Académique Documents

Professionnel Documents

Culture Documents

CE4030 Env Eng Lab Manual SMSN 31072013 PDF

Transféré par

Abhishek AryaDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CE4030 Env Eng Lab Manual SMSN 31072013 PDF

Transféré par

Abhishek AryaDroits d'auteur :

Formats disponibles

Environmental Engineering Laboratory Manual

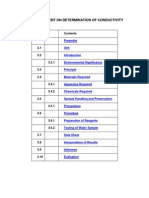

LIST

OF

ENVIRONMENTAL

LABORATORY EXPERIMENTS

Experiment

No

E1

E2

E3

E4

E5

E6

E7

E8

2013

ENGINEERING

Title of the Experiment

Page no

Determination

of

the

turbidity,

electrical conductivity and pH of the

given sample

Estimation of optimum coagulant

dosage

2-4

Determination of acidity, alkalinity

and types of hardness

Analysis of ions: copper, chlorides

and sulfate

Determination of solids

Determination of chemical oxygen

demand (COD).

Determination of dissolved oxygen

(D.O)and biological oxygen demand

(BOD)

Determination

of

break

point

chlorination

References

7-14

Department of Civil Engineering, IIT Madras

5-6

15-19

20-23

24-25

26-30

31-32

33

Page 1

Environmental Engineering Laboratory Manual

2013

Experiment No.E1

TURBIDITY, ELECTRICAL CONDUCTIVITY AND pH

Aim: To determine turbidity, electrical conductivity and pH of

the given samples.

(i) Turbidity: Turbidity is a measure of suspended matter that affects

the light scattering /light absorption properties of water. Jackson (light

absorption principle) and Nephelometric (intensity light scattering

principle) meters are mostly used to measure turbidity of water

samples. The units of turbidity are Jackson turbidity unit (JTU) and

Nephelometric turbidity unit (NTU).

Principle: Turbidity is measured photo-metrically by determining the

percentage of light of a given intensity is scattered or absorbed.

Apparatus: Turbidity meter; sample tubes

Reagents: Reference standard turbidity solutions (0.02, 20, 100 and

800 NTU)

Procedure:

1. Switch on turbidity meter and wait for few minutes till the

instrument warms up.

2. Shake the standard solution present in the cell/bottle before

keep it inside the sample chamber/holder and measure the

turbidity of the reference standard solutions.

3. In case, any deviation in reading the reference solution, calibrate

the instrument using calibration switch.

4. Shake the sample before keep it inside the sample

chamber/holder and note down the turbidity of the sample.

(ii) Electrical Conductivity: The electrical conductivity (EC) is a

measure of the capacity of a substance or solution to carry an

electrical current. The conductivity is represented by reciprocal value

of electrical resistance in ohms relative to cubic centimeter of water at

25oC. The measured EC value is used as an alternate method to

estimate the total dissolved solids (TDS) concentration of the sample.

EC is represented by the symbol k and its unit is millisiemens per

meter (mS/m) or micromhos per centimeter [mho/cm].

Principle: Conductivity is determined using the distance between the

electrodes and their surface area. According to Ohms law, the current

Department of Civil Engineering, IIT Madras

Page 2

Environmental Engineering Laboratory Manual

2013

through a conductor between two points is directly proportional to the

potential difference across the two points.

Apparatus: Conductivity meter, small beakers

Reagents:

Distilled water or deionised water: The water is to have an

electrical conductivity of less than 0.01 mS/m (< 0.1 mho/cm). Boil

the water shortly before use to minimize CO 2 content (equal to

atmospheric equilibrium).

0.01M Standard potassium chloride solution (KCl): Dissolve

745.6 mg anhydrous KCl (dried 1 hour at 180C) in distilled water and

dilute to 1000 ml. This solution has an electrical conductivity of 141.2

mS/m at 25o C.

Procedure:

1. Rinse conductivity cell with 0.01M KCl solution. Calibrate the

conductivity meter using the KCl reference solution to obtain cell

constant.

2. Measure the electrical conductivity of the 0.01M KCl solution at

room temperature.

3. Rinse cell with sample. Measure the electrical conductivity of the

sample.

4. Rinse the cell with deionised water between samples.

5. Thoroughly rinse the cell in distilled water after measurement,

keep it in distilled water when not in use.

Calculations

Compute the cell constant, KC according to the formula:

The conductance (G in mho) of standard potassium chloride (KCl)

solution is measured and from the corresponding conductivity, a cell

constant C is calculated by the expression: C = (k)/G. For 0.01 N KCl

solution the k value is 1412.

EC= Gs x C (mho/cm)

Where Gs= measured conductance of the given sample.

The TDS of an unknown sample is calculated using the following

relationship:TDS (mg/l) = C x EC (mmho/cm), where C is empirical

constant (it varies between 0.55 to 0.9 depending upon the soluble

solids present in water).

Department of Civil Engineering, IIT Madras

Page 3

Environmental Engineering Laboratory Manual

2013

(iii) pH: It is positive hydrogen ion concentration. The pH scale is

used to express the concentration of hydrogen ions in a liquid. The pH

scale ranges from 1 to 14 i.e. most acid to most alkaline. The

hydrogen ion concentration is an important parameter in determining

the quality of water and wastewater. The pH of the water/wastewater

sample is measured by pH meter. A pH meter consists of a measuring

probe connected to electronic meter that measures and displays the

pH reading.

Principle: The electro chemical potential between a known liquid

inside glass electrode and unknown liquid outside. The meaning of pH

is potential of hydrogen (H).

Apparatus: pH meter

Procedure:

1. Rinse the probe with distilled water. Calibrate the pH meter

using reference solution.

2. Rinse the probe with sample and dip the pH measuring probe in

sample and read the value of pH on the screen of the pH meter.

3. Rinse the probe with distilled/deionised water between samples.

4. Thoroughly rinse the probe in distilled water after measurement,

keep it in distilled water when not in use.

Observations and calculations:

Sample

Turbidity

(NTU)

Electrical

conductivity (S)

PH

1

2

3

4

Results

Turbidity

= ..NTU

Electrical conductivity = .S

PH

Department of Civil Engineering, IIT Madras

Page 4

Environmental Engineering Laboratory Manual

2013

Experiment No.E2

OPTIMUM COAGULANT DOSAGE

Aim: To find the optimum amount of coagulant required to treat given

water sample.

Coagulation: Coagulation is the process of destabilizing colloidal

particles so that particle growth can occur as a result of particle

collisions. In wastewater treatment settleable solids are effectively

removed by sedimentation process. But, the small size colloidal

particles are not possible to remove by gravitational settling due to

Brownian motion. However, if the colloidal particles are destabilized

through agglomeration of particles into group/large particles, increase

in settling velocities, they can be effectively removed by sedimentation

tank. The theory of chemical coagulation is very complex. The exact

mechanism of coagulation is not known, however, following four

mechanisms are thought to be occurring during coagulation process.

These include ionic layer compression, adsorption, charge

neutralization and inter-particle bridging. Typical coagulants used in

wastewater treatment are synthetic organic polymers, metal salts such

as alum or ferric sulphate, prehydrolized metal salts (polyaluminum

chloride and polyiron chloride).

Principle: Metal salts hydrolyse in presence of the natural alkalinity to

form metal hydroxides. The divalent cations can reduce the zetapotential, while the metal hydroxides are good absorbents and hence

remove the suspended particles by enmeshing them.

Alum [Al 2 S(SO 4 ) 3 . 18H 2 O] is the most widely used coagulant in water

treatment. When alum solution is added to water, the molecules

dissociate to yield SO 4 2- and Al3+. The +ve species combine with

negatively charged colloidal to neutralise part of the charge on the

colloidal particle. Thus, agglomeration takes place.

Coagulation is a quite complex phenomenon and the coagulant should

be distributed uniformly throughout the solution. A flash mix

accomplishes this.

Apparatus: Jar test apparatus, turbid meter, beakers, pipette and pH

meter.

Reagents: Alum, Ferric chloride

Department of Civil Engineering, IIT Madras

Page 5

Procedure

Environmental Engineering Laboratory Manual

2013

1. Measure the initial turbidity of the given sample.

2. Find the pH of the sample and adjust it to 6 to 8.5.

3. Take six jars of 1 litre capacity and take 0.5 litre of sample in

each jar and add varying doses of alum (1, 2, 4, 6, 8, 10 mg/l)

to each one of them.

4. Keep the sample in jar test apparatus and put it for rapid mixing

at 100 rpm for 1 min and then to slow mixing at 20 rpm for 20

min.

5. Stop the motor and allow the sample to settle for 30 min. Collect

the supernatant from each jar and find out the turbidity.

6. Plot a graph with alum dosage along x-axis and turbidity along

y-axis.

7. The dosage of alum, which represents least turbidity, gives

optimum coagulant dosage (O.C.D.).

8. Repeat steps 36 with higher dose of alum, if necessary.

Observations and calculations

Sl No

Concentration

(ppm)

Turbidity (NTU)

Result

Optimum coagulant dosage = .. mg/l

Department of Civil Engineering, IIT Madras

Page 6

Environmental Engineering Laboratory Manual

2013

Experiment No.E3

ALKALINITY, ACIDITY AND HARDNESS

ALKALINITY

Aim: To determine the alkalinity in the given water and waste water

samples.

(i) Alkalinity: The alkalinity of water is a measure of its capacity to

neutralize acids i.e. to absorb hydrogen ions, without significant pH

change. The alkalinity in water is primarily due to the presence of salts

of weak acids and strong bases. It is caused by presence of hydroxides

(OH-), carbonates (CO--) and bicarbonates (HCO 3 ).

Principle: Alkalinity can be obtained by neutralizing OH-,CO 3 2- and

HCO 3 - with standard H 2 SO 4 . Titration to pH 8.3 or decolourisation of

phenolphthalein indicator will show complete neutralization of OH- and

CO 3 2-, while to pH 4.4 or sharp change from yellow to pink of

methyl orange indicator will indicate total alkalinity.

Ca(OH) 2 + H 2 SO 4 CaSO 4 + 2H 2 O

2CaCO 3 + H 2 SO 4 Ca(HCO 3 ) 2 + CaSO 4

Ca(HCO 3 ) 2 + H 2 SO 4 CaSO 4 + CO 2

Apparatus: Burettes, volumetric flasks, conical flasks and beakers.

Reagents:

0.05N Standard sodium carbonate solution: Dry 3 to 5g of sodium

carbonate (Na 2 CO 3 ), at 250C for 4 hour and cool in a dessicator.

Accurately weigh 2.50.2g to the nearest mg, dissolve in distilled

water and make to 1litre.

0.1N Standard H 2 SO 4 solution: Dilute 2.8 ml concentrated sulphuric

acid to 1 litre. Standardise against 40.00 ml 0.05N Na 2 CO 3 with about

60 ml distilled water, in a beaker by titrating potentiometrically to pH

5. Lift out electrodes, rinse into the same beaker and boil gently for 3

to 5 min under a watch glass cover. Cool the solution to room

temperature, rinse cover glass into the beaker and finish titration to

pH 4.3. Calculate normality of sulphuric acid:

Department of Civil Engineering, IIT Madras

Page 7

Normality, N =

Environmental Engineering Laboratory Manual

2013

(AB)/(53.00 C)

where: A = g Na 2 CO 3 weighed into the 1 litre-flask for the Na 2 CO 3

standard

B = ml Na 2 CO 3 solution taken for standardisation titration

C = ml acid used in standardisation titration

0.02N Standard sulphuric acid solution: Dilute the approximate

0.1N solution to 1L. Calculate volume to be diluted as: ml volume =

N/20

where: N = exact normality of the approximate 0.1N solution.

Phenolphthalein indicator solution, alcoholic, pH 8.3. Dissolve 5

g phenolphthalein in 500 ml 95% ethyl alcohol. Add 500 ml distilled

water

Mixed indicator Dissolve 20g of methyl red, 100 mg of bromocrysol

green in 100ml 95% ethyl or isopropyl alcohol.

Procedure

Phenolphthalein alkalinity:

1. Take 25 to 50 ml sample in a conical flask.

2. Add 2 to 3 drops of phenolphthalein indicator. If it turns pink (pH >

8.3), titrate with 0.02 N H 2 SO 4 to disappearance of the colour.

Record ml of titrant used.

Observations and Calculations

Titration 1 (For Phenolphthalein alkalinity)

Burette solution: H 2 SO 4

Pipette solution: Sample

Indicator: phenolphthalein

End Point: Disappearance of pink colour

S.No

Volume of

sample(ml)

Burette reading

Initial(ml)

Department of Civil Engineering, IIT Madras

Final(ml)

Volume of

H 2 SO 4 (ml)

Page 8

Total alkalinity:

Environmental Engineering Laboratory Manual

2013

1. Add a drop of mixed indicator to the solution in which

phenolphthalein alkalinity determined.

2. Titrate it against 0.02N sulphuric acid. Appearance of pink colour

indicates the end point

Observations and Calculations

Titration 2 (For total alkalinity)

Burette solution: H 2 SO 4

Pipette solution: Sample

Indicator: mixed indicator

End Point: Appearance of pink colour

S.No

Volume of

sample(ml)

Burette reading

Initial(ml)

Final(ml)

Volume of

H 2 SO 4 (ml)

Phenolphthalein alkalinity (P):

P= (as CaCO 3 ) = (V1*N of H 2 SO 4 * 50,000)/Vol. of sample.

Total alkalinity (T):

T= (as CaCO 3 ) = (V2*N of H 2 SO 4 * 50,000)/Vol. of sample.

Result

Total alkalinity present in the water sample =

ACIDITY

Aim: To determine the acidity in the given water and waste water

samples.

(ii) Acidity: Acidity is the measure of the amount of base required to

neutralise a given sample to the specific pH. Strong mineral acids,

Department of Civil Engineering, IIT Madras

Page 9

Environmental Engineering Laboratory Manual

2013

weak acids such as carbonic, acetic and hydrolysing salt such as ferric

and aluminium sulphates may contribute acidity.

It is important

because acid contributes to corrosiveness and influences certain

chemical and biological processes. Dissolved CO 2 is usually the major

acidity component of unpolluted surface water. In the sample,

containing only carbon dioxide-bicarbonate carbonate, titration to pH

8.3 at 25C corresponds to stoichiometric neutralisation of carbonic

acid to carbonate. Since the colour change of phenolphthalein indicator

is close to pH 8.3, this value is accepted as a standard end point for

the titration of total acidity. For more complex mixture or buffered

solution fixed end point of pH 3.7 and pH 8.3 are used. Thus, for

standard determination of acidity of wastewater and natural water,

methyl orange acidity (pH 3.7) and phenolphthalein acidity (pH 8.3)

are used.

Principle: Hydrogen ions present in a sample as a result of

dissociation or hydrolysis of solutes are neutralised by titration with

standard alkali. The acidity thus depends upon the end point pH or

indicator used.

Apparatus : Burette, Pipette, conical flasks, volumetric flasks and

beakers

Reagents

0.02N NaOH Solution: Dissolve 0.8g of NaOH in distilled water and

dilute to 1000ml

Methyl orange indicator: Dissolve 50g of methyl orange powder in

distilled water and dilute to 100ml

Phenolphthalein indicator: Dissolve 1g of phenolphthalein in 100ml

of 95% ethyl alcohol or isopropyl alcohol, and add 100 ml of distilled

water to it and 0.02N NaOH solution by drop wise until faint pink

colour appears.

Procedure

1. Pipette out 25 ml of sample into conical flask. Add 2 drops of

methyl orange indicator to the sample solution.

2. Titrate the sample solution against 0.02N sodium hydroxide

solution. The end point is noted when colour change from orange

red to yellow.

Department of Civil Engineering, IIT Madras

Page 10

Environmental Engineering Laboratory Manual

2013

3. Add two drops of phenolphthalein indicator and continue the

titration till a pink colour formation. Note down the volume of

the titrant used.

Observations and calculations

Burette solution: NaOH

Pipette solution: Sample

Indicator: Methyl orange, Phenolphthalein

End Point: Yellow, Pink

S.No

Volume of

sample(ml)

Burette reading

Initial

(ml)

Final (ml)

Volume of

NaOH (ml)

Methyl orange acidity due to mineral acids (as CaCO 3 ) =

(V1*N of NaOH *50,000)/Vol. of sample

Phenolphthalein acidity =

Total acidity (as CaCO 3 ) = (V2*N of NaOH *50,000)/Vol. of sample

Result

Methyl orange acidity

Phenolphthalein acidity

Total acidity

=

=

=

HARDNESS

Aim: To determine the total hardness, calcium

magnesium hardness of the given water sample.

hardness

and

(iii) Hardness: It is the property of water that requires considerable

amount of soap to produce a foam or lather and produces scales in the

hot water units. Hardness in water is caused by multivalent metallic

cat ions.

Department of Civil Engineering, IIT Madras

Page 11

Environmental Engineering Laboratory Manual

2013

Principle: In alkaline solution ethylene diamine tetra acetate EDTA,

Ca and Mg to form a soluble chelated complex. Ca and Mg ions

develop wine red color with Erio chrome black T under alkaline

condition. When EDTA is added as titrant, Ca and Mg divalent ions get

complex resulting in sharp change from wine red to blue which

indicates end point of the reaction.

Ca2+ + Mg

2+

+ EDTA

PH +-0.1

Ca EDTA + Mg EDTA

Apparatus: Burette, pipette, conical flask

Reagents

Buffer solution : Dissolve 16.9g NH 4 Cl in 143 ml conc. NH 4 OH. Add

1.25g magnesium salt of ethylene diamine tetra acetate (EDTA) and

dilute to 250 ml with distilled water. Store in a air tight plastic bottle

for up to one month.

Complexing agent: Magnesium salt of 1,2 cyclohexane diamine tetra

acetic acid. Add 250mg per 100 ml sample only if interfering ions are

present and sharp end point is not obtained.

Indicator: Eriochrome Black T sodium salt. Dissolve 0.5g dye in

100 ml triethanolamine or 2 ethylene glycol monomethyl ether. The

salt can also be used in dry powder form by grinding 0.5g dye with

100g NaCl.

0.01M Standard EDTA solution: Weigh 3.723g di-sodium salt of

EDTA, dihydrate, dissolve in distilled water and dilute to 1000 ml.

Store in polyethylene bottle.

Standard Calcium Solution: Weigh 1.000g anhydrous CaCO3 in a

500 ml flask. Add 1ml HCl slowly through a funnel till all CaCO 3 is

dissolved. Add 200 ml distilled water and boil for a few minutes to

expel CO 2 . Cool and add a few drops of methyl red indicator and

adjust to the intermediate orange color by adding 3N NH 4 OH as

required. Transfer quantitatively and dilute to 1000 ml with distilled

water, 1 ml = 1mg CaCO 3 .

Department of Civil Engineering, IIT Madras

Page 12

Procedure

Environmental Engineering Laboratory Manual

2013

Total hardness:

1. Take 25 ml of sample in a conical flask. Add 2 ml of ammonia

buffer and 2 drops of erichrome black T to it. The sample will

turn to wine red in color.

2. Titrate the sample with 0.01 N EDTA till the wine red color turns

to blue. Note down the volume of EDTA used (V1).

3. Repeat the procedure with blank sample and note down the

volume of EDTA used (V2).

Calcium hardness:

1. Take 25 ml sample in a conical sample. Add 1 ml of NaOH to the

sample to raise pH to 12. Add a pinch of muroxide indicator to it.

The sample will turn to pink in color.

2. Titrate the sample with 0.01 N, EDTA till the pink color turn to

purple color. Note down the volume of EDTA used (V3).

3. Repeat the experiment for blank sample and note down the

volume of EDTA used (V4).

Permanent hardness:

1. Take 25 ml of sample in a conical flask. Add 2 ml of ammonia

buffer and 2-3 drops of EBT to it. The sample will turn to wine

red in color.

2. Titrate the sample with 0.01 N EDTA till the wine red color turns

to blue. Note down the volume of EDTA used (V5).

3. Repeat the procedure with blank sample and note down the

volume of EDTA used (V6).

Department of Civil Engineering, IIT Madras

Page 13

Environmental Engineering Laboratory Manual

2013

Observations and calculations

Hardness

type

Total

hardness

Calcium

hardness

Permane

nt

hardness

Sample Name

Initial burette Final burette Difference

reading

reading

Sample (V1)

Blank (V2)

Sample (V3)

Blank (V4)

Sample (V5)

Blank (V6)

Total harness (in mg/l as CaCO 3 ) =

sample (ml)

{(V1-V2) x1000} / vol of

Calcium harness (in mg/l as CaCO 3 ) =

sample (ml)

{(V3-V4) x1000} / vol of

Permanent hardness (in mg/l as CaCO 3 ) = {(V5-V6) x1000} / vol of

sample (ml)

Magnesium hardness = total hardness -calcium hardness

Results

Total harness (in mg/l as CaCO 3 )

..

Calcium harness (in mg/l as CaCO 3 )

Permanent hardness (in mg/l as CaCO 3 )

= .

Magnesium hardness (in mg/l as CaCO 3 ) = .

Department of Civil Engineering, IIT Madras

Page 14

Environmental Engineering Laboratory Manual

2013

Experiment No.E4

IONS: CHLORIDES, SULFATE AND COPPER

CHLORIDES

Aim: To determine the chlorides concentrations present in given water

sample.

(i) Chlorides: Chlorides present in water and wastewater in varying

concentration. Various sources such as mineral contents, sea water

droplets, human excreta discharging to natural water bodies

contributes chloride concentration to water.

Principle: Chloride ion concentration in the water can be determined

by titration with silver nitrate. As the silver nitrate solution is slowly

added, a precipitate of silver chloride forms.

Ag+ (aq) + Cl (aq) AgCl (s)

The end point of the titration occurs when all the chloride ions are

precipitated. Then additional silver ions react with the chromate ions of

the indicator, potassium chromate, to form a red-brown precipitate of

silver chromate.

2Ag+ (aq) + CrO 4 2 (aq) Ag 2 CrO 4 (s)

Titration should be carried out under conditions of pH 6.5 9. At

higher pH silver ions may be removed by precipitation with hydroxide

ions, and at low pH chromate ions may be removed by an acid-base

reaction to form hydrogen chromate ions or dichromate ions, affecting

the accuracy of the end point.

Apparatus: Weighing balance, burette, pipettes, conical flasks,

beakers, measuring cylinders

Reagents

Indicator: 5% potassium chromate (K 2 CrO 4 ): 1.0 g of K 2 CrO 4

was dissolved in 20 ml of distilled water.

Department of Civil Engineering, IIT Madras

Page 15

Environmental Engineering Laboratory Manual

2013

AgNO 3 solution: 9.0 g of AgNO 3 is transferred to a 500 ml volumetric

flask and made up to volume of flask with distilled water. The resulting

solution is approximately 0.1 M.

BaCl 2

Procedure

1. Take 25 ml of sample in the conical flask. Adjust the sample pH

between to be 7 to 8 by adding sulphuric acid or sodium

hydroxide solution.

2. Add 1 ml of potassium chromate to get light yellow color.

3. Titrate with standard silver nitrate (AgNO 3 ) solution till the color

changes from yellow to brick red. Note down the volume of

AgNO 3 solution added (V1).

4. Repeat the above procedure for the blank sample (distilled

water) and note down the volume of AgNO 3 solution added (V2).

Observations and calculations:

Trial

Volume of AgNO 3 (ml)

V1

V2

Chloride in mg/l = {(V1-V2) * N of AgNO 3 *35.45* 1,000}/Vol. of

sample

Result

Chloride concentration in the given sample =

SULFATE

Aim: To determine the sulfate concentration present in given water

sample

(ii) Sulfate: The sulfate ion is one of the major anions occurring in

natural waters. The presence of sulfate increases the formation of hard

scales in boilers and heat exchanger, reduction of sulfate to hydrogen

Department of Civil Engineering, IIT Madras

Page 16

Environmental Engineering Laboratory Manual

2013

sulfate under anaerobic conditions causes odor and sewer corrosion

problems.

Principle: The concentration of sulfate is determined by light

absorption principle. Sulfate ion (SO 4 2-) is precipitated in an acetic

acid medium with barium chloride (BaCl 2 ) by forming barium sulfate

(BaSO 4 ) crystals of uniform size.

SO 4 2- (aq) + Ba 2 + (aq) BaSO 4 (s)

Light absorbance of the BaSO 4 suspension is measured by spectrophotometer and the SO 4 2- concentration is determined by comparison

with the standard chart.

Apparatus: UV-Visible Spectrophotometer, weighing balance, stirrer,

conical flasks, beakers, measuring cylinders

Reagents:

BaCl 2

Buffer solution

Procedure

1.

Take 100 ml of sample in a conical flask and add 20 ml buffer

solution and mix in a stirring apparatus. During stirring add one

spoon of BaCl 2 crystals and stirrer for 1-2 minutes at constant

speed.

2.

Pour the solution in to spectrometer (420 nm) absorption cell

and measure the turbidity within 5 minutes.

3.

Estimate SO 4 2- concentration in the sample by comparing sample

turbidity with standard chart.

4.

Repeat the above procedure for determining the absorbance of

known SO 4 2- concentration in the range of 0 to 40 mg/l with an

increment of 5 mg /l and prepare standard chart.

Department of Civil Engineering, IIT Madras

Page 17

Environmental Engineering Laboratory Manual

2013

Observations and calculations:

Sulfate

concentration

(mg/l)

Absorbance

Result

Sulfate concentration in the given sample =

COPPER

Aim: To determine the copper concentration present in given water

sample

(iii) Copper: Copper rarely occurs naturally in water. Most copper

contamination in drinking water is due to corrosion of the copper pipes

or fittings. At very high concentrations, copper causes bitter metallic

taste in water and result in blue-green stains on plumbing fixtures. At

low concentrations, copper is not harmful to humans.

Principle: The concentration of copper is determined by light

absorption principle.

Apparatus: UV-Visible Spectrophotometer, weighing balance, conical

flasks, beakers, measuring cylinders.

Reagents

1N Acetic acid

5 % Potassium ferrocyanide

Department of Civil Engineering, IIT Madras

Page 18

Procedure:

Environmental Engineering Laboratory Manual

2013

1. Take known quantity of sample and add 1 ml of 1N acetic acid

and 5 ml of 5 % K 4 Fe (CN) 6 and mix thoroughly.

2. Dilute the sample using distilled water and make up to 25 ml.

Transfer the solution into spectrometer absorption cell and

measure the absorbance at 480 nm.

3. Find out the copper concentration from the standard graph

corresponding to the sample absorbance.

Observations and calculations:

Copper

concentration

(mg/l)

Absorbance

Results

Copper concentration in the given sample =

Department of Civil Engineering, IIT Madras

Page 19

Environmental Engineering Laboratory Manual

2013

Experiment No.E5

SOLIDS

Aim: To find the total, suspended, dissolved, volatile, fixed, settleable

solids present in the given sample.

Solids: Solids refers to residue remaining after a water/waste water

sample has been evaporated and dried at a specified temperature

(103-105c). High concentration of total solids will make drinking

water inpalatable and might have an adverse effect on human beings.

The main source of solids in water includes industrial discharge,

sewage treatment plant, fertilizers, road runoff, soil erosion etc.

Total solids (TS) consist of total suspended solids and dissolved solids.

Total dissolved solids (TDS) are mainly due to the organic matter

present in solution in water. The main constituent's are calcium,

magnesium, sodium and potassium. Hardness, scaly deposits,

sediments are some the effects caused by TDS. Total suspended solids

(TSS) are the materials that are retained in the filter paper when the

TDS is filtered.

The term fixed solids (FS) are applied to the residue remaining after

evaporation, drying at 103c followed by ignition at 600c. The loss of

weight in oxidation and volatilization on ignition is called volatile solids

(VS). Determination of fixed and volatile solids does not distinguish

precisely between inorganic and organic matter because loss on

ignition is not confined to organic matter. It includes losses on

volatilization of some mineral salts. The ratio of the VS to FS is often

used to characterize the waste water with respect to amount of

organic matter present.

The term settable solid refers to the materials in suspension settle due

to gravitational force under quiescent condition. Settleable solids in

surface and saline waters as well as domestic and industrial wastes

may be determined and expressed in ml/l. It can be either determined

by volumetric and gravimetric method. It is usually conducted in

Imhoff cone which is graduated glass cone of 1L capacity with a

narrow apex.

Principle: Gravimetric and filtration

Apparatus: Evaporating dishes/porcelain dish or crucible, drying

oven, dessicator, weighing balance, watman filter paper, muffle

furnace, filtration apparatus, Imhoff cone

Department of Civil Engineering, IIT Madras

Page 20

Procedure:

Environmental Engineering Laboratory Manual

2013

(i) Total solids:

1. Dry the evaporating dish at 104 1C for 1 hour, cool and store in

a dessicator.

2. Weigh the dish immediately before use. Note down the weight as

W1.

3. Stir sample with a magnetic stirrer. While stirring, pipette a

measured volume into the pre-weighed evaporating dish using a

wide bore pipette.

4. Evaporate the sample to dryness in an oven at 104 1C.If

necessary add successive portions to the same dish after

evaporation.

5. To prevent splattering, the oven temperature may be lowered

initially by 2C below boiling point and raised to 104C after

evaporation for 1 h. Cool the dish in a dessicator and note down

the weight asW2.

(ii) Total dissolved solids:

1. Measure the empty weight of porcelain dish and note down the

reading as W1.

1. Take known quantity of sample and pass it through the filter

paper and collect the filtrate.

2. Dry the filtrate sample in oven at 103c and cooled it in a

dessicator and note down the final weight as W2.

(iii) Total suspended solids:

1. Measure the empty weight of filter paper and note down reading

as W3.

2. Dry the filter paper with filtered sample in oven at 103c. Then

cool it in a dessicator and note down the final weight as W4.

(iv)Total Volatile and fixed solids:

1. Keep the sample which is oven dried (sample used for total

solids, whose weight=W1) in muffle furnace at a temperature of

600c for 1 hour.

2. Cool the sample and note down the final weight as W2. This will

give the amount of volatile solids.

3. The difference between total solids and total volatile solids gives

total fixed solids.

Department of Civil Engineering, IIT Madras

Page 21

Environmental Engineering Laboratory Manual

2013

(v) Settleable solids:

1. Fill the imhoff cone with sample and mix thoroughly.

2. Allow the solids to settle for 1 hour and note down the volume of

solids settled at the apex (in ml/liter).

Observations and calculations:

Total solids, mg/l = {(W2-W1)/V}*1000

Where W2= weight of dish + residue, mg after evaporation and

drying of sample at 103oC

W1 = weight of dish, mg

V = volume of sample (ml)

Total dissolved solids, mg/l = {(W2-W1)/V}*1000

Where W2= Final weight of the dish, mg

W1 = weight of dish, mg

V = volume of sample (ml)

Total suspended solids, mg/l = {(W4-W3)/V}*1000

Where W4= final weight of the filter paper containing the residue (mg)

W3= initial weight of the filter paper (mg)

V= volume of sample (ml)

Total volatile solids, mg/l= {(W1-W2)/V}*1000

Where W1= weight of dish + residue, mg after evaporation and

drying of sample at 103oC

W2 = Final weight of the dish, mg after evaporation of sample

at 600c

V = volume of sample (ml)

Total fixed solids, mg/l = Total solids Total volatile solids

Department of Civil Engineering, IIT Madras

Page 22

Environmental Engineering Laboratory Manual

Sample

No

TS

TDS

TSS

TFS

TVS

2013

SS

1

2

Results

1). Total solids (TS) present in the given sample was found to be

=..

2). Total dissolved solids (TDS) present in the given sample was found

to be =.

3). Total suspended solids (TSS) present in the given sample was

found to be =..

4).Total fixed solids (TFS) present in the given sample was found to be

=..

5).Total volatile solids (TVS) present in the given sample was found to

be =..

6).Total settable solids (SS) present in the given sample was found to

be =..

Department of Civil Engineering, IIT Madras

Page 23

Environmental Engineering Laboratory Manual

2013

Experiment No.E6

CHEMICAL OXYGEN DEMAND

Aim: To determine the chemical oxygen demand (COD) of the given

sample.

Chemical oxygen demand (COD): test is used to measure the

oxygen equivalent of the organic material in waste water that can be

oxidized chemically using dichromate in an acid solution. COD is widely

used as a means of measuring the organic strength of domestic and

industrial wastes. It allows measurement of a waste in terms of the

total quantity of oxygen required for oxidation to CO 2 and H 2 O. The

major advantage of COD test is the short time required for evaluation.

Many organic matter which are difficult to oxidized biologically such as

lignin can be oxidized chemically.

Principle: It is based on the principle that organic matter present in

the sample gets oxidized completely by potassium dichromate

(K 2 Cr 2 O 7 ) in the presence of sulphuric acid (H 2 So 4 ) and catalyst silver

sulphate (AgSo 4 ) to produce CO 2 and H 2 O. The excess of potassium

dichromate remaining after the reaction is treated with ferrous

ammonium sulphate. The dichromate consumed gives O 2 required for

oxidation of organic matter.

Apparatus: COD digestion vessel, COD digester, burette, pipette and

beaker.

Reagents

Standard potassium dichromate solution (K 2 Cr 2 O 7 ) 0.0417M

(0.25N): Dry the primary standard grade K 2 Cr 2 O 7 at 103C for 2

hours and dissolve 12.259 g K 2 Cr 2 O 7 , in distilled water and dilute to 1

liter.

Sulphuric acid reagent: Add 5.5g Ag 2 SO 4 technical or reagent

grade, per kg of conc.H 2 SO 4 , keep for a day or two to dissolve

completely .

Ferroin indicator solution: Dissolve 1.485g 1, 10-phenanthroline

monohydrate and 695 mg FeSO 4 .7H 2 O in distilled water and dilute to

100 ml. Commercial preparation may also be available.

Department of Civil Engineering, IIT Madras

Page 24

Environmental Engineering Laboratory Manual

2013

Standard ferrous ammonium sulphate (FAS): titrant, 0.25M:

Dissolve 98g Fe(NH 4 ) 2 (SO 4 ) 2 .6H 2 O in distilled water, add 20 ml conc.

H 2 SO 4 , cool and dilute to 1 liter.

Procedure

1. Take 2.5 ml of the sample in digestion vessel and add 1.5ml of

0.0417N of K 2 Cr 2 O 7 solution and 3.5ml of

Ag 2 SO 4 +H 2 SO 4

solution.

2. Reflux the mixture on a hot plate/digester for 2 hrs at 150c and

cool the mixture to room temperature.

3. Titrated mixture against ferrous ammonium sulphate (FAS)

solution using ferroin indicator till blue green color turns to

reddish brown color. Note down the volume of FAS used as Aml.

4. Repeat The experiment for blank sample (distilled water), note

down the volume of FAS used as Bml.

Observations and calculations:

COD (mg/l) = [{(B-A) *M *8000} * dilution factor (if any)]/ Volume of

Sample

where:

A = FAS used for sample in ml

B = FAS used for blank in ml

M = Molarity of FAS

Sample

no

sample

Sample 1

Burette reading

Initial

Final

Dilution

factor

Volume of FAS

consumed(ml)

(if any)

Hot blank

Diluted

sample

Sample 2

Hot blank

Diluted

sample

Results

The COD of the given water sample was found to be..

Department of Civil Engineering, IIT Madras

Page 25

Environmental Engineering Laboratory Manual

2013

Experiment No.E7

DISSOLVED OXYGEN (DO) AND

BIOLOGICAL OXYGEN DEMAND (BOD)

DISSOLVED OXYGEN (DO)

Aim: To determine the amount of dissolved oxygen present in the

given sample.

(i) Dissolved oxygen (DO): Dissolved oxygen is one of the most

important constituents of natural water system. It indicates the

pollution status of river. The dissolved oxygen in water depends upon

its temperature, solubility. Low DO value indicates the presence of

organic matter in water. At least 4 mg/l of DO is required for fish and

other species.

Principle: It is based on the principle that oxygen present in the

sample is oxidizes the divalent manganous to its higher valency under

alkaline conditions and manganese in higher states of valencies is

capable of oxidizing I- to I 2 under acidic conditions. Thus the amount of

I 2 released is equivalent to the dissolved oxygen present. The iodine is

measured using standard sodium thiosulphate solution.

If no oxygen is present, a pure white precipitate of Mn(OH) 2 forms

Mn 2 + 2OH- Mn(OH) 2 (s) ( white precipitate)

If oxygen is present

Mn 2 + + 2OH- + O 2 MnO 2 (s) + H 2 O

Under low pH

MnO 2 + 2I- + 4 H+ Mn 2 + + I 2 + 2H 2 O

I 2 is rather insoluble in water, but forms a complex with the excess

iodide present reversibly forms the more soluble tri-iodate thus

preventing escape of I 2 from the solution

I 2 + I- I 3 Apparatus: 300 ml BOD bottles, burette, pipette, conical flask etc.,

Department of Civil Engineering, IIT Madras

Page 26

Reagents

Environmental Engineering Laboratory Manual

2013

Manganous sulfate solution: Dissolve 480g MnSO 4 4H 2 O, or 400g

MnSO 4 2H 2 O, or 364g MnSO 4 H 2 O in distilled water, filter and dilute to

1 litre. This solution should not produce a blue color with starch

indicator when added to an acidified potassium iodide (KI) solution.

Alkaline-iodide-sodium azide solution: Dissolve 500g NaOH (or

700g KOH) and 135g NaI (or 150g KI) in distilled water and dilute to

IL. Add 10 g NaN 3 dissolved in 40 ml distilled water.

Starch indicator solution: Use either an aqueous solution or soluble

starch powder mixture. Prepare an aqueous solution by dissolving 2 g

of laboratory grade soluble starch powder and 0.2 g of salicylic acid

(as a preservative) in 100 ml of hot distilled water.

Sodium thiosulfate standard solution, 0.0250 N: Dissolve 6.205 g

Na 2 S 2 O 3 5H 2 O in distilled water. Add 1.5 ml 6 N NaOH or 0.4 g solid

NaOH and dilute to 1 litre. Standardize with bi-iodate solution.

Procedure

1. Collect the sample to be tested in a 300 ml BOD bottle taking

special care to avoid adding air to the liquid being collected. Fill

bottle completely and add stopper.

2. Remove bottle stopper and add 2 ml of the manganous sulfate

solution at the surface of the liquid. Add 2 ml of the

alkaline-potassium iodide-sodium azide solution at the surface of

the liquid. Replace the stopper, avoid trapping air bubbles and

shake well by inverting the bottle several times.

3. Repeat shaking after floc has settled halfway. Allow floc to settle

a second time.

4. Add 2 ml of concentrated sulfuric acid and close the bottle with

stopper. Rinse the top of the bottle to remove any acid and

shake well until the precipitate is completely dissolved (uniform

yellow color).

5. Take 203 ml of sample from the BOD bottle into a conical flask

and titrate with 0.0250 N sodium thiosulfate until the solution is

a pale yellow (straw) color.

6. Add a small quantity (approximately 1 ml) of starch indicator

continue the titration with 0.0250 N sodium-thiosulfate until blue

colour disappears (blue to colorless). Record the ml of sodiumthiosulfate used.

Department of Civil Engineering, IIT Madras

Page 27

Environmental Engineering Laboratory Manual

2013

Observations and Calculations

Calculate the concentration of DO in the sample using the

following formula:

Burette reading ml of (Na 2 S 2 O 3 5H 2 O)

Trial

Final reading

(FR)

Initial reading

(IR)

FR-IR

I

II

Average

Result

DO of the given sample =

BIOCHEMICAL OXYGEN DEMAND (BOD)

Aim: To determine the BOD of the given sample

(ii) Biochemical Oxygen Demand (BOD): BOD is defined as the

amount of oxygen required by bacteria while stabilizing decomposable

organic matter under controlled aerobic conditions. This test is widely

used to determine the pollution strength of domestic and industrial

wastes in terms of the oxygen demand. The BOD test relies on

measurable depletion of dissolved oxygen (DO) over a specified period

of time, generally 5 day at 20o C incubation. The BOD is considered

complete after 20 days. The 20 days is too long to wait. The 5 days is

a reasonable period for most (70-80 %) of the total BOD to be

exerted.

Principle: The BOD is measured by determining the oxygen consumed

(by the bacteria) from a sample placed in an air-tight container and

kept in a controlled environment for a preselected period of time.

Apparatus: BOD bottles, Burette, pipette, conical flask, BOD

Incubator

Department of Civil Engineering, IIT Madras

Page 28

Reagents

Environmental Engineering Laboratory Manual

2013

Phosphate buffer solution: Dissolve 8.5 g KH 2 PO 4 , 21.75 g

K 2 HPO 4 , 33.4 g Na 2 HPO 4 7H 2 O, and 1.7 g NH 4 Cl in about 500 ml

distilled water and dilute to 1 litre. The pH should be 7.2 without

further adjustment. Alternatively, dissolve 42.5 g KH 2 PO 4 or 54.3 g

K 2 HPO 4 in about 700 ml distilled water. Adjust pH to 7.2 with 30%

NaOH and dilute to 1 litre.

Magnesium sulfate solution: Dissolve 22.5 g MgSO 4 7H 2 O in

distilled water and dilute to 1 litre.

Calcium chloride solution: Dissolve 27.5 g CaCl 2 in distilled water

and dilute to 1 litre.

Ferric chloride solution: Dissolve 0.25 g FeCl 3 6H 2 O in distilled

water and dilute to 1 litre.

Dilution water: Place desired volume of distilled water in a suitable

bottle and add 1 ml each of phosphate buffer, MgSO 4 , CaCl 2 , and

FeCl 3 solutions/L of water. Seed dilution water, if desired. pH of the

dilution water should be between 6.5- 8.5 ( it is customary to buffer

the solution by means of a phosphate system at about pH 7) calcium

and magnesium salts are added to give buffering capacity and proper

osmotic conditions also serve to provide with any of these elements

that are needed in growth and metabolism. Ferric chloride and

magnesium sulphate supply the requirements for iron sulphur and

nitrogen. The phosphate buffer furnishes any phosphorous that may

be needed. The nitrogen should be eliminated in cases where

nitrogenous oxygen demand is being measured.

Procedure:

1. Dilute the settled sewage provided to 30-40 times using aerated

tap water.

2. Fill the BOD bottle in duplicate with diluted sewage by taking

care that no air bubble entraps.

3. Determine the DO (Do) of aerated water and fill the bottle with

aerated tap water.

4. Incubate both the sample and blank BOD bottles at 200 C. After

5 days take the bottles having sewage and blank and measure

DO calculate BOD 5.

Department of Civil Engineering, IIT Madras

Page 29

Environmental Engineering Laboratory Manual

2013

Observations and calculations

0th day reading

Trial

Burette reading ml of (Na 2 S 2 O 3 5H 2 O)

Final reading (FR) Initial reading

(IR)

DO in mg/l

FR-IR

I

II

Average

5 day reading

Trial

Burette reading ml of (Na 2 S 2 O 3 5H 2 O)

Final reading (FR) Initial reading

(IR)

DO in mg/l

FR-IR

I

II

Average

5 day BOD,= BOD 5 (mg/l) = {[D1-D2]-[B1-B2]}/ P

D 1 = DO of the sample immediately after preparation, mg/l,

D 2 = DO of the sample after 5 day incubation at 20C, mg/l,

B 1 = DO of blank immediately after preparation, mg/l,

B 2 = DO of blank after 5 day incubation at 20C, mg/l,

P= dilution factor

Ultimate BOD, L t =L 0 (1-e-kt)

L t = BOD at any time t

L 0 = ultimate BOD

t= time in days

k= BOD rate constant (0.23/day)

Result

BOD of the given sample =

Department of Civil Engineering, IIT Madras

Page 30

Environmental Engineering Laboratory Manual

2013

Experiment No.E8

BREAK POINT CHLORINATION

Aim: To determine the chlorine demand for given sample and break

point chlorination.

Chlorination: Water used for drinking and cooking should be free of

pathogenic (disease causing) microorganisms that cause illnesses such

as typhoid fever, dysentery, cholera, and gastroenteritis. Purification

of drinking water containing pathogenic microorganisms requires

specific treatment called disinfection. Several disinfection methods

eliminate disease-causing microorganisms in water, among them

chlorination is the most commonly used.

Principle: Chlorine combines with water to form hypochlorous and

hypochloric acid. Hypochlorous acid dissociates to give the OCl- and

HOCl depending upon pH of the solution. Hypochlorides also give the

OCl- ions, HOCl rupture the cell membrane of microbes (disease

producing organisms). These also react with the impurities like

ammonia, oxidizable organic matter like ferrous ions, nitrites, etc. to

form chloramines and stable ions of the latter respectively.

Figure 8.1: The Breakpoint Chlorination Curve: Reaction of HOCl

with Pure H 2 O + NH 3

Regions 1 and 2: formation of combined Cl 2 dominates over oxidation

of N; concentration of residual Cl 2 increases with increasing Cl 2 :N ratio

Region 3: Oxidation of N dominates over formation of combined Cl 2 ;

when Cl 2 :N ratio increases, more combined Cl 2 is oxidized.

Region 4: All N oxidized; increase in Cl 2 :N ratio leads to increase in

free Cl 2 residual

Department of Civil Engineering, IIT Madras

Page 31

Environmental Engineering Laboratory Manual

2013

Apparatus: Beakers, conical flasks, burette

Reagents: Standard chlorine solution, acetic acid, potassium iodide,

0.025N standard sodium thiosulphate solution, starch indicator.

Procedure:

1. Take 200ml of samples in six jars and add varying amount (1, 2,

3, 4, 5, 6, 8 mg/l) chlorine solution to each jar.

2. Stir the sample with a glass rod/mechanical mixer for complete

mixing. Allow 20 minutes contact time for chemical reaction.

3. Take 25 ml of sample in a conical flask and add 5 ml of acetic

acid and 1 gram of potassium iodide and allow the reaction to

complete.

4. Titrate the sample with 0.025 N standard sodium thio-sulphate

solution until the yellow color of the librated iodine is almost

faded out.

5. Add 1 ml of starch indicator, the solution turns blue. Continue

the titration till the blue color disappears. Note down the volume

of sodium thio-sulphate consumed (A).

6. Repeat the procedure for blank sample (B).

7. Determine the available residual chlorine in the sample using

following equation:

{(A-B)*N*35.45*1000}/volume of sample in ml.

8. Plot graph between concentration of chlorine added and residual

chlorine to find out the break point chlorination.

Observations and Calculations

Chlorine dosage (mg/l)

Residual chlorine(mg/l)

Result

Break point chlorination: ..

Department of Civil Engineering, IIT Madras

Page 32

References

Environmental Engineering Laboratory Manual

2013

Standard Methods for the Examination of Water and Waste Water,

1995. 20th Edition, APHA.

Peavy, H.S., Rowe, D.R., Tchobanoglous, G. Environmental

Engineering, 1985. McGraw Hill International Editions, New York.

Sawyer, C.L., McCarthy, P.L. and Parkin, G. F.,1994. Chemistry for

Environmental Engineering. McGraw Hill International Editions, New

York.

MetCalf and Eddy.,1991. Wastewater Engineering, Treatment, Disposal

and Reuse. 3rd Edition, Tata McGraw Hill, New Delhi.

Department of Civil Engineering, IIT Madras

Page 33

Vous aimerez peut-être aussi

- ICP Determination of Metal in Waste WaterDocument18 pagesICP Determination of Metal in Waste WaterNorshafiza Mohd Rosli100% (5)

- Carbonate-Bicarbonate Mixture Anal Chem Post LabDocument7 pagesCarbonate-Bicarbonate Mixture Anal Chem Post LabKennedy OrtegaPas encore d'évaluation

- Analytical ChemistryDocument33 pagesAnalytical ChemistryKuo Sarong100% (1)

- Environmental Engineering LabmanualDocument32 pagesEnvironmental Engineering LabmanualrupenderPas encore d'évaluation

- Challenging Experiments Lab Manual-CurtDocument20 pagesChallenging Experiments Lab Manual-Curtpramukhjain.9966Pas encore d'évaluation

- MethodologyDocument7 pagesMethodologyAliganyira NelsonPas encore d'évaluation

- Calculation: 2-44 Physical & Aggregate Properties (2000)Document5 pagesCalculation: 2-44 Physical & Aggregate Properties (2000)Ronald Figo Torres EchePas encore d'évaluation

- Technical Analysis Laboratory ManualDocument54 pagesTechnical Analysis Laboratory ManualP P SELVI selvi.chemPas encore d'évaluation

- 2510 ConductivityDocument7 pages2510 ConductivitySilvy SaavedraPas encore d'évaluation

- Water and Wastewater Engineering LaboratoryDocument20 pagesWater and Wastewater Engineering LaboratoryAditya Mani Tripathi100% (1)

- Laboratory Manual: Environmental EngineeringDocument24 pagesLaboratory Manual: Environmental EngineeringSai KumarPas encore d'évaluation

- 634914904072057500Document35 pages634914904072057500Arjun HerePas encore d'évaluation

- Analyzing The Presence of Iron by Spectrophotometer, Mangan by Persulfate Method, and Cloride by Argentrometric MethodDocument20 pagesAnalyzing The Presence of Iron by Spectrophotometer, Mangan by Persulfate Method, and Cloride by Argentrometric MethodC. A. ArdhaniPas encore d'évaluation

- Water Quality Assessment in Kannur DistrictDocument6 pagesWater Quality Assessment in Kannur DistrictIJRASETPublicationsPas encore d'évaluation

- Estimation of Chlorine in Water Samples-ELECTROANALYSISDocument3 pagesEstimation of Chlorine in Water Samples-ELECTROANALYSISAnonymous kw8Yrp0R5rPas encore d'évaluation

- EE LAB Manual (2018-Civ-311)Document35 pagesEE LAB Manual (2018-Civ-311)Iqra BatoolPas encore d'évaluation

- Kuznetsov - 2019 - J. - Phys. - Conf. - Ser. - 1348 - 012033Document6 pagesKuznetsov - 2019 - J. - Phys. - Conf. - Ser. - 1348 - 012033MMHFPas encore d'évaluation

- A Comparative Study of Chromium (III) Ion-Selective Electrodes Based On N, NBis (Salicylidene) - O-Phenylenediaminatechromium (III)Document9 pagesA Comparative Study of Chromium (III) Ion-Selective Electrodes Based On N, NBis (Salicylidene) - O-Phenylenediaminatechromium (III)Amramm Amiel MejiaPas encore d'évaluation

- Effects of Operating Conditions On Improving Alkali and Electrical Efficiency in Chlor-Alkali Diaphragm CellDocument10 pagesEffects of Operating Conditions On Improving Alkali and Electrical Efficiency in Chlor-Alkali Diaphragm Cellnikhilsingh1087Pas encore d'évaluation

- Electrocoagulation Treatment For Removal of Color and Chemical Oxygen Demand in Landfill Leachate Using Aluminum ElectrodeDocument4 pagesElectrocoagulation Treatment For Removal of Color and Chemical Oxygen Demand in Landfill Leachate Using Aluminum ElectrodeDarth FrootLoopsPas encore d'évaluation

- Potentiometric Determination of Chloride in Natural WatersDocument6 pagesPotentiometric Determination of Chloride in Natural WatersNaeem MalikPas encore d'évaluation

- Offshore CorrosionDocument16 pagesOffshore CorrosionpkannanPas encore d'évaluation

- Determination of Conductivity Exp3 - PDFDocument12 pagesDetermination of Conductivity Exp3 - PDFSusheel TalrejaPas encore d'évaluation

- Textile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateDocument13 pagesTextile Industries Wastewater Treatment by Electrochemical Oxidation Technique Using Metal PlateSanti LeoPas encore d'évaluation

- Post Lab and Pre Lab Questions - Cycle-I (2 Files Merged)Document11 pagesPost Lab and Pre Lab Questions - Cycle-I (2 Files Merged)Sayan GharPas encore d'évaluation

- Experiment: Aim: Estimation of COD in Water Sample PrincipleDocument2 pagesExperiment: Aim: Estimation of COD in Water Sample Principlenidhi varshneyPas encore d'évaluation

- Lab Protocal I Revised PDFDocument40 pagesLab Protocal I Revised PDFAswathyPas encore d'évaluation

- Study of The Production of Hydrogen Bubbles at Low Current Densities For Electroflotation ProcessesDocument6 pagesStudy of The Production of Hydrogen Bubbles at Low Current Densities For Electroflotation ProcessesFrancisco CampbellPas encore d'évaluation

- Applied Chemistry Practical Manual Session 12-13Document62 pagesApplied Chemistry Practical Manual Session 12-13Nikhil Anil GPas encore d'évaluation

- Chem 301 Lab OneDocument6 pagesChem 301 Lab OneGobe JamPas encore d'évaluation

- Experiment I1 Preparation of Some Cobaltammine ComplexesDocument7 pagesExperiment I1 Preparation of Some Cobaltammine ComplexesIftitah HauriyahPas encore d'évaluation

- WT ch1Document20 pagesWT ch1አድሜ ልስልሱPas encore d'évaluation

- Engineering Chemistry PDFDocument39 pagesEngineering Chemistry PDFYash NaiwarPas encore d'évaluation

- Public Health EngineeringDocument48 pagesPublic Health EngineeringrajendrakumarPas encore d'évaluation

- Removal of Zinc Metal From Industrial Wastewater Using GCC AdsorbentDocument9 pagesRemoval of Zinc Metal From Industrial Wastewater Using GCC AdsorbentIJRASETPublicationsPas encore d'évaluation

- Practical Report-1 PH ValueDocument6 pagesPractical Report-1 PH ValueKusanSanjitPas encore d'évaluation

- Null 1Document49 pagesNull 1AkxzPas encore d'évaluation

- Inorganic Lab Exp 2Document6 pagesInorganic Lab Exp 2Jekyll Rev67% (3)

- Kerja Kas JieDocument11 pagesKerja Kas JienazirulaliPas encore d'évaluation

- Experiments 2 Calcium, Total Hardness, and Alkalinity AnalysisDocument21 pagesExperiments 2 Calcium, Total Hardness, and Alkalinity AnalysisDita AmaraPas encore d'évaluation

- Matecconf Sicest2017 02010Document6 pagesMatecconf Sicest2017 02010Trecy RezatantiaPas encore d'évaluation

- Relazione AcquaDocument17 pagesRelazione AcquamalossigiulioPas encore d'évaluation

- The Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalDocument5 pagesThe Study and Invention of Portable Voltammetry For Detecting Contamination Heavy MetalOmar ReynosoPas encore d'évaluation

- Polarography 160508035043Document25 pagesPolarography 160508035043Mahmoud MahmoudmPas encore d'évaluation

- Improvement of NO Removal From Wastewater by Using Batch Electrocoagulation Unit With Vertical Monopolar Aluminum ElectrodesDocument9 pagesImprovement of NO Removal From Wastewater by Using Batch Electrocoagulation Unit With Vertical Monopolar Aluminum Electrodesnishu thathsaraniPas encore d'évaluation

- Chloride in Natural Waters: An Environmental Application of A Potentiometric TitrationDocument3 pagesChloride in Natural Waters: An Environmental Application of A Potentiometric TitrationJhefer Avila OlorteguiPas encore d'évaluation

- Ce3311 Set1 PDFDocument2 pagesCe3311 Set1 PDFmaniPas encore d'évaluation

- Electrolytic ConductivityDocument17 pagesElectrolytic ConductivitySandeep MatetiPas encore d'évaluation

- Physical Parameter TestDocument13 pagesPhysical Parameter TesteidalinPas encore d'évaluation

- Optimizing Electrocoagulation of Drinking Water For Turbidity Removal in A Batch ReactorDocument6 pagesOptimizing Electrocoagulation of Drinking Water For Turbidity Removal in A Batch ReactorAlifFiqriahPas encore d'évaluation

- Chapte 4 WSTDocument32 pagesChapte 4 WSTnimcanPas encore d'évaluation

- Lab Mauanl For Chemistry Btech 1 YearDocument35 pagesLab Mauanl For Chemistry Btech 1 YearTilak SharmaPas encore d'évaluation

- Chapte 4 WSTDocument32 pagesChapte 4 WSTnimcanPas encore d'évaluation

- (300-313) V9N5CT Kinetic Modeling For Cu and Fe Using Orange PeelDocument14 pages(300-313) V9N5CT Kinetic Modeling For Cu and Fe Using Orange Peelleelabhanu12Pas encore d'évaluation

- Environmental Engineering Laboratory Manual Department Ofcivil EngineeringDocument55 pagesEnvironmental Engineering Laboratory Manual Department Ofcivil EngineeringSELVA BHARATHIPas encore d'évaluation

- Alkalinity, Hardness, Turbidity & PH DeterminationDocument4 pagesAlkalinity, Hardness, Turbidity & PH DeterminationVara PrasadPas encore d'évaluation

- Ib Chemistry Answers ToolDocument19 pagesIb Chemistry Answers ToolGeorges FarahPas encore d'évaluation

- Application of DC and Mark-Space Bias Differential Electrolytic Potentiometry For Determination of Cyanide Using A Programmable Syringe PumpDocument6 pagesApplication of DC and Mark-Space Bias Differential Electrolytic Potentiometry For Determination of Cyanide Using A Programmable Syringe PumpBhisma DamarekaPas encore d'évaluation

- In Situ Monitoring of Electroactive Species by Using Voltammetry at MicroelectrodesDocument8 pagesIn Situ Monitoring of Electroactive Species by Using Voltammetry at MicroelectrodesOmar ReynosoPas encore d'évaluation

- Selected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionD'EverandSelected Constants: Oxidation–Reduction Potentials of Inorganic Substances in Aqueous SolutionPas encore d'évaluation

- Chemistry of Advanced Environmental Purification Processes of Water: Fundamentals and ApplicationsD'EverandChemistry of Advanced Environmental Purification Processes of Water: Fundamentals and ApplicationsPas encore d'évaluation

- Design of Roadways Is Carried Out Using Indian Sandard Codes Like Irc, Is Etc and Should Be Followed in Construction of Any RoadDocument1 pageDesign of Roadways Is Carried Out Using Indian Sandard Codes Like Irc, Is Etc and Should Be Followed in Construction of Any RoadAbhishek AryaPas encore d'évaluation

- ST7013-Design of Steel Concrete Composite Structures PDFDocument15 pagesST7013-Design of Steel Concrete Composite Structures PDFAbhishek AryaPas encore d'évaluation

- ST7013-Design of Steel Concrete Composite Structures PDFDocument15 pagesST7013-Design of Steel Concrete Composite Structures PDFAbhishek AryaPas encore d'évaluation

- Contracts & Forms (CPWD)Document5 pagesContracts & Forms (CPWD)Abhishek Arya100% (2)

- Environmental Engineering Laboratory ManualDocument58 pagesEnvironmental Engineering Laboratory ManualFi Fa50% (2)

- Textiles Mills Waste: Cotton Textile Mill Waste Woolen Textile Mills Waste Synthetic Textile Mill WasteDocument3 pagesTextiles Mills Waste: Cotton Textile Mill Waste Woolen Textile Mills Waste Synthetic Textile Mill WasteAbhishek AryaPas encore d'évaluation

- Waste Reduction Alternatives (Volume Reduction)Document4 pagesWaste Reduction Alternatives (Volume Reduction)Abhishek AryaPas encore d'évaluation

- ElectrochemistryDocument16 pagesElectrochemistryMidhunRameshThuvassery100% (1)

- Chemical Reactions: Amedeo Avogadro 1776-1856Document38 pagesChemical Reactions: Amedeo Avogadro 1776-1856ade dosmaria100% (1)

- Exp 7 (Solved)Document9 pagesExp 7 (Solved)mahmudul100% (1)

- Chemistry Labaratory Manual For First Years: Jomo Kenyatta University of Agriculture and TechnologyDocument65 pagesChemistry Labaratory Manual For First Years: Jomo Kenyatta University of Agriculture and Technologymark njeru ngigi100% (1)

- Chem Insem Question PaperDocument2 pagesChem Insem Question PaperVivek SonawanePas encore d'évaluation

- AP Orange MCQ+FRQ NewDocument16 pagesAP Orange MCQ+FRQ NewMaya SwailemPas encore d'évaluation

- 2 Lab Report 2Document5 pages2 Lab Report 2Sara AndréiaPas encore d'évaluation

- Chem Ppp3 July 2017 MsDocument7 pagesChem Ppp3 July 2017 MsWriter BettyPas encore d'évaluation

- Art16 PDFDocument3 pagesArt16 PDFlata.tara123Pas encore d'évaluation

- Analytical-Chemistry With AnswerDocument4 pagesAnalytical-Chemistry With AnswerPeter PanPas encore d'évaluation

- Revised Lab Manual 14-12-2018Document299 pagesRevised Lab Manual 14-12-2018Abhishek NayakPas encore d'évaluation

- Astm E-1064Document4 pagesAstm E-1064Nhu SuongPas encore d'évaluation

- CT 338Document17 pagesCT 338Assane RoquePas encore d'évaluation

- Aashto T259 & T260Document18 pagesAashto T259 & T260Malaz Abdul JalilPas encore d'évaluation

- Titrimetric Determination of Free Boric Acid and Tetrafluoroboric Acid in Nickel Plating BathsDocument3 pagesTitrimetric Determination of Free Boric Acid and Tetrafluoroboric Acid in Nickel Plating BathsDang ThinhPas encore d'évaluation

- S3S4Chem - Acid Base IntroDocument65 pagesS3S4Chem - Acid Base IntroKaren BismontePas encore d'évaluation

- Viscosity PDFDocument2 pagesViscosity PDFNindy Dellia PutriPas encore d'évaluation

- WAEC Chemistry Syllabus 2022 PDF Download AvailableDocument26 pagesWAEC Chemistry Syllabus 2022 PDF Download AvailableSamuel AikinsPas encore d'évaluation

- Application of Potentiometric Titration in PharmacyDocument5 pagesApplication of Potentiometric Titration in PharmacyMuhammad Shahedul Islam100% (1)

- Open Ended Lab Applied Chemistry (CY-109 and 110)Document2 pagesOpen Ended Lab Applied Chemistry (CY-109 and 110)Areesha AlamPas encore d'évaluation

- Exp.7 Alkalinity TestDocument12 pagesExp.7 Alkalinity Testhero100% (1)

- ASEAN Manual of Food Analysis PDFDocument196 pagesASEAN Manual of Food Analysis PDFCristina PlesaPas encore d'évaluation

- LAb Report 7Document3 pagesLAb Report 7Faisal MumtazPas encore d'évaluation

- Chang Chemistry Chapter 4 QuestionsDocument12 pagesChang Chemistry Chapter 4 QuestionsBlanche DauzPas encore d'évaluation

- Lab Manual For Physiological Studies of RiceDocument83 pagesLab Manual For Physiological Studies of RiceMGNMPas encore d'évaluation

- Chemical Engineering Department: Adamson University College of EngineeringDocument13 pagesChemical Engineering Department: Adamson University College of EngineeringElujekwute BenjaminPas encore d'évaluation

- CL10 PLUS - User Manual Vers 0 2 EngDocument75 pagesCL10 PLUS - User Manual Vers 0 2 EngMantementoligal LigalPas encore d'évaluation

- CHE1503-001 2016 4 B PDFDocument89 pagesCHE1503-001 2016 4 B PDFsal27adamPas encore d'évaluation