Académique Documents

Professionnel Documents

Culture Documents

Weld Finishes

Transféré par

Dee DeeCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

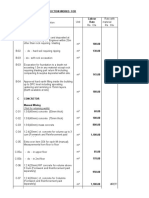

Weld Finishes

Transféré par

Dee DeeDroits d'auteur :

Formats disponibles

finishes

NOMMA #1

NOMMA #3

NOMMA #2

NOMMA #4

Photos NOMMA. Used with permission.

Welds

Custom Iron wrote the book on weld standards. Our expert

metalsmiths worked with the National Ornamental and

Miscellaneous Metals Association (NOMMA) to create the NOMMA

standards that exist today. The majority of Custom Iron products are

fabricated using a combination of NOMMA #2 and #3 weld finish

standards. Some product materials and designs restrict the type of

weld finish standards that are possible during normal fabrication.

Please inquire about pricing and availability for other weld finish

standards.

Fabrication Finish Options for Malleable Iron

Malleable iron direct from the foundry has an irregular rough

textured surface overall that reveals casting lines, voids, and other

imperfections. As Custom Iron works with the material to lengthen

or add ornamentation for a specific job, we add marks to the piece.

Lengthening a malleable iron baluster produces irregular flat or

smooth areas on the piece. Custom Iron offers three finish grades

for our malleable iron products:

Foundry Grade (FG) As received direct from the foundry. High level of surface texture variations and high

level of variation from piece to piece. Not recommended for most applications.

Commercial Grade (CG) Pieces from the foundry are selected for job uniformity and the largest variations

are cleaned up. Cast lines are still evident.

Architectural Grade (AG) Commercial grade malleable iron that is cleaned up to a higher degree and

sandblasted to minimize the surface texture variations.

Because of the irregularities that will be evident with any of the finish grades, we recommend a painted

finish for all malleable iron products. Custom Iron takes special care in handling sandblasted products. Any

residue (such as skin oils or fabric threads) must be removed before the paint coating is applied.

Foundry grade

FG primed

Commercial grade

CG primed

Architectural grade

AG primed

Fabrication and Finish Options for Clear Coated

Metal Railing Parts

Welds, tool, dye, and grind marks are part of the fabrication process. Those who enjoy the

rugged look of handmade metalwork will want to display these as fabricated marks of the

craft. Other customers will want to minimize the appearance of these marks. For customers

ordering a Clear Coat finish on balusters or panels, Custom Iron offers two grades of

fabrication for Clear Coat preparation: Clear Prep 2 and Clear Prep 1. Clear Prep 2 is the

standard fabrication for Custom Iron products. A painted finish covers the color distinction

of grind and tool marks, but will still leave some metal surface variations.

Clear Prep 2 is Custom Irons as fabricated product. The mill scale from the foundry is left

intact in areas where no additional process occurred, and it is absent from the worked areas.

These mill scale variations along with the tool and grind marks are left as fabricated and the

piece is clear coated in our Clear Coat 2 finish.

Clear Prep 1 is an upgrade to prepare for clear coating. The piece is specially fabricated to

conceal tool and grind marks and is then lightly sanded over raised surfaces to highlight the

texture variations before the clear coating is applied. This method works best where the basic

metal of the piece has a varied topography such as with hammered and chiseled bar or with

any of the twisted or scrolled balusters.

Clear Coat on Clear Prep 2

Uncoated Clear Prep 2 (left), Uncoated Clear Prep 1, (right)

Clear Coat on Clear Prep 1

Fabrication and Finish Options for Clear Coated Spiral Stairs

The materials and methods used to fabricate Custom Iron spiral stairs differ from the balusters

and panels of our metal railing systems. Due to the dissimilar materials used in fabrication of steel

spiral stairs, we do not sell spiral stairs with either of our Clear Coat finishes. For spiral stairs and

the companion railings, we offer an antiqued iron finish: Spiral Antique Natural.

First, the edges of the square tubing are lightly sanded. Then, using a mixture of clear coating and

black pigment, sanding and grinding marks are covered on the flat surfaces. Finally, the entire stair

and companion rail are sprayed with a clear top coat. Spiral Antique Natural finish is best suited for

use on spiral stairs with textured balusters.

Spiral Antique Natural finish

Vous aimerez peut-être aussi

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonD'EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonPas encore d'évaluation

- 2 Aluminium Fusion Welding 2015Document21 pages2 Aluminium Fusion Welding 2015Tuyen Nguyen100% (1)

- Repairing A Crack in CastingDocument2 pagesRepairing A Crack in CastingpriaPas encore d'évaluation

- Arc Welding Arc Welding Electrode Electrode: CCCCC CCCCCDocument36 pagesArc Welding Arc Welding Electrode Electrode: CCCCC CCCCCSantanu SarmahPas encore d'évaluation

- Tips For The Practitioner.: Flame StraighteningDocument2 pagesTips For The Practitioner.: Flame StraighteningmikirscPas encore d'évaluation

- Aluminium Alloys: Weldability of Materials Job Knowledge 21Document3 pagesAluminium Alloys: Weldability of Materials Job Knowledge 21kevin herryPas encore d'évaluation

- Introduction To Brazing of Aluminium Alloys: TALAT Lecture 4601Document24 pagesIntroduction To Brazing of Aluminium Alloys: TALAT Lecture 4601fedeloquiPas encore d'évaluation

- Introduction To Brazing V3 PDFDocument24 pagesIntroduction To Brazing V3 PDFMarcelo GuerraPas encore d'évaluation

- Joining Stainless Steel by Soldering, Brazing and Resistance WeldingDocument4 pagesJoining Stainless Steel by Soldering, Brazing and Resistance WeldingA K SinghPas encore d'évaluation

- Bend Testing: Job Knowledge 73Document3 pagesBend Testing: Job Knowledge 73kevin herryPas encore d'évaluation

- Welding Techniques NEWDocument95 pagesWelding Techniques NEWबंदनेश पाण्डेयPas encore d'évaluation

- Weldability: Introduction and Factor Affecting ItDocument15 pagesWeldability: Introduction and Factor Affecting ItAnant Ajithkumar100% (2)

- Copper and Copper AlloysDocument3 pagesCopper and Copper Alloyskevin herryPas encore d'évaluation

- Ferrous Material Structure and Binary Alloy SystemDocument68 pagesFerrous Material Structure and Binary Alloy SystemUsman FarooqPas encore d'évaluation

- WeldingDocument84 pagesWeldingJigar DodiaPas encore d'évaluation

- Aluminum Welding GuideDocument35 pagesAluminum Welding Guidenavas100% (1)

- Vacuum Brazing: Dawei Induction Heating Machine Co., LTDDocument9 pagesVacuum Brazing: Dawei Induction Heating Machine Co., LTDsajitha p sPas encore d'évaluation

- Weldability of Materials - Copper and Copper AlloysDocument5 pagesWeldability of Materials - Copper and Copper AlloysmanimaranPas encore d'évaluation

- What Are Nonferrous Metals?: AdvantagesDocument29 pagesWhat Are Nonferrous Metals?: AdvantagesHunter On HighwayPas encore d'évaluation

- Maxal Guide For Aluminum (Guía para Aluminio)Document44 pagesMaxal Guide For Aluminum (Guía para Aluminio)Jose AntonioPas encore d'évaluation

- 05 - Phase Transformation in Welding PDFDocument36 pages05 - Phase Transformation in Welding PDFIrfan KhanPas encore d'évaluation

- Projection WeldDocument20 pagesProjection WeldCebrac ItatibaPas encore d'évaluation

- Introduction To BrazingDocument24 pagesIntroduction To BrazingSundaravaradhan Iyengar100% (1)

- Brazing, Soldering, AdhesivesDocument31 pagesBrazing, Soldering, AdhesivesAchinthya PereraPas encore d'évaluation

- WeldingDocument19 pagesWeldingAlexander Muñoz SánchezPas encore d'évaluation

- Welding WireDocument20 pagesWelding WirefoxmancementPas encore d'évaluation

- Fundamentals of Welding InspectionDocument53 pagesFundamentals of Welding InspectionIlyes kPas encore d'évaluation

- Gas WeldingDocument5 pagesGas WeldingAbdullah ArshadPas encore d'évaluation

- Metal Repairs: Laser WeldingDocument24 pagesMetal Repairs: Laser WeldingV DhinakaranPas encore d'évaluation

- Gen - Importance of Welding in L & T PDFDocument30 pagesGen - Importance of Welding in L & T PDFSivaPas encore d'évaluation

- Welding Lecture 4 Fusion (Liquid) State Welding Processes (Resistance Welding)Document30 pagesWelding Lecture 4 Fusion (Liquid) State Welding Processes (Resistance Welding)Adel AbdelmaboudPas encore d'évaluation

- AluminiumDocument48 pagesAluminiumGhiffariAwliyaMuhammadAshfaniaPas encore d'évaluation

- 1434529014349-Welding DefectsDocument61 pages1434529014349-Welding DefectsJayaneela PrawinPas encore d'évaluation

- Resistance AWSDocument82 pagesResistance AWSaravindan100% (1)

- Weldability of Materials - Carbon Manganese and Low Alloy SteelsDocument6 pagesWeldability of Materials - Carbon Manganese and Low Alloy SteelsmanimaranPas encore d'évaluation

- Murex Oxy Welding Poster 2008 PDFDocument1 pageMurex Oxy Welding Poster 2008 PDFPCPas encore d'évaluation

- 9 Different Types of Welding Processes & Their AdvantagesDocument14 pages9 Different Types of Welding Processes & Their AdvantagesMohamedPas encore d'évaluation

- Documents - Pub - Advanced Welding TechnologyDocument60 pagesDocuments - Pub - Advanced Welding TechnologybalamuruganPas encore d'évaluation

- MIG Welding Vs Oxy - Docx Aasiemnet 2Document9 pagesMIG Welding Vs Oxy - Docx Aasiemnet 2IsaiahPas encore d'évaluation

- Resistance WeldingDocument13 pagesResistance WeldingAashishSethiPas encore d'évaluation

- Resistance WeldingDocument5 pagesResistance WeldingJoel BrasilBorgesPas encore d'évaluation

- Aluminum Welding GuideDocument8 pagesAluminum Welding Guideharish3742Pas encore d'évaluation

- New StandardsWELDING STANDARDS - VOLVODocument22 pagesNew StandardsWELDING STANDARDS - VOLVORadivojJovanovPas encore d'évaluation

- Thermanit 17-06 (Boehler)Document1 pageThermanit 17-06 (Boehler)queno1Pas encore d'évaluation

- WJ 2013 05Document128 pagesWJ 2013 05Matija BušićPas encore d'évaluation

- Casting DefectsDocument4 pagesCasting DefectsHamza KayaniPas encore d'évaluation

- Effect of Different Metalurgical Phases On The Welding Residual Stresses of Base MetalDocument71 pagesEffect of Different Metalurgical Phases On The Welding Residual Stresses of Base Metalsalmanzafar_37304938Pas encore d'évaluation

- Casting Processes CompleteDocument49 pagesCasting Processes CompleteRavi KumarPas encore d'évaluation

- Basic Guide To WeldingDocument7 pagesBasic Guide To WeldingJaveed A. KhanPas encore d'évaluation

- Powder MetallurgyDocument6 pagesPowder MetallurgyjayadevakodiPas encore d'évaluation

- Optimization of MIG Welding ParametersDocument6 pagesOptimization of MIG Welding ParametersMario Antonio Araya MorosoPas encore d'évaluation

- Gmaw & Fcaw-MsmeDocument73 pagesGmaw & Fcaw-MsmemilindPas encore d'évaluation

- Lincoln Welding MachineDocument4 pagesLincoln Welding MachinemevansmetreelPas encore d'évaluation

- The Iron Puddler My life in the rolling mills and what came of itD'EverandThe Iron Puddler My life in the rolling mills and what came of itPas encore d'évaluation

- Adiabatic Shear Localization: Frontiers and AdvancesD'EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddPas encore d'évaluation

- The Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelD'EverandThe Working of Steel: Annealing, Heat Treating and Hardening of Carbon and Alloy SteelPas encore d'évaluation

- Remedial Law Suggested Answers (1997-2006), WordDocument79 pagesRemedial Law Suggested Answers (1997-2006), Wordyumiganda95% (38)

- Bracket With SteelDocument1 pageBracket With SteelDee DeePas encore d'évaluation

- Remedial Law Suggested Answers (1997-2006), WordDocument79 pagesRemedial Law Suggested Answers (1997-2006), Wordyumiganda95% (38)

- 2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Document173 pages2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Jay-Arh97% (103)

- 2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Document173 pages2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Jay-Arh97% (103)

- 0812Document38 pages0812Dee DeePas encore d'évaluation

- 2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Document173 pages2007-2013 MERCANTILE Law Philippine Bar Examination Questions and Suggested Answers (JayArhSals)Jay-Arh97% (103)

- Astm A234Document8 pagesAstm A234Joffre ValladaresPas encore d'évaluation

- Unitized PanelDocument1 pageUnitized PanelDee DeePas encore d'évaluation

- Ansi H35.2 (M) - 2009Document53 pagesAnsi H35.2 (M) - 2009Dee Dee100% (3)

- Tealsheets PDFDocument37 pagesTealsheets PDFDee DeePas encore d'évaluation

- Astm 20M PDFDocument33 pagesAstm 20M PDFDee DeePas encore d'évaluation

- Astm b308b308mDocument6 pagesAstm b308b308mDee DeePas encore d'évaluation

- Astm A234Document8 pagesAstm A234Joffre ValladaresPas encore d'évaluation

- 16CFRPt2 1201Document24 pages16CFRPt2 1201Dee DeePas encore d'évaluation

- SteelWise Tolerances IllustratedDocument6 pagesSteelWise Tolerances IllustratedkenetjPas encore d'évaluation

- Astm A36Document7 pagesAstm A36Dianna LambertPas encore d'évaluation

- GalvanizingDocument3 pagesGalvanizingPankaj_Taneja_9684100% (2)

- M 102Document18 pagesM 102Shankar GurusamyPas encore d'évaluation

- BooksDocument34 pagesBooksDee DeePas encore d'évaluation

- Jotun Touchup Guideline PDFDocument1 pageJotun Touchup Guideline PDFDee DeePas encore d'évaluation

- LEGAL ETHICS BAR EXAM With Suggested Answers.Document5 pagesLEGAL ETHICS BAR EXAM With Suggested Answers.Blake Clinton Y. Dy91% (11)

- Types of Sliding DoorsDocument28 pagesTypes of Sliding Doorsnaveenarora298040Pas encore d'évaluation

- Aama 2604 Color Card120 - RalDocument2 pagesAama 2604 Color Card120 - RalDee DeePas encore d'évaluation

- Arch - Coating SecguideDocument222 pagesArch - Coating SecguideDee DeePas encore d'évaluation

- E 32 - 86 R01 - RtmyDocument5 pagesE 32 - 86 R01 - RtmyDee DeePas encore d'évaluation

- GPS - Prod: Production Control For IGU, Laminated and Toughened GlassDocument2 pagesGPS - Prod: Production Control For IGU, Laminated and Toughened GlassDee DeePas encore d'évaluation

- Jotun Touchup GuidelineDocument1 pageJotun Touchup GuidelineDee DeePas encore d'évaluation

- QUALANOD Spec. Ed 01.07.10 Final - Without Signature - 24.06.2010Document56 pagesQUALANOD Spec. Ed 01.07.10 Final - Without Signature - 24.06.2010jchemPas encore d'évaluation

- Midjourney Prompts Master Guide V 115Document252 pagesMidjourney Prompts Master Guide V 115james100% (6)

- Lesson Plan-ArtDocument1 pageLesson Plan-Artapi-589998076Pas encore d'évaluation

- MUSIC 10 FinalDocument13 pagesMUSIC 10 FinalJoanna Mari HubacPas encore d'évaluation

- Soal Bahasa Inggris Kelas 6Document2 pagesSoal Bahasa Inggris Kelas 6mutia ambarwatiPas encore d'évaluation

- Evidence 2Document3 pagesEvidence 2Antonio NaelsonPas encore d'évaluation

- Module Na Tunay 2 HandicraftDocument11 pagesModule Na Tunay 2 HandicraftJustina Servillon SumagpangPas encore d'évaluation

- Gato TricolorDocument4 pagesGato TricolorLieBee LiePas encore d'évaluation

- Rate 2012 CecbDocument254 pagesRate 2012 CecbChathuranga PriyasamanPas encore d'évaluation

- Phases 3 2nd Ed Test U6 BDocument2 pagesPhases 3 2nd Ed Test U6 BAmPas encore d'évaluation

- Deriving Meaning From Art: LaughterDocument4 pagesDeriving Meaning From Art: LaughterMira Aurumtin100% (1)

- Adjective OrderDocument11 pagesAdjective OrderCAROLINA DELGADO VASQUEZPas encore d'évaluation

- Renaissance ArchitectureDocument11 pagesRenaissance ArchitectureIonut Popescu100% (1)

- Unit Plan Goals and ObjectivesDocument2 pagesUnit Plan Goals and Objectivesapi-315423352Pas encore d'évaluation

- StealingDocument15 pagesStealinggera.maahiPas encore d'évaluation

- Cinema & SensationDocument16 pagesCinema & SensationSerge RyappoPas encore d'évaluation

- EVantage - VMware VSphere - Install, Configure, Manage (V8) STUDENT Lecture ManualDocument626 pagesEVantage - VMware VSphere - Install, Configure, Manage (V8) STUDENT Lecture Manualjiwoong.ohPas encore d'évaluation

- Conceptual Framework For Artmaking PDFDocument10 pagesConceptual Framework For Artmaking PDFPatrícia NogueiraPas encore d'évaluation

- English-PT 1Document24 pagesEnglish-PT 1Jane Nicole Miras SolonPas encore d'évaluation

- Comic Book: From Wikipedia, The Free EncyclopediaDocument10 pagesComic Book: From Wikipedia, The Free EncyclopediaWolf MoonPas encore d'évaluation

- BCA Booklet Content Drywall Internal Partition Sept 2013Document72 pagesBCA Booklet Content Drywall Internal Partition Sept 2013Carl XhingPas encore d'évaluation

- Color Harmony - Why Hulk Wears Purple PantsDocument53 pagesColor Harmony - Why Hulk Wears Purple Pantsalexandre-chenuPas encore d'évaluation

- 10 клас Natural ClassicDocument2 pages10 клас Natural ClassicМаряна ШукаткоPas encore d'évaluation

- Amy WinehouseDocument17 pagesAmy WinehouseCarlaPas encore d'évaluation

- Evolution of MinaretDocument7 pagesEvolution of MinaretClare GallagherPas encore d'évaluation

- Paterson Ewen: Life & WorkDocument117 pagesPaterson Ewen: Life & WorkArt Canada Institute100% (1)

- Aituts Midjourney For Fantasy ArtDocument94 pagesAituts Midjourney For Fantasy ArtvenomlustPas encore d'évaluation

- Utg PogDocument14 pagesUtg Pogjoe mamaPas encore d'évaluation

- White 1010 Sewing Machine Instruction ManualDocument46 pagesWhite 1010 Sewing Machine Instruction ManualiliiexpugnansPas encore d'évaluation

- Tumbang Preso: 15 Larong Pinoy and Its Rules/MechanicsDocument11 pagesTumbang Preso: 15 Larong Pinoy and Its Rules/MechanicsRasmey Marcos100% (1)

- Madeleine VionnetDocument8 pagesMadeleine Vionnetjbtpopicon100% (1)