Académique Documents

Professionnel Documents

Culture Documents

Absolute Roughness of Pipe Material

Transféré par

ea88b5Description originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Absolute Roughness of Pipe Material

Transféré par

ea88b5Droits d'auteur :

Formats disponibles

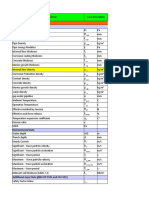

ABSOLUTE ROUGHNESS OF PIPE MATERIAL

1. SUMMARY

Absolute roughness is a measure of the surface roughness of a

material which a fluid may flow over. Absolute roughness is

important when calculating pressure drop particularly in the

turbulent flow regime. This article provides some typical absolute

roughness values for common conduit materials.

2. DEFINITIONS

Absolute

roughness

3. INTRODUCTION

The roughness of pipes, ducts and channels impacts on the flow

rates and pressure losses for fluids passing through them. This

roughness is generally expressed in units of length as the absolute

roughness of the conduit material. For use in calculating the

friction factor the absolute roughness is divided by the pipe

diameter resulting in the relative roughness.

4. ABSOLUTE ROUGHNESS FOR COMMON

MATERIALS

This table contains typical values of absolute roughness for

common construction materials.

Material

Drawn Tubing, Glass, Plastic

Drawn Brass, Copper, Stainless Steel

(New)

Flexible Rubber Tubing - Smooth

Flexible Rubber Tubing - Wire

Reinforced

Roughness

(mm)

0.0015-0.01

>0.0015-0.01

0.006-0.07

0.3-4

Stainless Steel

0.03

Wrought Iron (New)

0.045

Carbon Steel (New)

0.02-0.05

Carbon Steel (Slightly Corroded)

0.05-0.15

Carbon Steel (Moderately Corroded)

Carbon Steel (Badly Corroded)

0.15-1

1-3

Carbon Steel (Cement-lined)

1.5

Asphalted Cast Iron

0.1-1

Cast Iron (new)

0.25

Cast Iron (old, sandblasted)

Sheet Metal Ducts (with smooth joints)

1

0.02-0.1

Galvanized Iron

0.025-0.15

Wood Stave

0.18-0.91

Wood Stave, used

Smooth Cement

Concrete Very Smooth

Concrete Fine (Floated, Brushed)

Concrete Rough, Form Marks

Riveted Steel

Water Mains with Tuberculations

Brickwork, Mature Foul Sewers

0.25-1

0.5

0.025-0.2

0.2-0.8

0.8-3

0.91-9.1

1.2

3

Vous aimerez peut-être aussi

- Pipeline FrictionDocument17 pagesPipeline FrictionAbelardo ContrerasPas encore d'évaluation

- Dorization of Natural GasDocument18 pagesDorization of Natural GasManthan TalaPas encore d'évaluation

- Fully Deteriorated Cipp DesignDocument3 pagesFully Deteriorated Cipp DesignAnonymous YcAZv5qF67Pas encore d'évaluation

- Major and Minor LossesDocument8 pagesMajor and Minor Lossesapi-376123036Pas encore d'évaluation

- 4.3 Basic Design Awwa D100 & Api 650Document7 pages4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- 2010-07 PipeMaterialsDocument32 pages2010-07 PipeMaterialsenjoygurujiPas encore d'évaluation

- Compressibility Factor Z CalcDocument3 pagesCompressibility Factor Z Calclutfi awnPas encore d'évaluation

- 3Document6 pages3Petrus Jese Patarmatua PardedePas encore d'évaluation

- Landfill Off Gas Collection System CalculationsDocument15 pagesLandfill Off Gas Collection System CalculationsJhon Jairo Mazuera Guzman100% (1)

- Design Burried PipelineDocument44 pagesDesign Burried PipelineSk Abdul RavoofPas encore d'évaluation

- Well Design PDFDocument29 pagesWell Design PDFPratul ChoudhuryPas encore d'évaluation

- Art's Fluid Flow 1Document64 pagesArt's Fluid Flow 1Jagadeesh UnnamPas encore d'évaluation

- F2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic PipeDocument8 pagesF2686-14 Standard Specification For Glass Fiber Reinforced Thermoplastic Pipemasoud132Pas encore d'évaluation

- Design and Installation of Buried PipesDocument2 pagesDesign and Installation of Buried PipesmapasabcPas encore d'évaluation

- Advanced Tubing DesignDocument116 pagesAdvanced Tubing DesignDinesh KumarPas encore d'évaluation

- Gas RegulationsDocument168 pagesGas RegulationsJijo GeorgePas encore d'évaluation

- WorldPipelines November 2015Document108 pagesWorldPipelines November 2015Integridad de Equipos y Gestión de Activos NelcamPas encore d'évaluation

- Furmanite Failure ModesDocument34 pagesFurmanite Failure ModespkannanPas encore d'évaluation

- Cavitation in Restriction Orifices and Valves - NeutriumDocument8 pagesCavitation in Restriction Orifices and Valves - NeutriumAbbasPas encore d'évaluation

- Static Calculation of Pipeline Free SpansDocument1 pageStatic Calculation of Pipeline Free SpansMannattil Krishna KumarPas encore d'évaluation

- APPROVED - Module 15 - Mechanical Installation in Buildings - July 09Document109 pagesAPPROVED - Module 15 - Mechanical Installation in Buildings - July 09George100% (1)

- Offshore Applications of SRTPDocument5 pagesOffshore Applications of SRTPArif AshrafPas encore d'évaluation

- E07 QDocument20 pagesE07 QSoledad Fernández SantosPas encore d'évaluation

- PPI Handbook Above GroundDocument24 pagesPPI Handbook Above GroundNeil MalottPas encore d'évaluation

- Chilled Water Pipe DESIGNDocument22 pagesChilled Water Pipe DESIGNTanjim FakirPas encore d'évaluation

- Fusion-Bonded Epoxy-Coated Structural Steel H-Piles and Sheet PilingDocument5 pagesFusion-Bonded Epoxy-Coated Structural Steel H-Piles and Sheet PilingSama UmatePas encore d'évaluation

- Dual-Pot Sand Filter Type B (DSF-B)Document2 pagesDual-Pot Sand Filter Type B (DSF-B)kanchanabalajiPas encore d'évaluation

- Bonstrand PipeDocument24 pagesBonstrand Pipejayhuacat7743Pas encore d'évaluation

- Strength of Materials - PUPDocument60 pagesStrength of Materials - PUPshirelyna100% (1)

- Ilnas-En Iso 15493:2003Document11 pagesIlnas-En Iso 15493:2003Hassan0% (1)

- Inspection and Maintenance of Steel Girders-12Document10 pagesInspection and Maintenance of Steel Girders-12vpmohammedPas encore d'évaluation

- GREPipe Systems Marine Industry June 2010Document45 pagesGREPipe Systems Marine Industry June 2010vinonagu100% (1)

- Data Input Flowline Properties: Pipe Pipe Pipe 3Document12 pagesData Input Flowline Properties: Pipe Pipe Pipe 3Septian FirdausPas encore d'évaluation

- Underground PE Wrapped Pipe 21 Years Paling LamaDocument14 pagesUnderground PE Wrapped Pipe 21 Years Paling Lamahengkiirawan2008Pas encore d'évaluation

- Cathodic Protection of Underground Gas PipelineDocument59 pagesCathodic Protection of Underground Gas PipelineCepi Sindang KamulanPas encore d'évaluation

- Standard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterDocument7 pagesStandard Guide For Selection of Weirs and Flumes For Open-Channel Flow Measurement of WaterdrakenhavenPas encore d'évaluation

- Multiphase Flow 1995D'EverandMultiphase Flow 1995A. SerizawaPas encore d'évaluation

- Gas Pipeline Hydraulic Analysis CalculationDocument10 pagesGas Pipeline Hydraulic Analysis Calculationbalakrishna100% (3)

- SPE-29342 Gas Migration RatesDocument7 pagesSPE-29342 Gas Migration RatesRyan HengPas encore d'évaluation

- Corrosion Failures: Theory, Case Studies, and SolutionsD'EverandCorrosion Failures: Theory, Case Studies, and SolutionsPas encore d'évaluation

- Resolving of Steam and Feed-Water Piping Vibration Matter at Loviisa NPP - Vitor KostarevDocument8 pagesResolving of Steam and Feed-Water Piping Vibration Matter at Loviisa NPP - Vitor KostarevJose PradoPas encore d'évaluation

- John GumbelDocument18 pagesJohn GumbelJMF_CORD100% (1)

- Structural Analysis 1: Statically Determinate StructuresD'EverandStructural Analysis 1: Statically Determinate StructuresPas encore d'évaluation

- TFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Document12 pagesTFP and TFT Back in Town (Tight Fit CRA Lined Pipe and Tubing)Deadnightvikernes100% (1)

- What Is HDPE PIPEDocument7 pagesWhat Is HDPE PIPEKarthikeyan MoorthyPas encore d'évaluation

- Surge ManualDocument91 pagesSurge Manual31james100% (2)

- Calculation of The Built Up Back Pressure - LESERDocument4 pagesCalculation of The Built Up Back Pressure - LESERArjed Ali ShaikhPas encore d'évaluation

- OZKAN Butterfly ValvesDocument11 pagesOZKAN Butterfly ValvesAhmed AbdelwaneesPas encore d'évaluation

- Astm F2164-13Document5 pagesAstm F2164-13Chris SchnurchPas encore d'évaluation

- On The Prediction of Long-Term Creep-Failure of GRP PipesDocument35 pagesOn The Prediction of Long-Term Creep-Failure of GRP PipesMuhammad EhtshamPas encore d'évaluation

- Perforation: James A. Craig Omega 2011Document68 pagesPerforation: James A. Craig Omega 2011mbw000012378Pas encore d'évaluation

- Rocker Pipe PDFDocument8 pagesRocker Pipe PDFMahmoud GwailyPas encore d'évaluation

- Compipe BrochureDocument48 pagesCompipe Brochureninju1Pas encore d'évaluation

- Section 12 - Sanitary Sewer System (PDF) - 201601061536408543Document26 pagesSection 12 - Sanitary Sewer System (PDF) - 201601061536408543Sean ChanPas encore d'évaluation

- Plastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Document1 pagePlastics Pipe Institute Handbook of Polyethylene Pipe: Handbook Errata Sheet - March 2009Alfonso José García LagunaPas encore d'évaluation

- Intech-Natural Gas OdorizationDocument20 pagesIntech-Natural Gas OdorizationdhaktodesatyajitPas encore d'évaluation

- Sump Design GuidanceDocument8 pagesSump Design GuidanceHuget StPas encore d'évaluation

- Bin Tariq Pipes Intro 2013Document61 pagesBin Tariq Pipes Intro 2013Munir Ahmed MusianiPas encore d'évaluation