Académique Documents

Professionnel Documents

Culture Documents

TDEI v17 n10 p709 Xlpe Effects Water TR

Transféré par

gari_monsantoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

TDEI v17 n10 p709 Xlpe Effects Water TR

Transféré par

gari_monsantoDroits d'auteur :

Formats disponibles

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 17, No. 3; June 2010

709

Chemical Crosslinking of Polyethylene and its Effect

on Water Tree Initiation and Propagation

Florin Ciuprina

ELMAT, Faculty of Electrical Engineering,

University Politehnica of Bucharest,

Splaiul Independentei 313, 060042, Bucharest, Romania

Gisle Teissdre, Jean Csar Filippini

G2E Laboratory CNRS/INPG/UJF,

25 Avenue des Martyrs, 38042, Grenoble, France

Annika Smedberg, Alfred Campus

Borealis AB,

SE-444 86 Stenungsund, Sweden

and Nigel Hampton

NEETRAC, College of Engineering,

Georgia Tech, Atlanta, USA

ABSTRACT

The water tree resistance of chemically crosslinked polyethylene and of low density

polyethylene were compared in order to elucidate whether the crosslinking itself

influences or not the water tree characteristics of polymeric cable insulation materials.

For this purpose, water trees were grown in compression moulded disks, obtained from

pellets of either thermoplastic or chemically crosslinked polyethylene. Three types of

crosslinked polyethylene were evaluated: one containing only peroxide (XLA) and two

others having, besides peroxide, a tree retarding additive system (XLB and XLC), and

the results were compared with those obtained on their thermoplastic correspondents

(A, B and C). Results were determined for both Water Tree Propagation and Water

Tree Initiation. The results obtained for Water Tree Propagation indicate that there is

generally a large difference between the types (A, B & C) yet only small difference

between thermoplastic and crosslinked samples. However for two cases (A & B) these

small differences between crosslinking are statistically significant. The complementary

Water Tree Initiation results show both large and significant differences between

material types and the crosslinking.

Index Terms Cross linked polyethylene insulation, water trees, cable insulation.

1 INTRODUCTION

DURING the last decades crosslinked polyethylene (XLPE)

has been extensively used as extruded cable insulation in

underground transmission and distribution cables, replacing low

density polyethylene (LDPE) which was previously used. The

main reason for the change was that crosslinking improved the

thermal and the dimensional stability, especially at elevated

temperatures. Besides the mechanical resistance and electrical

performance, another property that needs to be considered when

choosing the insulating material for medium voltage (MV) power

cables is the water tree resistance. Indeed ageing due to water

Manuscript received on 24 February 2009, in final form 23 June 2009.

treeing had been earlier identified as one of the main cause of

MV cable insulation breakdown [1]. Therefore the question is if

the crosslinking itself plays a role in water treeing in

polyethylene insulation? It is indeed widely accepted that XLPE

is outperforming the thermoplastic LDPE technology in the

electrical cable distribution networks.

In our first study [2] the crosslinking of the polyethylene was

obtained by irradiating the samples with high energy electron

beams. The results showed no difference with respect to the

growth of water trees between thermoplastic polyethylene and

irradiation-crosslinked polyethylene. The conclusion was that the

crosslinking network, created by irradiation, did not prevent the

propagation of water trees.

1070-9878/10/$25.00 2010 IEEE

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

710

F. Ciuprina et al.: Chemical Crosslinking of Polyethylene and its Effect on Water Tree Initiation and Propagation

Since the most common technique used today for XLPE cable

insulation manufacturing is not irradiation but chemical

crosslinking, it was of interest to perform a similar study using

different chemically crosslinkable compounds designed for cable

insulation. The chemical crosslinking using dicumyl peroxide

has been extensively studied and it has been shown that byproducts originating from decomposition of the peroxide, in this

case acetophenone, influence the propagation of water trees, thus

introducing an additional parameter which has to be taken into

consideration [3]. Experiments which were performed about

twenty years ago on samples where the by-products have been

removed did not reveal any difference concerning the growth of

water trees between thermoplastic and crosslinked materials [4].

However, the large dispersion of the water tree lengths observed

by de Bellet and al. in 1987 has led us to question if a better

accuracy, presently available, could reveal a difference between

XLPE and LDPE with respect to water tree growth kinetics.

The materials used in this study were three polyethylenes

designed for use as insulation of MV cables. One sample was a

base polymer containing only dicumyl peroxide to avoid the

possible influence of any other components on water treeing

other than that of polymer crosslinking. Then two different

compounds based on the same polymer but containing

additionally a tree retardant additive, intended to reduce the

number and the size of water trees, were included as well.

2 EXPERIMENTAL

2.1 MATERIALS

The water treeing tests were performed on samples provided

by Borealis AB. All materials for the samples in thermoplastic

form, labelled A, B and C, were based on low density

polyethylene (LDPE) prepared by the high pressure

polymerization process usually used to manufacture compounds

for power cable insulation and they all had a Melt Flow Rate

(2.16 kg) (MFR2) of 2 g/10 min.

The material A contained no further additives.

The materials B and C were based on material A and

contained antioxidant to impart thermo-oxidative ageing

protection during cable manufacture and service life. These

samples also contain different water tree retardant additive

systems (one for B and another for C), both of polar nature.

Many studies have been conducted on the effect of peroxide

crosslinking on a number of important properties of cable

insulations [5-7]. In keeping with these studies, the samples

labelled XLA, XLB and XLC were obtained from the materials

A, B and C, respectively, by crosslinking using 2% wt of

dicumyl peroxide. These levels provide very comparable

performance with insulations used for a range of power cables

[7].

2.2 SAMPLE PREPARATION

Disks of 0.5 mm thickness and 50 mm diameter were press

moulded from pellets of polyethylene, in a CARVER press

(model 2696) using a mould with 12 holes of 50 mm diameter

and 0.5 mm thickness (Figure 1).The thermoplastic polyethylene

pellets of (A) were pressed 5 min at 150 C and 40 bar and

afterwards, the samples were cooled in air at room temperature.

The crosslinkable polyethylene pellets (used for obtaining XLA)

were pressed 14 min at 195 C and 4 MPa (40 bar) and then the

cooling was made with a rate of 15 C/min. In order to obtain

identical samples, the quantity of pellets used in each hole of the

pattern was set by taking into account the whole volume and the

density of polyethylene.

Figure 1. Pattern used to manufacture the samples.

After manufacturing, the crosslinked samples were degassed in

vacuum at 90 C for 72 h.

The sample preparation for the thermoplastic samples B and C

was performed in a somewhat different way compared to the

description above. The mould used for pressing was preheated at

130 C for 10 min. Then the pellets were pressed into a plaque of

0.6 - 0.65 mm thickness at 130 C, 2 min at 2 MPa (20 bar) and 5

min at 10 MPa (100 bar) followed by cooling to room

temperature at a cooling rate of 15 C/min. For the preparation of

the crosslinked samples XLB and XLC the mould was preheated

for 10 min. Then the pellets were pressed into a plaque of 0.6 0.65 mm thickness using the following conditions: 2 min at 130

C and 2 MPa (20 bar) followed by 20 min at 200 C and 10 MPa

(100 bar) and then cooling to room temperature at a cooling rate

of 15 C/min.

Five plaques were prepared of each formulation. After

manufacturing the crosslinked samples were heat treated in an

oven at 90 C, no vacuum, for 72 h to remove the peroxide

decomposition products. The level after heat treatment of

dicumyl peroxide, acetophenone, cumyl alcohol, alpha methyl

styrene and cumene were all found to be below 10 ppm. Also the

thermoplastic samples were heat treated in the same way in order

to have the same thermal history in all the samples. The purpose

of the heat treatment was to remove the crosslinking byproducts

that are known to have large influence on the treeing [8]. The

conditions used in this experiment do not significantly affect the

insulation morphology as they are considerably below those

employed in cable manufacture. Furthermore, any small effect

that may be present due to the heat treatment is excluded from

the experiment by applying the same conditions to all of the

tested samples. Initially there were some concerns that the

temperatures and times employed for the degassing of the

samples might induce some morphological change that would

affect the electrical performance of the insulations.

Confirmation of the fact that this is not true comes from the

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 17, No. 3; June 2010

inspection of data obtained from experiments where selected

crystallization and annealing conditions were applied to a

similar type of LDPE to that discussed in this paper [9]. These

experiments show that the conditions used here for degassing

only effect the breakdown strength by 3% and these changes

are not statistically significant due to the inherent scatter in

breakdown tests. It is important to note that the results

reported in the present paper display large and more

significant changes than can be attributed to any

morphological changes.

The crosslinking degree was assessed by gel fraction

measurements in accordance to the ASTM D2765 procedure by

refluxing xylene close to its boiling point, and the extraction was

carried out until the insoluble gel reached a constant weight. The

extraction time was of at least 96 h.

2.3 WATER TREES

To compare the water tree resistance of polymeric materials, it is

critical to grow water trees under well defined conditions which

include: (a) a defect at the water-polymer interface which

amplifies the electric field, (b) an ac electric field, (c) an ionic

solution. For consistency of the results, the shape of the defect,

the frequency and amplitude of the voltage and the concentration

711

of the ionic solution have to be well defined and consistent. As

defects acting as initiation sites for water trees, small needle-like

imprints, were created on one side of the compression moulded

sample, by pressing a sheet of abrasive paper (P240 type with an

average particle size smaller than 25 m) for 2 min at 50 MPa

(500 bar) at room temperature.

The images in Figure 2 show the typical distribution of

defects achieved for each of the tested samples. Inspection of

the images shows that the initiation sites are evenly (in

separation and size) on the surface of the samples. Figure 3

gives the concentrations of the initiating defects in a Box and

Whisker format, segregated for the three material types, both

thermoplastic and crosslinked versions. The median defect

contribution for this approach is expected to lie within the

range (set by the lower and upper quartiles) 100 to 140 defects

per mm2. Analysis of the data (Kruskal Wallis test) shows that

there is no significant difference between the material types

(Figure 3a) However, the same analysis shows that the

thermoplastic versions have 25% more initiation sites than the

crosslinked versions (Figure 3b) and it also confirms that this

difference is statistically significant. Consequently one would

expect the thermoplastic samples to contain 25% more

initiated water trees.

Figure 2. Defects acting as initiation sites for water trees, created on samples by pressing a sheet of abrasive paper before water tree tests.

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

712

F. Ciuprina et al.: Chemical Crosslinking of Polyethylene and its Effect on Water Tree Initiation and Propagation

Figure 3. Concentration of defect sites estimated from images shown in Figure 2, represented in a box and whisker plot the boxes enclose 50% of the data, the

whiskers 100%, the central lines represent the medians: (a) materials A, B and C - both forms, (b) crosslinked and thermoplastic - all materials

In our experiments, water trees were grown in cells (Figure 4)

arranged by fixing the sample on a polyethylene tube using

LOCTITE 401 in combination with an adequate surface

treatment. The electrolyte was a NaCl solution of concentration

c = 0.1 mol/l. Groups of five cells were fixed in a cell-holder and

water trees were grown by applying a voltage of 2 kV at a

frequency of 5 kHz for 25 h at room temperature.

After ageing the samples were detached and dyed in a

rhodamine solution at 60 C for 3 days to facilitate the

measurements of the water tree lengths. Three slices of 200

m thickness were microtomed from each sample (Figure 5a),

and the lengths of all water trees from each slice were

measured using the experimental setup shown in Figure 6. The

average length La for each sample was determined as the

average of the water trees lengths Lk measured on the three

slices of the sample (Figure 5b). The number of trees in each

slice was counted to determine the water tree density on the

sample surface

Ten samples of each type were tested according to the

procedure described above.

3 RESULTS AND DISCUSSION

Table 1 gives the average water tree lengths Lai obtained

from each of the ten samples tested for each material, the

average length of the ten average tree lengths, and the

measured crosslinking degree.

Figure 4. Cell used to produce water trees.

Figure 5. (a) Slices for measuring water trees dimensions. (b) Water tree

length Lk as measured on a slice.

Figure 6. Setup used to measure water tree lengths and water tree

densities.

3.1 RESULT ACCURACY

To evaluate the accuracy of the measurements both the

scattering between samples and the uncertainty on the

measurements of the water tree lengths need to be

considered. In fact, the scattering in the Lai values is very

small, in the order of 3%. Based on this finding it was

decided to consider the measurement error on the length

values as well. Among the different sources of error, the

depth and the shape of the water tree initiation sites as well

as the determination of the water tree front could be

mentioned. The last one is by far the most important and

the scatter in the length measurements can be estimated to

be in the range between 10 and 15%, depending on the type

of material used. It has been observed that different types of

materials give rise to trees that are more or less marked.

Finally, it was concluded that each material can be

characterized by the average length L affected by an overall

uncertainty of less than 15%, which is a lower value than

the previous work on this subject [4]. Figure 7 gives the

distribution of the individual average water tree lengths for

different material types and crosslinking conditions.

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

IEEE Transactions on Dielectrics and Electrical Insulation

Samples

Vol. 17, No. 3; June 2010

713

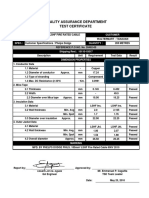

Table 1. Water tree lengths and crosslinking degree for the tested materials.

Water tree lengths of the ten tested samples

Crosslinking

degree

Average

length [m]

[m]

[%]

La1

La2

La3

La4

La5

La6

La7

La8

La9

La10

281

275

282

283

255

273

259

262

262

260

269

XLA

81

281

293

275

279

309

282

283

285

289

283

286

67

59

68

73

68

69

81

68

67

78

70

XLB

84

100

94

81

81

93

91

83

78

82

89

87

150

129

149

161

157

133

146

140

163

155

148

XLC

81.5

121

144

139

156

135

147

127

151

129

144

139

3.2 INFLUENCE OF CROSSLINKING ON WATER

TREE GROWTH

A detailed discussion of the statistical tests is outside the scope

of this paper and will be dealt with elsewhere. Nevertheless

inspection of Table 1 and Figure 7 shows three very interesting

features. Firstly these data confirm the results published in earlier

studies, by de Bellet et al [4], generated under other conditions

and with a lower accuracy, and they are also in agreement with

the findings in our previous study where water trees were grown

in irradiation crosslinked polyethylene [2].

The second feature is the large and significant differences

between the lengths of water trees grown in the three types of

materials, irrespective of the state of crosslinking.

Finally, and somewhat surprisingly, the differences in tree

length that can be ascribed to the crosslinking are small. Yet in

two of the cases (A & B) these small differences in crosslinking

are significant, namely the scatter within the lengths are smaller

than the differences between the crosslinking states.

One explanation for this third observation could be that a

polyethylene crosslinked to 80-85% gel has a network density,

i.e. a molecular weight between crosslinks, in the range of 50006000 g/mol.

200

3.3 INFLUENCE OF CROSSLINKING ON WATER

TREE DENSITY

In addition to water tree growth, the same samples yielded

information concerning the behavior of different materials with

respect to water tree initiation.

150

Table 2. Surface densities of water trees in tested materials.

300

Water Tree Length (microns)

During peroxide crosslinking of polyethylene, the radicals

generated from the decomposed peroxide abstract hydrogen

atoms from the polyethylene chain forming macroradicals.

When two macroradicals combine a crosslink is formed.

However, several authors have suggested that during

crosslinking the entanglements naturally present in a

polymer melt become trapped to different degrees (so-called

physical crosslinks) by the chemical crosslinks thereby

contributing to the network density. It has been reported that

in the network formed in crosslinked low density

polyethylene, around 1/3 of the crosslinks originate from

chemical crosslinks and around 2/3 from physical crosslinks

[10]. Thus the number of chemical crosslinks is not large

and therefore this could be the explanation for the small

difference observed on the water tree growth rate between

thermoplastic and chemically crosslinked samples, at the

investigated degree of crosslinking.

Our work also shows that materials B and C which contain

additives, e.g. antioxidants and water tree retardant substances,

have a degree of crosslinking that is essentially the same as in

the reference material XLA, indicating that the additives have

only a minor influence on the crosslinked network.

250

Non-crosslinked

samples

100

Water tree

density

[mm-2]

50

Form

Material

TP

XL

A

TP

XL

B

TP

XL

C

Figure 7. Mean water tree length (La) data, represented in a box and whisker

plot the boxes enclose 50% of the data, the whiskers 100%, the central lines

represent the medians.

Crosslinked

samples

Water tree

density

[mm-2]

16

XLA

XLB

2.5

10.5

XLC

5.5

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

714

F. Ciuprina et al.: Chemical Crosslinking of Polyethylene and its Effect on Water Tree Initiation and Propagation

Mean Water Tree Length (microns)

300

Material

A

A

B

B

C

C

250

Form

TP

XL

TP

XL

TP

XL

200

150

100

B

2

6

8

10

12

Mean Water Tree Density (mm-2)

14

16

Figure 8. Water tree length vs. water tree density for the tested materials

After sectioning, the surface densities of water trees in the

materials tested in this study were estimated and they are given in

Table 2. The relationship between these densities and water tree

lengths is graphically shown in Figure 8.

Interestingly, it can be seen that only a small fraction of the

defect sites actually initiated a water tree: 10% of thermoplastic

and 4% of crosslinked. It can be also observed that for all

materials the density of water trees is significantly higher in

the thermoplastic version compared to the corresponding

crosslinked version (Table 2). The initial defect concentration

was identical for all of the samples; thus this result is not

correlated with the manner in which the defects were

introduced. Despite that it was found that crosslinking did not

greatly influence the propagation of water trees, as determined

by their length after a prescribed time, there is an effect in the

initiation stage of water trees. This is consistent with the

superior performance of XLPE insulated cables that has been

established in the electrical distribution network versus

thermoplastic constructions [1, 11]. It is well known that

water tree initiation is strongly influenced by the nature and

shape of the initiation site, i.e. the defect which amplifies the

electric field and at which the ionic solution starts migrating

into the polymer [12]. According to our method of producing

the defects, i.e. imprints obtained by pressing a sheet of

abrasive paper of known particle size, the surface density of

imprints was almost the same for all samples (and this can be

seen from Figures 2 and 3), but the shape of the imprints at

their tips may be different in thermoplastic materials and in

crosslinked ones. Since the stress-cracking resistance of

crosslinked materials is clearly higher than that of

thermoplastic materials, the number and depth of micro-cracks

at the tips of the defects could be lower, which could explain

the observed difference.

4 CONCLUSIONS

The results obtained under our experimental conditions

have shown no large influence of the chemical crosslinking on

water tree propagation, for the range of water tree lengths

smaller than 300 microns, in the tested materials. This is in

agreement with the results of a previous work in which water

trees were grown in irradiation crosslinked polyethylene. It is

plausible that the crosslinked network formed in the

polyethylene was not able to hinder the migration of water

through the polymer under the action of the electric field,

thereby the water tree growth was not influenced once

initiated.

One may conclude that crosslinking itself does not

influence the water tree propagation but it plays a role in the

water tree initiation due to the better stress-cracking resistance

of crosslinked materials. We assume that different additives

added to polyethylene influence the initiation in different

ways according to the nature of additives.

REFERENCES

[1]

L. A. Dissado and J.C. Fothergill, Electrical Degradation and

Breakdown in Polymers, Peter Peregrinus Ltd., London, United

Kingdom, 1992.

[2] F. Ciuprina, G. Teissdre and J.C. Filippini, Polyethylene Crosslinking

and Water Treeing, Polymer, Vol. 42, pp. 7841-7846, 2001.

[3] S. L. Nunes and M. T. Shaw, Water Treeing in Polyethylene - A Review

of Mechanisms, IEEE Trans Electr. Insul., Vol. 15, pp. 437-448, 1980.

[4] J. J. de Bellet, G. Matey, J. Rose, L. Rose, J. C. Filippini, Y. Poggi and

V. Raharimalala, Some Aspects of the Relationship between Water

Treeing, Morphology and Microstructure of Polymers, IEEE Trans.

Electr. Insul., Vol. 22, pp. 211-217, 1987.

[5] S.T. Hagen, AC Breakdown Strength of XLPE Cable Insulation - The

Effect of Artificial Inclusions and Byproducts from the Crosslinking

Process, Ph.D. Thesis, University of Trondheim, 1993,

[6] B. Sanden, XLPE Cable Insulation Subjected to HVDC Stress - Space

Charge & Conduction, PhD Thesis, University of Trondheim, 1996

[7] A. Smedberg, B. Gustafsson and T Hjertberg, What is Crosslinked

Polyethylene, IEEE Intern. Conf. Solid Dielectrics, pp. 415418, 2004.

[8] Y.L. Chong, G. Chen, I. L. Hosier, A. S. Vaughan and Y.F.F. Ho, "Heat

Treatment of Cross-linked Polyethylene and its Effect on Morphology

and Space Charge Evolution", IEEE Trans. Dielectr. Electr. Insul., Vol.

12, pp. 1209-1221, 2005.

[9] R.S. Blacker, A.S. Vaughan, D.C. Bassett, S.M. Moody and R.N.

Hampton, Thermal processing, morphology, and electrical breakdown

of polyethylene, Intern. Conf. on Conduction and Breakdown in Solid

Dielectrics, pp. 214218, 1995.

[10] A. Smedberg, T. Hjertberg, and B. Gustafsson, The Role of

Entanglements in Network Formation in Unsaturated Low Density

Polyethylene, Polymer, Vol. 45, pp. 4867-4875, 2004.

[11] M. Fischer and B Hochstein, DISCAB Failure Statistics to Date for MV

Extruded Insulation Cables, UNIPEDE Workshop on Medium-Voltage

Cables, Darmstadt, Germany, 1996.

[12] J. C. Filippini and C. T. Meyer, "Water treeing test using the water

needle method. The influence of the magnitude of the electric field at the

needle tip", IEEE Trans. Electr. Insul., Vol. 23, pp. 275-278, 1998.

Florin Ciuprina (M93) was born in Galati,

Romania, in 1965. He received the M.Sc. and Ph.D.

degrees in electrical engineering from the University

Politehnica of Bucharest (UPB) in 1989 and 1997,

respectively. Since 1991 he has been with UPB,

Faculty of Electrical Engineering, working as an

assistant professor, lecturer, associate professor and,

presently, Professor of Electrical Materials. His

research activity have been developed mainly at

Electrical Materials Laboratory (ELMAT) from UPB,

but also at Laboratoire dElectrostatique et de Matriaux Dilectriques

(LEMD) CNRS Grenoble, France, during several research visits between

1995 and 2007. His main research fields include water treeing in cable

insulation, ageing and conduction phenomena in polymers and electrical

properties of nanodielectrics. He authored/co-authored several scientific

publications and communications.

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

IEEE Transactions on Dielectrics and Electrical Insulation

Vol. 17, No. 3; June 2010

Gisle Teissdre was born in France, in 1968. She

received the Ph.D. degree in physico-chemistry from

the Blaise Pascal University, Clermont Ferrand,

France in 1995. Since 1997 she has been with the

Joseph Fourier University of Grenoble, working as

assistant professor in the materials department of

PolytechGrenoble engineer school. Her research

activity was first carried out at the Macromolecular

and Molecular Photochemistry Laboratory of Blaise

Pascal University and since 1997 she has been

working at the Laboratory for Electrostatics and Dielectric Phenomena of

CNRS in Grenoble. Her main research fields include ageing mechanisms of

polymers, physico chemical ageing of polymers used for electrical insulation.

715

Robert Nigel Hampton is the Program Manager for

Reliability work at the National Electrical Energy

Testing Research and Applications Center

(NEETRAC) of Georgia Tech in Atlanta, GA, USA.

He has B.Sc. and Ph.D. degrees in physics from the

University of Bath in the UK and holds an M.Sc. in

polymer engineering. He has spent more that 18 years

working in the power cable arena, holding positions

within BICC, Pirelli, Borealis, and NEETRAC.

Jean Csar Filippini was born in Calvi, Corsica in

1939. He received the degree of electrical engineer from

the Polytechnical Institute of Grenoble, France in 1964.

He went to scientific research at CNRS in 1965 and

received the Ph.D. degree in physics in 1972 from the

Joseph Fourier University. He has made a career of

researcher in physics at the Laboratory for Electrostatics

and Dielectric Phenomena of CNRS in Grenoble. His

main subjects of research were electrical conduction in

insulating

liquids

and

electrohydrodynamics,

electrooptics in polar liquids, pretransitional phenomena in liquid crystals,

water treeing in cable insulation. He is presently working on ageing and

conduction phenomena in polymers.

Authorized licensed use limited to: Florin Ciuprina. Downloaded on June 24,2010 at 20:03:29 UTC from IEEE Xplore. Restrictions apply.

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Regression Analysis AssignmentDocument8 pagesRegression Analysis Assignmentضیاء گل مروت100% (1)

- QW 3221Document4 pagesQW 3221gari_monsantoPas encore d'évaluation

- Fault Current Cond Graph 3c Arm Cables PetronDocument1 pageFault Current Cond Graph 3c Arm Cables Petrongari_monsantoPas encore d'évaluation

- What's The Difference Between EPR and TR-XLP Cable - Border StatesDocument6 pagesWhat's The Difference Between EPR and TR-XLP Cable - Border Statesgari_monsantoPas encore d'évaluation

- TDS 240MM CU XLPE CTS PVC 8.7 - 15kVDocument1 pageTDS 240MM CU XLPE CTS PVC 8.7 - 15kVgari_monsantoPas encore d'évaluation

- IEC (0.6/1kV) Vs ICEA (600V) Comparison XLPE Insulation Wall Thickness SizesDocument2 pagesIEC (0.6/1kV) Vs ICEA (600V) Comparison XLPE Insulation Wall Thickness Sizesgari_monsantoPas encore d'évaluation

- UV-stabilized PDX (Blk&Red)Document1 pageUV-stabilized PDX (Blk&Red)gari_monsantoPas encore d'évaluation

- 336.4mcm Acsr-AwDocument1 page336.4mcm Acsr-Awgari_monsantoPas encore d'évaluation

- 185MM Fire Rated Qa Test CertificateDocument1 page185MM Fire Rated Qa Test Certificategari_monsantoPas encore d'évaluation

- Results: Installation Type: Buried DuctsDocument10 pagesResults: Installation Type: Buried Ductsgari_monsantoPas encore d'évaluation

- Nlupc 800mcm DBP 2ckts 05092014 SummaryDocument1 pageNlupc 800mcm DBP 2ckts 05092014 Summarygari_monsantoPas encore d'évaluation

- Results: Study: Execution: Date: Frequency: Conductor ResistancesDocument1 pageResults: Study: Execution: Date: Frequency: Conductor Resistancesgari_monsantoPas encore d'évaluation

- QW 3221Document4 pagesQW 3221gari_monsantoPas encore d'évaluation

- Meralco: Single Core 35Kv Cu/Trxlpe/Cts/Llope It Power CableDocument2 pagesMeralco: Single Core 35Kv Cu/Trxlpe/Cts/Llope It Power Cablegari_monsantoPas encore d'évaluation

- TDS Alum-DC Cables 1kVDocument1 pageTDS Alum-DC Cables 1kVgari_monsantoPas encore d'évaluation

- Tds Multicore Xlpe Cts PVC 600vDocument1 pageTds Multicore Xlpe Cts PVC 600vgari_monsantoPas encore d'évaluation

- Acsr DC ResistanceDocument1 pageAcsr DC Resistancegari_monsantoPas encore d'évaluation

- Tinned Cu - PVC - PVC 600v 105d Control Cable TdsDocument1 pageTinned Cu - PVC - PVC 600v 105d Control Cable Tdsgari_monsantoPas encore d'évaluation

- Codigo Ficheros PHPDocument33 pagesCodigo Ficheros PHPm_montielPas encore d'évaluation

- P103154 - 7.00 - Doc - Manual - 8000 WindlassDocument43 pagesP103154 - 7.00 - Doc - Manual - 8000 WindlassDanPas encore d'évaluation

- Arthashastra: Citation NeededDocument4 pagesArthashastra: Citation NeededtusharPas encore d'évaluation

- WDM Bi553Document138 pagesWDM Bi553florea_madfoxPas encore d'évaluation

- 7 - Introduction To Intelligent ControlDocument21 pages7 - Introduction To Intelligent ControlIsmael Espinoza100% (1)

- 2020 Specimen Paper 1 Mark SchemeDocument16 pages2020 Specimen Paper 1 Mark SchemesarabPas encore d'évaluation

- Part 1Document120 pagesPart 1Raju Halder0% (1)

- Kraken Intelligence's Taproot Primer - An Upgrade For The AgesDocument37 pagesKraken Intelligence's Taproot Primer - An Upgrade For The AgesT. CC ElficPas encore d'évaluation

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteDocument4 pagesStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniPas encore d'évaluation

- Computer Networks: Introduction (Chapter 1)Document92 pagesComputer Networks: Introduction (Chapter 1)Speed PianoPas encore d'évaluation

- MS Word 3Document2 pagesMS Word 3Misha RaviPas encore d'évaluation

- MSC Academic Guide - Admission Test PDFDocument13 pagesMSC Academic Guide - Admission Test PDFTonoy Peter CorrayaPas encore d'évaluation

- JAVA NotesDocument12 pagesJAVA NotesVarun BawaPas encore d'évaluation

- Precima Frenos FDW ATEX Operating InstructionsDocument6 pagesPrecima Frenos FDW ATEX Operating InstructionsToni RenedoPas encore d'évaluation

- 1 Egg & Egg Cookery LectureDocument15 pages1 Egg & Egg Cookery LectureErin DelavinPas encore d'évaluation

- Crane Wheels-General InformationDocument3 pagesCrane Wheels-General InformationArvind VaishPas encore d'évaluation

- Infinix NOTE 5 Stylus Quick Guide: Together We Can!Document16 pagesInfinix NOTE 5 Stylus Quick Guide: Together We Can!LescribeurPas encore d'évaluation

- 29 - CHAPTER 3 Intermolecular Forces and Potential Enegy SurfacesDocument9 pages29 - CHAPTER 3 Intermolecular Forces and Potential Enegy SurfacesMohit Kamboj100% (2)

- Reducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaDocument1 pageReducing The Efficiency Gap by Optimal Allocation Using Modified Assignment Problem For Apparel Industry in Sri LankaShivam BhandariPas encore d'évaluation

- Circuits in MatlabDocument38 pagesCircuits in MatlabRana UsmanPas encore d'évaluation

- Stacks - Quesues and DequesDocument23 pagesStacks - Quesues and DequesAbdallateef ShohdyPas encore d'évaluation

- Direct Synthesis of Sodalite From Kaolin: The Influence of AlkalinityDocument7 pagesDirect Synthesis of Sodalite From Kaolin: The Influence of AlkalinityIsye RahmaenaPas encore d'évaluation

- Coding 3 D ShapesDocument10 pagesCoding 3 D ShapesgmconPas encore d'évaluation

- Earthquake EnginneringDocument11 pagesEarthquake EnginneringkkkPas encore d'évaluation

- Caliper Xy MemoryDocument6 pagesCaliper Xy MemoryA MuPas encore d'évaluation

- Tugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)Document4 pagesTugas HKSA Deskriptor (Fitriani Choerunnisa (11171013) 3FA1)fitriani choerunnisaPas encore d'évaluation

- ISG Services OverviewDocument12 pagesISG Services OverviewsdonPas encore d'évaluation

- Deductive ReasoningDocument2 pagesDeductive ReasoningMariel C. BombitaPas encore d'évaluation

- Midterm BUS510Document8 pagesMidterm BUS510Ramesh KomarapuriPas encore d'évaluation