Académique Documents

Professionnel Documents

Culture Documents

Agility 125 Section 08 Cylinder Piston PDF

Transféré par

dabura1986Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Agility 125 Section 08 Cylinder Piston PDF

Transféré par

dabura1986Droits d'auteur :

Formats disponibles

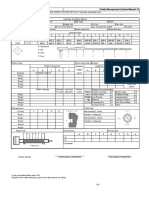

8.

CYLINDER/PISTON

AGILITY 125

1.0kg-m

8

Do not bend

8-0

8. CYLINDER/PISTON

AGILITY 125

SERVICE INFORMATION.......................8-1

PISTON REMOVAL................................. 8-2

TROUBLESHOOTING..............................8-1

PISTON INSTALLATION........................ 8-6

CYLINDER REMOVAL ...........................8-2

CYLINDER INSTALLATION ................. 8-6

SERVICE INFORMATION

GENERAL INSTRUCTIONS

The cylinder and piston can be serviced with the engine installed in the frame.

After disassembly, clean the removed parts and dry them with compressed air before inspection.

SPECIFICATIONS

Item

I.D.

Warpage

Cylinder

Cylindricity

True roundness

Ring-to-groove Top

clearance

Second

Top

Ring end gap

Second

Piston,

piston ring

Oil side rail

Piston O.D.

Piston O.D. measuring position

.

Piston-to-cylinder clearance

Piston pin hole I.D.

Piston pin O.D

Piston-to-piston pin clearance

Connecting rod small end I.D. bore

Standard (mm)

Service Limit (mm)

52.40052.410

52.50

0.05

0.05

0.05

0.0150.055

0.09

0.0150.055

0.09

0.100.25

0.5

0.100.25

0.5

0.20.7

52.37052.390

52.3

9mm from bottom of skirt

0.0100.040

0.1

15.00215.008

15.04

14.99415.000

14.96

0.0020.014

0.02

15.01615.034

15.06

TROUBLESHOOTING

When hard starting or poor performance at low speed occurs, check the crankcase breather for

white smoke. If white smoke is found, it means that the piston rings are worn, stuck or broken.

Compression too low or uneven

compression

Excessive smoke from exhaust muffler

Worn, stuck or broken piston rings

Worn or damaged piston rings

Worn or damaged cylinder and piston

Worn or damaged cylinder and piston

Compression too high

Excessive carbon build-up in combustion

chamber or on piston head

8-1

Abnormal noisy piston

Worn cylinder, piston and piston rings

Worn piston pin hole and piston pin

8. CYLINDER/PISTON

AGILITY 125

Cylinder

CYLINDER REMOVAL

Remove the cylinder head.

Remove the cam chain guide.

Remove the cylinder base bolts.

Remove the cylinder.

Remove the cylinder gasket and dowel pins.

Clean any gasket material from the cylinder

surface.

Gasket

Dowel Pins

PISTON REMOVAL

Remove the piston pin clip.

Place a clean shop towel in the crankcase

to keep the piston pin clip from falling

into the crankcase.

Press the piston pin out of the piston and

remove the piston.

Piston Rings

Piston

8-2

8. CYLINDER/PISTON

AGILITY 125

Inspect the piston, piston pin and piston rings.

Remove the piston rings.

Take care not to damage or break the

piston rings during removal.

Clean carbon deposits from the piston ring

grooves.

Install the piston rings onto the piston and

measure the piston ring-to-groove clearance.

Service Limits:

Top: 0.09mm replace if over

2nd: 0.09mm replace if over

Remove the piston rings and insert each

piston ring into the cylinder bottom.

Use the piston head to push each piston

ring into the cylinder.

Measure the piston ring end gap.

Service Limit: 0.5mm replace if over

Measure the piston pin hole I.D.

Service Limit: 15.04mm replace if over

8-3

Gap

8. CYLINDER/PISTON

AGILITY 125

Measure the piston pin O.D.

Service Limit: 14.96mm replace if below

Measure the piston O.D.

Take measurement at 9mm from the

bottom and 90 to the piston pin hole.

Service Limit: 52.3mm replace if below

Measure the piston-to-piston pin clearance.

Service Limit: 0.02mm replace if over

CYLINDER INSPECTION

Inspect the cylinder bore for wear or damage.

Measure the cylinder I.D. at three levels of

top, middle and bottom at 90 to the piston

pin (in both X and Y directions).

Service Limit: 52.50mm repair or replace if

over

Measure the cylinder-to-piston clearance.

Service Limit: 0.1mm repair or replace if

over

The true roundness is the difference between

the values measured in X and Y directions.

The cylindricity (difference between the

values measured at the three levels) is subject

to the maximum value calculated.

Service Limits:

True Roundness: 0.05mm repair or replace

if over

Cylindricity: 0.05mm repair or replace if over

Top

Middle

Bottom

8-4

8. CYLINDER/PISTON

AGILITY 125

Inspect the top of the cylinder for warpage.

Service Limit:

0.05mm repair or replace if over

Measure the connecting rod small end I.D.

Service Limit: 15.06mm replace if over

PISTON RING INSTALLATION

Install the piston rings onto the piston.

Apply engine oil to each piston ring.

Be careful not to damage or break the

piston and piston rings.

All rings should be installed with the

markings facing up.

After installing the rings, they should

rotate freely without sticking.

Top

Second

Side Rail

Oil Ring

Side Rail

8-5

8. CYLINDER/PISTON

AGILITY 125

PISTON INSTALLATION

Remove any gasket material from the

crankcase surface.

Be careful not to drop foreign matters

into the crankcase.

Install the piston, piston pin and a new piston

pin clip.

Position the piston IN mark on the

intake valve side.

Place a clean shop towel in the

crankcase to keep the piston pin clip

from falling into the crankcase.

Piston Pin Clip

Piston Pin

Piston

CYLINDER INSTALLATION

Install the dowel pins and a new cylinder

gasket on the crankcase.

Gasket

Coat the cylinder bore, piston and piston

rings with clean engine oil.

Carefully lower the cylinder over the piston

by compressing the piston rings.

Cylinder

Be careful not to damage or break the

piston rings.

Stagger the ring end gaps at 120 to the

piston pin.

8-6

8. CYLINDER/PISTON

AGILITY 125

Loosely install the cylinder base bolts.

Cam Chain Guide

Install the cam chain guide.

Insert the tab on the cam chain guide into

the cylinder groove.

Install the cylinder head.

Tighten the cylinder base bolts.

Cylinder Base Bolt

8-7

Vous aimerez peut-être aussi

- Agility 125 Section 16 Starting System PDFDocument8 pagesAgility 125 Section 16 Starting System PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 15 Ignition System PDFDocument6 pagesAgility 125 Section 15 Ignition System PDFdabura1986Pas encore d'évaluation

- F50LX Cap 17 (Imp Elettrico)Document6 pagesF50LX Cap 17 (Imp Elettrico)pivarszkinorbertPas encore d'évaluation

- Agility 125 Section 18 Evaporative Exhaust Emission Control System PDFDocument8 pagesAgility 125 Section 18 Evaporative Exhaust Emission Control System PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 01 General Information PDFDocument26 pagesAgility 125 Section 01 General Information PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 13 Rear Wheel Rear Brake Rear Suspension PDFDocument7 pagesAgility 125 Section 13 Rear Wheel Rear Brake Rear Suspension PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 09 Drive Pulleys Kick Starter PDFDocument16 pagesAgility 125 Section 09 Drive Pulleys Kick Starter PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 11 Crankcase Crankshaft PDFDocument6 pagesAgility 125 Section 11 Crankcase Crankshaft PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 10 Final Reduction PDFDocument6 pagesAgility 125 Section 10 Final Reduction PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 14 Battery Charging System AC Generator PDFDocument11 pagesAgility 125 Section 14 Battery Charging System AC Generator PDFdabura1986Pas encore d'évaluation

- AGILITY50 Cap 12 (Ruota Freno Sospens Ant)Document23 pagesAGILITY50 Cap 12 (Ruota Freno Sospens Ant)api-3759317Pas encore d'évaluation

- Agility 125 Section 06 Engine Removal Installation PDFDocument5 pagesAgility 125 Section 06 Engine Removal Installation PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 03 Inspection Adjustment PDFDocument12 pagesAgility 125 Section 03 Inspection Adjustment PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 07 Cylinder Head Valves PDFDocument12 pagesAgility 125 Section 07 Cylinder Head Valves PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 05 Fuel System PDFDocument15 pagesAgility 125 Section 05 Fuel System PDFdabura1986Pas encore d'évaluation

- Agility 125 Section 04 Lubrication System PDFDocument7 pagesAgility 125 Section 04 Lubrication System PDFdabura1986Pas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 02 - ISB6.7G B6.7N Base EngineDocument13 pages02 - ISB6.7G B6.7N Base EngineJulio MezaPas encore d'évaluation

- Părțile motorului Jawa 889Document14 pagesPărțile motorului Jawa 889GreereCristianPas encore d'évaluation

- TMD 22 PDocument2 pagesTMD 22 PdeepakgkdPas encore d'évaluation

- Cummins ISM11/M11/QSM11 engine parts catalogueDocument2 pagesCummins ISM11/M11/QSM11 engine parts cataloguehamdi galip100% (2)

- Parts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-46Document1 pageParts Catalog Cummins, 6LTAA8.9G2 - ESN 82312099 - CPL 3079-46Hardiansyah SimarmataPas encore d'évaluation

- Parts Book WB140 2N S N A20637 Up PDFDocument413 pagesParts Book WB140 2N S N A20637 Up PDFCledison Silva Dias100% (5)

- DetroitDocument56 pagesDetroitAbabsa KomatsuPas encore d'évaluation

- 0CV10-M86900EN: Last Update Mar., 2013Document26 pages0CV10-M86900EN: Last Update Mar., 2013Linzaw OoPas encore d'évaluation

- AB35049U English VersionDocument214 pagesAB35049U English VersionsaifulPas encore d'évaluation

- F-A P-S: Global Carriers LTD Safety Management System Manual 10Document2 pagesF-A P-S: Global Carriers LTD Safety Management System Manual 10trobasPas encore d'évaluation

- Guide de Puissance 2016 Genelec PDFDocument64 pagesGuide de Puissance 2016 Genelec PDFDhrubajyoti BoraPas encore d'évaluation

- Assembly and Parts Drawing: Wuxi Kipor Power Co., LTDDocument2 pagesAssembly and Parts Drawing: Wuxi Kipor Power Co., LTDDuvan Garridt MillanPas encore d'évaluation

- HF2620Document38 pagesHF2620DieselkPas encore d'évaluation

- Service ManualDocument52 pagesService ManualRonald Piedrahita92% (13)

- TAD540-542VE: Low Cost of OwnershipDocument2 pagesTAD540-542VE: Low Cost of OwnershipHorea CordunianuPas encore d'évaluation

- Ice 600 Stage Iiia / Tier 3: Specification SheetDocument6 pagesIce 600 Stage Iiia / Tier 3: Specification SheetGibbs PerPas encore d'évaluation

- Cylinder Head 10001 10778Document2 pagesCylinder Head 10001 10778muhammad nurhidayatPas encore d'évaluation

- Inline Pump SpecsDocument1 pageInline Pump SpecsAgustinus Leonardo SijabatPas encore d'évaluation

- 3512B - 1500 KVA Maintenance ScheduleDocument18 pages3512B - 1500 KVA Maintenance ScheduleHeryy TanujayaPas encore d'évaluation

- Mazda B2500, 1999, 2.5L-SpecsDocument4 pagesMazda B2500, 1999, 2.5L-SpecsAdiel Alexis Pérez100% (3)

- PMB 778 - 2206 Service ToolsDocument3 pagesPMB 778 - 2206 Service ToolsMohammad ShaatPas encore d'évaluation

- Hydraulic pump parts list and diagramsDocument9 pagesHydraulic pump parts list and diagramsIvan Andres Seguel BristiloPas encore d'évaluation

- Perkins Diesel Engines: 1004-42 (AR), 1006-60 (YG), 1006-60T (YH)Document132 pagesPerkins Diesel Engines: 1004-42 (AR), 1006-60 (YG), 1006-60T (YH)Walter100% (2)

- MAnual Do MotorDocument17 pagesMAnual Do MotorGileno MotaPas encore d'évaluation

- Yuchai YC4D120-20 D1008 PDFDocument75 pagesYuchai YC4D120-20 D1008 PDFAbel Gheller100% (1)

- Tamd 63Document2 pagesTamd 63Cristiano NunesPas encore d'évaluation

- RAIDER R150 High REBORN (FU150SCD2L4-P31)Document70 pagesRAIDER R150 High REBORN (FU150SCD2L4-P31)GAYLE GOPas encore d'évaluation

- SK SeriesDocument1 pageSK SeriesanggiePas encore d'évaluation

- Mak M25Document57 pagesMak M25Andrey Bogorodskiy100% (1)

- 18V46 INST MANUAL SRI LANKA - 91518, 91519, 91558, 91559, 91609 and 91614Document450 pages18V46 INST MANUAL SRI LANKA - 91518, 91519, 91558, 91559, 91609 and 91614Cihan YasarPas encore d'évaluation