpage and MessagesDocument14 pagesCoverpage and MessagespragatheeskPas encore d'évaluation

- Power PointDocument29 pagesPower PointswordprakashPas encore d'évaluation

- Transmittal TPCL 09004Document1 pageTransmittal TPCL 09004pragatheeskPas encore d'évaluation

- MBR WebDocument1 pageMBR WebpragatheeskPas encore d'évaluation

- New Word 2007 DocumentDocument1 pageNew Word 2007 DocumentpragatheeskPas encore d'évaluation

- Industrial Transmission CatalogueDocument22 pagesIndustrial Transmission CatalogueAzhar MandhraPas encore d'évaluation

- DISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFDocument16 pagesDISJUNTOR DE MÉDIA TENSÃO COOPER VN2-24E+Brochure PDFedmarrobPas encore d'évaluation

- Vend RegDocument49 pagesVend RegProcaeHexdofPas encore d'évaluation

- List of Organisations SAR147 Apr2012Document2 pagesList of Organisations SAR147 Apr2012Tan Lian KiatPas encore d'évaluation

- Slump and Compacting Factor Test Values and Uses in Concrete WorkabilityDocument2 pagesSlump and Compacting Factor Test Values and Uses in Concrete WorkabilityNick GenesePas encore d'évaluation

- Andrews General Usability HeuristicsDocument1 pageAndrews General Usability HeuristicsGhaniPas encore d'évaluation

- MC Lab Manual ModifiedDocument64 pagesMC Lab Manual ModifiedBaswamy CsePas encore d'évaluation

- Dell Operation ManagementDocument13 pagesDell Operation ManagementIsha GosainPas encore d'évaluation

- Turbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowDocument3 pagesTurbo Machines and Propulsion Exam Questions on Pumps, Turbines, Pipe FlowAdams100% (1)

- INDIAN BEAMSDocument18 pagesINDIAN BEAMSSushmita GhoshPas encore d'évaluation

- Chapter 5-The Memory SystemDocument80 pagesChapter 5-The Memory Systemjsanandkumar22Pas encore d'évaluation

- Physics 110A: Electromagnetism: 1 Introduction and OverviewDocument4 pagesPhysics 110A: Electromagnetism: 1 Introduction and OverviewJoshua LinPas encore d'évaluation

- 90ma012 - CarrierDocument32 pages90ma012 - Carrierrafaelpaiva871531Pas encore d'évaluation

- INNOVATIVE TRENDS - FLYER-converted-mergedDocument6 pagesINNOVATIVE TRENDS - FLYER-converted-mergedPandimadevi MPas encore d'évaluation

- 11 Iso 10110Document28 pages11 Iso 10110fmeylanPas encore d'évaluation

- Static Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. KarandeDocument5 pagesStatic Analysis of VMC Spindle For Maximum Cutting Force: Mahesh M. Ghadage Prof. Anurag V. Karandefujy fujyPas encore d'évaluation

- TUK EECQ 5291 - Professional Engineering Practice - April 2018Document314 pagesTUK EECQ 5291 - Professional Engineering Practice - April 2018gaza manPas encore d'évaluation

- Portfolio Isaura SagredoDocument22 pagesPortfolio Isaura SagredoIsauraPas encore d'évaluation

- Sika PDS - E - Sika FastFix - 138 TPDocument2 pagesSika PDS - E - Sika FastFix - 138 TPlwin_oo2435Pas encore d'évaluation

- LTODriveSCSI - 040809 (GA32-450-10)Document346 pagesLTODriveSCSI - 040809 (GA32-450-10)Eduardo Rodriguez NajarPas encore d'évaluation

- Projection Achievement ReportDocument8 pagesProjection Achievement ReportPskaruppiah KarupsPas encore d'évaluation