Académique Documents

Professionnel Documents

Culture Documents

ZBC2000 Ok

Transféré par

Farhanah OnnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ZBC2000 Ok

Transféré par

Farhanah OnnDroits d'auteur :

Formats disponibles

Pendulum Impact Testing Machine for metal Charpy impact

ZBC 2000 Series

150J-750J

ZBC2000 Series

The model ZBC2000 series pendulum impact tester comes from SANS pendulum

impact testing machines series family, fashionable design and complete assembly

with SANS high technology satisfied with impact resistance tests of metal material

under dynamic loading, It is widely applied into the following industries:

manufacturer of metal material, quality control of products, institutes and colleges,

R&D.

Comply with ISO R148, ISO R83, EN10045, ASTM E23

Page

1/6

Key Features of ZBC2000

7. One-piece cast frame design of seat

and column provide high stability and

rigidity.

8. Front

and

rear

columns

are

symmetrical.

Pendulum

arm

is

designed of cantilever beam support,

with simple structure and high

machined precision.

9. Apply high precision bearing with small

friction. Absorbing energy without

loading is less than 0.3%.

10. Double reduction gear system replaces

old style drive system with high

efficiency and avoiding transmission

failure.

11. Round pendulum head design reduces

windage losses to the most. Striking bit

is fixed by bolts and wedge pressing

blocks, and easy to change. High rigid

pendulum arm prevents axial and

transverse vibrations.

12. Exchangeable pendulum is simple to

change to satisfy impact energy of

150J, 300J, 450J, 600J, 750J.

13. Electromagnetic release of pendulum

hammer.

14. Electromagnetic clutch for braking the

pendulum and lifting to it to its initial

position. A damper is equipped to

prevent strong bump when clutching.

15. Be equipped with full-closed enclosure

with nice appearance and high safety.

1. Apply industrial PLC to control

pendulum, and high precision rotary

encoder to measure striker real time

position. The whole system is stable,

reliable and accurate.

2. A mini LCD monitor may real-time

displays striker angle, impact energy,

toughness, and other parameters.

User can input specimen data and

other information such as company

information into this monitor. When

connected to a printer, user input

information and test results will be

printed.

3. Traditional analogue round display

inclusive of drag-pointer and scales

for immediate display of the used

impact energy in Joule.

4. Optional computer with software

control is available to realize

semiautomatic operation. Operator

only need charge specimens. Others

can be controlled by software.

5. Optional specimen feeding system

is

available.

Combined

with

computer

and

software,

fully

automatic operation can be realized.

6. Optional

cooling

chamber

is

available to satisfy cold specimen

test down to -100.

Specimen collection and filtering device

Motorized device is used for collecting broken

specimens after impact, instead of manual

cleaning, which fully prevents striker from

getting stuck.

Unique

specimen

filtering

function.

Automatically judge and transport qualified

and unqualified specimens to different

collecting box.

Page

2/6

Optional

specimen feeding system and cooling chamber

Liquid Nitrogen Cylinder

Specimen

Automatic specimen feeding system

rack

Cooling chamber

Features

z

z

z

z

z

z

Specimen rack can accommodate 40 pieces specimen

Cooling chamber can accommodate 40 pieces specimen

The modular system makes an economical adaptation to specific customer

requirements possible

Pneumatic actuation provides high positioning accuracy of the automatic

specimen feeding, eliminating human influences

Reproducibility of the testing requirements even over a long operating time,

no influences through different operators

Smoothly connected to impact tester, fully automatic, laborsaving, high

productivity and safety

Page

3/6

Customized model ZBC2503 for metal DT test

Only used for dynamic tear testing (DT test) of metallic materials, impact

energy is 5000J.

Fully automatic control allows program input only by pressing the buttons.

Easy to operation and high efficient.

Automatically brake after impact then raise the pendulum and lock.

Compatible control panel and display can satisfy customers requirements. It

can display impact absorbing energy, pendulum raising angle, energy loss and

continuous impact frequency.

High impact energy is suitable for black metal test with more impact ductility,

such as steel and alloy.

It fully complies with ASTM E604 <Standard Test Method for Dynamic Tear

Testing of Metallic Materials>

Note:

DT test is to determine absorbed energy by dynamic tear specimens in Charpy

impact test in accordance with relative standards (I.e. dynamic tear energy

means the dynamic tear resistance of specific thickness metallic material), and

to determine fiber fracture surface ratio.

Page

4/6

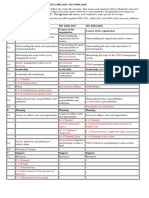

Technical Specifications of ZBC2000 series

Model No.

ZBC2152

ZBC2302

ZBC2452

ZBC2602

ZBC2752

ZBC2503

Max impact energy(J)

150J

300J

450J

600J

750J

5000J

Pendulum moment (Nm)

80.3848

160.7695

241.1543

321.5390

401.9238

2928.932

Distance from striking

750mm

1380

Raising angle

150

135

Angle resolution

0.1

0.1

Impact speed

5.24m/s

6.797m/s

Anvil span

40mm

1650.8mm

Radius of anvils

1-1.5mm

12.70.8mm

Angle of taper of anvil

111

11

Radius of striker edge

2-2.5mm

12.70.8mm

Angle at tip of striker

301

301

Width of striker

16mm

37mm

Specimen dimensions

10mm /7.5mm/5mm X 10mm X 55mm

(1812mm)x(40.6

center to support center

1mm)x5~161m

Dimension (LXWXH)

960mm X 735mm X 1500mm

3760mmx2735mmx

3660mm

Weight(Net)

900kg

6500kg

Power supply

Three-phase, 380V10%, 2A

Three-phase,

380V10%

Standard Accessories

Optional Accessories

z Main frame, one set (including one

piece photoelectric encoder)

z LCD monitor, one set

z Dial display: one set

z Charpy pendulum, one piece

z Charpy support and anvil: one set

z Base adjusting device, one set

z Safety shield, one set.

z Motorized , one set

z printer, one set

z Tool kit, one set

z

z

z

z

Automatic specimen feeding

system

Specimen

collection

and

filtering device

Computer and software

Cold chamber

Page

5/6

Technical Specifications of cold chamber

Model Number

Cooling method

Temperature range

Cooling speed

LN2 cylinder capacity

Weight

Power supply

Space for specimen

Specimen accommodation

Temperature gradient

Temperature vibration

Temperature accuracy

Temperature resolution

Cooling medium

ZDW1102

ZDW2601

liquid nitrogen (LN2)

compressor

Ambient~-100

Ambient~ -60

20 minutes

80 minutes

From ambient to -100

from ambient to -60

15L/160L (customer order)

----------200Kg

80Kg

Single-phase, 220V2A 50Hz

Single-phase, 220V8A 50Hz

120mmX120mmX80mm (LXWXH)

120 pieces Charpy specimen

0.5

1

0.3

0.1

Liquid nitrogen

anhydrous alcohol99.7%

Note: For ZDW1102, Specimen placement space can be made according to

customers requirements to meet DT, NDT and DWTT test.

Software

The ZBC Test software provides real-time display pendulum raising angles, impact

energy and other parameters. All operations can be completed in the software, like

pendulum raising, releasing, impacting, and returning. Test results can be saved

automatically to Access database, or easily exported to Excel. The software is simple and

easy to operate.

Page

6/6

Vous aimerez peut-être aussi

- M. Tech Geotechnical Engineering Lab ManualDocument6 pagesM. Tech Geotechnical Engineering Lab ManualHarikishoreguptha KovooriPas encore d'évaluation

- Usage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SDocument7 pagesUsage: Power: Brand Name: Weight: Model Number:: Digital Display Impact Testing Machine JB-300SRavi TyagiPas encore d'évaluation

- List of The Equipments (R)Document12 pagesList of The Equipments (R)Rubel RanaPas encore d'évaluation

- MECH Lab RequirementDocument4 pagesMECH Lab RequirementJaishree ChauhanPas encore d'évaluation

- 111 1400 Simon Black Jaguar Land RoverDocument29 pages111 1400 Simon Black Jaguar Land RoverseehariPas encore d'évaluation

- Material Testing LabDocument3 pagesMaterial Testing LabJaishree ChauhanPas encore d'évaluation

- WDW 300eDocument10 pagesWDW 300e1970fabPas encore d'évaluation

- C225-E020 Servopulser GeneralDocument14 pagesC225-E020 Servopulser GeneralKokYee ChanPas encore d'évaluation

- CNC Wire Cut Edm: 1. Non Traditional Machining LaboratoryDocument5 pagesCNC Wire Cut Edm: 1. Non Traditional Machining LaboratoryAkash KumarPas encore d'évaluation

- Actuator Types MaterialsDocument27 pagesActuator Types MaterialsshibasholmarcPas encore d'évaluation

- ZL-3011A Electric Heating Water Cooling Banbury Mixer - MAY TAN TRONDocument9 pagesZL-3011A Electric Heating Water Cooling Banbury Mixer - MAY TAN TRONlucas.hoang.119Pas encore d'évaluation

- 3650x200 Es-11115 PDFDocument12 pages3650x200 Es-11115 PDFmpcd07Pas encore d'évaluation

- 6969-350 FlextensionalDocument8 pages6969-350 FlextensionalAdnan QaseemPas encore d'évaluation

- UTM CatalogDocument6 pagesUTM CatalogAsmita AcharyaPas encore d'évaluation

- FIBER LASER TechnologiesDocument30 pagesFIBER LASER Technologieschathuranga chandrasekaraPas encore d'évaluation

- System 3R EMD Electrode Holder T-2389-E - EdmDocument108 pagesSystem 3R EMD Electrode Holder T-2389-E - EdmNamtien UsPas encore d'évaluation

- Manufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Document3 pagesManufacturers & Suppliers: Izod and Charpy Apparatus Make "Dinesh" Model DS 102Ashish VermaPas encore d'évaluation

- Surge Arrestors AmericaDocument8 pagesSurge Arrestors AmericagustavopaloPas encore d'évaluation

- AutoWinder XTDocument1 pageAutoWinder XTTuan Nguyen MinhPas encore d'évaluation

- University of Misan Engineering College Civil EngineeringDocument7 pagesUniversity of Misan Engineering College Civil EngineeringoPas encore d'évaluation

- STP280 - 24Vd - UL (H4 Connector) - AZDocument2 pagesSTP280 - 24Vd - UL (H4 Connector) - AZkiranpandey87Pas encore d'évaluation

- 1800J High Speed Drop Weight TesterDocument10 pages1800J High Speed Drop Weight TesterJeyalalPas encore d'évaluation

- Hanil Catalogue (2012)Document100 pagesHanil Catalogue (2012)Soma GhoshPas encore d'évaluation

- CNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WDocument16 pagesCNC Fiber Laser Cutter For Cutting Plate and Tube 3015 1000WSot DesignPas encore d'évaluation

- Sample Preparation: ApplicationDocument3 pagesSample Preparation: ApplicationDilhara WickramaarachchiPas encore d'évaluation

- Bypass - Damper Johnson ControlDocument6 pagesBypass - Damper Johnson Controlamirin_kingPas encore d'évaluation

- Limit Switches PanasonicDocument81 pagesLimit Switches PanasonicArturoPas encore d'évaluation

- SOLARWORLD Sunmodule Plus 190 Mono BlackDocument2 pagesSOLARWORLD Sunmodule Plus 190 Mono BlackCristian SandovalPas encore d'évaluation

- Suntech DATA Sheet PDFDocument2 pagesSuntech DATA Sheet PDFduckman2009Pas encore d'évaluation

- KGE1000Ti Service ManualDocument41 pagesKGE1000Ti Service Manualmarksmods100% (1)

- Hydraulic UTMDocument14 pagesHydraulic UTMEduardo CruzPas encore d'évaluation

- Friction and Wear Testing MachineDocument7 pagesFriction and Wear Testing MachineElkallati FettahPas encore d'évaluation

- AutoWrap XTDocument1 pageAutoWrap XTTuan Nguyen MinhPas encore d'évaluation

- Automatic Compression Testers For Cylinders: SeriesDocument4 pagesAutomatic Compression Testers For Cylinders: SeriesJosé Fco. Cerda M.Pas encore d'évaluation

- Nuflo Ez-InDocument8 pagesNuflo Ez-InAnonymous Wu6FDjbPas encore d'évaluation

- Rebound Hammer DigitalDocument6 pagesRebound Hammer DigitalTanmay GuptaPas encore d'évaluation

- Sds 02 en Cubcyl RGB 170116 PDFDocument4 pagesSds 02 en Cubcyl RGB 170116 PDFHazel Gomero CamposPas encore d'évaluation

- Equotip 3Document6 pagesEquotip 3raveeceePas encore d'évaluation

- Round Duct Making MachinesDocument15 pagesRound Duct Making MachinesMARCOPas encore d'évaluation

- Preliminary Mechanical Design of Fast Photo MeterDocument16 pagesPreliminary Mechanical Design of Fast Photo MeternandishvjPas encore d'évaluation

- Laboratory Equipment ReportDocument16 pagesLaboratory Equipment ReportNavneeth G MenonPas encore d'évaluation

- Quotation Sheet (Pentagon Knit Company LTD & Gas) 210224-1Document14 pagesQuotation Sheet (Pentagon Knit Company LTD & Gas) 210224-1Md MasumPas encore d'évaluation

- ADH Single Table Laser Cutter ULF-3015 2000w RaycusDocument21 pagesADH Single Table Laser Cutter ULF-3015 2000w RaycusAbubaker KakulePas encore d'évaluation

- Boom Barrier Technical DetailsDocument8 pagesBoom Barrier Technical Detailshkjain19891545Pas encore d'évaluation

- EMMVEE On-Grid Data Sheet Revised 2014Document2 pagesEMMVEE On-Grid Data Sheet Revised 2014pradeepq100% (1)

- Parameter MachineDocument10 pagesParameter MachinePhuong Thuc Duong LePas encore d'évaluation

- EV Series CNC Vertical Machining Center2019Document32 pagesEV Series CNC Vertical Machining Center2019SamiPas encore d'évaluation

- Kendrion Ib Broschuere Servo Line Englisch LowDocument12 pagesKendrion Ib Broschuere Servo Line Englisch LowhamonPas encore d'évaluation

- Solarworld 315 XL MonoDocument2 pagesSolarworld 315 XL Monoapi-285232606Pas encore d'évaluation

- EP-SJ12025 Optical Cable Sheath Production LineDocument7 pagesEP-SJ12025 Optical Cable Sheath Production Linemehran khamsehzadehPas encore d'évaluation

- GN CFD I8 3015c 6000w Raycus Technical SolutionDocument23 pagesGN CFD I8 3015c 6000w Raycus Technical SolutionigorPas encore d'évaluation

- EN - Top-of-the-Range Automatic Compression Testers For Cubes and Cylinders AUTOMAX PRODocument7 pagesEN - Top-of-the-Range Automatic Compression Testers For Cubes and Cylinders AUTOMAX PROHaikalPas encore d'évaluation

- Pipe Punching Machine-Soar MachineDocument11 pagesPipe Punching Machine-Soar MachineKarla Margaret Vargas MirandaPas encore d'évaluation

- Automated Punching MachineDocument8 pagesAutomated Punching MachineMohamed IbrahemPas encore d'évaluation

- RoboticAutomatic Tool Changer PDFDocument36 pagesRoboticAutomatic Tool Changer PDFTesfahun GirmaPas encore d'évaluation

- Equotip 2 User Manual E - 200605Document35 pagesEquotip 2 User Manual E - 200605mgmqro100% (1)

- Dynamometer: Theory and Application to Engine TestingD'EverandDynamometer: Theory and Application to Engine TestingPas encore d'évaluation

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisD'EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisÉvaluation : 4 sur 5 étoiles4/5 (2)

- Indentec en PI VisionLiteDocument2 pagesIndentec en PI VisionLiteFarhanah OnnPas encore d'évaluation

- Charpy & Izod Metals Impact TestingDocument2 pagesCharpy & Izod Metals Impact TestingFarhanah OnnPas encore d'évaluation

- D Limits&TolerancesDocument22 pagesD Limits&TolerancesFarhanah OnnPas encore d'évaluation

- BS en 10130 DC01 Datasheet b3.1Document3 pagesBS en 10130 DC01 Datasheet b3.1Farhanah OnnPas encore d'évaluation

- Memory Management Unit 5Document58 pagesMemory Management Unit 5Nishant NalawadePas encore d'évaluation

- Assignment Chapter 1Document2 pagesAssignment Chapter 1Sothearith SvayPas encore d'évaluation

- ASCII CodesDocument17 pagesASCII CodesAndleeb RazzaqPas encore d'évaluation

- FSAE Data Analysis Day 2 To PrintDocument55 pagesFSAE Data Analysis Day 2 To PrintJorge CorderoPas encore d'évaluation

- cs2201 Unit1 Notes PDFDocument16 pagescs2201 Unit1 Notes PDFBal BolakaPas encore d'évaluation

- The Importance of Basic Printing Education For Human Resource Development in Printing IndustryDocument12 pagesThe Importance of Basic Printing Education For Human Resource Development in Printing IndustryAries Chandra AnandithaPas encore d'évaluation

- Why Implements AmDocument23 pagesWhy Implements Amdayanx2014Pas encore d'évaluation

- Ulss Ulsm UlslDocument1 pageUlss Ulsm UlslHamzaPas encore d'évaluation

- Microsync Rx800 AcdcDocument68 pagesMicrosync Rx800 AcdcUMcuatrocerocincoPas encore d'évaluation

- 5 - Signal Flow Graphs Masons RuleDocument19 pages5 - Signal Flow Graphs Masons RuleMGR fanPas encore d'évaluation

- Annex SL 9001 14001 45001 Management System MapDocument3 pagesAnnex SL 9001 14001 45001 Management System MapPramod AthiyarathuPas encore d'évaluation

- Tomorrow'S Technology For Today'S Security: Product HighlightsDocument2 pagesTomorrow'S Technology For Today'S Security: Product HighlightsBanu AtamPas encore d'évaluation

- EEE Department Brochure - 02.04-1Document3 pagesEEE Department Brochure - 02.04-1Sivaraman PandarinathanPas encore d'évaluation

- Md. Shahid Uz Zaman Dept. of CSE, RUETDocument18 pagesMd. Shahid Uz Zaman Dept. of CSE, RUETJarir AhmedPas encore d'évaluation

- 3b6 Load Moment Indicator (Lmi) For MRT Telescopic Handlers User Manual PDFDocument1 page3b6 Load Moment Indicator (Lmi) For MRT Telescopic Handlers User Manual PDFUebi Alves0% (1)

- BEC Preliminary Practice File - : Answers and Marking GuidelinesDocument1 pageBEC Preliminary Practice File - : Answers and Marking GuidelinesErik MonteroPas encore d'évaluation

- Lexium 05 Catalog USA SchneiderDocument98 pagesLexium 05 Catalog USA SchneiderRobert Caicedo ValenciaPas encore d'évaluation

- Backend - Assignment - InternshipDocument2 pagesBackend - Assignment - InternshipRahul NainawatPas encore d'évaluation

- Cartilla Informativa Plan LectorDocument11 pagesCartilla Informativa Plan LectorHilarioPaniuraHuayhuaPas encore d'évaluation

- How To Use 6211Document23 pagesHow To Use 6211ahmed4665Pas encore d'évaluation

- An Update On The 3x+1 Problem Marc ChamberlandDocument32 pagesAn Update On The 3x+1 Problem Marc ChamberlandFajar Haifani100% (1)

- KEM DensitometersDocument8 pagesKEM DensitometersTank Top 2Pas encore d'évaluation

- Presentacion Trazador CNCDocument15 pagesPresentacion Trazador CNCNery Alexander CaalPas encore d'évaluation

- 7.0 Loop Single - 0Document2 pages7.0 Loop Single - 0tidachinPas encore d'évaluation

- Ut 2217Document1 pageUt 2217alisintaxPas encore d'évaluation

- 12 Best Practices For Core Banking MigrationDocument9 pages12 Best Practices For Core Banking MigrationitouzenPas encore d'évaluation

- KauneDocument7 pagesKauneEnos Marcos Bastos100% (1)

- COP User Manual 2.0 PDFDocument5 pagesCOP User Manual 2.0 PDFخالدعبدالله100% (1)

- How To Control Speed of Stepper Motor by PotentiometerDocument5 pagesHow To Control Speed of Stepper Motor by PotentiometerMihai Bogdan100% (1)

- Catalog Altivar Process ATV600 Variable Speed DrivesDocument133 pagesCatalog Altivar Process ATV600 Variable Speed Drivesrabia akramPas encore d'évaluation