Académique Documents

Professionnel Documents

Culture Documents

United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1

Transféré par

Kalai SelvanDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1

Transféré par

Kalai SelvanDroits d'auteur :

Formats disponibles

US 20140021016A1

(19)

United States

(12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1

Schulakow- Klass et al.

(54)

(43) Pub. Date:

PALLET CAR CHANGING DEVICE

Jan. 23, 2014

Publication Classi?cation

(51)

Int. Cl.

B65G 35/08

(52) us C]_

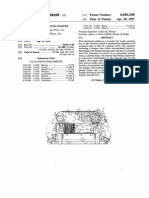

(75) Inventors: Andrej SchulakoW- Klass, Wiesbaden

(DE); Juergen Emmel, Biebesheim

(2006.01)

(DE); Thomas Holzhauer, Frankfurt

CPC .................................... .. B65G 35/08 (2013.01)

(DE)

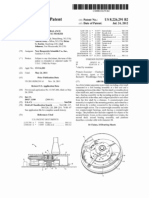

USPC ......................................... .. 198/617; 198/712

(57)

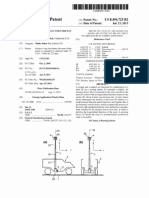

ABSTRACT

(73) Assignee: OUTOTEC OYJ, Espoo (Fl)

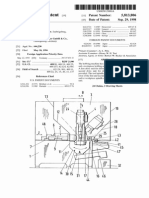

A device for changing a pallet car in a plant for the treatment

(21)

Appl. NO.I

of bulk materials Where pallet cars that are continuously

conveyed by means of a lifting Wheel and a lowering Wheel on

(22)

PCT Flled:

14/110,191

(86)

(30)

an outer rail and an inner rail in an endless chain includes, in

Mar- 29 2012

a regions of a bottom and top strand of the lifting Wheel, ?rst

PCT NO:

371 (6X1),

PCT/EP2012/055624

and second outer curve links of the outer rail openable such

that the pallet car is removable from the chain and another

pallet car is insertable into the chain. The device includes a

(2) (4) Date;

Oct 7, 2013

removal sWitch disposed in the region of the bottom strand of

the lifting Wheel, via Which the pallet car is movable out from

the chain, and a supply sWitch disposed in the region of the top

strand of the lifting Wheel, via Which the pallet car is insert

Foreign Application Priority Data

Apr. 8, 2011

(DE) .................... .. 10 2011 016 467.7

able into the chain.

if

pmcess ?ne

zstrand

5'; .......... .2

discharge

station

1

ti?ing wh eel

bottom-1 strand

return 1 :5 ~ hm-1.10m strand"

Patent Application Publication

Jan. 23, 2014 Sheet 1 0f 8

US 2014/0021016 A1

/

w

m

M\VXRP9$2/?E;81Xr

83.09x%3

Patent Application Publication

Jan. 23, 2014 Sheet 2 0f 8

L,

US 2014/0021016 A1

A0

%/ Yea 2A

A4

i

\/

5i

Q3) @5 (:2

rm..."

ki

iE

/ L

Patent Application Publication

Jan. 23, 2014 Sheet 3 0f 8

M12

1/

2:2,,

if

29

7/15 i

US 2014/0021016 A1

'

<53 <51; 12

A,

Patent Application Publication

'3

Jan. 23, 2014 Sheet 4 0f 8

66> Q (C)

W;

(0

3%

M

Kiwi?)

LN!- ' \d x

PM..............

FREE

kg

(a!)

I

@313:

US 2014/0021016 A1

(a

(\J

{FA/{K713

Q}

Patent Application Publication

Jan. 23, 2014 Sheet 5 0f 8

US 2014/0021016 A1

'

(I)

@J

Patent Application Publication

Jan. 23, 2014 Sheet 6 0f 8

US 2014/0021016 A1

Patent Application Publication

Jan. 23, 2014 Sheet 7 0f 8

US 2014/0021016 A1

Patent Application Publication

Jan. 23, 2014 Sheet 8 0f 8

US 2014/0021016 A1

US 2014/0021016A1

Jan. 23, 2014

PALLET CAR CHANGING DEVICE

chain and a neW pallet car is inserted in the free chainposition.

CROSS-REFERENCE TO PRIOR APPLICATIONS

The change is effected With running traveling grate, so that

tWo different plant positions are required for the partial func

tions of bringing out and bringing in. The changing device

[0001] This application is a US. National Phase Applica

tion under 35 USC 371 of International Application No.

PCT/EP2012/055624, ?led on Mar. 29, 2012, and claims

bene?t to German Patent Application No. DE 10 2011 016

467.7, ?led on Apr. 8, 2011. The International Application

Was published in English on Oct. 11, 2012, as WO 2012/

136558 under PCT Article 21(2).

FIELD

[0002] The invention relates to a device for changing a

pallet car in a plant for the treatment of bulk materials, such as

iron or Zinc ore pellets or sinter material, in Which the pallet

cars are continuously conveyed by means of a lifting Wheel

and a loWering Wheel on rails in an endless chain, Wherein in

the region of the bottom strand of the lifting Wheel an outer

link of the curve rail (outer curve link) can be opened and the

pallet car or the like can be removed from the chain by means

of a transfer means, and Wherein in the region of the top strand

of the lifting Wheel an outer curve link of the rail can be

opened and the pallet car or the like can be inserted into the

chain by means of a transfer means. The invention also relates

to a method for changing a pallet car in such a plant.

BACKGROUND

[0003]

In pelletiZing or sintering plants the bulk material to

be treated, for example iron ore or Zinc ore, is charged onto

pallet car Which form an endless chain of pallet cars also

referred to as traveling grate (cf. FIG. 1). The pallet cars are

?lled With the bulk material and pass through various treat

ment stations, in Which a thermal treatment of the material,

such as drying, ?ring and cooling, is effected. By a lifting or

drive Wheel, the pallet car chain is moved through the treat

ment stations along a top strand, Wherein the Wheels of the

pallet cars are guided in rails. At the end of the top strand, the

heat-treated material is dumped by gravity at a loWering

Wheel or tipping Wheel (discharge station), Whereupon the

consists of tWo separate units Which operate one after the

other.

[0006] An example of a continuous changing device is

described in US. Pat. No. 6,523,673. The changing device is

arranged in the lifting Wheel bottom strand and in the lifting

Wheel top strand. Removal of the pallet car is effected in the

bottom strand. For this purpose, the guide rail is opened

doWnWards and the pallet car is brought out on a movable

conveying means. The conveying means is a sliding table

Which has the same translatory direction of action as the

traveling grate conveyance in the bottom strand. In the top

strand, a neW pallet car is lifted into the traveling grate by

means of a rotatable gripping mechanism, Wherein the nec

essary insertion opening in the curve rails is generated by

means of a rotatable ?ap Which is opened upWards. Here as

Well, hoWever, additional lifting and conveying means are

required for removing and inserting the pallet cars.

SUMMARY

[0007] In an embodiment, the present invention provides a

device for changing a pallet car in a plant for the treatment of

bulk materials. The plant has pallet cars that are continuously

conveyed by means of a lifting Wheel and a loWering Wheel on

an outer rail and an inner rail in an endless chain. In a region

of a bottom strand of the lifting Wheel, a ?rst outer curve link

of the outer rail is openable such that the pallet car is remov

able from the chain. In a region of a top strand of the lifting

Wheel, a second outer curve link of the outer rail is openable

such that the pallet car is insertable into the chain. The device

includes a removal sWitch disposed in the region of the bot

tom strand of the lifting Wheel, via Which the pallet car is

movable out from the chain, and a supply sWitch disposed in

the region of the top strand of the lifting Wheel, via Which the

pallet car is insertable into the chain.

BRIEF DESCRIPTION OF THE DRAWINGS

empty pallet cars are returned upside doWn along a bottom

strand to the lifting Wheel. During conveyance in the top

strand and the bottom strand, a contact pressure betWeen the

individual pallet cars brings about the necessary chain con

nection. Gear Wheels of the lifting and loWering Wheels

engage pressure rollers Which are arranged on the axle of the

pallet cars beside the track rollers, in order to lift the pallet

cars and convey the same in vertical direction.

[0004] Since the pallet cars With their components are sub

ject to a high thermal and mechanical Wear during the pro

duction, they must be exchanged after a certain degree of

Wear or damage. Conventionally, such change requires stop

ping of the lifting Wheel for 5 to 10 minutes, Which can lead

to an additional thermal damage of the pallet cars in the top

strand. Moreover, production must also be stopped in this

shut-doWn period. After the pallet car change, the pelletiZing

[0008] The present invention Will be described in even

greater detail beloW based on the exemplary ?gures. The

invention is not limited to the exemplary embodiments. All

features described and/or illustrated herein can be used alone

or combined in different combinations in embodiments of the

invention. The features and advantages of various embodi

ments of the present invention Will become apparent by read

ing the folloWing detailed description With reference to the

attached draWings Which illustrate the folloWing:

[0009] FIG. 1 schematically shoWs a pelletiZing machine

With traveling grate,

[0010] FIGS. 2A to C schematically shoW the removal of a

pallet car at the bottom strand of the lifting Wheel With the

device according to the invention,

and sintering process must then again adjust to a stable pro

duction level. This adjustment phase, Which in most cases

only is terminated after a feW turnaround cycles, likeWise has

an adverse effect on the product quality.

[0005] To avoid the above-described disadvantages of the

[0011] FIGS. 3A to C schematically shoW the supply of a

pallet car in the top strand of the lifting Wheel With a device

discontinuous changing devices, it has also been proposed

[0013] FIGS. 5A to C schematically shoW the supply of a

pallet car to the bottom strand of the lifting Wheel, While the

already to perform a continuous pallet car exchange. The

pallet car to be changed here is removed from the pallet car

according to the invention,

[0012]

FIGS. 4A to D schematically shoW the removal of a

pallet car, While the pelletiZing machine is stopped,

pelletiZing machine is stopped,

US 2014/0021016Al

[0014]

FIG. 6 shows a schematic vieW of a pallet car With a

representation of the track roller and the pressure roller,

[0015] FIGS. 7A and B schematically shoW a partial rep

resentation of a pallet car changing device according to the

invention including a supply and removal arrangement on a

pelletiZing machine in a front vieW and a side vieW, respec

tively,

[0016]

FIG. 8 schematically shoWs the device for removing

Jan. 23, 2014

[0025]

In accordance With a particularly preferred aspect of

the invention, the pivotable curve link forms both the outer

curve guide and the rail for inserting the pallet car. The posi

tion of the sWitch is realiZed by a doWnWardly directed move

ment, With Which at the same time the curve guide is opened

for inserting the pallet car. This reduces the time required for

the changing operation, Which is limited by the velocity of the

moving traveling grate. The plane of action of the adjusting

the pallet car at the bottom strand of the lifting Wheel in the

mechanism lies parallel to the translational pallet car move

region of the outer guide rail, and

[0017] FIG. 9 schematically shoWs the device for supplying

the lifting Wheel in the top strand of the lifting Wheel in the

region of the inner guide rail.

ment. To ensure a collision-free course of movement of the

DETAILED DESCRIPTION

[0018] In an embodiment, the invention provides a simpler,

more reliable, safer and less expensive possibility for

exchanging the pallet cars While the plant is running.

[0019] In an embodiment, the region of the bottom strand of

the lifting Wheel a removal sWitch is provided, by means of

Which a pallet car or the like can be moved out from the chain,

and that in the region of the top strand of the lifting Wheel a

supply sWitch is provided, by means of Which a pallet car or

the like can be moved into the chain. Hence, the change can be

carried out Without a plant shutdoWn, but at the minimum

production speed.

[0020]

With the sWitch solution according to the invention,

the pallet car movement on its oWn Wheels is exploited, so that

no additional gripping and conveying mechanisms must be

used, on Which a complete pallet car Would have to be posi

tioned. Correspondingly, the times for the gripping and posi

tioning functions of the conventional solutions also are elimi

nated. By lifting the pallet car at the lifting Wheel from the

bottom strand onto the top strand, the traveling grate chain is

interrupted, so that during lifting no pressure contact exists

adjusting mechanism, the inner curve guide is adapted to the

transmission shape of the sWitch curve link in accordance

With the invention.

[0026] In accordance With a development of this invention,

a common actuator transmission is provided for positioning

the supply sWitch and opening the outer curve guide, Wherein

the actuator transmission preferably is arranged above the

curve rail. By combining the functions of opening the curve

guide and positioning the sWitch in a transmission member, a

minimum siZe of the actuators is realiZed. The actuator trans

mission can be realiZed With simple and positively guided

types of transmission, Wherein a simple rotary arm and a

four-joint system suf?ciently satisfy all tasks.

[0027]

For inserting the pallet car into the tooth gap of the

lifting Wheel, a pushing device is assigned to the supply

sWitch in accordance With the invention.

[0028] The above-described con?guration of the pallet car

changing device is conceived for a continuous change during

ongoing operation of the plant. Due to the high thermal and

mechanical loads in the plant it also occurs, hoWever, that the

pressure rollers Which should be engaged by the ?xed sWitch

for removing the pallet car are damaged. In such a case, the

pallet car no longer can be exchanged during ongoing opera

tion of the plant, so that a manual changing operation must be

provided.

betWeen the pallet cars. Thus, an additional means for releas

[0029]

ing the traveling grate chain is not necessary.

[0021] In accordance With a preferred aspect of the inven

tion, the removal sWitch, preferably on the inside of the outer

ous change are designed such that the pallet car can be moved

out from the traveling grate on their rollers, the resulting

curve opening is not su?icient for lifting out a complete pallet

rail, includes a ?xed sWitch Which engages the pressure roll

ers of the pallet cars. Due to the ?xed sWitch, more time is

car. In accordance With the invention it therefore is provided

that on the outer curve guide adjacent to the pivotable curve

link a second pivotable arc is provided, Which increases the

gained for bringing out and opening the curved rail, since the

Since the necessary curve openings for the continu

succeeding pallet cars still can perform a translational move

removable opening by sWinging open.

ment on the ?xed sWitch, before they are again inserted into

closing the outer curve guide. It is important here that the rear

[0030] For lifting out the pallet car, the existing curve open

ing mechanism can be employed. HoWever, the lever length

must be increased, because the roller spacing is greater than

pallet car axle is positively guided by a lifting Wheel tooth.

[0022] For opening the outer guide rail according to the

the effective lever length of the curve opening. In accordance

With a development of the invention, a second, parallel curve

the corresponding tooth gap in the rotating lifting Wheel by

invention, a pivotable curve link is provided on the removal

arm or arc therefore is provided, Which can be added by

sWitch, Which preferably is driven by an actuator transmis

means of a rotary movement or by a translational movement.

sion. As a result, the outer link of the curve rail can easily be

opened, so that the pallet car can be moved out from the plant

In accordance With the invention, this second curve arc has a

on the ?xed sWitch.

[0023]

Since the pallet cars do not have their oWn drivesi

in the pelletiZing or sintering plant the driving force is pro

vided via the lifting Wheeliit is provided in accordance With

a development of the invention to associate a pulling device to

the removal sWitch for pulling out the pallet cars. Since the

pallet cars roll on the ?xed sWitch, it is not required to lift

them, and a simple pulling device is su?icient for removal.

[0024] In accordance With the invention, a pivotable curve

link also is provided at the supply sWitch, in order to open the

outer curve guide at the top strand of the lifting Wheel.

greater length than the movable outer link of the curve rail, so

that it can accommodate the rollers of both axles of the lift

truck. In continuous operation, this second curve arc can be

folded aWay, so as not to impede the removal of a pallet car

With the traveling grate moving on.

[0031] After moving the pallet car out from the traveling

grate, the same is moved out on the track rollers like during

the continuous change. There can be provided an additional

conveyor, such as a crane, Which serves to remove the

exchanged pallet car from the rail guide and insert a neW

pallet car. The neW pallet car is positioned via the extended

rotary arc and is again inserted into the traveling grate. It is of

US 2014/0021016A1

course also possible to utilize the above-described supply

switch at the top strand of the lifting Wheel for inserting the

neW pallet car.

Jan. 23, 2014

[0039] As is clearly shoWn in FIG. 2A, the direct contact

betWeen the pallet car 3 of the traveling grate 4 is separated

due to the pallet car 3 being lifted by the lifting Wheel 10. As

The invention also comprises a method for changing

a result, the pallet cars 3 are accessible individually. When a

a pallet car or the like in a plant for the treatment of bulk

materials, such as iron or Zinc ore pellets or sinter material, in

Which the pallet car are continuously conveyed on rails in an

pallet car 3 noW should be removed from the traveling grate 4,

the outer curve guide 9 is opened in the region of the bottom

strand 15 at the lifting Wheel 10 by sWiveling out an outer

endless chain via a lifting Wheel and a loWering Wheel,

Wherein in the region of a bottom strand of a lifting Wheel an

outer link of the curve rail is opened and the pallet car is

moved out from the chain via a removal sWitch, Wherein the

outer curve link then is sWiveled back, in order to close the

curve link 16. A ?xed sWitch 17 extends parallel to the outer

curve link 16, With a pressure roller 12 (cf. FIG. 6) of the

pallet car 3 running up onto said sWitch. In continuation of the

translational movement in the bottom strand 15, the pallet car

3 thereby can be removed from the traveling grate 4 in hori

Zontal direction. Subsequent to the ?xed sWitch 17, a guide

rail 18 extending in extension of the outer rail guide is pro

vided, onto Which the track rollers 7 of the pallet car 3 are

running up, so that the pallet car 3 can easily be moved out

[0032]

rail, Wherein in the region of a top strand of the lifting Wheel

an outer curve link of the rail is sWiveled for opening a supply

sWitch and the pallet car is moved into the chain via the supply

sWitch, and Wherein the outer curve link is again sWiveled

back, in order to close the rail.

[0033]

By Way of example, FIG. 1 shoWs a pelletiZing plant

1 for producing ore pellets, in Which the invention is

employed. At a non-illustrated supply station under a hood 2,

the bulk material is charged onto pallet cars 3 Which form an

endless pallet car chain referred to as traveling grate 4.

Under the hood 2, the bulk material transported on the g pallet

car 3 passes through a plurality of thermal treatment stations

in Which the bulk material for example is dried, preheated,

?red and ?nally cooled again. At the treatment stations under

the hood 2, the traveling grate 4 is guided on a top strand 5 of

a continuous conveyor 6, Wherein the track rollers 7 of the

pallet car 3 are guided betWeen an inner rail guide 8 and an

outer rail guide 9. The drive of the traveling grate 4 is effected

via a drive or lifting Wheel 10, Which is formed as gear Wheel

and With its tooth gaps (clearances) 11 engages pressure

rollers 12 ofthe pallet cars 3 (cf. FIG. 6).

[0034] After passing through the hood 2, the lift trucks 3 of

the traveling grate 4 reach a discharge station Which is asso

ciated to a loWering or driven Wheel 13 of the continuous

conveyor 6. At the loWering Wheel 13, like at the lifting Wheel

10, tooth gaps 14 of the driven gear Wheel engage the pressure

rollers 12 of the pallet car 3. The pallet car 3 are tilted, so that

their load is dumped by gravity. Since the pallet cars 3 are

guided by the outer rail guide 9, they do not fall doWn them

selves, but are returned upside doWn to the lifting Wheel 10 in

a bottom strand 15 of the continuous conveyor 6.

[0035]

In normal operation, the traveling grate 4 circulates

endlessly on the continuous conveyor 6 and transports the

bulk material to be treated through the treatment stations

from the traveling grate 4 (cf. FIG. 2C). Due to the high

Weight of such pallet car 3, a pulling device 28 is provided for

removing the pallet car 3 from the traveling grate 4 (cf. FIG.

7), Which engages the pallet car 3 and pulls the same aWay via

the ?xed sWitch 17 and the guide rail 18.

[0040]

By employing the ?xed sWitch 17, time is gained for

bringing out and opening the curve rail, since the succeeding

pallet cars 3 temporarily can continue their translational

movement on the ?xed sWitch 17, until they are again inserted

into the corresponding tooth gap 11 of the lifting Wheel 20 by

closing the outer curve link. To ensure an unambiguous posi

tioning, the rear pallet car axle is positively guided by the

lifting Wheel tooth.

[0041] By removing the pallet car 3 at the bottom strand 15

of the lifting Wheel 10 a gap is obtained betWeen the pallet

cars 3 (cf. FIG. 3A), Which must be closed again to form a

continuous traveling grate 4. In the region of the top strand 5

of the lifting Wheel 10, a neW pallet car 3 therefore is moved

into the free lifting Wheel position. This is schematically

shoWn in FIG. 3. On the outer curve guide 9 a pivotable curve

link 20 is provided, Which in normal operation (cf. FIG. 3A)

guides the pallet cars 3 of the traveling grate 4. For inserting

the neW pallet car 3, the curve link 20 is sWivelled inWards via

an actuating device described beloW, in order to position the

sWitch 21 for supplying the pallet car 3 (cf. FIG. 3B). The

pallet car 3 noW can be inserted via the supply rail 22 and the

curve link 20, so that its pressure rollers 12 engage in a tooth

gap 11 of the lifting Wheel 10 and the neWly inserted pallet car

3 is moved on by the lifting Wheel 10. Again, a continuous

and further processed in a Way not described here in detail.

traveling grate 4 is obtained. As soon as the neW pallet car 3

has passed the sWitch 21 With its rear axle, the curve link 20

can be sWiveled back again, in order to close the outer guide

[0036]

rail 9 (cf. FIG. 3C). The operation of the traveling grate 4 thus

under the hood 2, before it is dumped at the discharge station

Due to the high thermal and mechanical load, the

pallet cars are damaged, so that the same repeatedly have to be

can again be continued as usual.

moved out from the pelletiZing machine 1 for maintenance

and repair Work. To avoid a shut-doWn of the plant, a continu

ous pallet car changing device is provided according to the

invention, With Which the pallet cars 3 to be serviced can be

[0042] The continuous pallet car change as described With

reference to FIGS. 2 and 3 only is possible When the pressure

rollers 12 of the pallet car 3, Which are engaged by the ?xed

removed from the traveling grate 4 Without stopping the pel

letiZing machine 1.

damaged, they cannot be moved out from the traveling grate

[0037] The procedure of removing a pallet car 3 from the

traveling grate 4 is schematically illustrated in FIG. 2. FIGS.

2 to 5 each shoW only one rail of the rail pairs of the outer and

sWitch 17, still are in time. If the pressure rollers 12 are

4 via the sWitch 17. In this case, a manual change is provided,

as it Will be explained With reference to FIGS. 4 and 5. In the

folloWing description of this embodiment, merely the differ

side of the pallet car 3 (cf. FIG. 6). The folloWing description

ences to the continuous pallet car change Will be discussed. In

accordance With the invention, the additional means for the

discontinuous pallet car changes are provided in addition to

the elements Which are used for the continuous pallet car

analogously applies to the rail not shoWn here.

change.

inner curve guides 8 and 9.

[0038] Of course, a corresponding rail is associated to each

US 2014/0021016Al

[0043] In FIGS. 4A to 4C, the removal of a damaged pallet

car 3 from the traveling grate is shown. In FIG. 4A, the

damaged pallet car 3 is arranged in the region of the pivotable

curve link 16. Since it is not possible to move the pallet car 3

out on the ?xed sWitch 17, the pallet car 3 must be held on its

track rollers 7. For this purpose a second, pivotable curve arm

24 is provided, Which is longer than the pivotable curve link

16 and in any case is provided parallel to the pivotable curve

link 16 When performing the pallet car change. Since the

space provided by the curve link 16 for sWiveling out the

pallet car 3 is not suf?cient, a second arc 25 is provided in

extension of the curve link 16, Which can be sWiveled in

Jan. 23, 2014

can roll, When the same is pulled out from the traveling grate

4. In the draWing, the ?xed sWitch 17 is arranged behind the

rail elements 9, 16 and 18, Which sWitch is slightly higher than

the rail elements 9 and 18 and hence approximately lies at the

level of the pressure roller 12 of the pallet car 3, as it is shoWn

in FIG. 6.

[0051] Parallel to the outer curve link 16, the pivotable

extended curve arc 24 is provided for the manual exchange.

The extended curve arc 24 is pivotable about a joint 34 from

the illustrated Waiting position 24' into a position 24 directly

beside the outer curve link 16, in Which it can be used for the

manual change. If no manual change is required, the extended

opposite direction and provides a larger opening. After open

curve arc 24 can be sWiveled aWay or be utiliZed as reinforce

ing the second arc 25 (FIG. 4B), the extended curve arc 24 is

ment of the curve rail.

sWiveled doWnWards, until the front track roller 7 of the pallet

[0052]

car 3 comes to rest on the guide rail 18 (cf. FIG. 4C). NoW, like

also in the continuous change principle, the pallet car 3 can be

moved out on the guide rail 18 via its track rollers 7.

nism for locking the additional arc 25.

[0044]

For inserting a neW pallet car (cf. FIG. 5), the pallet

car 3 is put onto the guide rail 18 via an additional conveyor,

eg a crane (cf. FIG. 5A). Via the rail 18, the neW pallet car

noW is moved into the free position on the traveling grate

4iWherein the pressure rollers 12 noW also can engage the

Reference numeral 35 designates a closing mecha

[0053] FIG. 9 shoWs the lifting device 40 for actuating the

supply sWitch 21 in the top strand of the lifting Wheel 10. On

a frame 41, a coupler mechanism With hydraulic positioning

cylinder 42 is provided, Which engages the curve link 20. On

its loWer (inner) side, the curve link 20 has a contour Which

corresponds to the inner geometry of the outer rail guide 9.

FIG. 9 shoWs the condition in Which the curve link 20 is

?xed sWitch 17iand by sWiveling back the extended curve

arc 24 and closing the opening by means of the second arc 25

it is then again inserted into the traveling grate 4 (cf. FIGS. 5B

and 5C). NoW, the drive can be sWitched on again and the

curve link 20 forms a path for bringing the neW pallet car 3

onto the inner curve guide 8 of the continuous conveyor 6.Via

a closing mechanism 43 in the form of a coupler mechanism

traveling grate can be moved through the pelletiZing plant 1 in

With hydraulic positioning cylinder 44, the lifting device 42

the usual Way.

[0045] It is ofcourse also possible to also use the supply for

the continuous change, as it is shoWn in FIG. 3, instead of

can be locked after the changing operation. This ensures a

stable guidance by the outer rail guide 9. To achieve a more

uniform transition to the inner rail guide 8 of the continuous

sWiveled doWnWards for positioning the sWitch 21, so that the

supplying a neW pallet car 3 as shoWn in FIG. 5. As a result,

conveyor 6, a transition element 20a can be provided on the

the shut-doWn periods of the plant can further be reduced,

since the plant can already be started While supplying the neW

curve link 20.

pallet car.

[0046] FIG. 6 schematically shoWs a pallet car 3 Which Will

cars of a traveling grate can be achieved in a simple Way,

only brie?y be described here. The bulk material is loaded

onto a grate 26 and held by side Walls 27 of the pallet car 3. In

normal operation, the pallet car 3 runs on the rails of the

continuous conveyor 6 With its track rollers 7. On lifting by

the lifting Wheel 10 or loWering by the loWering Wheel 13, the

tooth gaps 11 and 14 engage the pressure rollers 12 of the

pallet cars 3 provided inWards of the track rollers 7. These

pressure rollers 12 also are utiliZed for conveying the pallet

car 3 on the ?xed sWitch 17 for removal from the traveling

grate 4.

[0047] FIG. 7 schematically shoWs a pallet car changing

device including supply and removal arrangement, With FIG.

7A shoWing a front vieW of the device and FIG. 7B shoWing

a side vieW of the device.

[0048] FIG. 7B shoWs a pulling means 28 for pulling out the

pallet cars 3 from the traveling grate 4. For inserting neW

pallet cars in the top strand of the lifting Wheel 10, hoWever,

a pushing device 29 is provided, by means of Which the pallet

cars 3 can be pushed into the traveling grate 4.

[0049] Next, the construction of the removal sWitch 30,

Which is arranged on a frame 36, Will be explained in detail

With reference to FIG. 8.

[0050] As can be taken from FIG. 8, the pivotable outer

curve link 16 is provided subsequent to the outer rail guide 9,

[0054]

With the invention, a continuous change of pallet

Without expensive lifting means being required for lifting out

the pallet cars. Due to the sWitch solution according to the

invention, in Which the pallet cars are moved out from the

traveling grate on their track and pressure rollers, a simpler,

faster and safer change of the pallet cars can be realiZed. If a

pallet car is damaged such that it cannot be removed from the

traveling grate via its pressure rollers, a device for a manual

change is provided in addition, Which is hoWever only used in

exceptional cases.

[0055] While the invention has been illustrated and

described in detail in the draWings and foregoing description,

such illustration and description are to be considered illustra

tive or exemplary and not restrictive. It Will be understood that

changes and modi?cations may be made by those of ordinary

skill Within the scope of the folloWing claims. In particular,

the present invention covers further embodiments With any

combination of features from different embodiments

described above and beloW. Additionally, statements made

herein characterizing the invention refer to an embodiment of

the invention and not necessarily all embodiments.

[0056] The terms used in the claims should be construed to

have the broadest reasonable interpretation consistent With

the foregoing description. For example, the use of the article

a or the in introducing an element should not be inter

Which is actuatable via an actuator transmission 31 consisting

preted as being exclusive of a plurality of elements. LikeWise,

the recitation of or should be interpreted as being inclusive,

of a positioning cylinder 32 and a four-j oint arrangement 33.

In horizontal extension of the outer curve link 9 the guide rail

18 is provided, on Which the track rollers 7 of the pallet car 3

B, unless it is clear from the context or the foregoing descrip

tion that only one of A and B is intended. Further, the recita

such that the recitation of A or B is not exclusive of A and

US 2014/0021016A1

Jan. 23, 2014

tion of at least one of A, B and C should be interpreted as

one or more of a group of elements consisting of A, B and C,

and should not be interpreted as requiring at least one of each

in a region of a top strand of the lifting Wheel, a second outer

curve link of the outer rail is openable such that the pallet car

is insertable into the chain, the device comprising a removal

of the listed elements A, B and C, regardless of Whether A, B

sWitch disposed in the region of the bottom strand of the

lifting Wheel, via Which the pallet car is movable out from the

chain, and a supply sWitch disposed in the region of the top

strand of the lifting Wheel, via Which the pallet car is insert

able into the chain.

2. The device according to claim 1, Wherein the removal

and C are related as categories or otherwise. Moreover, the

recitation of A, B and/or C or at least one of A, B or C

should be interpreted as including any singular entity from the

listed elements, e.g., A, any subset from the listed elements,

e.g., A and B, or the entire list of elements A, B and C.

LIST OF REFERENCE NUMERALS

[0057]

1 pelletiZing machine

[0058]

[0059]

[0060]

[0061]

[0062]

[0063]

[0064]

[0065]

[0066]

[0067]

[0068]

[0069]

[0070]

[0071]

2 hood

3 pallet car

4 traveling grate, pallet car chain

5 top strand

6 continuous conveyor

7 track roller of the pallet car

8 inner rail guide

9 outer rail guide

10 lifting or drive Wheel

11 tooth gap

12 pressure roller of the pallet car

13 lowering or driven Wheel

14 tooth gap

15 bottom strand

[0072]

16 outer curve link

[0073]

17 ?xed sWitch

[0074] 18 guide rail

[0075]

20 pivotable curve link

[0076]

[0077]

21 supply sWitch

22 supply rail

[0078]

24 extended curve arc

[0079]

25 second arc

[0080]

26 grate

[0081]

27 side Wall

[0082]

[0083]

28 pulling device

29 pushing device

[0084]

30 removal sWitch

[0085]

31 lifting device

[0086] 32 positioning cylinder

[0087] 33 closing mechanism

[0088] 34 joint

[0089] 35 closing mechanism

[0090]

36 frame

[0091]

40 lifting device

[0092]

41 frame

[0093] 42 positioning cylinder

[0094]

43 closing mechanism

[0095] 44 positioning cylinder

1. A device for changing a pallet car in a plant for the

treatment of bulk materials, the plant having pallet cars that

are continuously conveyed by using a lifting Wheel and a

loWering Wheel on an outer rail and an inner rail in an endless

chain, Wherein, in a region of a bottom strand of the lifting

Wheel, a ?rst outer curve link of the outer rail is openable such

that the pallet car is removable from the chain, and Wherein,

sWitch includes a ?xed sWitch con?gured to engage pressure

rollers of the pallet car.

3. The device according to claim 1, Wherein the ?rst outer

curve link is pivotable, the removal sWitch including the ?rst

outer curve link.

4. The device according to claim 1, further comprising a

pulling device for pulling out the pallet cars Which is associ

ated to the removal sWitch.

5. The device according to claim 1, Wherein the second

outer curve link is pivotable, the supply sWitch including the

second outer curve link.

6. The device according to claim 1, further comprising a

common actuator transmission con?gured to position the

supply sWitch and open the second outer curve link at the top

strand of the lifting Wheel.

7. The device according to claim 6, Wherein the actuator

transmission is arranged above the second outer curve link.

8. The device according to claim 5, Wherein the second

outer curve link forms both an outer curve guide and a rail for

inserting the pallet car.

9. The device according to claim 1, further comprising a

pushing device for inserting the pallet car Which is associated

to the supply sWitch.

10. The device according to claim 1, further comprising a

second, parallel and movable curve arc disposed on the

removal sWitch.

11. The device according to claim 10, Wherein the second

curve arc has a greater length than the ?rst outer curve link.

12. The device according to claim 10, Wherein the outer rail

includes a second pivotable arc disposed adjacent to the ?rst

outer curve link.

13. A method for changing a pallet car in a plant for the

treatment of bulk materials, the plant having pallet cars that

are continuously conveyed on an outer rail and an inner rail in

an endless chain via a lifting Wheel and a loWering Wheel, the

method comprising:

opening a ?rst outer curve link of the outer rail in a region

of a bottom strand of the lifting Wheel and moving the

pallet car out from the chain via a removal sWitch,

sWiveling the ?rst outer curve link back again so as to close

the outer rail,

sWiveling a second outer curve link of the outer rail in a

region of a top strand of the lifting Wheel an so as to open

a supply sWitch and moving another pallet car into the

chain via the supply sWitch, and

sWiveling the second outer curve link so as to close the

outer rail.

Vous aimerez peut-être aussi

- Us 20080264323Document26 pagesUs 20080264323ASeaSlugPas encore d'évaluation

- Unlted States Patent (19) (11) Patent Number: 4,660,248: IllllllDocument15 pagesUnlted States Patent (19) (11) Patent Number: 4,660,248: Illllll113314Pas encore d'évaluation

- United States Patent (19) 4,671,227: Hollerweger Et A1. Jun. 9, 1987Document17 pagesUnited States Patent (19) 4,671,227: Hollerweger Et A1. Jun. 9, 1987marcglebPas encore d'évaluation

- European Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorDocument16 pagesEuropean Patent Application F04B 27/10: Rotor For Variable Displacement Swash Plate CompressorSelvaraji MuthuPas encore d'évaluation

- Us 6388353Document10 pagesUs 6388353Feno Mena AhhadPas encore d'évaluation

- United States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1Document9 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2007/0256911 A1DANESIPas encore d'évaluation

- Bbbebeb: 60088401 NNNNMNNS 1110000315 66606262Document12 pagesBbbebeb: 60088401 NNNNMNNS 1110000315 66606262ErkanAksoyluPas encore d'évaluation

- United States Patent (16) Patent N6 US 8,226,291 B2: Zamirowski Et Al. (45) Date of Patent: Jul. 24, 2012Document26 pagesUnited States Patent (16) Patent N6 US 8,226,291 B2: Zamirowski Et Al. (45) Date of Patent: Jul. 24, 2012Soma GhoshPas encore d'évaluation

- EP2065596A1Document10 pagesEP2065596A1duffy5555Pas encore d'évaluation

- Az 3420192022Document4 pagesAz 3420192022IJMERPas encore d'évaluation

- EP09166154NWA1Document10 pagesEP09166154NWA1maes.daan1Pas encore d'évaluation

- Sliding Gate Movement SystemDocument8 pagesSliding Gate Movement SystemRohit BirajdarPas encore d'évaluation

- EP06808858NWB1Document13 pagesEP06808858NWB1keikhosravy.mPas encore d'évaluation

- United States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Document31 pagesUnited States Patent (19) (11) Patent Number: 4,727,781: Yuehui Et Al. (45) Date of Patent: Mar. 1, 1988Siul OtreborPas encore d'évaluation

- EP1939114A1Document17 pagesEP1939114A1Chaman KumarPas encore d'évaluation

- 518 STD USA Centrifuge Manual Part 90-90-061-RevADocument109 pages518 STD USA Centrifuge Manual Part 90-90-061-RevAkanwarPas encore d'évaluation

- Patent Application Publication (10) Pub. No.: US 2010/0105516 A1Document11 pagesPatent Application Publication (10) Pub. No.: US 2010/0105516 A1KrozePas encore d'évaluation

- Umted States Patent (191 (111 4,372,411: Flower ' (45) Feb. 8, 1983Document8 pagesUmted States Patent (191 (111 4,372,411: Flower ' (45) Feb. 8, 1983Sugarboy3 SurPas encore d'évaluation

- Construction and Manufacture of AutomobilesD'EverandConstruction and Manufacture of AutomobilesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Compressed Air MotorDocument10 pagesCompressed Air Motorjahson362Pas encore d'évaluation

- US 518 Centrifuge ManualDocument109 pagesUS 518 Centrifuge ManualMarius50% (2)

- United States Patent (19) : ChiappettiDocument6 pagesUnited States Patent (19) : ChiappettiOctavio HernandezPas encore d'évaluation

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Document13 pages(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuPas encore d'évaluation

- EP2369289A1Document10 pagesEP2369289A1awe234100% (1)

- Patent Application Publication (10) Pub. No.: US 2013/0157528A1Document7 pagesPatent Application Publication (10) Pub. No.: US 2013/0157528A1Tâm DươngPas encore d'évaluation

- Braking RollerDocument14 pagesBraking Rollerbhargav hhPas encore d'évaluation

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioPas encore d'évaluation

- Transmission Inertia Brake Ball Ramp ActuationDocument15 pagesTransmission Inertia Brake Ball Ramp Actuationolduren53Pas encore d'évaluation

- Fractal Impeller Agitator PatentDocument21 pagesFractal Impeller Agitator PatentDilip MauryaPas encore d'évaluation

- EP1321438B1Document10 pagesEP1321438B1Alessandro PatanèPas encore d'évaluation

- EP99108363NWA2Document16 pagesEP99108363NWA2d54ddqcpfqPas encore d'évaluation

- Thrust Reverser Hook Latch System PatentDocument13 pagesThrust Reverser Hook Latch System PatentkevnwongPas encore d'évaluation

- (Gina Carol Barney) Elevator Traffic Handbook The (BookFi)Document7 pages(Gina Carol Barney) Elevator Traffic Handbook The (BookFi)AdiyPas encore d'évaluation

- Monorail - US4996928Document8 pagesMonorail - US4996928Rob ZelPas encore d'évaluation

- United States Patent (10) Patent N0.: US 8,494,725 B2Document11 pagesUnited States Patent (10) Patent N0.: US 8,494,725 B2sarkrassPas encore d'évaluation

- Detc2014-34171 Design and Evaluation of A Passive Ankle ProsthesisDocument7 pagesDetc2014-34171 Design and Evaluation of A Passive Ankle ProsthesisFABIANCHO2210Pas encore d'évaluation

- Scissor Lift ReportDocument32 pagesScissor Lift ReportPranav Ekhande100% (3)

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiPas encore d'évaluation

- Optimizing Screw ConveyorDocument6 pagesOptimizing Screw ConveyorChem.Engg100% (1)

- Laboratory Experiment Sheet: Universiti Kuala Lumpur Malaysia France Institute Mechanical Engineering SectionDocument9 pagesLaboratory Experiment Sheet: Universiti Kuala Lumpur Malaysia France Institute Mechanical Engineering SectionluqmanmazelanPas encore d'évaluation

- Link Belt LS278H Specifications PDFDocument52 pagesLink Belt LS278H Specifications PDFJorge BarceloPas encore d'évaluation

- TEPZZ - 4 885B - T: European Patent SpecificationDocument10 pagesTEPZZ - 4 885B - T: European Patent SpecificationshamsPas encore d'évaluation

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaPas encore d'évaluation

- 1-S1548 FinalDocument13 pages1-S1548 Finalpandavision76Pas encore d'évaluation

- United States Patent (19) : Johnston (11) Patent Number: (45) Date of PatentDocument9 pagesUnited States Patent (19) : Johnston (11) Patent Number: (45) Date of Patentsanjay0910Pas encore d'évaluation

- United States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2012/0227970 A1zbhdzpPas encore d'évaluation

- Us 5271461Document18 pagesUs 5271461ask101Pas encore d'évaluation

- 414 Centrifuge IOM Rev2Document104 pages414 Centrifuge IOM Rev2Giorgiana RosuPas encore d'évaluation

- MP-I - Lab Manual DarshanDocument159 pagesMP-I - Lab Manual DarshanNitinGothiPas encore d'évaluation

- EP1070663A2Document4 pagesEP1070663A2atabPas encore d'évaluation

- Us 8485010Document14 pagesUs 8485010dnddownloaderPas encore d'évaluation

- Us 2912244Document9 pagesUs 2912244alexhkiPas encore d'évaluation

- Operating InstructionsDocument34 pagesOperating InstructionsCarlos IntriagoPas encore d'évaluation

- Design of A Self-Balancing Tower CraneDocument7 pagesDesign of A Self-Balancing Tower Cranesuresh_501Pas encore d'évaluation

- ?T T T - FT ?: April 9, 1968Document6 pages?T T T - FT ?: April 9, 1968Pooria1989Pas encore d'évaluation

- Crane How+to+Use+Load+ChartDocument7 pagesCrane How+to+Use+Load+ChartAnonymous d2wsnS9UkPas encore d'évaluation

- European Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftDocument23 pagesEuropean Patent Specification: Rotating Proprotor Arrangement For A Tiltrotor AircraftgorgiPas encore d'évaluation

- General Design Energy Principles For Bulk Conveying of Particulate Solids John Dartnall, 2003Document9 pagesGeneral Design Energy Principles For Bulk Conveying of Particulate Solids John Dartnall, 2003slitantPas encore d'évaluation

- Pressure Vessel and Stacks Field Repair ManualD'EverandPressure Vessel and Stacks Field Repair ManualÉvaluation : 4 sur 5 étoiles4/5 (4)

- Panki FGD Gds r00 1600398998Document120 pagesPanki FGD Gds r00 1600398998Kalai SelvanPas encore d'évaluation

- 03c EIL MR 3002 dd1059Document146 pages03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- Amendment No. 2ererDocument345 pagesAmendment No. 2ererKalai SelvanPas encore d'évaluation

- 22.1 Itp Rot 001 PDFDocument3 pages22.1 Itp Rot 001 PDFAdades Safede EfdPas encore d'évaluation

- 2 Instructions To Bidders (ITB)Document265 pages2 Instructions To Bidders (ITB)Saurabh Kumar SharmaPas encore d'évaluation

- Oil IndiaDocument445 pagesOil IndiaJayadevDamodaranPas encore d'évaluation

- Mucg06m1tw - List of DocumentsDocument62 pagesMucg06m1tw - List of DocumentsKalai SelvanPas encore d'évaluation

- DSR PuneDocument298 pagesDSR PuneAsif KhanPas encore d'évaluation

- Hood Design Data - Range of Capture VelocitiesDocument3 pagesHood Design Data - Range of Capture VelocitieszshehadehPas encore d'évaluation

- Full TextDocument341 pagesFull Textcevapcic100Pas encore d'évaluation

- A133 3211 1062 MR 0Document49 pagesA133 3211 1062 MR 0Kalai SelvanPas encore d'évaluation

- Engineering Consultancy Services: Tender Document FORDocument69 pagesEngineering Consultancy Services: Tender Document FORKalai SelvanPas encore d'évaluation

- FL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionDocument8 pagesFL Flywheel Coupling/ Guardex Type FLD Pulley Coupling: Altra Industrial MotionKalai SelvanPas encore d'évaluation

- Mohitdhullprojectreport12162035 141124013553 Conversion Gate01Document53 pagesMohitdhullprojectreport12162035 141124013553 Conversion Gate01Kalai SelvanPas encore d'évaluation

- A133 3211 1062 MR 0Document49 pagesA133 3211 1062 MR 0Kalai SelvanPas encore d'évaluation

- Norsok StandardDocument58 pagesNorsok StandardstephlyonPas encore d'évaluation

- 5.4 Design Basis For Co2 Recovery PlantDocument41 pages5.4 Design Basis For Co2 Recovery PlantBao KimPas encore d'évaluation

- Flywheel Drive Couplings & Engine Pump Mounts: Altra Industrial MotionDocument4 pagesFlywheel Drive Couplings & Engine Pump Mounts: Altra Industrial MotionKalai SelvanPas encore d'évaluation

- TS For NML Supply of ValvesDocument19 pagesTS For NML Supply of ValvesKalai SelvanPas encore d'évaluation

- Engineering Layout of Fuel Tanks in A Tank Farm - J of LPDocument7 pagesEngineering Layout of Fuel Tanks in A Tank Farm - J of LPthawdarPas encore d'évaluation

- RivSol Article 2 - Engineering ProcessDocument1 pageRivSol Article 2 - Engineering ProcessKalai SelvanPas encore d'évaluation

- Deluge System ManualDocument64 pagesDeluge System ManualAsman Ahmad100% (3)

- Cat CSVDocument36 pagesCat CSVaqhammamPas encore d'évaluation

- Astrum BrochureDocument22 pagesAstrum BrochureKalai SelvanPas encore d'évaluation

- CDQDocument2 pagesCDQKalai SelvanPas encore d'évaluation

- GDN 145Document123 pagesGDN 145pandyatushar100% (1)

- HPCL - Palanpur Terminal EIADocument130 pagesHPCL - Palanpur Terminal EIAKalai SelvanPas encore d'évaluation

- Apt 60928 Evs TM 08 1Document108 pagesApt 60928 Evs TM 08 1Mohan JhaPas encore d'évaluation

- Fan Laws PDFDocument3 pagesFan Laws PDFKalai SelvanPas encore d'évaluation

- File20 PDFDocument1 pageFile20 PDFKalai SelvanPas encore d'évaluation

- 74 L3 Oct07 XDocument20 pages74 L3 Oct07 XJimmy HaddadPas encore d'évaluation

- SJ6832RT Service Manual PDFDocument144 pagesSJ6832RT Service Manual PDFszerelPas encore d'évaluation

- Ue117 Pressure SwitchDocument12 pagesUe117 Pressure SwitchkurmakkPas encore d'évaluation

- Manual Maquina de CapsulasDocument30 pagesManual Maquina de CapsulasJose SanchezPas encore d'évaluation

- Installation and Instruction Manual: Eminox Electronic Service IndicatorDocument20 pagesInstallation and Instruction Manual: Eminox Electronic Service Indicatorsixin93551Pas encore d'évaluation

- MPPT T40Document5 pagesMPPT T40situ omongPas encore d'évaluation

- Belt Conveyor - Pull Rope Switch NTS: Kiepe 638Document4 pagesBelt Conveyor - Pull Rope Switch NTS: Kiepe 638lewinPas encore d'évaluation

- Series Switch IB-016IDocument13 pagesSeries Switch IB-016Imastelecentro100% (1)

- ALC-20658-Relay Pack For ZN551Document4 pagesALC-20658-Relay Pack For ZN551usgl-scbd3639Pas encore d'évaluation

- EKC 202ABC ManualDocument16 pagesEKC 202ABC ManualJose CencičPas encore d'évaluation

- Additional Pressure and Temperature Switch Application InformationDocument2 pagesAdditional Pressure and Temperature Switch Application InformationJean GonzalezPas encore d'évaluation

- Product Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 32 A - On DoorDocument2 pagesProduct Data Sheet: Tesys Vario - Emergency Stop Switch Disconnector - 32 A - On DoorEdu SilvaPas encore d'évaluation

- SR200 Electrical PDFDocument5 pagesSR200 Electrical PDFAnonymous Hd32bhq100% (2)

- Acs 1026Document11 pagesAcs 1026José InácioPas encore d'évaluation

- Water Cooled Screw Chiller: PFS Sizes: 150 - 200 Vintage: ADocument33 pagesWater Cooled Screw Chiller: PFS Sizes: 150 - 200 Vintage: AAbdulSattarPas encore d'évaluation

- Experiment 5Document8 pagesExperiment 5suprotipPas encore d'évaluation

- Renishaw Encoders - RH200 Encoder SystemDocument2 pagesRenishaw Encoders - RH200 Encoder SystemjuliangoalPas encore d'évaluation

- Technical Training Level II HA12CJ - EN - E02-14Document118 pagesTechnical Training Level II HA12CJ - EN - E02-14Enrique EmmanuelPas encore d'évaluation

- EVO192 Zone Expansion ZXD-EI02Document2 pagesEVO192 Zone Expansion ZXD-EI02Dan RaducanuPas encore d'évaluation

- Fire Safety RFQDocument71 pagesFire Safety RFQAbdulgaffar HawaldarPas encore d'évaluation

- Lenovo Ideapad Yoga 13: Hardware Maintenance ManualDocument72 pagesLenovo Ideapad Yoga 13: Hardware Maintenance Manualsandmike_83Pas encore d'évaluation

- Ats 01 ManualDocument34 pagesAts 01 ManualRoberto BernalPas encore d'évaluation

- SR881 PDFDocument43 pagesSR881 PDFUltisolarPas encore d'évaluation

- Scania Electrical System in P, R, T Series - Introduction and General TroubleshootingDocument72 pagesScania Electrical System in P, R, T Series - Introduction and General Troubleshootinglaurens100% (2)

- 2.change Over Switch - L&TDocument12 pages2.change Over Switch - L&Trajpre1213Pas encore d'évaluation

- 570Document205 pages570Brijendra Singh100% (1)

- Operation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C SequenceDocument165 pagesOperation Manual: The Fifth Edition Edited JULY 01, 1997 FOR TM6X+T6C SequenceJam AnjumPas encore d'évaluation

- CPFG 3000Document2 pagesCPFG 3000kothat82Pas encore d'évaluation

- Uk - Usa: Read This Manual Carefully Before UseDocument12 pagesUk - Usa: Read This Manual Carefully Before UseВасяPas encore d'évaluation

- Ansaldo STS US Railway Signaling Catalog - 2013Document497 pagesAnsaldo STS US Railway Signaling Catalog - 2013anders_wallen5420Pas encore d'évaluation