Académique Documents

Professionnel Documents

Culture Documents

2871-Circular Clips #1 PDF

Transféré par

syllavethyjim0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues1 pageTitre original

2871-Circular Clips #1.pdf

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

26 vues1 page2871-Circular Clips #1 PDF

Transféré par

syllavethyjimDroits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 1

1

By GEOMETER

CIRCULAR

CLIPS

A

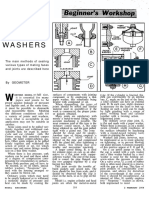

LTHOUGH OBTAINABLE in variety, commercial clips for

circular sections do not

meet all needs---either because of

size or type so, on occasion, it is

necessary to make such items.

The widest variety in commercial

clips is, perhaps, those for rubber,

joints and one of the best known is

This

the worm drive type.

consists essentially of a band with

shallow teeth on the outside; one end

is fixed to a small housing and the

other is pulled through the housing

by a screw or worm engaging

with the teeth.

In another type of clip the band is

much thinner, making two turns;

the free end passes through the slit

of a substantial split pin and tightening is effected by rolling the band

round the pin-turning this with a

punch through the eye. Clips may

also consist. of bands of springy wire

provided with eyes to accept screws or bolts.

Simple clips can be made from flat

strip of suitable thickness and width

-if necessary cut from sheet material

in small sizes. For a clip as at A, the

depth of the small lug is set with

pliers, the strip rolled round a bar

to shape it; then the other lug is set,

leaving a length for a supporting

piece if required. The hole for the

bolt is drilled with the clip off the

bar and the lugs are clamped together.

The clip at B can be made in similar

fashion. This type with two bolts or

screws avoids the necessity for springing open to fit it-if free access to

slip it on from the end of the circular

section is not available. A simple clip

can have support from a stud or bolt

as at C.

For a single supporting clip used on

a flat surface an important feature is

the turned-over lip at the free end

of the lug, D. With this, tightening

the bolt pulls the clip firmly on the

circular section, providing secure

support.

Duralumin hint

A clip for a true machined circular

section can be made from rectangular

bar stock as at E. In duralumin,

it is not too heavy or laborious to

make. The bore is drilled in the bar,

and reamed if possible, or the cut off

piece can be machined in an independent chuck. The cross hole for

the bolt is drilled, and careful work

with a slitting saw-not hacksawproduces a neat slit. Corners can be

rounded as required.

Light clips for holding a pair of

wires or steadying two pipes can be

arranged as F and G, turning from

strip or sheet metal, and using a

single screw or bolt for fixing. When

attaching to thin metal. work a selftapping screw can be used after

drilling the core hole.

When heating is available for

brazing or welding very accurate,

light and powerful steel clips can be

fabricated from tube or washersdepending on the width required.

Such clips can be in sizes from the

smallest upwards.

Tube or washer should be of the

31 MAY 1956

893

internal diameter required or bored

out in a lathe to size. The boss for

bolt or screw can be smaller tube or

rod drilled out, the hole being continually cleared or tapped halfway

for a setscrew. Filed on the outside

to suit the diameter of tube or washer

the boss is then brazed or welded on.

Finally, boss and tube are cut through.

Diagrams H and I show end and plan

views of a clip made from steel tube.

One from a washer would be narrower,

with the boss overlapping the sides.

Either clip must be fitted from the

end of the circular section to be

clamped, since opening the clip

would spoil it

The alternativepermitting easy assembling and dismantling-is bosses each side of the

clip, using two bolts, as for that at B.

At J and K are end and plan

views of a clip from sheet metal,

while L depicts the opened-out shape

before bending. Marked with dividers

the outside is sheared and filed, and

the inside carefully chain drilled and

tiled.

Distance X from the centre of the

clamping bolt when the clip is bent

is equal to the diameter of the bolt

plus the thickness of the material

multiplied by 1.57.

Splaying is

prevented by using washers under the

bolt and nut.

q

MODEL

ENGINEER

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimPas encore d'évaluation

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimPas encore d'évaluation

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimPas encore d'évaluation

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimPas encore d'évaluation

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimPas encore d'évaluation

- 2853-Simple Drilling JigsDocument1 page2853-Simple Drilling JigssyllavethyjimPas encore d'évaluation

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimPas encore d'évaluation

- 2877-Roller Chain & Sprockets PDFDocument1 page2877-Roller Chain & Sprockets PDFsyllavethyjimPas encore d'évaluation

- 2852-Polishing Metal SurfacesDocument1 page2852-Polishing Metal SurfacessyllavethyjimPas encore d'évaluation

- 2858-How To Use Scrapers PDFDocument1 page2858-How To Use Scrapers PDFsyllavethyjimPas encore d'évaluation

- 2847-Keys & Driving PinsDocument1 page2847-Keys & Driving PinssyllavethyjimPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- CP Carrillo HardwareDocument23 pagesCP Carrillo HardwarePaul ZiddyPas encore d'évaluation

- Long Products Rolling MillsDocument21 pagesLong Products Rolling Millsralish12Pas encore d'évaluation

- Chopper Jig-Plans PDFDocument10 pagesChopper Jig-Plans PDFMphilipTPas encore d'évaluation

- Specification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Document43 pagesSpecification: Hot Coiled Helical Springs Mainline Coaches, Emu and Freight Stock No. WD-01-HLS-94 (Rev.3)Anonymous PSNjTGUPas encore d'évaluation

- You Are Managing A Small Project That Is Expected To Take 11 Weeks To CompleteDocument1 pageYou Are Managing A Small Project That Is Expected To Take 11 Weeks To CompletealokPas encore d'évaluation

- 63 Best Angle Grinder HacksDocument66 pages63 Best Angle Grinder HacksPhillip Howarth100% (1)

- Ultrasonic Cleaning EquipmentDocument4 pagesUltrasonic Cleaning EquipmentAsishKumarPas encore d'évaluation

- C95300Document2 pagesC95300Romeo DequitoPas encore d'évaluation

- Arcelor Mittal Newcastle WorksDocument12 pagesArcelor Mittal Newcastle WorkssinhabillolPas encore d'évaluation

- Is 7283.1992 PDFDocument10 pagesIs 7283.1992 PDFTuff qualityPas encore d'évaluation

- Layup ToolingDocument47 pagesLayup ToolingGrittyBurnsPas encore d'évaluation

- Rolling Mill ReportDocument25 pagesRolling Mill ReportrohitPas encore d'évaluation

- Is 3739 1987Document13 pagesIs 3739 1987Kiran KumarPas encore d'évaluation

- Stuckey Casing ScrapersDocument5 pagesStuckey Casing ScrapersGeorge Lamey0% (1)

- Training Report: Industrial Training of Automobile EngineeringDocument16 pagesTraining Report: Industrial Training of Automobile EngineeringPavneet SurjanPas encore d'évaluation

- Aluminium CompaniesDocument4 pagesAluminium CompaniesHumayun KhanPas encore d'évaluation

- Browning Machine Gun Cal .30 - Technical Air Intelligence Report 21 - Examination of Japanese Browning Machine Gun - 1944Document15 pagesBrowning Machine Gun Cal .30 - Technical Air Intelligence Report 21 - Examination of Japanese Browning Machine Gun - 1944ab212amisarPas encore d'évaluation

- Manufacturing Process PliersDocument17 pagesManufacturing Process PliersVahap ÖzdemirPas encore d'évaluation

- Is 10138 2010 PDFDocument13 pagesIs 10138 2010 PDFIndira BanerjeePas encore d'évaluation

- 06 ExtrusionDocument43 pages06 ExtrusionSreekumar RajendrababuPas encore d'évaluation

- 1038A01 Noric, Plant Configuration 230kt, Rev00Document46 pages1038A01 Noric, Plant Configuration 230kt, Rev00Unsa KhuwajaPas encore d'évaluation

- Hot Rolled SectionsDocument30 pagesHot Rolled SectionsDuncan HarrisonPas encore d'évaluation

- Literature ReviewDocument15 pagesLiterature Reviewlekan4realPas encore d'évaluation

- Morgan Vee Mini BlockDocument5 pagesMorgan Vee Mini BlockRAUL VILLAMILPas encore d'évaluation

- Boxford Set UpDocument10 pagesBoxford Set UpANTONIO JOSE R S CRUZPas encore d'évaluation

- A582A582M-12e1 Standard Specification For Free-Machining Stainless Steel BarsDocument4 pagesA582A582M-12e1 Standard Specification For Free-Machining Stainless Steel Barstjt4779Pas encore d'évaluation

- Railway Venders Emails PDFDocument126 pagesRailway Venders Emails PDFRamiahNagarajanPas encore d'évaluation

- Products 08 SpaltfixDocument14 pagesProducts 08 Spaltfixspeeder86mePas encore d'évaluation

- Hot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesDocument7 pagesHot-Rolled and Cold-Finished Age-Hardening Stainless Steel Bars and ShapesRoland CepedaPas encore d'évaluation

- Hollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartDocument7 pagesHollow Lateral Extrusion Stuttgart Rudolf Ifu StuttgartjoaopedrosousaPas encore d'évaluation