Académique Documents

Professionnel Documents

Culture Documents

5.2.1 Concrete Works

Transféré par

Paul KwongCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

5.2.1 Concrete Works

Transféré par

Paul KwongDroits d'auteur :

Formats disponibles

5.2.

1 Concrete Works

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

CONCRETE WORK

CW.1 MATERIALS

CW.1.1

General

Materials used in the works shall be of the qualities and kinds specified herein and equal

to approved samples. Delivery shall be made sufficiently in advance to enable samples to

be taken and tested if required. No materials shall be used until and unless approved and

materials not approved shall be immediately removed from the works at the Contractor's

expense.

Materials shall be transported, handled and stored on the site or elsewhere in such a

manner as to prevent damage, deterioration or contamination all to the satisfaction of the

RO. The RO reserves the right to inspect any materials to be used on the works at any

time and at any place of storage.

Unless otherwise specified or otherwise agreed to by the RO (Representative of Owner),

materials shall comply with the appropriate American Standards.

Where the

requirements of the relevant Standards are in conflict with this Specification then this

Specification shall take precedence.

If required, the Contractor shall supply to the RO the appropriate certificate of

compliance with the Standards. Notwithstanding the above, tests shall be carried out as

and when directed by the RO in accordance with the relevant Standards. Materials for

tests shall be provided and delivered by the Contractor at his cost, to an approved

laboratory.

Cutting of structural members shall not be permitted without prior approval from the RO.

The work includes all miscellaneous concrete work as indicated in Drawings and

specified under any trades and Nominated sub-contractor.

The Contractor shall be fully conversant with all contract drawings and other information

on works including mechanical, electrical and utility drawings and specifications to be

carried out by sub-contractors and specialist contractors.

The main contractor shall co-ordinate and make necessary provisions for the built-in

work and embedded pipes or conduits by all Nominated sub-contractors and specialist

contractors.

CW.1.2

Cement

Cement shall be ordinary Portland cement complying to American Standard unless

otherwise specified. Before starting any work the Contractor shall submit for approval

the type and brand of cement he proposes to use. The Contractor shall not change the

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

cement brand unless he has specific reasons to do so and permission in writing shall be

obtained from the RO.

High alumina cement shall not be used for any concrete work.

All cement shall be delivered to site in sealed and branded bags of the manufacturer or in

properly designed bulk containers.

All cement shall be stored in a weather proof dry shed with raised boarded floor, or in

properly designed bulk storage tanks.

Cement of different manufacture and of different types shall be kept separately and shall

not be used in the same mix.

Cement that becomes lumpy or otherwise deteriorated in transit or storage shall not be

used for concreting. All cement unfit for use shall be removed from site immediately.

Consignment of cement shall be used in the order of delivery.

The Contractor shall at the request of the RO, produce a certificate showing the date and

place of manufacture of the cement. As and when directed by the RO, samples of cement

shall be provided for testing. Any cement failing to comply with the requirements of the

relevant Standards shall be rejected.

CW.1.3

Aggregates

Coarse aggregates shall be 'granite' or other hard stone from a source approved by the RO

Limestone aggregates shall NOT be used unless otherwise specified.

CW.1.4

Quality

Aggregate is to consist of naturally occurring sand, gravel or rock, whole or crushed or a

combination thereof, and is to be hard, durable, clean and free from adherent coatings,

such as clay.

Aggregates are not to contain harmful impurities such as iron pyrites, coal, mica, shale or

similar laminated materials.

Aggregates are not to contain flaky or elongated particles.

Qualitative tests are to be carried out on all aggregates in accordance with American

Standards. The Contractor is to execute all sampling and testing at his own expense. If

RO directed he is to deliver duplicate samples to the RO, properly packed and clearly

labeled so as to be identifiable with the samples used in the tests. The results of the tests

are to be submitted to the RO for his approval prior to the delivery or use of the

aggregates.

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

When tested in accordance with the methods described in American Stanstard aggregates

are to have the following properties :

(i)

Aggregate crushing value : not more than 45%

(ii)

Flakiness Index : not more than 30%

Unless evidence of general performance is offered which is satisfactory to the RO, the

maximum quantities of clay, silt and fine dust, and of organic impurities, are not to

exceed the limits given in American Standard.

CW.1.5

Definitions

The term 'fine aggregate' 'coarse aggregate' and all-in aggregate', are as defined in

American Standard.

CW.1.6

Water

Water shall be obtained from a public supply. If water for the works is not available from

a public supply, approval shall be obtained regarding the source of water.

Water obtained from sources other than public supply shall be clean fresh water free from

chemical and organic impurities. When required by the RO, the Contractor shall arrange

for tests of the water to be carried out in accordance with American Standard before and

during the progress of the work.

CW.1.7

Admixture

Admixture shall not be used unless approved by the RO. The Contractor shall be required

to furnish the following to the RO prior to the approval for the use of admixture:

*

*

*

*

type and the proprietary brand

the typical dosage and the effects of underdosage and overdosage.

chemical name and main constituents of the admixture.

design dosage and method of use.

Admixture used shall generally comply with American Standard. Requests for

permission to use other types of admixtures not covered by these Standards may only be

considered when accompanied by full supporting information. Admixture containing

calcium chloride shall not be used.

CW.2 CONCRETE MIXES

CW.2.1

General

Unless otherwise stated, concrete mix refers to "designed mix". However, "nominal mix"

may be used in place of "designed mix" provided:

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

*

*

*

CW.2.2

the works are of minor nature or involving a small quantity of concrete

the RO's approval is given

the strength of the concrete is still the responsibility of the Contractor

Designed Mix

In designed mixes, the strength shall be the main criterion specified, with compliance to

minimum and maximum cement content, and maximum water/cement ratio. The

workability of the mix shall be in accordance with American Standard. Mix design shall

be based on a target mean strength not less than the specified characteristic strength plus

7N/mm. The Contractor shall design the mix and shall be responsible to ensure that the

mix supplied will give the required properties including strength. Unless otherwise

specified for protection against aggressive soil conditions, designed concrete mixes shall

comply with the specifications in Table.

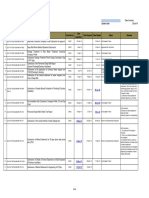

TABLE SPECIFICATIONS FOR DESIGNED

Grade

Characteristic

Strength N/mm at 28 days

Minimum cement content in

kg/m of fully compacted

concrete

Maximum cement content in

kg/m of fully compacted

concrete

Maximum water/cement

ratio

55

55

50

50

45

45

40

40

35

35

CONCRETE MIX

30

30

25

25

20

20

475 425 375 350 350 325

300

270 205 175

550 550 550 550 550 550

550

550 550 550

0.4 0.45 0.45 0.5

0.55

0.6

0.5

0.5

15

15

0.7

10

-

0.8

Design of mix shall ensure no segregation, no excessive bleeding and ability to achieve

specified surface finish. Segregation and bleeding shall be determined by visual

inspection.

The total chloride content of the concrete mix when expressed as a percentage of chloride

ion by mass of cement shall not exceed the limits specified in Table .

TABLE - MAXIMUM TOTAL CHLORIDE CONTENT

Type of Concrete

Prestressed Concrete

Steam-cured Concrete

Other concrete

CW.2.3

Max.Total Chloride Content

0.10%

0.35%

Trial Mixes

The mix design shall be verified by preparation of trial mixes. Twelve cubes shall be

taken; six of which shall be tested at 7 days and the other six at 28 days. The average of

the six cubes tested at 28 days shall satisfy the above target mean strength in 6.2.2. Trial

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

mixes need not be undertaken provided the supplier can furnish evidence of test results for

the proposed mix satisfactory to the RO.

No concrete shall be placed in the work until the results of the trial mix are approved by

the RO.

CW.2.4

Modification of Mix Design

The RO reserves the right to instruct the Contractor to modify and improve the mix

design from time to time during the progress of work as and when he considers necessary

to meet the requirements. This shall not entitle the Contractor to any extra payment.

CW.3

MIXING CONCRETE

Concrete shall be thoroughly mixed in a batch type mechanical mixer. The quantity

of material in each batch shall not exceed the rated capacity of the mixer.

Mixing shall continue until the concrete is uniform in colour and consistency.

The first batch of concrete fed into the drum or pan shall have an increase of an

appropriate amount of dry mortar similar in proportion to that of the concrete to be

mixed and of mixing water for coating the drum or pan.

The entire contents of the drum shall be discharged before the materials for the

succeeding batch are fed into the drum or pan. Mixers which have been out of use for

more than 30 minutes should be thoroughly cleaned before any fresh concrete is

mixed.

No concrete shall be mixed by hand except with the specific approval of the RO for a

small amount. Where such approval is granted, the Contractor shall at his own

expense increase the proportion of cement by 10%. Mixing shall be continued until

the concrete is of uniform colour and consistency.

CW.4

WORKABILITY AND CONSISTENCY

The workability shall be such as to produce a concrete which can be well compacted,

be worked into corners of the shuttering and around the reinforcements, give the

specified surface finish and attain the specified strength. The required workability for

any part of the work shall be determined by the Contractor, subject to the agreement

of the RO. It shall be reviewed during the progress of the work and adjustments shall

be made as necessary subject to the agreement of the RO.

Workability shall be assessed on site at the discharge point of either the mixer or the

ready mixed concrete vehicle by means of the slump test in accordance with

American Standard. If the measured slump deviates from the agreed value by more

than 25mm or one third of the required value whichever is greater, the concrete shall

be rejected unless the RO decides otherwise.

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

CW.5

DISTRIBUTION OF CONCRETE

CW.5.1

General

The concrete shall be distributed from the mixer to the position of placing in the works by

approved means which do not cause segregation or otherwise impair the quality of the

concrete. Concrete which has in the opinion of the RO becomes unduly segregated shall

be remixed by hand before deposited in the work.

Details of any proposed pumping conveyor belt or chuting plant must be approved by the

RO before such plant is delivered to the site.

All distributing equipment shall be cleaned before commencing mixing and distribution

of the concrete and such equipment shall be kept free from set concrete.

CW.5.2

Concrete Pumps and Pipelines

The rate of supply shall match with the rate of pumping.

Prior to commencement of pumping, check must be carried out to ensure that the feeder

hopper and the pipelines are free from obstruction, the coupling pipe joints are properly

tightened and the pipeline is firmly secured and anchored. Pipeline and its support must

not be rigidly connected to formwork.

Pumping shall commence first with blowing of water through the pipeline, followed by

cement mortar, both of sufficient quantities and all these shall be discharged away from

the area to be concreted.

Pumping and the agitator inside the feeder hopper shall normally be operated in a

continuous manner. When a stoppage is unavoidable, the concrete inside the hopper

must be maintained at a level high enough to prevent any entry of air into the pipeline to

form an air pocket. For temporary stoppage, the concrete in the pipeline shall be moved

occasionally by a few strokes of the piston of the pump, thus preventing it from sticking.

Pumping shall be stopped in the following occasions:

*

*

*

*

presence of foreign matters which may block the valves or pipelines

level of concrete in the hopper is too low

an unsuitable batch of concrete is placed in the hopper

extra lengths of pipe are to be added

Foreign matter and unsuitable batch of concrete must be removed immediately from the

hopper before pumping is resumed.

When extra sections of pipe are to be added, each length or pipe must be thoroughly

wetted inside but no free water shall remain in the pipe.

When the pipeline is exposed to the sun, the line shall be protected against absorption of

heat by covering with damp sacking or staw mats during pumping.

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

CW.6 PLACING CONCRETE

No concrete shall be placed prior to the RO's approval.

Immediately prior to placing the concrete, the shuttering shall be well wetted and

inspection openings shall be closed.

The interval between adding the cement to aggregate and the completion of the placing of

the concrete shall not exceed 30 minutes. When the mix is transported by purpose made

agitators, operating continuously, and when retarders are used such interval may be

extended to maximum 2 hours but the interval between the discharge from the agitators

and the placing of the concrete shall not exceed 20 minutes.

Suspended gangways for the workmen placing and vibrating the concrete are to be

provided wherever possible and so constructed as to avoid damaging and displacing the

reinforcement. Steel fixers and carpenters shall be constantly in attendance while

concreting is in progress to maintain the reinforcement in correct position.

Old concrete surface shall be prepared in accordance with 6.21 before placing the new

concrete.

Except where otherwise approved, concrete shall be placed in the shuttering by shovels

or other approved implements and shall not be dropped from a height or handled in a

manner which cause segregation. Accumulation of set concrete on the reinforcement

shall be avoided. Concrete shall be placed directly in the permanent position and shall

not be worked along the shuttering to that position.

Any water accumulating on the surface of newly placed concrete shall be removed by

approved means and no further concrete shall be placed thereon until such water has been

removed.

No unset concrete shall be brought into contact with unset concrete containing cement of

a different type or manufacture.

Unless otherwise approved, concrete (for beams and similar members) shall be placed in

a single operation to the full thickness and concrete (in walls, columns and similar

members) shall be placed in horizontal layers each not exceeded 0.5m deep. Placing of

concrete shall be continuous and temporary interruption shall not normally exceed 30

minutes.

If stopping of concrete placing is unavoidable elsewhere, a construction joint shall be

made where the work is stopped, subject to the agreement of the RO.

CW.7 COMPACTION OF CONCRETE BY VIBRATION

All concrete shall be compacted to produce a dense homogeneous mass. Unless

otherwise agreed by the RO it shall be compacted with mechanical vibration. Sufficient

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

numbers of vibrators in serviceable condition shall be used on site to compact the

concrete at the rate at which it is placed, and adequate number of standby vibrators shall

be readily available for use in case of breakdowns. Vibrators shall be of sturdy

construction, adequately powered and capable of transmitting to the concrete not less

than 10,000 cycles per minute for internal type and 3,000 cycles per minute for external

type.

Vibration, with any type of vibrator, shall not be continued in any one spot to the extent

that pools of grout are formed. Care shall be taken to avoid any disturbance of concrete

which has become too stiff to regain plasticity when vibrated.

Vibration shall not be applied by way of the reinforcement. Where vibrators of the

immersion type are used, contact with reinforcement and all inserts shall be avoided so

far as is practicable.

Vibration shall not be used as a means of distributing heaped concrete into position.

After being compacted and finished, the concrete must be left absolutely undisturbed

while setting.

CW.8 CURING AND PROTECTION OF CONCRETE

(1)

Immediately after compaction, finished concrete shall be protected against

harmful effects of weather, running water and drying out. The protection shall be

applied by using one of the following method:

(a)

Except for surface against which concrete or applied finishes is subsequently to

be placed, the concrete shall be cured by application of an approved liquid curing

membrance. Application shall be by a low-pressure spray at the rate

recommended by the manufacturer. On horizontal surfaces the membrance shall

be applied immediately after finishing the concrete, and on vertical surfaces

immediately after removing the formwork.

(b)

After thoroughly wetting, the concrete shall be covered with a layer of approved

water-proof paper or plastic membrane until the concrete has reached the age of 4

days.

(2)

For liquid-retaining structures, one of the following methods shall be used to

provide curing:

(a)

After completion of the finishing process, all exposed surfaces shall be covered

with a layer of approved plastic sheeting until such time as the concrete has

hardened sufficiently to permit water curing. Water curing shall be effected

whenever possible by the continuous spraying of cool water for a period of 2

days. Particular care shall be taken to avoid terminal shock at the surface of the

concrete caused by the intermittent application of large quantities of cold water.

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

Thereafter, spraying of cool water shall continue or be substituted by the method

as (1) (b) until the concrete has reached the age of 7 days.

(b)

Formwork to concrete walls and columns shall be kept cool by water sprays as

soon as the concrete has hardened sufficiently and until the formwork is removed,

then one of the curing methods as (1) (b) and (1) (c) shall be adopted until the

concrete has reached the age of 7 days.

(3)

No traffic shall be allowed over any part of the finished concrete until it has been

set and properly protected to the satisfaction of the RO.

CW.9 HOT WEATHER CONCRETING

The Contractor is to comply with the recommendations of American Standard.

The Contractor is to cool formwork made of metal, concrete or other materials with water

before placing concrete against it.

The Contractor is to ensure that no standing water is left in the formwork.

CW.10 READY-MIXED CONCRETE

Ready-mixed concrete (RMC) may be used subject to the approval of the RO.

The Contractor shall ensure that the RMC products comply toAmerican Standard and its

complementary standard. Additionally, he shall ensure that concrete for building and civil

engineering structures is obtained from RMC plants which have been certified under

Local Organization such as CQHP for RMC.

The Contractor shall furnish the name of his ready-mixed concrete supplier to the RO for

approval. He shall make such arrangements as may be required for the RO to inspect his

supplier's work and provide all facilities for samples of cement, fine and coarse

aggregates and admixture to be taken for testing.

Notwithstanding any such inspection made and/or approval given by the RO, the

Contractor shall take full responsibility for ensuring that all ready-mixed concrete

supplied shall conform to and this Specification. Concrete that does not comply with this

Specification shall be rejected and removed from site.

The Contractor shall furnish to and obtain the approval of the RO at least 1 day in

advance of the date set for each casting of concrete, the number of transit trucks/truck

mixers/truck agitators proposed to be used to supply the concrete and the frequency at

which the loads of concrete are to be delivered to the site.

For each truck load of concrete delivered, the following information shall appear on the

delivery docket:

___________________________________________________________________________________

Technical Specification

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

*

*

*

*

*

*

*

*

*

*

*

*

*

*

*

name of ready-mixed concrete batch plant

serial number of docket

date and the licence number of the truck

name of the purchaser

name and location of job

specified characteristic concrete strength and the amount of cement used (kg) or the

mix proportions

quantity of concrete

time of loading or of first mixing of cement and aggregate, whichever is earlier

agreed slump

maximum size of coarse aggregates specified

trade name of admixture, if any

the signature of the Supervisor who shall also enter the time of arrival of the truck

and the time of completion of discharge

position where concrete is placed

number of cubes taken, if any, and cube references

any other requirements as may be instructed

One copy of the docket shall be given to the RO on delivery.

The RO reserves the right to instruct the Contractor to change the supplier due to

unsatisfactory performance for further use of ready-mixed concrete during the progress of

the works, if any of the requirements has, in his opinion, not been satisfactorily complied

with.

No water in excess of the quantity required in the approved mix shall be allowed to be

added to the concrete to increase its workability affected by elapsed time and/or

temperature.

While it is not being discharged, the concrete in a transit truck/truck mixer/agitator shall

be kept continuously agitated.

The concrete shall be placed in its final position and left undisturbed within 2 hours from

the time when the cement was added to the mix.

CW.11 CONCRETE COMPRESSIVE STRENGTH TESTS

CW.11.1

General

The compressive strength of concrete shall be measured by crushing tests on nominal

150mm cubes. Tests shall be carried out in an approved Engineering Laboratory.

CW.11.2

Sampling, Testing and Compliance Requirements

All sampling, curing, testing and compliance of cubes shall be carried out in accordance

with CQHPs guideline. A sample shall be taken from a randomly selected batch of

concrete chosen by the RO The sample shall be obtained by taking a number of

___________________________________________________________________________________

Technical Specification

10

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

increments in accordance with CQHPs guideline, and whenever practicable, at the point

of discharge from the mixer or ready-mixed truck.

CW.11.3 Action to be Taken in the Event of Non-Compliance

In the event of non-compliance, the Contractor shall redesign his mix based on an

increased target mean strength. The section of work represented by the samples which

fail the test shall be removed and replaced by concrete meeting this Specification.

Alternatively, the RO may direct that other measures be taken to make the works secure.

The RO may instruct that additional tests be carried out on the hardened concrete. If even

the additional test are not satisfactory, casted concrete to be hacked and recast with

redesigned concrete.

All works instructed under this subclause shall be at the Contractor's expense and no

extension of time will be granted for such works.

CW.11.4 Cubes Tested at 7 Days

The average strength of the three cubes tested at 7 days shall be used as an indication

only. If the average strength is less than 0.75 of the characteristic strength, the RO may

instruct that the mix design be modified to increase the mean strength of subsequent

concrete until satisfactory evidence is obtained of its adequacy. If the average 7-day

strength is less than 0.67 of the characteristic strength, no more concrete shall be placed

on the suspect concrete until the 28-day strength is found to comply or unless the RO

specifically approves. Any additional expense and/or delay shall be borne solely by the

Contractor.

CW.12 STRUCTURAL TESTS

CW.12.1 General

The RO may instruct the Contractor to make a load test on the works or any part thereof

if in the RO opinion such a test is necessary.

If the test so instructed is to be made because of:

*

cube test failure, or

*

the finished work, in the opinion of the RO is

structurally defective and therefore unacceptable unless proven otherwise;

then the test shall be made at the Contractor's expense irrespective of the test result.

CW.12.2

Test Results

If the test result of any of the test is not satisfactory, at the RO's instruction, that part of

the works shall be rejected and reconstructed to comply with this Specification, or other

approved measures be taken to make the works secure, all at the Contractor's expense.

No extension of time shall be entertained in this connection.

___________________________________________________________________________________

Technical Specification

11

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

CW.13 REINFORCEMENT

CW.13.1 General

The reinforcement shall be complying to the CQHPs guideline.

Where the letter T is used in the structural detailing, it shall mean that such reinforcement

shall be high-yield bars having a minimum characteristic strength of 350N/mm unless

otherwise specified.

The letter R, where used, shall indicate that such reinforcement shall be mild steel bars

with a minimum characteristic strength of 250N/mm.

Reinforcement bar not designated by any letter shall be of high yield having a minimum

characteristic strength of 350N/mm.

Reinforcement shall be free from pitting, loose rust, mill scale, paint, oil, grease, adhering

earth or any other material which may impair the bond between the concrete and the

reinforcement or which may cause corrosion of the reinforcement or disintegration of the

concrete.

Neither the nominal size nor the length of a bar shall be less than the size or length shown

on the drawings.

The reinforcement shall be tested in accordance with the relevant American Standard.

Certificate of original and manufacturer's test certificates shall be produced if required.

Selection of test pieces shall be made by the RO. The Contractor shall bear all costs

involved in making these tests.

CW.13.2 Bending Reinforcement

Reinforcement bars shall be cut and/or bent in accordance with American Standard. Bars

shall be bent cold.

Bars incorrectly bent shall be used only if the means used for straightening and rebending

be such that in the opinion of the RO it will not injure the material. No reinforcement

shall be bent down into position in the works without approval, whether or not it is

partially embedded in hardened concrete.

CW.13.3 Fixing Reinforcement

Reinforcement shall be accurately fixed and maintained by approved means in the

position described on the drawings or elsewhere. Bars intended to be in contact at

passing points shall be securely wired together with 1.626mm (16 SWG) soft iron tying

wire or other approved means. Binders and the like shall tightly embrace the bars with

___________________________________________________________________________________

Technical Specification

12

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

which they are intended to be in contact and shall be securely wired or if approved

welded thereto.

Before the inspection and approval by the RO, the Contractor or his competent

representative shall be required to examine the accuracy of the fixing, placing and

cleanliness of the steel reinforcement.

No concreting shall commence until the RO has inspected the reinforcement in position

and until his approval has been obtained. Reinforcements shall not be displaced from the

approved positions during concreting.

Reinforcement projecting from work being concreted or already concreted shall be

protected from deformation or other damage.

The cover shall be provided by means of distance pieces of cement mortar, concrete or

other approved material. The proportions of the mortar or concrete used for casting the

distance pieces shall not be inferior to those of the concrete in which they are embedded.

The vertical distances between successive layers of bars in beams of similar members

shall be maintained by the provision of steel spacer bar of the size of the largest bar in the

two successive layers to be kept separate or the maximum size of coarse aggregate plus

5mm, whichever is the greater. The spacer shall be inserted at such intervals that the

main bars do not perceptibly sag between adjacent spacer bars. A pair of bars in contact

or a bundle of three or four bars in contact shall be considered as a single bar of

equivalent area when considering size.

CW.13.4

Welding Reinforcement

Butt jointing of reinforcement bars by welding may be permitted under suitable

conditions and with suitable safeguard in accordance with American Standard.

Welding shall not be done unless approved by the RO. All welding shall be done by

appropriately skilled welder. Twisted bars or other reinforcement, the strength of which

depends on cold working, shall not be welded.

CW.13.5 Mechanical Splicing of Reinforcement

(1)

Where the use of mechanical splicing is specified on the Drawings or is

proposed by the Contractor and approved by the RO, its use shall

comply with the following subclauses.

(2)

Splices shall be staggered so that no more than half of the bars are

spliced at any cross section of the structural member.

(3)

The splicing shall be carried out in strict compliance with supplier's

specification. It shall be carried out by persons fully trained by the

supplier in the correct operation and procedures and using equipment

and tools as specified by the supplier.

___________________________________________________________________________________

Technical Specification

13

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

(4)

The spacing of the bars to be spliced shall be checked by the supplier to

ensure that it is sufficient and suitable for the splicing to be properly

carried out.

(5)

At least one sample for every 100 splices shall be tested. The RO may

order additional tests to be carried out to ensure the quality and

workmanship at all times.

(6)

Test results shall be submitted to the RO within 14 days after testing.

CW.13.6 Protection of Reinforcement

(1)

Where starter bars or projecting reinforcement are to be left exposed for

a prolonged period, they shall be protected by coating thoroughly but

thinly with cement slurry, denso-tapes, or other approved methods.

CW.13.7 Testing of Hot Rolled Steel Bars

(1)

Every batch of hot rolled steel bars delivered to Site shall be covered

by:

(a)

certificate of origin from the local supplier, indicating the source

of steel and the quantity to be delivered;

(b) Manufacturer's mill certificate to certify its compliance to

American Standard; and

(c)

report of tests carried out by an approved local laboratory.

(2)

The above three items of (1)(a), (b) & (c) shall be submitted in

one lot for each batch delivered to site within 14 days after the

steel bars are delivered to site.

(3)

Ten (10) samples of each batch shall be tested. If the bar pattern of

the batch is acceptable by the Building Authority for abbreviated

testing, 3 samples shall be tested.

(4)

The list of bar patterns acceptable by the Building Authority for

abbreviated testing will be updated periodically. The Contractor

shall ensure that he obtains the latest list from the Building

Authority at the time of delivery of steel bars to Site.

(5)

The items of local tests to be carried out are:

___________________________________________________________________________________

Technical Specification

14

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

(a)

(b)

(c)

(d)

(e)

(6)

measured mass;

calculated effective cross-sectional area;

yield stress;

tensile strength;

elongation; and

The test report referred to in subclause (1)(c) shall include:

(7)

(a)

full description of test sample including name of steel

manufacturer, country of origin, grade and size;

(b)

bar pattern;

(c)

identification of the batch and date of delivery to the Site;

(d)

measured mass and calculated effective cross-sectional area

of the test sample; and

(e)

results of yield stress, tensile strength, elongation and, if

required, bend test.

(a)

The test results shall comply with the requirements of

CQHPs guideline.

(b) If one or more valid test results is less than 93% of the minimum

yield strength, the batch shall be deemed not to comply.

(8)

(c)

If one or more valid test results fails to meet any of the mass,

tensile strength, elongation, or bend test requirements, two

additional samples for each failure shall be taken from different

bars of the same batch and be subjected to the test(s) in which the

original sample failed. If any one of the additional samples fails,

the batch shall be deemed not to comply.

(d)

In the case of 3-sample test, if one or more valid test results has a

yield stress between the minimum yield strength and 93% of it, 7

additional samples shall be taken from different bars of the same

batch and be tested. The results of the total 10 samples shall be

judged as in (b) & (c) above.

Any batch if deemed not to comply shall be removed from Site totally

and all rebar are not allowed to use.

___________________________________________________________________________________

Technical Specification

15

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

CW.14 FORMWORK AND SUPPORTS

CW.14.1 Materials

Prior to the commencement of the construction of formwork, the Contractor shall submit

the details of the type of formwork and the materials to be used for the approval of the

RO.

Timber used in the formwork shall be well seasoned, free from loose knots and unless

otherwise approved, wrought on all faces. Form face in contact with concrete shall be

free from direct, adhering grout, projecting nails, splits and other defects. Formwork not

in use shall be cleaned, oiled and stored flat and well protected against gross changes of

moisture.

CW.14.2 Design

Formwork shall be designed in accordance with the latest American Code.

Any form lining used shall be appropriate to the surface finish required and subject to the

approval of the RO.

If required, the Contractor shall submit the details of the design of the formwork and the

supports for the approval of the RO. Not withstanding the approval by the RO, the

strength and adequacy of the formwork and falsework shall remain the responsibility of

the Contractor and/or his Professional Engineers.

CW.14.3 Construction

Formwork shall be constructed in accordance with the latest American Code.

Formwork shall be constructed sufficiently rigid and tight to prevent loss of grout from

the concrete at all stages of placing and compacting.

The arrangement of formwork shall be such that it can be dismantled and removed

readily from the cast concrete without causing shock, disturbance or damage. For beams

and slabs the arrangement shall be such that the formwork and supports for the slab

soffits and beam sides can be removed without disturbing the formwork and supports of

the beam soffits.

Supports of an upper floor shall rest on the lower floor only if the lower floor has

developed adequate strength to bear the load. If in the opinion of the RO, the lower floor

does not have the required strength to carry the support of the upper floors, then the

method adopted to support the formwork of the upper floor shall have to be approved by

the RO

Connections in formwork shall be either nailed, screwed bolted, clamped or otherwise

secured. Ties that are anchored against the timber shall pass through a plate washer at

least 50 x 50 mm in size and of sufficient thickness such that the load is transferred to the

timber without any visible deflection or penetration into the timber. All holes left in the

___________________________________________________________________________________

Technical Specification

16

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

concrete shall be filled with mortar and finished to the approval of the RO. Wire ties

passing through the concrete may be used only when approved and the ends of the wire

shall be concealed and measures taken to prevent rust stains on the concrete.

All rubbish, chippings, shavings etc shall be removed from the interior of formwork

immediately before concrete is placed, first by compressed air and then by a jet of water.

Temporary openings shall be formed for the inspection of the inside of the formwork and

for the escape of water used for washing. The Contractor may use approved form oil

which is compatible with the required finish to coat the faces of the formwork in contact

with the concrete. Such oils shall be insoluble in water, non-staining, not injurious to the

concrete and shall not become flaky or be removed by rain or wash water. Diesel oil and

liquids which retard the setting of the concrete shall not be used. The same approved

type of form oil shall be used throughout all works. The application of the form oil shall

be such that no reinforcement or prestressing tendons shall be coated by the oil and there

shall be no accumulation of the oil at the bottom of the formwork.

.

CW.14.4 Removal of Formwork

Formwork supporting cast-in-situ concrete shall not be removed unless:

i)

such removal will not result in unacceptable deflections due to shrinkage,

creep, etc

ii)

such removal has been accounted for in the sequence of construction

which has been previously agreed upon between the Contractor and the

RO

iii) the cube strength of the cast concrete is 10N/mm or twice the stress to

which it will then be subjected, whichever is higher.

In the absence of the cube test result and stress calculations, the minimum periods before

striking of the formwork for ordinary Portland cement concrete, as given in Table

In any event, no formwork or support shall be struck or removed without the RO's

consent in writing. Striking or removal of formwork shall be done only in the presence

of the RO's representative at site.

TABLE :MINIMUM PERIOD FOR STRIKING FORMWORK

Location

Sides of columns, walls and beams

Soffits of slabs (props left under)

Soffits of beams (props left under)

Props to slabs

Props to beams

Minimum Period For Ordinary of

Portland Cement Concrete

24 hrs

3 days

7 days

7 days

14 days

___________________________________________________________________________________

Technical Specification

17

ASIA SPEED CONSTRUCTION COM,. LTD.

___________________________________________________________________________________

All formwork shall be removed without damage to the concrete. The Contractor shall be

responsible for any injury to the work and any consequential damage caused by or arising

from the method adopted for the striking or moving of the formwork or supports.

Immediately after the removal of the formwork, it is the Contractor's responsibility to

notify the RO for inspection and any remedial treatment required by the RO shall be

carried out without delay. Any remedial treatment which has been carried out before the

RO's inspection and approval shall render the member liable for rejection.

CW.15 FINISHES

CW.15.1 Concrete to Receive Applied Finish

When the concrete is to receive an applied finish, the form work shall be made of

closely jointed wrought boards. Alternatively, steel or other materials may also be

used, subject to the RO agreement. On removal of the form work and upon RO

inspection, defects shall be treated as provided in Section of Removal of Formwork.

The concrete face shall then be roughened by approved means to form a key before the

finish is applied.

CW.15.2 Slabs to Receive Topping

The top face of slab intended to receive topping shall be first spaded and then left

roughened with approved means.

Just prior to placing the topping, the base slab shall be thoroughly cleaned, prepared for

bond and wetted. No pools of water shall be left standing on the wetted surface. A thin

coat of neat cement grout shall be applied onto the surface of the slab for a short

distance ahead of the topping. The wearing surface shall be applied before the grout has

hardened.

When surface hardeners are required to be used, the Contractor shall submit for the RO

approval, the type, colour, composition, details of manufacture and the manufacturer's

method of use. Any hardener consisting of soluble alkaline compounds, rust and

materials designed to disguise rust shall not be allowed to be used. Upon approval of

the type, the application of the hardener shall be as specified by the manufacturer.

CW.16 DIMENSIONAL DEVIATIONS OF CONSTRUCTION

(1)

The Contractor shall check the actual positions, sizes and alignments of the

finished works. He shall report to the RO when any dimensional deviations

exceed the permissible values and shall carry out any rectification works,

including cutting out and rebuilding part or the whole of the finished works, as

directed by the RO

___________________________________________________________________________________

Technical Specification

18

(2)

When required by the RO, the Contractor shall furnish all necessary instruments

and labour for the use of the RO for checking the finished structure.

(3)

The maximum dimensional deviation of finished structural members, resulting

from all human errors, limitations of materials and formwork, deflection of

formwork, and any other factors that may affect the positions, sizes and

alignments of the finished structural members, shall not exceed the permissible

deviations specified in Table 6. These permissible deviations on Drawings and

such values shall not be cumulative.

Table - Permissible DimensionalDeviation

Description

Member and location

Permissible deviation

Position

External face of

structural member and

wall

Internal member and

opening

Internal beam and

external beam over

window frame

Beam

Slab

Column

Wall thickness

Corewall, lift enclosure

wall, internal panel

wall, and external face

of

structural member

3mm

Cear height under soffit

to floor

Sectional dimension

Alignment

(vertically&

horizontally)

Level of floor

Internal faces of

column

General floor level

(with

due allowance for

rendering and finishes)

6mm

3mm

6mm

3mm

6mm

3mm

1 in 1000

1 in 500

3mm from specified

P.D. level

CW.17 LOAD IN EXCESS OF DESIGN LOAD

No load in excess of the design loading shall be placed on any portion of the structure

without the written permission of the SO. If such permission is granted, all beams or

other members of the structure which are subjected to a load other than the designed load

shall be strengthened and supported to the satisfaction of the SO at the Contractor's

expense. The Contractor shall be responsible for making good to the satisfaction of the

SO any damage to the permanent structure which may be caused by such excess loads.

CW.18 CONSTRUCTION JOINTS

The positions and details of the construction joints shall be as shown and prescribed on

the drawings. Concreting shall be carried out continuously up to the construction joint.

The position and details of construction joints not prescribed on the drawing shall be

subject to the approval of the RO and shall be arranged so as to minimise the possibility

of occurrence of shrinkage cracks. The Contractor may be required to submit a drawing

showing the intended sequence of pouring, location, and details of such construction

joints. No casting shall commence until approval has been received from the RO

Construction joints shall be at right angles to the general direction of the member and

shall take due account of shear and other stresses.

Concrete in a beam shall be placed throughout without a joint, but if the provision is

unavoidable, the joint shall be vertical and at the middle of a span as far as possible.

Concrete shall not be allowed to run to a feather edge and vertical joints shall be formed

against a stop board. Wherever possible, joint lines shall be so arranged to coincide with

the features of the finished work.

Immediately prior to recommencement of concreting, the surface of the previous concrete

shall be made free from laitance and roughened to the extent that the largest aggregate is

exposed but not disturbed. The joint surface shall be cleaned and thoroughly wetted

immediately before the fresh concrete is placed against it. The new concrete shall be well

compacted using a vibrator.

Construction joints in all waterproof construction shall incorporate an approved

waterproof by RO.

CW.19 WATER TANKS

(1)

The provisions of this clause apply to water tanks, swimming pools and other

water retaining structures.

(2)

The minimum cement content shall be 325 kg/m3 for maximum size of aggregate

of 20 mm and the water/cement ratio shall not exceed 0.55. The maximum

cement content shall be 400 kg/m3 for reinforced concrete works and 500 kg/m3

for prestressed concrete works.

(3)

Admixtures containing calcium chloride or other chlorides shall not be used.

Other admixtures shall not be used without the approval of the RO

(4)

The Contractor shall ensure that, on completion of the work, it is free from any

evidence of seepage of water to the outside faces, and that the criteria of the water

tightness test in subclause (10) are satisfied.

(5)

Unless construction joints are specified on the Drawings, the position of the joints

shall be proposed by the Contractor and be submitted to the ROs.

(6)

Water stops shall be provided at all construction joints and movement joints

unless otherwise directed. Water stops shall be of an approved type and shall be

fixed in accordance with the manufacturer's written specification. Purpose-made

junction pieces shall be used at all intersections. Water stops shall be maintained

in correct position during concreting.

(7)

Kickers shall be cast monolithic with the base slab. Supports for kicker formwork

shall not penetrate through any water retaining elements.

(8)

Form ties which leave an open hole through the concrete shall not be used. All

recesses for form ties shall be plugged with 0.45:1:2 water-cement-sand dry-pack

mortar well rammed into place.

(9)

All pipes, sleeves, ducts, fittings, bolts and the like which are to be embedded in

or pass through the concrete shall be fitted with puddle flanges and be cast-in.

Boxing-out for such items, drilling or cutting the finished concrete shall not be

permitted.

(10)

A water tightness test for the water retaining structure shall be carried out after

the concrete has attained its specified grade strength and before any finishes are

applied. The procedures and criteria of acceptance shall be as follows:

(a)

The structure is cleaned and filled to the normal maximum level with

water.

(b)

The work is protected such that the water level is not affected by rainfall or

undue evaporation during the test.

(c)

When first filled, the water level is maintained by the addition of further

water for a stabilizing period. This stabilizing period is not less than 7

days.

(d)

After the stabilizing period, the level of the water surface is recorded at

24-hour intervals for a test period of 7 days.

(e)

During this 7-day test period, the total permissible drop in level shall be

1/500 of the average water depth and 10 mm, whichever is less.

(f)

The water retaining structure shall be deemed not water tight if the total

drop in water level during the 7-day test period exceeds the permissible

value, or if there is any evidence of seepage of water to the outside faces.

(g)

Any necessary remedial treatment of the concrete, cracks or joints shall be

proposed by the Contractor and subject to the approval of the RO, and

shall be carried out from the water face. If remedial lining is proposed, it

shall have adequate flexibility and have no reaction with the retained

water.

(h)

After the completion of the remedial treatment, the structure shall be

refilled, left for a further stabilizing period if necessary, and retested for a

further 7 days in accordance with the same procedures.

CW.20 FILLING OPENINGS FOR SERVICES PENETRATION

Where openings have been left through floors and walls to allow pipes, conduits and

trunking to penetrate through one compartment to another, the openings shall be filled

after the installation of the services.

Large openings, such as at the pipe ducts through floors, shall be filled with the same

grade of concrete as the adjacent floor. Small openings, such as sleeves for individual

pipes, shall be filled with 1:3 cement-sand dry-pack mortar well rammed in. Before

filling, the pipes or trunking shall be painted with bituminous paint or wrapped with

anticorrosive tape. Where it is necessary to allow for expansion of the pipes, they shall

be wrapped with compressible and fire-proofing linings after painting.

CW.21 DEFECTIVE WORKS

(1)

The Contractor shall inspect the concrete immediately after removing formwork

and report any honeycombing or other defects to the SO

(2)

Where in any part of the works:

(a)

there are serious honey combing, cracking, excessive creep or shrinkage,

or other serious defects; or

(b)

the specified grade strength of the concrete are deemed not to be attained

and investigations by non-destructive tests, core tests or other tests as

directed by the SO have revealed that the finished concrete is

unacceptable;

that part of the works shall be cut out and properly reconstructed at the

Contractor's expense. Such cutting out shall extend to a position suitable

for a construction joint.

(3)

Where the defective works may be remedied by methods other than

reconstruction, the Contractor shall submit his remedial proposal for the approval

of the SO No remedial works shall be carried out until the proposal has been

approved and the defects and any necessary surface preparation works have been

inspected and accepted by the SO

(4)

If the specified grade strength of the concrete in any part of the structure are

deemed not to be attained, the SO may stop concreting at other parts of the

structure which would otherwise affect or be affected by the defective part until

investigations and, if necessary, remedial works are complete.

Vous aimerez peut-être aussi

- Conopy & Passge WayDocument5 pagesConopy & Passge WayPaul KwongPas encore d'évaluation

- 5.2.2 Excavation & FillingDocument6 pages5.2.2 Excavation & FillingPaul KwongPas encore d'évaluation

- 5.2.3 Piling WorksDocument12 pages5.2.3 Piling WorksPaul KwongPas encore d'évaluation

- Colliers International Yangon Condominium Report 4Q 2014Document4 pagesColliers International Yangon Condominium Report 4Q 2014Paul KwongPas encore d'évaluation

- YCDC Notification No 9 1999Document16 pagesYCDC Notification No 9 1999Paul KwongPas encore d'évaluation

- 5.2.4 Structural SteelworksDocument9 pages5.2.4 Structural SteelworksPaul KwongPas encore d'évaluation

- Architectural Material Specification for SC Auto Bus FactoryDocument4 pagesArchitectural Material Specification for SC Auto Bus FactoryPaul Kwong100% (1)

- Tender Presentation: Qingjian International (Myanmar) Group Development Co., LTDDocument1 pageTender Presentation: Qingjian International (Myanmar) Group Development Co., LTDPaul KwongPas encore d'évaluation

- Tax Flow ChartDocument1 pageTax Flow ChartPaul KwongPas encore d'évaluation

- Vetting Sheet SampleDocument4 pagesVetting Sheet SamplePaul KwongPas encore d'évaluation

- Analysis of Myanmar Foreign Investment Law - Part 2Document5 pagesAnalysis of Myanmar Foreign Investment Law - Part 2Paul KwongPas encore d'évaluation

- Analysis of Myanmar's Foreign Investment Law - Part 1Document3 pagesAnalysis of Myanmar's Foreign Investment Law - Part 1Paul KwongPas encore d'évaluation

- How To Develop Underdeveloped Countries Through Proper PlanningDocument3 pagesHow To Develop Underdeveloped Countries Through Proper PlanningPaul KwongPas encore d'évaluation

- Doing Business in Burma - Commercial Guide 2014 (US)Document68 pagesDoing Business in Burma - Commercial Guide 2014 (US)Paul KwongPas encore d'évaluation

- YCDC Notification No 9 1999Document16 pagesYCDC Notification No 9 1999Paul KwongPas encore d'évaluation

- Material Catalogue Submission List (6-Aug-15)Document2 pagesMaterial Catalogue Submission List (6-Aug-15)Paul KwongPas encore d'évaluation

- Construction and Infrastructure Developments in Myanmar Feb 2014Document3 pagesConstruction and Infrastructure Developments in Myanmar Feb 2014Paul KwongPas encore d'évaluation

- Doing Business in BurmaDocument2 pagesDoing Business in BurmaPaul KwongPas encore d'évaluation

- Trade Policy Reform-Myanmar - As of 23 Sept 14Document21 pagesTrade Policy Reform-Myanmar - As of 23 Sept 14Paul KwongPas encore d'évaluation

- How To Develop Underdeveloped Countries Through Proper PlanningDocument3 pagesHow To Develop Underdeveloped Countries Through Proper PlanningPaul KwongPas encore d'évaluation

- Myanmar - A Nation in CrisisDocument19 pagesMyanmar - A Nation in CrisisPaul KwongPas encore d'évaluation

- Food and Beverage To Myanmar (Australia)Document5 pagesFood and Beverage To Myanmar (Australia)Paul KwongPas encore d'évaluation

- Myanmar Capital Gains Tax Rates, and Property Income TaxDocument8 pagesMyanmar Capital Gains Tax Rates, and Property Income TaxPaul KwongPas encore d'évaluation

- Material Catalogue Submission List (19-Aug-15)Document1 pageMaterial Catalogue Submission List (19-Aug-15)Paul KwongPas encore d'évaluation

- Myanmar Government Reverses Prohibition On Foreign WinesDocument2 pagesMyanmar Government Reverses Prohibition On Foreign WinesPaul KwongPas encore d'évaluation

- Shop Drawings Submission List (6-Aug-15)Document3 pagesShop Drawings Submission List (6-Aug-15)Paul KwongPas encore d'évaluation

- Myanmar New Tax LawDocument4 pagesMyanmar New Tax LawKo NgePas encore d'évaluation

- Tech SubDocument10 pagesTech SubPaul KwongPas encore d'évaluation

- Date Over-Due Don't Need To Submit Revise & Resubmit M&E Shop Drawing Register Combine Service Drawing & Structural Electrical and Mechanical Drawing (CSD & SEM) Updated Date: 25-Jul-15Document36 pagesDate Over-Due Don't Need To Submit Revise & Resubmit M&E Shop Drawing Register Combine Service Drawing & Structural Electrical and Mechanical Drawing (CSD & SEM) Updated Date: 25-Jul-15Paul KwongPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Low Cost Housing PDFDocument4 pagesLow Cost Housing PDFkalimPas encore d'évaluation

- Clearing & Grubbing (With Stripping)Document6 pagesClearing & Grubbing (With Stripping)Marielle MenorPas encore d'évaluation

- USDCM Volume 2 2016 PDFDocument350 pagesUSDCM Volume 2 2016 PDFLinn Kyaw ZawPas encore d'évaluation

- Ramco Cement AR 2020 21Document283 pagesRamco Cement AR 2020 2135Komala venkata ramya seelaPas encore d'évaluation

- Female Apartment Project Construction Methods and Cost EstimatesDocument13 pagesFemale Apartment Project Construction Methods and Cost EstimatesNur Fitria PermatasariPas encore d'évaluation

- SustainableDocument17 pagesSustainablekomal50% (2)

- Building Regulations Approved Document A - 1Document5 pagesBuilding Regulations Approved Document A - 1rahuljainPas encore d'évaluation

- Tolerances and Limits For Construction Drilling and Sawing: Edition E Second Edition May 2006 FinalDocument8 pagesTolerances and Limits For Construction Drilling and Sawing: Edition E Second Edition May 2006 FinalvazrodriPas encore d'évaluation

- Method Statement Drainage WorkDocument13 pagesMethod Statement Drainage WorkShua ChuahPas encore d'évaluation

- The Future of 3D Printing Technology in The Construction Industry: A Systematic Literature ReviewDocument16 pagesThe Future of 3D Printing Technology in The Construction Industry: A Systematic Literature ReviewSamuel Coquilla Solis Jr.Pas encore d'évaluation

- Faculty of Science and TechnologyDocument18 pagesFaculty of Science and TechnologyEMINAT PRINCEPas encore d'évaluation

- MAcreadDocument23 pagesMAcreadVictor Hugo BarbosaPas encore d'évaluation

- Masterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingDocument3 pagesMasterprotect 1815: A Non-Toxic, Flexible High Build, Epoxy Polysulfide CoatingEngTamerPas encore d'évaluation

- Strip FoundationDocument11 pagesStrip FoundationNguyen Quoc AnhPas encore d'évaluation

- Concrete Durability in Persian Gulf PDFDocument14 pagesConcrete Durability in Persian Gulf PDFMahmood MuftiPas encore d'évaluation

- Concrete Thesis PDFDocument167 pagesConcrete Thesis PDFRicardo Dalisay100% (1)

- Experimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesDocument5 pagesExperimental Investigation On Partial Replacement of Aggregates in Concrete Using Ceramic and Tyre WastesInternational Journal of Innovative Science and Research TechnologyPas encore d'évaluation

- ETAG020 Plastic Anchors Part1 0603finalDocument41 pagesETAG020 Plastic Anchors Part1 0603finalSerban RaduPas encore d'évaluation

- Pile Load TestDocument18 pagesPile Load TestDanu Sutanto100% (1)

- Super Seal CatalogueDocument4 pagesSuper Seal Cataloguebpchimera0% (1)

- Navaneetha Content 1Document5 pagesNavaneetha Content 1Pavithran ParameshwaranPas encore d'évaluation

- TOOLS AND EQUIPMENT USE IN CONCRETE WORKS - BadioDocument4 pagesTOOLS AND EQUIPMENT USE IN CONCRETE WORKS - BadioAshiya SampacoPas encore d'évaluation

- Standard Test Methods For Determining The Chemical Resistance of Concrete Products To Acid AttackDocument1 pageStandard Test Methods For Determining The Chemical Resistance of Concrete Products To Acid AttackSanil JPas encore d'évaluation

- Estimate FormatDocument63 pagesEstimate FormatMARY LORRAINE MENDOZAPas encore d'évaluation

- Wbs RCC BuildingDocument43 pagesWbs RCC BuildingAvinashTiwariPas encore d'évaluation

- Locust Bean Pod Waste Improves Clay Brick StrengthDocument16 pagesLocust Bean Pod Waste Improves Clay Brick StrengthJubril Sanusi DanlamiPas encore d'évaluation

- Presentation FRPDocument35 pagesPresentation FRPANKESH SHRIVASTAVAPas encore d'évaluation

- Self Curing Concrete Report 1Document4 pagesSelf Curing Concrete Report 1TANNERU SHRAVAN KUMARPas encore d'évaluation

- Samir NAHI Publication 2020Document11 pagesSamir NAHI Publication 2020Na SamPas encore d'évaluation

- Types of Ties Used in Building Construction, Their Design and Uses PDFDocument6 pagesTypes of Ties Used in Building Construction, Their Design and Uses PDFnasirjamal33Pas encore d'évaluation