Académique Documents

Professionnel Documents

Culture Documents

ABB Systems Work For JSW Steels Ladle Cranes

Transféré par

KudremukhTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ABB Systems Work For JSW Steels Ladle Cranes

Transféré par

KudremukhDroits d'auteur :

Formats disponibles

Crane Systems

ABB systems work for JSW Steels Ladle Cranes

at Toranagallu

ABB Crane Systems India delivered its first ISU based

Multidrive System for a Steel Plant Ladle Crane in India

.

JSW Steel Limited, Tornagallu, Karnataka

JSW Steel Limited is one among the largest Indian Steel

companies in India today with capacity of 7.8MT. The

company consists of the most modern, eco-friendly steel

plants with the latest technologies for both upstream and

downstream processes.

Customer requirements

1. 5 Nos. 300+75/10T Ladle Cranes along with 11 other

cranes of lesser capacity for other Steel Melt Shop.

2. Squirrel cage induction motors and some field devices,

the complete electrics including drives, automation,

power distribution panels, encoders, etc.

3. Automation package for the 300T Ladle cranes.

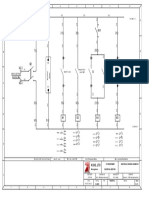

4. ISU based Multidrive system with full ISU redundancy for

the five 300T Ladle cranes.

5. The automation package consists of AC800M based PLC

system with a Crane Maintenance Station.

Challenges

1. Having complete ISU based multidrive solution for an

EOT crane in Steel Melting shop.

2. Integration of our all electrical system with the Chinese

OEM and accommodate all the equipments in their

design.

3. To configure the remote I/Os of different girders, operator

cabin and drives.

Solution by ABB

The ISU redundancy delivered on the cranes is a unique

installation that prevents a critical crane operation from

coming to a stop in the event of an ISU / Convertor failure.

In the event of an ISU failure the entire drive system and the

crane come to a halt. This could lead to unacceptable loss

of production time and hot metal in the ladle. In the delivered

configuration with 2 nos. ISUs, the failed ISU is isolated from

the DC bus, and the standby ISU is switched into the circuit

to power the DC bus to continue the operation without any

further loss of production time. The failed ISU can then be

physically isolated and suitable repairs can be undertaken

without stoppage to the crane operation.

Benefits received from ABB

1. The Crane Maintenance Station (CMS) used generates

historical data of the cranes, real time display of

parameters and signals, hours of operation and much

other information that is useful to JSW Steel to plan their

maintenance schedules of the cranes.

2. The Crane Maintenance Station (CMS) system also

provides trends, graphical displays of the crane motion,

various parameters like speed, current and voltage levels

of different drives, fault indications and recommended

remedial actions among others.

3. JSW can not only maintain past records of operation,

but also can use this information for analysis and take

suitable preventive actions to prevent future occurrences

of undesirable events.

3AST003458D0089 RevA

For more information please contact:

ABB AB

Process Automation

Crane Systems, 2nd Floor Plot # 5 & 6, 2nd Phase

Peenya Industrial Area

Bangalore - 560058

Karnataka, INDIA

Tel: +91 80 2294 9449

www.abb.co.in/cranes

ABB AB

Crane Systems

SE-721 59 Vsters, Sweden

Phone: +46 21 32 50 00

Fax:

+46 21 34 02 90

e-mail: cranes.sales@se.abb.com

www.abb.com/cranes

Note:

We reserve the right to make technical changes or modify

the contents of this document without prior notice. ABB AB,

Crane Systems does not accept any responsibility whatsoever

for potential errors or possible lack of information in this

document. We reserve all rights in this document and in

the subject matter and illustrations contained herein. Any

reproduction, disclosure to third parties or utilization of its

contents in whole or in part is forbidden without prior

written consent of ABB AB, Crane Systems.

Copyright 2010 ABB. All rights reserved.

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Year's Best Horror Stories - Karl Edward Wagner PDFDocument298 pagesThe Year's Best Horror Stories - Karl Edward Wagner PDFAmbaejo96100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Tracing Practice Preschool Workbook PDFDocument20 pagesTracing Practice Preschool Workbook PDFO ga100% (3)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- NadiAstrologyAndTransitspart 2Document7 pagesNadiAstrologyAndTransitspart 2Jhon Jairo Mosquera RodasPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Medi ManualDocument39 pagesMedi ManualBabuPD75% (8)

- Indirectness and Euphemism PDFDocument30 pagesIndirectness and Euphemism PDFmgar10Pas encore d'évaluation

- Bolted Connection in Glass StructureDocument52 pagesBolted Connection in Glass StructureCristiana Gruia-Paun100% (2)

- SLE Lesson 7 - Weather CollageDocument4 pagesSLE Lesson 7 - Weather CollageKat Causaren LandritoPas encore d'évaluation

- Quantitative Aptitude For Competitive Exams (WWW - Sarkaripost.in) PDFDocument137 pagesQuantitative Aptitude For Competitive Exams (WWW - Sarkaripost.in) PDFgencoPas encore d'évaluation

- Training D112 - V3 - 02E PDFDocument77 pagesTraining D112 - V3 - 02E PDFkratmelPas encore d'évaluation

- Clinical OpticsDocument88 pagesClinical OpticsKris ArchibaldPas encore d'évaluation

- Work Performance Report in Project ManagementDocument3 pagesWork Performance Report in Project Managementmm.Pas encore d'évaluation

- Jackson - Chimu Sculptures of Huacas Takaynamo and El DragonDocument26 pagesJackson - Chimu Sculptures of Huacas Takaynamo and El DragonguillermoPas encore d'évaluation

- Technical Specifications: Latest Version CpuDocument1 pageTechnical Specifications: Latest Version CpuKudremukhPas encore d'évaluation

- Organization Chart of Kiocl Limited: Director (Production & Projects)Document8 pagesOrganization Chart of Kiocl Limited: Director (Production & Projects)KudremukhPas encore d'évaluation

- Arc Machine DLDocument7 pagesArc Machine DLKudremukhPas encore d'évaluation

- Page 2a of 6Document1 pagePage 2a of 6KudremukhPas encore d'évaluation

- SINE 03 GreenDocument1 pageSINE 03 GreenKudremukhPas encore d'évaluation

- SINE 03 SolderDocument1 pageSINE 03 SolderKudremukhPas encore d'évaluation

- A User Guide of Dvdfab9 PDFDocument43 pagesA User Guide of Dvdfab9 PDFKudremukhPas encore d'évaluation

- SINE 03 CompDocument1 pageSINE 03 CompKudremukhPas encore d'évaluation

- Abb DCS600ServiceManualDocument126 pagesAbb DCS600ServiceManualmeikker1100% (2)

- Arc Machine DLDocument7 pagesArc Machine DLKudremukhPas encore d'évaluation

- FROG Chapter08 PDFDocument37 pagesFROG Chapter08 PDF신재호Pas encore d'évaluation

- GIS Thermografie Audits PDFDocument2 pagesGIS Thermografie Audits PDFkhalidfarooq009Pas encore d'évaluation

- 1 CHPDocument72 pages1 CHPsuganrhithuPas encore d'évaluation

- Customer Relationship Management: Summer Internship ProjectDocument16 pagesCustomer Relationship Management: Summer Internship ProjectSoniNitinPas encore d'évaluation

- CV 4Document2 pagesCV 4api-312667938Pas encore d'évaluation

- List of HEIsDocument2 pagesList of HEIsNadine MercadoPas encore d'évaluation

- Multicast Live Video Broadcasting Using Real Time TransmissionDocument2 pagesMulticast Live Video Broadcasting Using Real Time Transmissionaruna2707Pas encore d'évaluation

- Pulse / Pulsefit: Software For Electrophysiological Research, Data Acquisition, Review and Online AnalysisDocument8 pagesPulse / Pulsefit: Software For Electrophysiological Research, Data Acquisition, Review and Online AnalysisHRCPas encore d'évaluation

- KG 2 Week 5 - (133089689484163457) - 0Document3 pagesKG 2 Week 5 - (133089689484163457) - 0Nahdat Al Ghad International SchoolPas encore d'évaluation

- English 1 - R&J - Character Comparison PaperDocument2 pagesEnglish 1 - R&J - Character Comparison PaperDexter 'Koogi Mane' DaysPas encore d'évaluation

- User fc20 PDFDocument34 pagesUser fc20 PDFjesus diasPas encore d'évaluation

- Active CitizenshipDocument2 pagesActive CitizenshiprachidPas encore d'évaluation

- Whats Dupont SGP Interlayerldsts PDFDocument3 pagesWhats Dupont SGP Interlayerldsts PDFnightact44Pas encore d'évaluation

- The Influence of Beauty Projected in The Mass Media On Female Students.Document7 pagesThe Influence of Beauty Projected in The Mass Media On Female Students.Maggie SamsudinPas encore d'évaluation

- (One Village One Product) Berbasis KoperasiDocument11 pages(One Village One Product) Berbasis KoperasiIndah Kumala SariPas encore d'évaluation

- Subaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveDocument2 pagesSubaltern Voice in The Novel of Anita Nair's Lessons in Forgetting: A Female PerspectiveIJELS Research JournalPas encore d'évaluation

- Art of First DueDocument32 pagesArt of First DuedadaditdahPas encore d'évaluation

- Phase Transformations in Metals and Alloys PDFDocument37 pagesPhase Transformations in Metals and Alloys PDFWillmans Nolberto Ticlla MostaceroPas encore d'évaluation

- Port of Spain Case StudyDocument18 pagesPort of Spain Case StudyThe Cropper Foundation83% (6)