Académique Documents

Professionnel Documents

Culture Documents

Slides 83-91 Seals Bearings

Transféré par

Ariel AnnaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Slides 83-91 Seals Bearings

Transféré par

Ariel AnnaDroits d'auteur :

Formats disponibles

Mechanical Shaft Seal

(TSO-Carbon Seal)

EDS/CD-83

Like the pump seal, the contact type compressor seal has a rotating member and a

stationary member. A floating carbon bushing is between the two members.

Process gas leaks across the labyrinth on the right side of the seal and fills a gas

chamber. This gas is at a lower pressure than the process because of the pressure

drop across the labyrinth. Seal oil is introduced on the bearing side of the seal

faces. Most of the oil goes around the seal back to the reservoir. The oil pressure is

maintained higher than the gas pressure in the gas chamber. The oil lubricates the

seal and about 10 liters per day of oil leaks into the gas chamber. This sour oil is

drained. Note that most of the UOP processes contain some H2S or HCl. If the sour

oil is put back in the oil reservoir, the lube oil can become contaminated at bearing

or seal problems can result.

83

Liquid Film Sleeve Seal

(TSO-Sleeve Seal)

EDS/CD-84

Bushing type seal. Oil leakage is greater than contact type but there is no normal

seal wear.

84

Thrust Bearing

EDS/CD-85

Thrust bearings are designed to withstand the axial forces on the shaft. The thrust

pads are designed to pivot to the contour of the shaft.

85

EDS/CD-86

Thrust bearing. The bearing pads ride against the thrust disc and absorb force in

either axial direction.

86

Journal Bearing

EDS/CD-87

The journal bearings are designed to withstand the radial forces on the shaft. The

bearing pads can tilt to fit the contour of the shaft. Note the temperature monitors

on the back side of the pads.

87

C:\Doents and

Settings\bmlieber\Deskt

op\P0003697.tif

EDS/CD-88

88

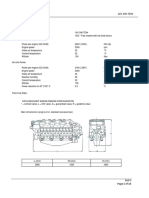

Compressor Lube Oil System

s/d: 2 out of 3 voting

Filters

Coolers

Pumps

EDS/CD-89

Centrifugal compressor bearings are typically lubricated by an external pressurized

oil system. Oil is stored in a large reservoir. There are two pumps, one operating

and one spare. On low oil pressure, the spare pump comes on-line automatically.

The two pumps should be driven by different power supplies, typically electric

motor and steam turbine, to insure a supply of oil to the compressor. The spare

pump must be motor driven. A steam turbine will take too long to come on-line.

Note the twin coolers and filters. Also note the three separate low oil pressure

shutdown switches. The shutdown is two of three voting. Two of the switches must

vote to shutdown before the driver is tripped. This avoids spurious shutdowns and

insures a shutdown if one is needed.

89

Compressor Seal Oil System

EDS/CD-90

If the compressor has an oil lubricated seal, the seal must be supplied with

pressurized oil. The seal oil system is very similar to the lube oil system

90

Compressor Lube and Seal Oil System

EDS/CD-91

There are many common components between the lube and seal oil systems, such as

pumps, coolers, filters, etc. Many compressors have combined lube and seal oil

systems. Only one reservoir and one set of pumps, coolers, filters, etc., is required.

If the compressor has a high suction pressure or contains a large quantity of H2S

(Hydrocracking Units), the oil systems are kept separate. Otherwise, UOP specified

combined lube and seal oil systems. Today, UOP specifies dry gas seals so only the

lube oil system is required.

91

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- 2005 Ford Pickup 6.0L Pump Flow TestingDocument38 pages2005 Ford Pickup 6.0L Pump Flow TestingGinshun Ray Spedowski100% (2)

- Slides 24-30 Recip ControlDocument7 pagesSlides 24-30 Recip ControlAriel AnnaPas encore d'évaluation

- See Gasolineairquality - PDF File: Environmental Issues Section Handout Index 2004Document22 pagesSee Gasolineairquality - PDF File: Environmental Issues Section Handout Index 2004Ariel AnnaPas encore d'évaluation

- ReadmeDocument1 pageReadmeAriel AnnaPas encore d'évaluation

- Visvesvaraya Technological University, BelgaumDocument44 pagesVisvesvaraya Technological University, BelgaumAnonymous Wq5eKxGPas encore d'évaluation

- Science Volume 219 Issue 4585 1983 (Doi 10.1126/science.219.4585.728) Cooney, C. L. - Bioreactors - Design and OperationDocument6 pagesScience Volume 219 Issue 4585 1983 (Doi 10.1126/science.219.4585.728) Cooney, C. L. - Bioreactors - Design and OperationAriel AnnaPas encore d'évaluation

- Role of Sparger Design in Mechanically Agitated Gas-Liquid ReacDocument8 pagesRole of Sparger Design in Mechanically Agitated Gas-Liquid ReacAriel AnnaPas encore d'évaluation

- Medical GasDocument39 pagesMedical GasFrancisco M. Ramos100% (1)

- Design of Vacuum SystemDocument5 pagesDesign of Vacuum SystemDongwon ShinPas encore d'évaluation

- Data Sheet - Item FW 001: Issued On: 27.02.2006 Issued By: 1100/freDocument3 pagesData Sheet - Item FW 001: Issued On: 27.02.2006 Issued By: 1100/freChiriacMariusPas encore d'évaluation

- Gen Set 30 KVA HA 494Document21 pagesGen Set 30 KVA HA 494Manjeet DalalPas encore d'évaluation

- Drilling Mechanics Measurements Drive Usage of Hole Cleaning Sweeps in Deiated WellsDocument14 pagesDrilling Mechanics Measurements Drive Usage of Hole Cleaning Sweeps in Deiated WellsGabo Merejildo QuimiPas encore d'évaluation

- 10000B 1 - CSM - CTR215 03 - 10 09 13Document724 pages10000B 1 - CSM - CTR215 03 - 10 09 13Sa PoPas encore d'évaluation

- T-900 Series ManualDocument14 pagesT-900 Series ManualSonyer YFPas encore d'évaluation

- Ceramic Filter-Installation InstructionDocument57 pagesCeramic Filter-Installation InstructionKasjdkasd AksdjasdjPas encore d'évaluation

- Aircraft Maintenance ManualDocument100 pagesAircraft Maintenance ManualcleberPas encore d'évaluation

- Sop Drilling Peer ReviewedDocument51 pagesSop Drilling Peer ReviewedErland Prasetya67% (3)

- 6923 PDFDocument5 pages6923 PDFMEHDIPas encore d'évaluation

- Non SlamDocument6 pagesNon SlamFLOWSYSPas encore d'évaluation

- HORIZONTAL SPLIT CASE PUMPS SINGLE STAGE DOUBLE SUCTION Type AEFDocument20 pagesHORIZONTAL SPLIT CASE PUMPS SINGLE STAGE DOUBLE SUCTION Type AEFKSBPas encore d'évaluation

- BARQUILLERA HELADO SOFT CARPIGIANI Mod. XLV 3Document2 pagesBARQUILLERA HELADO SOFT CARPIGIANI Mod. XLV 3Proingmeca CAPas encore d'évaluation

- Circulating Water BathDocument4 pagesCirculating Water BathLabtron orgPas encore d'évaluation

- Multiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataDocument2 pagesMultiphase Pump MPC 208 - 38/1 / N: 1.0 Project DataRabah Semassel100% (1)

- Yb Series Pump ManualDocument8 pagesYb Series Pump ManualAlexander CallaPas encore d'évaluation

- Atmos GIGA N 32-160Document1 pageAtmos GIGA N 32-160Efril dilen franciscoPas encore d'évaluation

- 03-Mechanical Seal &seal System Basics-REV01Document39 pages03-Mechanical Seal &seal System Basics-REV01Fayez Al-ahmadiPas encore d'évaluation

- Presure Regulator Calculate PDFDocument5 pagesPresure Regulator Calculate PDFGorast KolevPas encore d'évaluation

- Self-Priming Centrifugal Pumps What You Need To Know PDFDocument2 pagesSelf-Priming Centrifugal Pumps What You Need To Know PDFhumshkhPas encore d'évaluation

- NOL18to100HLMANUAL (9) 50-34Document24 pagesNOL18to100HLMANUAL (9) 50-34ronaldmarcellePas encore d'évaluation

- 16 A330 Ata 28Document152 pages16 A330 Ata 28Owen100% (1)

- UK HydralokCatalogueDocument45 pagesUK HydralokCatalogueBat-Oyun DagdanPas encore d'évaluation

- Fluor Daniel - GENERAL RECOMMENDATIONS FOR SPACINGDocument7 pagesFluor Daniel - GENERAL RECOMMENDATIONS FOR SPACINGharishcsharmaPas encore d'évaluation

- MTUDocument16 pagesMTUWira Karya Diesel50% (6)

- 3175a.pdfrefrigeracion Twingo FallasDocument27 pages3175a.pdfrefrigeracion Twingo FallasMiguel Alfredo Muñoz Morillo100% (2)

- D5G Hidraulico Serie RKG PDFDocument7 pagesD5G Hidraulico Serie RKG PDFAnonymous KOtSfT6qPas encore d'évaluation

- Chapter Three Performance Equations and Engine CharacteristicsDocument15 pagesChapter Three Performance Equations and Engine CharacteristicsbroPas encore d'évaluation