Académique Documents

Professionnel Documents

Culture Documents

Basic-Material 2 PDF

Transféré par

cristhianTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Basic-Material 2 PDF

Transféré par

cristhianDroits d'auteur :

Formats disponibles

Using within min. -29 C to max.

425 C

General

The Carbon Equipvalent (CE) for carbon steel intended for welding

shall not exceed 0.43% base on the long formula: CE=C + Mn / 6 +

( Cr + Mo + V ) / 5 + ( Cu + Ni ) / 15

Service

A) Carbon Steel

Pipes

Non-corrosive piping system ( fresh water, plant air, nitrogen, fuel gas, etc.)

ASTM A106 Gr.B, API 5L Gr.B

Applications

Fittings

ASTM A234 Gr.WPB

Natural Rubber->NR

Forgings

Styrene Butadiene Rubber->SBR

ASTM A105

Neoprene Rubber->CR

Butyl Rubber->IIR

Using if the minimum service temperature is below -29 C

General

Chlorosulphonated polyethylene->CSM

Nitrile Butadiene Rubber->NBR, HNBR

Ethylene Propylene Rubber->EPDM

Service

I) Elastomeric

Pipes

Fluoroelastomers->FKM

B) Low Temp Carbon Steel

Low temperature non-corrosive piping system ( flare system )

ASTM A333 Gr.6

Applications

Perfluoro Polymer->FFKM

Fittings

ASTM A420 Gr.WPL6

Fluor-Silicone Rubbers->VMQ, PMQ, FMQ

Polyurethane Rubbers->AU,EU

Forgings

Glassfibre Rainforced Epoxy->GRE

The use of austenitic stainless steel in offshore is

limited to a maximum service temperature of 60 C

Glassfibre Rainforced Vinylester->GRV

No use in hydrocarbon and methanol system

Glassfibre Rainforced Plastic->GRP

Maxinternal design temperature 20 bargs

Design temperature range for -40 C up to

95C for epoxy and up to 80 C for

vinylester

ASTM A350 Gr.LF2

General

Any hydrostatic testing of austenitic stainless steel shall be conducted with water

containing less than 2 mg/kg chlorides, and any open ends sealed after drying to

ensure no moisture ingress.

H) Non-Metallic

Using

Using when the corrosion rate is too high to use carbon steel ( typical

more than 3mm or 6mm max. corrosion allowance for the design life )

Commonlly used for the sea water system in offshore

Service

C) Austenitic Stainless Steel

Plasticised Polyvinyl chloride->PVC

Pipes

Unplasticised PVC->UPVC

Fuel gas, chemical injection, instrument air, wet

hydrocarbon ( corrosive ).

ASTM A312 Gr.TP304/304L, ASTM A312 Gr.TP316/316L

Application

Polyethylene->PE

Basic Material

Polyamide->PA

www.azpiping.com

Polypropylene->PP

ASTM 403 Gr.WP304/304L, ASTM 403

Gr.WP316/316L

Fittings

Forgings

ASTM A182 Gr.F304/304L, ASTM A 182 Gr.F316/316L

PolyTetraFluoroEthyleme->PTFE

Polychlorotrifluoroethylen->PCTFE

Perfluoralkoxy->PFE

Fluoropolymers

Using when the the design condition is exceed the limit do SS316

G) Thermoplastic

General

Fluorinated ethylene propylene->FEP

Polyvinylidenefluoride->PVDF

Polyphenylenesulpone->PPS

Cross-linked Polyethylene->PEX

Polyketone->PK

Any hydrostatic testing of austenitic stainless steel shall be conducted with water

containing less than 2 mg/kg chlorides, and any open ends sealed after drying to

ensure no moisture ingress.

Service

Pipes

D) Duplex Stainless Steel

Application

Polyetheretherketone->PEEK

Fittings

Forgings

Including Inconel and incoloy

ASTM A790 UNS S31803

ASTM A815 UNS S31803

ASTM A182 Gr.F51

Nickel Alloys

Commonly used because of the high ppm

Monel is a nickel-copper alloy, 10%~90% commonly used

Cr-Mo heat resistant steel contain 0.5~9% Cr and

0.5~1.0% Mo. Carbon content max 0.20%

Monel

Service: sea water

General

Cu-Ni 90/10, Cu-Ni 70/30

Copper-Nickel

Services: sea water piping system

Good corrosion resistance, especially chlorite

induced pitting and stress-corrosion cracking

Elevated Temperature Services

Pipes

ASTM A 335 Gr.P11, A335 Gr.P22

Non-Alloyed grade

Titanium

Good resistance to oxidizing media, e.g. nitric acid

Resistance to reducing media superior to non-alloyed titanium

Supplied in normalized and tempered, quenched and

tempered or annealed condition

These Alloy Steels are used up to max temperature about 650 C

F) Non-Ferrous Alloy

Appication

Alloyed grade

Fittings

ASTM A234 Gr.WP11, A234 Gr.WP22

Forgings

E) Alloy Steel

General

ASTM A182 Gr.F11, A182 Gr.F22

Application with temperature form 0 C to

195C, Nickel steels is typically used

Pipes

ASTM A 333 Gr.3

Low Temperature Services

Application

Fittings

Forgings

ASTM A420 Gr.WPL3

ASTM A350 Gr.LF3

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Integrated Project DeliveryDocument79 pagesIntegrated Project Deliverymorro2002Pas encore d'évaluation

- CNT 0011279 02 PDFDocument2 pagesCNT 0011279 02 PDFcristhianPas encore d'évaluation

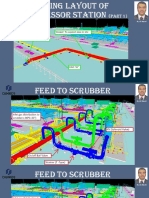

- Piping Layout of Compressor Station Part 1Document17 pagesPiping Layout of Compressor Station Part 1cristhianPas encore d'évaluation

- Piping Layout of Compressor Station Part 2Document9 pagesPiping Layout of Compressor Station Part 2cristhianPas encore d'évaluation

- CNT 0011186 01 PDFDocument10 pagesCNT 0011186 01 PDFcristhianPas encore d'évaluation

- Visual LayersDocument2 pagesVisual LayerscristhianPas encore d'évaluation

- Ref. Piping DesignDocument7 pagesRef. Piping DesigncristhianPas encore d'évaluation

- Mine Cycle Material HandlingDocument17 pagesMine Cycle Material HandlingcristhianPas encore d'évaluation

- PDS MineCycle-Material-Handling LTR en LRDocument2 pagesPDS MineCycle-Material-Handling LTR en LRcristhianPas encore d'évaluation

- Tuberias ConduitDocument2 pagesTuberias ConduitcristhianPas encore d'évaluation

- Cant. Total P57 Plancha 1 36BDocument1 pageCant. Total P57 Plancha 1 36BcristhianPas encore d'évaluation

- CNT 0011279 02 PDFDocument2 pagesCNT 0011279 02 PDFcristhianPas encore d'évaluation

- Cant. Total P96 Plancha 1 36BDocument1 pageCant. Total P96 Plancha 1 36BcristhianPas encore d'évaluation

- Flanges - Fitting Soldable PDFDocument2 pagesFlanges - Fitting Soldable PDFcristhianPas encore d'évaluation

- ROHR2 Program System for Static and Dynamic Piping AnalysisDocument33 pagesROHR2 Program System for Static and Dynamic Piping Analysisaddai262Pas encore d'évaluation

- CC2800 62151 Part1 - enDocument448 pagesCC2800 62151 Part1 - encristhian100% (1)

- Ensamblado Caja Baul Con FlorDocument0 pageEnsamblado Caja Baul Con FlorFlores AlfredoPas encore d'évaluation

- Module 2 - Editing CadWorx SpecificationDocument28 pagesModule 2 - Editing CadWorx SpecificationHuynh Thanh Tam100% (1)

- Bouquet (Roses) : Assembly Instructions: Assembly Instructions: Three A4 Sheets (No. 1 To No. 3)Document3 pagesBouquet (Roses) : Assembly Instructions: Assembly Instructions: Three A4 Sheets (No. 1 To No. 3)sgtjcPas encore d'évaluation

- Bouquet Tulip e A4Document29 pagesBouquet Tulip e A4sgtjcPas encore d'évaluation

- CNT 0010980 01 PDFDocument3 pagesCNT 0010980 01 PDFcristhianPas encore d'évaluation

- Gift-box-A I e A4Document0 pageGift-box-A I e A4Melchisedek Edwin Pérez BuitragoPas encore d'évaluation

- CNT 0011229 01 PDFDocument3 pagesCNT 0011229 01 PDFcristhianPas encore d'évaluation

- CNT 0010272 02Document4 pagesCNT 0010272 02cristhianPas encore d'évaluation

- Gift-box-A I e A4Document0 pageGift-box-A I e A4Melchisedek Edwin Pérez BuitragoPas encore d'évaluation

- Bouquet Rose e A4Document28 pagesBouquet Rose e A4sgtjcPas encore d'évaluation

- CNT 0011186 01 PDFDocument10 pagesCNT 0011186 01 PDFcristhianPas encore d'évaluation

- CNT 0010980 01 PDFDocument3 pagesCNT 0010980 01 PDFcristhianPas encore d'évaluation

- CNT 0010354 02Document3 pagesCNT 0010354 02cristhianPas encore d'évaluation

- Gift Box E: PartsDocument3 pagesGift Box E: PartscristhianPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Analiza-Indicatorilor-Fizici-Ai-Unor-Ape-Din-Romania1Document6 pagesAnaliza-Indicatorilor-Fizici-Ai-Unor-Ape-Din-Romania1Florin Ionita0% (1)

- Olechomical Ester Plant-Merged (This)Document21 pagesOlechomical Ester Plant-Merged (This)Calvin Lin Jia RongPas encore d'évaluation

- B. Tech. - I (All Branches) ASP102ABC (T) : Engineering Physics (Theory) L T P C 3 0 2 4Document2 pagesB. Tech. - I (All Branches) ASP102ABC (T) : Engineering Physics (Theory) L T P C 3 0 2 4Harikrishna ShenoyPas encore d'évaluation

- Valvulas de Bola 2Document20 pagesValvulas de Bola 2claudio godinezPas encore d'évaluation

- The Periodic Table and The Physics That Drives ItDocument22 pagesThe Periodic Table and The Physics That Drives ItSandipPas encore d'évaluation

- Stoichiometry Notes - 2014 KEYDocument10 pagesStoichiometry Notes - 2014 KEY5020NitinPas encore d'évaluation

- Proses ManufakturDocument5 pagesProses ManufakturAchmad HabibiePas encore d'évaluation

- BIOC 315 - Biochemistry of Food Processing Lecture NotesDocument55 pagesBIOC 315 - Biochemistry of Food Processing Lecture NotesPerry MasonPas encore d'évaluation

- Acoustic Resistivity NMR Well Logging InterpretationDocument2 pagesAcoustic Resistivity NMR Well Logging InterpretationMark MaoPas encore d'évaluation

- Stabilization of Expansive Soil Using Bagasse Ash & LimeDocument6 pagesStabilization of Expansive Soil Using Bagasse Ash & LimeRajveer SaePas encore d'évaluation

- SpokeshaveDocument6 pagesSpokeshavestuckinthestudioPas encore d'évaluation

- Heterogeneous CatalystDocument24 pagesHeterogeneous Catalystlalukalu420Pas encore d'évaluation

- API 570 practice test questionsDocument2 pagesAPI 570 practice test questionstipu321100% (3)

- Chromatography and Its Applications PDFDocument234 pagesChromatography and Its Applications PDFmeriemPas encore d'évaluation

- MSE Strength and PropertiesDocument20 pagesMSE Strength and PropertiesEdrian A. MañalongPas encore d'évaluation

- Asme B30.9 - FinalDocument3 pagesAsme B30.9 - FinalDavidNaulaPas encore d'évaluation

- VERSAMUL - Product BulletinDocument2 pagesVERSAMUL - Product BulletinIgorCencičPas encore d'évaluation

- ExperimentalDocument5 pagesExperimentalbabuPas encore d'évaluation

- Glydant Plus Liquid (I) 2006Document2 pagesGlydant Plus Liquid (I) 2006Enrique Alberto Valenzuela Hernandez0% (1)

- Safety Data Sheet: Revision Date: 15/06/2012 According To (EC) No. 1907/2006 (REACH), Annex II - United Kingdom (UK)Document8 pagesSafety Data Sheet: Revision Date: 15/06/2012 According To (EC) No. 1907/2006 (REACH), Annex II - United Kingdom (UK)AmirmasoudPas encore d'évaluation

- JBC Common Boiler FormulasDocument12 pagesJBC Common Boiler Formulasnesrine10Pas encore d'évaluation

- This PDF Is The Sample PDF Taken From Our Comprehensive Study Material For IIT-JEE Main & AdvancedDocument11 pagesThis PDF Is The Sample PDF Taken From Our Comprehensive Study Material For IIT-JEE Main & AdvancedGod is every wherePas encore d'évaluation

- Riverside Dilemma (Extra Credit)Document7 pagesRiverside Dilemma (Extra Credit)Odaro Osayimwen0% (2)

- Interaction of Sodium Alginate With Cetyltrimethylammonium Bromide in Aqua-Organic Mixed Solvents: Influence of Temperatures and CompositionsDocument10 pagesInteraction of Sodium Alginate With Cetyltrimethylammonium Bromide in Aqua-Organic Mixed Solvents: Influence of Temperatures and CompositionsKhairun Nisa ArgiantiPas encore d'évaluation

- SemiconductorsDocument37 pagesSemiconductorsANSHU RAJPas encore d'évaluation

- Test Bank For Anatomy and Physiology 1st Edition Michael MckinleyDocument37 pagesTest Bank For Anatomy and Physiology 1st Edition Michael Mckinleyreidelsebirew100% (12)

- Section 1.4: Isotopes, Radioisotopes, and Atomic MassDocument4 pagesSection 1.4: Isotopes, Radioisotopes, and Atomic MassgzboyzonePas encore d'évaluation

- Chapter 8Document6 pagesChapter 8Jerico LlovidoPas encore d'évaluation

- As Topic 4 Notes - Bonding & PeriodicityDocument8 pagesAs Topic 4 Notes - Bonding & PeriodicityJoyce LimPas encore d'évaluation

- Coal Fired Power Plant Termopaipa Iv: Compañía Eléctrica de Sochagota S.A. E.S.PDocument16 pagesCoal Fired Power Plant Termopaipa Iv: Compañía Eléctrica de Sochagota S.A. E.S.PControl Office and Technical Department CESPas encore d'évaluation