Académique Documents

Professionnel Documents

Culture Documents

ME2134cheatsheet PDF

Transféré par

benTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

ME2134cheatsheet PDF

Transféré par

benDroits d'auteur :

Formats disponibles

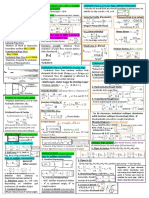

ME2134-2

Analysis of Pipe Flow

Assumptions:

Applies to homogeneous fluid

of constant viscosity and

density; & gases provided

density changes are small

Darcy-Weisbach Eqn; LOSS in straight

pipe cos of friction

-Using V (average) = Q/A

-Using energy eqn & momentum eqn (prev. chapter)

Laminar:

Turbulent/V:

hf =

LAMINAR Flow in Circular Pipe [SMOOTH/ROUGH]

-Velocity of a real fluid at a fixed boundary is always zero to

satisfy no-slip condn. r=R, u=0.

Velocity Profile (Parabolic)

Pressure Drop (+ve value)

(Hagen-Poiseuille Flow)

Umax (max velocity)

Red DETERMINES TYPE OF

FLOW, INTEGRAL STEP

Laminar Pipe Flow

-Motion of fluid in layers//to

boundary surface (Red<2300)

Transitional Pipe Flow

- (Red~2300)

Turbulent Pipe Flow (Red>>2300)

-Random, irregular & unsteady

motion of fluid particles

Shear Stress

Valid for duct flow of ANY x-section &

both laminar/turbulent flow

= 2V (average velocity)

AND Darcy Friction Factor,

Entrance Length: distance from

entrance of pipe flow travels before

fully developed

Head Loss, h (Darcy)

Friction Factor, f (Red<2300)

[Le]

Laminar:

Turbulent:

TURBULENT Flow in SMOOTH Circular Pipe

- Turbulent flow has random eddies that

dissipate KE into heat. (Dragturbulent > Draglaminar)

- Turbulent flow (3 regions) is affected by

surface roughness unlike laminar.

- Wall Layer, Outer Layer & Overlap Layer

- Friction velocity =

& (R-r) = y

Velocity Profile:

TURBULENT Flow in ROUGH Circular Pipe

- EDDIES can form in rough+turb since protrusions

*Extent of submersion of roughness elements into

laminar sublayer of turbulent boundary layer

1. Hydraulically Smooth Walls:

- turbulent flow similar to in smooth pipe

[Velocity Profile:]

2. Hydraulically Rough Walls:

- protrude into main flow

[Velocity Profile:]

Friction in noncircular pipes

- Replace diameters; d or D with

hydraulic diameter, DH

Frictional Loss & Factor

3. Transitional Roughness:

- Some submerged some protrude

Average Velocity, V:

[Velocity Profile:]

B from B -

Max Velocity, Umax

; f from Darby

graph

*as Re increases, turbulent sublayer dominates

while laminar sublayer increasingly thins

(hydraulically smooth to rough transition)

Moody Diagram (Friction Factor)

flaminar=64/Red (Red<2300) ; fsmooth pipe or hydrau smooth

RHS of AB, fhydrau rough :

Not so accurate for laminar flow since V is not a

good approximation of velocity profile unlike

(Independent of Red)

turbulent which is mostly uniform (flat part)

Between AB & EF (smooth):

MINOR LOSSES explaning eddy losses

OR

Minor loss with

Loss coeff, K

Multiple Pipe System [for head losses, take darcy

& minor losses in each pipe [all networks]

1. Pipes in Series: Q=Q1=Q2=Q3; HL=HL1+HL2+HL3

Loss in sudden expansion:

1. Exit Loss: k=1; tank is

big, A2 is v big compared

Loss in sudden contraction:

(general)

(after venaC)

Ac is area of vena contracta; Cc=Ac/A2,

[Between

vena

contracta

&

downstream narrower section 2]

MINOR LOSSES explaning eddy losses

Loss in sudden contraction:

2. Gradual Expansion

1. Entrance Loss: Ksc will vary

depending on whether got

protrusion of smaller d pipe

2. Gradual Expansion

- KL includes frictional loss

- >60o, sudden expansion better

- 6o is optimum angle; 8o in

rougher pipes

3. Losses in Bends (=loss from flow

Diffuser reduces losses fr certain angles

separation,wall friction+secondary flow)

2. Pipes in //:

- Q=Q1+Q2+Q3; HL=HL1=HL2=HL3 (unless got pump Q1=Q2=Q3)

3. Branching Pipes: (Q&H&Hloss=HL)

Generally, Head/

energy at a point

3. Losses in Bends =

- if R/d=0, K~1.1

- K includes frictional loss

Regardless of pipe network,

must satisfy: Continuity, only

one energy level (head) at given

point & friction eqn must be

satisfied for each pipe. (Diff in

head = head loss between 2 pts)

Vous aimerez peut-être aussi

- InverterDocument53 pagesInverterAgus SetyawanPas encore d'évaluation

- Ac Ac ConverterDocument56 pagesAc Ac ConverterPutri Hanifah SPas encore d'évaluation

- ME2142 Feedback Control Systems SolutionsDocument8 pagesME2142 Feedback Control Systems SolutionsdesmondlimmPas encore d'évaluation

- Design Considerations For An LLC Resonant ConverterDocument29 pagesDesign Considerations For An LLC Resonant Converterbacuoc.nguyen356Pas encore d'évaluation

- Lab 5 - BJT As InverterDocument3 pagesLab 5 - BJT As InverterKamal ChapagainPas encore d'évaluation

- Control Systems Resource SheetDocument12 pagesControl Systems Resource SheetCharlie Ho SiPas encore d'évaluation

- DC Motor Transfer Functions ExplainedDocument4 pagesDC Motor Transfer Functions ExplainedKareem AbouelwafaPas encore d'évaluation

- Adobe Photoshop CS3 Keyboard Shortcuts PCDocument4 pagesAdobe Photoshop CS3 Keyboard Shortcuts PCHDevolution100% (1)

- Verify Thevenin's TheoremDocument10 pagesVerify Thevenin's TheoremJay SathvaraPas encore d'évaluation

- Linear Wave ShapingDocument29 pagesLinear Wave Shapingapnrao100% (6)

- DC Characteristics of Opamps ExplainedDocument23 pagesDC Characteristics of Opamps ExplainedMichael CampbellPas encore d'évaluation

- Lec 13 PDFDocument15 pagesLec 13 PDFkapil chander100% (1)

- Laplace Transform C4 - StudentsDocument21 pagesLaplace Transform C4 - StudentsJing ZePas encore d'évaluation

- Feedback Amplifiers: EMT 212/4 - Analog Electronic IIDocument54 pagesFeedback Amplifiers: EMT 212/4 - Analog Electronic IIJoshua DuffyPas encore d'évaluation

- NDW Series Computer Controlled Torsion Testing MachineDocument5 pagesNDW Series Computer Controlled Torsion Testing Machinegosaye desalegnPas encore d'évaluation

- Tutorial 2Document2 pagesTutorial 2kenny5shinPas encore d'évaluation

- Cmos ComparatorDocument26 pagesCmos Comparatorvipul4792100% (3)

- Polar & Nyquist Plots MCQDocument18 pagesPolar & Nyquist Plots MCQRajeev Singh BishtPas encore d'évaluation

- Differential AmplifierDocument15 pagesDifferential AmplifierrppvchPas encore d'évaluation

- Routh-Hurwitz Stability CriterionDocument33 pagesRouth-Hurwitz Stability CriterionFarhan d'Avenger0% (1)

- Voltage Source InverterDocument77 pagesVoltage Source InverterSaied Aly SalamahPas encore d'évaluation

- BJT Multistage Amplifier StagesDocument9 pagesBJT Multistage Amplifier StagesYue KaiPas encore d'évaluation

- Signal Generator Project StatementDocument16 pagesSignal Generator Project StatementHussain Bin AliPas encore d'évaluation

- Example 3.1 Finding The Performance Parameters of A Full-Wave Rectifier With A Center-Tapped TransformerDocument4 pagesExample 3.1 Finding The Performance Parameters of A Full-Wave Rectifier With A Center-Tapped TransformersoberPas encore d'évaluation

- FM Balanced Slope DetectorDocument5 pagesFM Balanced Slope DetectorPujjalPandeyPas encore d'évaluation

- Small Signal Analysis of Amplifiers (BJT & Fet) : Narayana Engineering College:: NelloreDocument12 pagesSmall Signal Analysis of Amplifiers (BJT & Fet) : Narayana Engineering College:: NelloreTharun kondaPas encore d'évaluation

- 8051 Microcontroller Module 5 NotesDocument27 pages8051 Microcontroller Module 5 Notesrakesh rakiPas encore d'évaluation

- Self Oscillating Flyback ConverterDocument7 pagesSelf Oscillating Flyback ConverterNaren DranPas encore d'évaluation

- EXPT - 02 - Study of Single Stage BJT AmplifierxDocument5 pagesEXPT - 02 - Study of Single Stage BJT AmplifierxPrakash Narkhede100% (1)

- T8 - Root Locus Technique - 2021Document51 pagesT8 - Root Locus Technique - 2021James ChanPas encore d'évaluation

- Experiment - 05Document17 pagesExperiment - 05Sagar SharmaPas encore d'évaluation

- Evaluation of The Transient Response of A DC MotorDocument6 pagesEvaluation of The Transient Response of A DC MotorNesuh MalangPas encore d'évaluation

- Bode PlotDocument7 pagesBode Plotnabilo20Pas encore d'évaluation

- DSB SSB Am Transmitter Trainer Kit Scientech 2201Document2 pagesDSB SSB Am Transmitter Trainer Kit Scientech 2201mohitPas encore d'évaluation

- Biasing DC and Ac Load LinesDocument15 pagesBiasing DC and Ac Load Linesarjuna4306Pas encore d'évaluation

- Analyze Buck-Boost Converter Lab Using Power MOSEFTDocument6 pagesAnalyze Buck-Boost Converter Lab Using Power MOSEFTFALSERPas encore d'évaluation

- Full Wave Rectifier Guide: Circuit, Theory & UsesDocument7 pagesFull Wave Rectifier Guide: Circuit, Theory & UsesArun PratapPas encore d'évaluation

- Signals and SystemsDocument3 pagesSignals and SystemsArjun Arjun100% (1)

- Chapter 3: Ac Power AnalysisDocument40 pagesChapter 3: Ac Power AnalysisAtyia Javed100% (1)

- Electrical and Electronic MeasurementsDocument47 pagesElectrical and Electronic MeasurementsAkashGauravPas encore d'évaluation

- AC-DC Converter - DDocument39 pagesAC-DC Converter - DBishnu100% (1)

- Square Wave Generator Using Op-Amp Lab ReportDocument6 pagesSquare Wave Generator Using Op-Amp Lab ReportRahul KunduPas encore d'évaluation

- Me2142 T1 182Document2 pagesMe2142 T1 182kenny5shinPas encore d'évaluation

- Hybrid Equivalent For CC TransistorDocument9 pagesHybrid Equivalent For CC TransistorPriya BalakrishnanPas encore d'évaluation

- BJT and JFET Frequency ResponseDocument16 pagesBJT and JFET Frequency ResponseVert WheelerPas encore d'évaluation

- Emitter FollowerDocument8 pagesEmitter FollowerjerlineprincyPas encore d'évaluation

- Me2134 PDFDocument1 pageMe2134 PDFbenPas encore d'évaluation

- ME2134Document2 pagesME2134benPas encore d'évaluation

- Hydraulics - Chapter 3Document8 pagesHydraulics - Chapter 3thuaiyaalhinaiPas encore d'évaluation

- Pipe FlowDocument10 pagesPipe Flowproghosh7Pas encore d'évaluation

- Jayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Document17 pagesJayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Muthuvel MPas encore d'évaluation

- Fluid MechanicsDocument52 pagesFluid Mechanicsmanneli talpagiriPas encore d'évaluation

- Flow in Pipes Faculty - Washington.eduDocument18 pagesFlow in Pipes Faculty - Washington.eduils411Pas encore d'évaluation

- Air-Condtioning: Course No. ME40107Document34 pagesAir-Condtioning: Course No. ME40107bhalchandrapatilPas encore d'évaluation

- Calculating Pipe Diameter in a Series Pipe SystemDocument19 pagesCalculating Pipe Diameter in a Series Pipe SystemJohn Paul CordovaPas encore d'évaluation

- Guide 1 (19.10.2022)Document5 pagesGuide 1 (19.10.2022)Iyad AboissaPas encore d'évaluation

- Chapter 9 Flow in Open ChannelDocument28 pagesChapter 9 Flow in Open ChannelolescootPas encore d'évaluation

- Steady Conduit FlowDocument13 pagesSteady Conduit FlowEyuelAdamPas encore d'évaluation

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterD'EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterPas encore d'évaluation

- Dimensional Analysis & Similitude: (K Is Dimensionless Constant and The Rest Are Unknown Indices)Document2 pagesDimensional Analysis & Similitude: (K Is Dimensionless Constant and The Rest Are Unknown Indices)benPas encore d'évaluation

- ME2134Document2 pagesME2134benPas encore d'évaluation

- ME2134Document2 pagesME2134benPas encore d'évaluation

- ME2134cheatsheet PDFDocument1 pageME2134cheatsheet PDFbenPas encore d'évaluation

- Me2134 PDFDocument1 pageMe2134 PDFbenPas encore d'évaluation

- Me2134 PDFDocument1 pageMe2134 PDFbenPas encore d'évaluation

- Fluid Loading On Offshore Structures Vol-1 (OTH 90-322)Document297 pagesFluid Loading On Offshore Structures Vol-1 (OTH 90-322)Anonymous 7fIHDkX22pPas encore d'évaluation

- Water SupplyDocument27 pagesWater SupplyLnazerA.CecePas encore d'évaluation

- Machine Safety HandbookDocument78 pagesMachine Safety HandbookLâm ToànPas encore d'évaluation

- Minnesota Carbon-Free Energy Generation Standard, SF 4-1, Feb. 2, 2023Document26 pagesMinnesota Carbon-Free Energy Generation Standard, SF 4-1, Feb. 2, 2023Michael AchterlingPas encore d'évaluation

- Plant OptimizationDocument8 pagesPlant OptimizationNaveen RathaniPas encore d'évaluation

- QuaranTEAM Goodwill IndustriesDocument24 pagesQuaranTEAM Goodwill IndustriesAshmit ChaudharyPas encore d'évaluation

- Chapter 11Document35 pagesChapter 11sukhpalPas encore d'évaluation

- Part 3 Technology and Livelihood Education PDFDocument10 pagesPart 3 Technology and Livelihood Education PDFFernandoPas encore d'évaluation

- MV Switchgear Alfa12Document36 pagesMV Switchgear Alfa12ABDUL HASEEBPas encore d'évaluation

- Zain Ahmed Siddiqee Ce - E07 - 103Document17 pagesZain Ahmed Siddiqee Ce - E07 - 103zainsiddiqee80% (10)

- VW Lupo May00 PDFDocument4 pagesVW Lupo May00 PDFJohn CaruanaPas encore d'évaluation

- Natural Gas Prices and Charts - Data From QuandlDocument4 pagesNatural Gas Prices and Charts - Data From QuandlPrakarn KorkiatPas encore d'évaluation

- Plumbing Systems - CommissioningDocument4 pagesPlumbing Systems - CommissioningLouie MirandaPas encore d'évaluation

- Book of Abstracts ICM12Document430 pagesBook of Abstracts ICM12Teka KamPas encore d'évaluation

- Válvulas ConcentricasDocument1 pageVálvulas ConcentricasOdlanier José MendozaPas encore d'évaluation

- Wind Turbine Blade Geometry PDFDocument9 pagesWind Turbine Blade Geometry PDFchandruPas encore d'évaluation

- Chapter 16 Amino Acids, Proteins, and EnzymesDocument92 pagesChapter 16 Amino Acids, Proteins, and EnzymesDennis ZhouPas encore d'évaluation

- Build a TENS machine for pain reliefDocument11 pagesBuild a TENS machine for pain reliefnenad100% (1)

- Design of Battery-Super Capacitors Combination in Uninterruptible Power Supply (UPS)Document7 pagesDesign of Battery-Super Capacitors Combination in Uninterruptible Power Supply (UPS)Tyo WayPas encore d'évaluation

- 8W-80 Connector Pin-Outs and FunctionsDocument1 page8W-80 Connector Pin-Outs and FunctionsEduardo MacMasterPas encore d'évaluation

- Exploded Views and Parts ListDocument8 pagesExploded Views and Parts ListRichard CarvajalPas encore d'évaluation

- Stock Register StoreDocument1 218 pagesStock Register StoreSantanu Kumar SahuPas encore d'évaluation

- How Dew Point Reveals Air Moisture Better than Relative HumidityDocument2 pagesHow Dew Point Reveals Air Moisture Better than Relative HumiditySyed Fayaz AhmedPas encore d'évaluation

- Electrical Safety in Biomedical EquipmentDocument18 pagesElectrical Safety in Biomedical EquipmentlchirinoscautinhoPas encore d'évaluation

- The Zonal-Belt Hypothesis - A New Explanation of The Cause of The Ice Ages 1908Document410 pagesThe Zonal-Belt Hypothesis - A New Explanation of The Cause of The Ice Ages 1908dubilujPas encore d'évaluation

- MFS 75 115 Tohatsu ManualDocument89 pagesMFS 75 115 Tohatsu Manualabdulateefnsr100% (1)

- Engineering Design & Specifications of Cyclone Separator: Nelson Pynadathu, Paul Thomas, Arjun PDocument6 pagesEngineering Design & Specifications of Cyclone Separator: Nelson Pynadathu, Paul Thomas, Arjun PhosseinPas encore d'évaluation

- PistonDocument247 pagesPistonmeyyiti01Pas encore d'évaluation

- Extraction of Ethanol From CelluloseDocument20 pagesExtraction of Ethanol From CellulosePriyanka NagpurePas encore d'évaluation

- Petrobras N-2913Document14 pagesPetrobras N-2913dylkanPas encore d'évaluation