Académique Documents

Professionnel Documents

Culture Documents

Kitz 3 Way - 4 Seated

Transféré par

mtbecerrap0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues6 pagesbrochure

Titre original

Kitz 3 way - 4 seated

Copyright

© © All Rights Reserved

Formats disponibles

PDF ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentbrochure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

15 vues6 pagesKitz 3 Way - 4 Seated

Transféré par

mtbecerrapbrochure

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 6

KITS

A Product of Technology

FLANGED 3-WAY, 4-SEATED BALL VALVES.

CLASS 150

L-PORT (150UTB4LAM %

T-PORT (150UTB4TAM %

15OUTR4LAM 6'~8")

150UTR4TAM 6'~8")

+ Used for straight through flow and

diverting or mixing process media.

+ One 3.Way valve can replace

several other valves PLUS the

associated piping spool piaces.

+ Rugged back entry configuration

for easier maintenance,

© Full Port %'~4"

Regular Port 6"~8"

+ NACE MR.01-75

Integral actuator mounting flange

Low operating torques

Anti-static device

Traditional KITZ quality and

durability

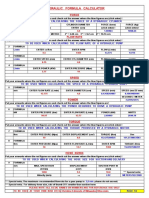

DIMENSIONAL and WEIGHT DATA

VALVE LENGTH | BRANCH | APPROX

SIZE, in Lin Lt, in WT, lbs

% 472 2.56 8.60 ho i 7

Ve S51 276 11.47 u

[Se] a ei

6 16,02 8.01 180.81

ALLOWABLE PORT ORIENTATION

FORM1

Flow is between Ports "A" and "C”

and can be in either direction.

There is a positive shutoff from

Port "B". However, if the system

pressure in this direction is much

higher than in the flow direction

there may be sight leakage to

either Port "A" or Port "C"

FORM 2

Flow is between Port "B" and

and can be in either direction.

There is a positive shutoff from

Port "A’, However, if the system

pressure in this direction is much

higher than in the flow direction

thore may be slight leakage to

either Port "B"or Port °C"

PROCESS MEDIA MAY MIX WHEN]

SWITCHING PORT ORIENTATION

FORM1

AllPorts are apen.

FORM2

Flow is between Ports "B" and "C'

and can be in either diraction.

a positive shutoff from

However, if the system

ressure in this direction is much

igher than in the flow direction

there may be slight leakage to

either Port "B* or Port °C"

FORM3

Flow is between Ports

and can be in either direx

and "B"

n,

There, is a positive shutoff from

Port "C” However, if the system

ressure in this direction is much

igher than in the flow direction

there may be slight leakage to

either Port"A" or Port "B".

FORM4

Flow is between Port "A’ and

and can be in either direction.

There, is a positive shutoff from

Port "B". However, if, the. system

fessure’in this direction is much

iigher than in the flow direction

there may be slight leakage to

either Port "A" or Port "C"

MOUNTING PAD AND STEM PROJECTION DATA

Size %"~1" Size 14"-214" Size 3"-4"

4

+ Bd Ft ~

= | :

Size 6"~6"

VALVE DIMENSIONS, Inches

SIZE, in H Ht H2 B Pt d Dt s B

% 177 1.42 o7e | 197 - Me oss | 040 1.08

% 139 142 | 078 197 s MB oso | odo 1108

4 2.05 1.42 0.78 1.97 ™ Me 0.59 0.40 1.06

1% | 319 | 224 ee wiz | 103 | 0.67 ‘et

z 3.54 2.24 142 2.95 1.65 M12 1.03 0.67 1.61

2% | 420 | 283 a7e | 35a | 213 mis | 138 | oot 197

3 476 283 17a | 354 | 213 mis | 138 | 091 197

4 5.83, 335 | 228 | 386 | 217 mis | 158 1.07 232

6 650 | 335 | 226 | 388 | 217 mis | 1.58 1.07 232

8 reo | 373 | 242 | 42t 2.36 mis | 180 1126 268

FLOW

OPERATIONAL TORQUE, In-Ibs* COEFFICIENT

VALVE NOMINAL MAX RATED VALVE APPROX

SIZE, in | AP (150 psi) | AP (285 psi) SIZE, in cv

% 104 104 ” 9

% 162 182 x 14

1 220 220 1 26

A 577 577 % 64

2 1,039 4,039 2 408

2% 1,386 1,386 2% 182

3 2,540 2,540 3 265

4 3.463 3.483 4 460

8 6,204 665 6 860

8 8,313 8774 8 960

* contains 33% safety factoriciean quid

CONSTRUCTION and MATERIALS

NO, PARTS MATERIALS SPECIFICATIONS

1 BODY STAINLESS STEEL ‘A351 Gr. CFM

2 BODY CAP STAINLESS STEEL ‘A351 Gr. CFEM

3 ‘STEM STAINLESS STEEL A276 TYPE 315,

4 BALL STAINLESS STEEL A276 TYPE 315,

(Upto 1")

A351 Gr. CFEM

(1" and larger)

7 GLAND STAINLESS STEEL A351 Gr. CFB

8 GLAND PACKING PTFE

9 HANDLE DUCTILE IRON

9A HANDLE BAR CARBON STEEL

9B HANDLE HEAD DUCTILE IRON

19 GASKET PTFE

20 PACKING WASHER STAINLESS STEEL A276 TYPE 316

30 BALL SEAT HYPATITE PTFE

35 CAP BOLT STAINLESS STEEL A193 Gr. BB

36 GLAND BOLT STAINLESS STEEL A193 Gr. BB

47 THRUST WASHER GIF PTFE (214" and larger. Integral with

‘Stem Bearing (#67) 2" and smaller)

48A SNAP RING STAINLESS STEEL A276 TYPE 304

488 SNAP RING STAINLESS STEEL A276 TYPE 316

49 STOPPER STAINLESS STEEL

67 STEM BEARING GIF PTFE

123A, HANDLE BOLT CARBON STEEL

1238 HANDLE BOLT CARBON STEEL

124A SPRING & PIN STAINLESS STEEL A313 & A276 TYPE 316

(4" and larger)

1248 RING SPRING STAINLESS STEEL A313 TYPE 316

(%4" only)

re

ve

"Se

) = y we 909 raf

WIA /

aS

/\ CAUTION

Pressure-temperature ratings and other performance data published

in this catalog have bean developed from our design calculation,

in-housetesting, field reports provided by our customers andlor

published offical standards or spectfcations. They are good only to

cover typical applications as a general guideline to users of KITZ

products introcuced in this caiaiog.

For any spectic application, users are kindly requested to contact

KITZ Corporation for technical advice, or to carry out their own

study and evaluation for providing suitabilty ofthese products to such

an application. Failure to follow this request could resutt in property

damage andlor personal injury, for which we shell not be liable,

While this catalog has been compiled with the utmost care, we

assume no responsibilty for errors, impropriety or inadequacy. Any

information provided in this catalog is subject to from-time-tocime

Change without notice for error rectification, product discontinuation

design modification, new product introduction or any other cause

that KITZ Corporation considers necessary, This edition cance's all

Previous issues.

ISO 9001 certified since 1989

KITS

KITZ CORPORATION OF AMERICA

10750 Corporate Drive, Stafor, Texas 77477, USA

Phone: 261-401-7333 Fax: 261-491-0402

Tol Free: 800-772-0073

wa kltz,com

= Distributed by -

Vous aimerez peut-être aussi

- Mechanical FiberingDocument1 pageMechanical FiberingmtbecerrapPas encore d'évaluation

- Piping Design InfoDocument279 pagesPiping Design InfoPradeep SarodePas encore d'évaluation

- Catalogo Leeson Electric Co PDFDocument534 pagesCatalogo Leeson Electric Co PDFmtbecerrapPas encore d'évaluation

- BPVCDocument1 pageBPVCmtbecerrapPas encore d'évaluation

- Control - Tuberia - 530 IVAN TUADocument58 pagesControl - Tuberia - 530 IVAN TUAmtbecerrapPas encore d'évaluation

- Pesos de Componentes SPG-SBRG-SPRGDocument3 pagesPesos de Componentes SPG-SBRG-SPRGmtbecerrapPas encore d'évaluation

- Renold Conveyor Section1&2 0508 PDFDocument51 pagesRenold Conveyor Section1&2 0508 PDFmtbecerrapPas encore d'évaluation

- Tsubaki Backstop AntiretornoDocument12 pagesTsubaki Backstop Antiretornomtbecerrap100% (1)

- Ev DG05Document14 pagesEv DG05mtbecerrapPas encore d'évaluation

- Boston ReducersDocument356 pagesBoston ReducersVicente Banda ZuñigaPas encore d'évaluation

- SSPC Vis 1Document2 pagesSSPC Vis 1cesar100% (3)

- Copia de Hirsch-Hydraulic-CalculatorDocument1 pageCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- Astm D2657 - 07Document7 pagesAstm D2657 - 07dsalguero_2100% (2)

- Pipe Dimensions Imperial/MetricDocument3 pagesPipe Dimensions Imperial/MetricmtbecerrapPas encore d'évaluation

- Boiler Material and Typical ApplicationsDocument1 pageBoiler Material and Typical Applicationsmtbecerrap100% (1)

- Lincoln Er-308l Gtaw Acero InoxidableDocument2 pagesLincoln Er-308l Gtaw Acero InoxidablemtbecerrapPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)