Académique Documents

Professionnel Documents

Culture Documents

AWSD1 1WPSForm

Transféré par

Haleem Ur Rashid BangashTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

AWSD1 1WPSForm

Transféré par

Haleem Ur Rashid BangashDroits d'auteur :

Formats disponibles

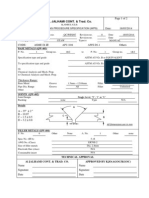

AWS D1.

1:2010

WELDING PROCEDURE SPECIFICATION (WPS) Yes

PREQUALIFIED

QUALIFIED BY TESTING

.

or PROCEDURE QUALIFICATION RECORDS (PQR) Yes

Company Name

Welding Process(es)

Supporting PQR No.(s)

Identification #

Revision

Authorized by

Type---Manual

Mechanized

JOINT DESIGN USED

POSITION

Type:

Single

Backing:

Position of Groove:

Vertical Progression:

Double Weld

No

Backing Material:

Root Opening

Root Face Dimension

Groove Angle

Radius (J-U)

Back Gouging:

Yes

No

Method

Date

By

Date

Semiautomatic

Automatic

Up

Fillet:

Down

Yes

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW)

Current: AC

DCEP

Power Source:

CC

Other

Tungsten Electrode (GTAW)

Size:

Type:

BASE METALS

Material Spec.

Type or Grade

Thickness:

Groove

Diameter (Pipe)

Fillet

Short-Circuiting

Globular

Spray

DCEN

Pulsed

CV

FILLER METALS

TECHNIQUE

AWS Specification

AWS Classification

Stringer or Weave Bead:

Multi-Pass or Single Pass (per side)

Number of Electrodes

Electrode Spacing

Longitudinal

Lateral

Angle

Contact Tube to Work Distance

Peening

Interpass Cleaning:

SHIELDING

Flux

Gas

Composition

Flow Rate

Gas Cup Size

Electrode-Flux (Class)

PREHEAT and INTERPASS TEMPERATURE

POST WELD HEAT TREATMENT

Min for Thicknesses 1/8" - 3/4" (included)

Min for Thicknesses over 3/4" - 1 1/2" (included)

Min for Thicknesses 1 1/2" - 2 1/2" (included)

Min for Thicknesses over 2 1/2"

Max Interpass Temperature

Temperature

Time

WELDING PROCEDURE

Pass or

Weld

Layer(s)

Filler Metals

Process

Class

Diameter

Current

Type &

Polarity

Amps or Wire

Feed Speed

Joint Details

Volts

Travel

Speed

Vous aimerez peut-être aussi

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Formato AWSDocument3 pagesFormato AWSDuverlyOrlandoMattaVásquezPas encore d'évaluation

- WPS Aws D1 1Document2 pagesWPS Aws D1 1Rohit MalhotraPas encore d'évaluation

- WPS Aws D1.1Document2 pagesWPS Aws D1.1tuatk60% (5)

- Welding Procedure Specification (WPS) Yes Prequalified Qualified by Testing or Procedure Qualification Records (PQR) YesDocument4 pagesWelding Procedure Specification (WPS) Yes Prequalified Qualified by Testing or Procedure Qualification Records (PQR) YesAugusto Q. SerranoPas encore d'évaluation

- M 2 GMAW FCAW D1.1 2015 FormDocument1 pageM 2 GMAW FCAW D1.1 2015 FormEhab HarbPas encore d'évaluation

- Aws PQR FormDocument3 pagesAws PQR Formndi101Pas encore d'évaluation

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Ehab HarbPas encore d'évaluation

- AWSPWPSDocument1 pageAWSPWPSVrangalov PeroPas encore d'évaluation

- AWS - Prequalified Welding Procedure Specification (PWPS) : Joint Design Used PositionDocument1 pageAWS - Prequalified Welding Procedure Specification (PWPS) : Joint Design Used PositionMarcelle PollPas encore d'évaluation

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniPas encore d'évaluation

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedPas encore d'évaluation

- PQR FormatDocument2 pagesPQR Formatravi0009880% (5)

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusPas encore d'évaluation

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Daniel Simar Herrera MorenoPas encore d'évaluation

- Wps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International AirportDocument5 pagesWps For Ss Welding in Pump Room: Phase-3A Development at Indira Gandhi International Airportamit rajputPas encore d'évaluation

- Qw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel CodeDocument2 pagesQw-482 Welding Procedure Specification (WPS) : SECTION IX, ASME Boiler and Pressure Vessel Codesreejithr86Pas encore d'évaluation

- WPQRDocument1 pageWPQRShani MalikPas encore d'évaluation

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRAhmed Shaban KotbPas encore d'évaluation

- Sample Forms AWS, ASME and APIDocument14 pagesSample Forms AWS, ASME and APIaamirtec301Pas encore d'évaluation

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- Welding Procedure Specification Structural-3GDocument3 pagesWelding Procedure Specification Structural-3Gdndudc78% (9)

- Annex Form J2 D1.1 D1.1M 2020 PDFDocument3 pagesAnnex Form J2 D1.1 D1.1M 2020 PDFDarioPas encore d'évaluation

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyPas encore d'évaluation

- WPS B-U2a-GF - GMAWDocument1 pageWPS B-U2a-GF - GMAWwentropremPas encore d'évaluation

- Sample WPS Form (SAW) Welding Procedure Specification (WPS)Document4 pagesSample WPS Form (SAW) Welding Procedure Specification (WPS)Brayan MartinezPas encore d'évaluation

- Suggested Wps Forms ASME - IX 2010Document5 pagesSuggested Wps Forms ASME - IX 2010Ajay ChodankarPas encore d'évaluation

- Wps A53 Gtaw R00Document2 pagesWps A53 Gtaw R00Richard PeriyanayagamPas encore d'évaluation

- Annex Form J2 D1.1 D1.1M 2020Document3 pagesAnnex Form J2 D1.1 D1.1M 2020Wegig WijanaPas encore d'évaluation

- Welding Procedure Specification: Technip KT India LimitedDocument5 pagesWelding Procedure Specification: Technip KT India LimitedDeepak100% (1)

- Stud Welding Procedure Specification WpsDocument2 pagesStud Welding Procedure Specification WpsEnrique Santiago BenavidesPas encore d'évaluation

- Annex Form J1 D1.1 D1.1M 2020 PDFDocument4 pagesAnnex Form J1 D1.1 D1.1M 2020 PDFDarioPas encore d'évaluation

- Ab-076a Welder Qualification Record WQRDocument1 pageAb-076a Welder Qualification Record WQRvinodPas encore d'évaluation

- ASME WELDER QUALIFICATION WORKSHEET NoDocument1 pageASME WELDER QUALIFICATION WORKSHEET NoDemetrio RodriguezPas encore d'évaluation

- WPS PQR As Per IsDocument3 pagesWPS PQR As Per Istarun kaushalPas encore d'évaluation

- WPQR Sample FormDocument1 pageWPQR Sample FormshwayePas encore d'évaluation

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremPas encore d'évaluation

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyPas encore d'évaluation

- PQR FormatDocument2 pagesPQR FormatBE GPas encore d'évaluation

- WPS FormDocument1 pageWPS FormNabil RadyPas encore d'évaluation

- Welder Certificate Sample1Document1 pageWelder Certificate Sample1Buddy EkoPas encore d'évaluation

- WPS GMAW FCAW D1.1 2015 Form PDFDocument1 pageWPS GMAW FCAW D1.1 2015 Form PDFHoque AnamulPas encore d'évaluation

- Welding Procedure Specification Pipe - 6GDocument3 pagesWelding Procedure Specification Pipe - 6Gdndudc97% (29)

- WPQ CS SmawDocument1 pageWPQ CS Smawniket0Pas encore d'évaluation

- PQRDocument3 pagesPQRCatalina Sorina ParfenePas encore d'évaluation

- M 2 GTAW SMAW D1.1 2015 FormWPS PDFDocument1 pageM 2 GTAW SMAW D1.1 2015 FormWPS PDFUmi MaryanaPas encore d'évaluation

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Jithin VPas encore d'évaluation

- M 2 GTAW SMAW D1.1 2015 Form PDFDocument1 pageM 2 GTAW SMAW D1.1 2015 Form PDFRameshBaskaranPas encore d'évaluation

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Umi MaryanaPas encore d'évaluation

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)AZaiPas encore d'évaluation

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- DHA JED DOM Cds C: OriginDocument1 pageDHA JED DOM Cds C: OriginHaleem Ur Rashid BangashPas encore d'évaluation

- 1437 Eng PDFDocument1 page1437 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- Cable Damage Incident Report ABGOSP2Document2 pagesCable Damage Incident Report ABGOSP2Haleem Ur Rashid BangashPas encore d'évaluation

- Loan With PeopleDocument2 pagesLoan With PeopleHaleem Ur Rashid BangashPas encore d'évaluation

- Chemical Hazard Bulletin: Chemtronics Pow-R-Wash VZDocument1 pageChemical Hazard Bulletin: Chemtronics Pow-R-Wash VZHaleemUrRashidBangashPas encore d'évaluation

- 1359 Eng PDFDocument1 page1359 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 185 Eng PDFDocument1 page185 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 3692 Eng PDFDocument1 page3692 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 1359 Eng PDFDocument1 page1359 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 1437 Eng PDFDocument1 page1437 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- Chemical Hazard Bulletin: Chemtronics Pow-R-Wash VZDocument1 pageChemical Hazard Bulletin: Chemtronics Pow-R-Wash VZHaleemUrRashidBangashPas encore d'évaluation

- 3692 Eng PDFDocument1 page3692 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

- Concrete Cutting in Progress 01 PDFDocument1 pageConcrete Cutting in Progress 01 PDFHaleem Ur Rashid BangashPas encore d'évaluation

- 185 Eng PDFDocument1 page185 Eng PDFHaleem Ur Rashid BangashPas encore d'évaluation

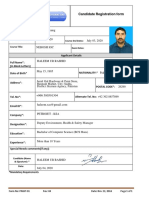

- PNGIT Application Form 2Document1 pagePNGIT Application Form 2Haleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - Applicant Registration Form PDFDocument1 pagePNGIT - Applicant Registration Form PDFHaleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - Applicant Registration Form PDFDocument1 pagePNGIT - Applicant Registration Form PDFHaleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - Applicant Registration Form - 2 PDFDocument1 pagePNGIT - Applicant Registration Form - 2 PDFHaleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - Applicant Registration Form - 2Document1 pagePNGIT - Applicant Registration Form - 2Haleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - NEBOSH Registration Form PDFDocument1 pagePNGIT - NEBOSH Registration Form PDFHaleem Ur Rashid BangashPas encore d'évaluation

- Nebosh Course Evaluation.V2 NewDocument2 pagesNebosh Course Evaluation.V2 NewHaleem Ur Rashid BangashPas encore d'évaluation

- PNGIT - NEBOSH Registration Form PDFDocument1 pagePNGIT - NEBOSH Registration Form PDFHaleem Ur Rashid BangashPas encore d'évaluation

- PNGIT Application Form 2Document1 pagePNGIT Application Form 2Haleem Ur Rashid BangashPas encore d'évaluation

- Nebosh RA FormDocument1 pageNebosh RA FormHaleem Ur Rashid BangashPas encore d'évaluation

- Flash Card 6 PDFDocument9 pagesFlash Card 6 PDFAjay PatelPas encore d'évaluation

- PNGIT - Applicant Registration Form - 2 PDFDocument1 pagePNGIT - Applicant Registration Form - 2 PDFHaleem Ur Rashid BangashPas encore d'évaluation

- Ansi/Aiha Z10: Atomic NumberDocument11 pagesAnsi/Aiha Z10: Atomic NumberRehman MuzaffarPas encore d'évaluation

- PNGIT - Applicant Registration Form - 2Document1 pagePNGIT - Applicant Registration Form - 2Haleem Ur Rashid BangashPas encore d'évaluation

- Flash Card 4 PDFDocument10 pagesFlash Card 4 PDFAjay PatelPas encore d'évaluation

- 1 Foot Candle How Many Lux 10.764 Lux and Also 1 Lumen Asymmetry MultiplierDocument10 pages1 Foot Candle How Many Lux 10.764 Lux and Also 1 Lumen Asymmetry MultiplierRehman MuzaffarPas encore d'évaluation