Académique Documents

Professionnel Documents

Culture Documents

Acid-Degradable Polymers For Drug Delivery (Review) PDF

Transféré par

georgiaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Acid-Degradable Polymers For Drug Delivery (Review) PDF

Transféré par

georgiaDroits d'auteur :

Formats disponibles

ChemComm

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

FEATURE ARTICLE

Cite this: Chem. Commun., 2013,

49, 2082

View Journal | View Issue

Acid-degradable polymers for drug delivery: a decade

of innovation

Sandra Binauld and Martina H. Stenzel*

Polymers that start degrading under acidic conditions are increasingly investigated as a pathway to

trigger the release of drugs once the drug carrier reached the slightly acidic tumour environment or

after the drug carrier has been taken up by cells, resulting in the localization of the polymer in the

Received 11th September 2012,

Accepted 7th December 2012

DOI: 10.1039/c2cc36589h

acidic endosomes and lysosomes. The advances in the design of acid-degradable polymers and drug

delivery systems have been summarized and discussed in this review article. Various acid-labile groups

such as acetals, orthoester, hydrazones, imines and cis-aconityl, that can undergo cleavage in slightly

acidic conditions, have been employed to create polymer architectures or polymerdrug conjugates that

www.rsc.org/chemcomm

can degrade under lysosomal and endosomal conditions, triggering the fast release of drugs or DNA.

Introduction

Polymers are a popular choice for the design of drug delivery

carriers. The use of polymer therapeutics has evolved into a

broad discipline, employing a wide range of architectures either

at the macroscale (gels and hydrogels) or nanoscale (polymer

drug conjugates, polymeric micelles, nanogels and cross-linked

particles, polyplexes for DNA delivery, etc.). Particularly, the

development of multifunctional nanoscale devices has drawn a

lot of attention. The versatility of modern synthetic chemistry

as well as recent developments of very ecient click reaction

enabled the careful design of polymer-based therapeutic agents

with engineered characteristics such as colloidal stability, tunable sizes with narrow distribution, protection of drugs during

circulation, and transportation to targeted organ or tissue.

In summary, controlled release of encapsulated therapeutics

is an active research field. A few strategies have been developed

including bioconjugation with cell-targeting biomolecules for

specific delivery and the use of stimuli-responsive polymers to

create intelligent polymer therapeutics.

Stimuli-responsive polymers are defined as polymers that

undergo relatively large and abrupt, physical or chemical

changes in response to small external changes in the environmental conditions. These stimuli could be classified as either

physical (temperature, electric or magnetic fields, mechanical

stress) or (bio)chemical (pH, ionic strength and chemical

agents) stimuli. The response of a polymer can be defined

in various ways, from a reversible change in their chain conformation or their degree of intermolecular association to more

Centre for Advanced Macromolecular Design, (CAMD), The University of

New South Wales, Sydney NSW 2052, Australia. E-mail: m.stenzel@unsw.edu.au

2082

Chem. Commun., 2013, 49, 2082--2102

dramatic alterations such as degradation by irreversible bond

breakage. Some systems have been developed to combine two

or more stimuli-responsive mechanisms into one polymer

system. This behaviour can be utilised for the preparation of

so-called smart drug delivery systems, which aim to mimic

biological response behaviour. Recent advances of stimuliresponsive polymers in bio-related applications have been

thoroughly reviewed elsewhere.13

Among the various existing stimuli-responsive systems,

pH-sensitive polymers have been widely studied for drug delivery

applications. Indeed, it has been shown that the environment

in tumour tissue is often 0.51.0 pH units lower than in normal

tissue.4 Moreover, a larger pH shift from 7.27.4 in the blood or

extracellular spaces to 4.06.5 in the various intracellular

compartments takes place during cellular uptake that can be

used for intracellular drug delivery.

These changes in the external pH can be exploited by

pH-responsive polymers which respond to pH changes with

an altered solubility, volume, configuration or conformation.

They can be divided in two categories: polymers with ionizable

groups in their backbone and those containing a degradable

linker. The first category includes polyelectrolytes containing

weak acids or bases like carboxylic acids, phosphoric acid and

amines, respectively, that will exhibit a change in the ionisation

state upon pH variation. This will lead to a reversible conformational change for the soluble polymers and a change in the

swelling behaviour for cross-linked systems. These systems

have already been thoroughly discussed,5,6 and are beyond

the scope of the present review. The second category is

composed of polymers containing an acid-degradable linkage.

The acidic conditions in tumour tissue, endosomes, and lysosomes can induce the cleavage of such systems. Coupling drugs

This journal is

The Royal Society of Chemistry 2013

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Feature Article

to suitable carriers through acid-sensitive bonds is one way of

ensuring the triggered release of the drug in an acidic environment. These acid-degradable systems have been quite popular

for the design of smart drug delivery devices in the past decade,

and surprisingly poorly reviewed except some reports on polymeric prodrugs79 or micellar systems.10,11 Moreover, the multitude of names or keywords coined for acid-degradable,

including acid-labile, acid-cleavable, acid-sensitive,

pH-dependant, makes them dicult to track in the literature.

The aim of this review is to highlight the dierent strategies

based on acid-degradable polymeric systems that have been

developed in the past decade and their application. Acidsensitive polymers have been utilized in various drug delivery

devices such as degradable linear polymers and hydrogels,

cross-linked particles, self-assembled particles, polymerdrug

conjugates, and polyplexes (Fig. 1). For each strategy, the

performances of various systems such as degradation time or

drug release will be compared.

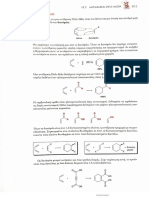

Common acid-degradable bonds

A range of chemical bonds are known to be instable in strong

acid or basic solution. This is the case for the various protective

groups commonly used in organic synthesis. However, only a

few of them show an enhanced degradation or hydrolysis in

the presence of slightly acidic media, while being stable at

neutral pH. This unique property, determined by the chemical

Sandra

Binauld

studied

materials science and polymer

chemistry at the National

Institute of Applied Sciences

of Lyon (INSA), a French

engineering school. She received

her PhD degree in 2009 from

the

University

of

Lyon

(France), after working with

Prof. E. Drockenmuller and

Prof. E. Fleury on the

elaboration of macromolecular

objects using Click Chemistry.

Sandra Binauld

In 2010, she moved to Australia

to work as a research associate at the Center for Advanced

Molecular Design (University of New South Wales, Sydney)

under the supervision of Prof. M. Stenzel, where she developed

smart drug delivery systems using RAFT polymerization. In 2012,

she joined Prof. B. Charleuxs group (C2P2, Lyon) as a casual

lecturer, and her current research focuses on the development of

nanomaterials using MADIX polymerization induced self-assembly

in aqueous media.

This journal is

The Royal Society of Chemistry 2013

ChemComm

structure of the bond, makes them candidates of choice for the

preparation of acid-degradable drug delivery systems. The acidsensitive linkers most commonly employed in the literature

include orthoester, acetal, hydrazone, imine, cis-aconytil and

trityl bonds. Their chemical structure and degradation products are given in Fig. 2. The orthoester bond is a functional

group containing three alkoxy groups attached to one carbon

atom that can be prepared by the reaction of nitriles with

alcohols under acid catalysis. They are readily hydrolyzed in

mild aqueous acid to form esters, and therefore usually used as

protecting groups for esters. The acetal bond is a molecule with

two single-bonded oxygen atoms attached to the same carbon

atom (or two carbon-bonded R groups in the case of ketal). In

an acidic solution, one oxygen of the acetal group is protonated,

which activates the neighbouring carbon. This facilitates the

attack of water, resulting in the cleavage of the acetal to the

appropriate aldehyde and alcohol. An imine is a functional

group containing a carbonnitrogen double bond, with the

nitrogen attached to a hydrogen atom or an organic group. If

this group is not a hydrogen atom, then the compound is more

stable and defined as a Schi base. They are obtained by

reaction of an aldehyde or ketone with a primary amine. When

an amine group is attached to the nitrogen, the imine is called

hydrazone. Hydrazones are usually formed by the reaction of

hydrazine on ketones or aldehydes. The cis-aconityl linker is a

derivate of natural aconitic acid that has a carboxylic acid (C-4)

in cis-position to a hydrolytic bond (C-1). This linker undergoes

Martina

Stenzel

studied

chemistry at the University of

Bayreuth, Germany, before

completing her PhD in 1999 at

the

Institute

of

Applied

Macromolecular

Chemistry,

University

of

Stuttgart,

Germany. She started working

as a DAAD postdoctoral fellow

at the University of New South

Wales

(UNSW),

Sydney,

Australia, where she currently

holds the position of full

Martina H. Stenzel

professor and ARC Future

Fellow. Her research interest encompasses the synthesis of

functional polymers with complex architectures such as

glycopolymers and other polymers for biomedical applications,

especially polymers with in-build metal complexes for the delivery

of metal-based anti-cancer drugs. Martina Stenzel has authored

more than 190 peer reviewed papers and 7 book chapters mainly

on RAFT polymerization. She is currently the Honorary Secretary

of the Royal Australian Chemical Institute and a member of the

Australian Research Council (ARC) college of experts. She is an

editor of the Australian Journal of Chemistry and also serves on

several editorial boards (Polymer, Progress in Polymer Science,

Macromolecules, Biomacromolecules, ACS MacroLetters). She

received a range of awards including the 2011 Le Fe`vre Memorial

Prize of the Australian Academy of Science.

Chem. Commun., 2013, 49, 2082--2102

2083

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

ChemComm

Fig. 1

Feature Article

Examples of acid-degradable systems for drug delivery.

processed into microparticles to branched and crosslinked

polymer with a focus on gel and crosslinked microparticles.

Linear bioerodible polymers and their use in

microparticles preparation

Fig. 2

Examples of acid-degradable bonds and their degradation products.

an intramolecular assisted C-4 acid-catalysed hydrolysis at the

C-1 bond, due to the proximity of the pendent carboxylic acid.

Degradable linear polymers and hydrogels

Biomaterial design often relies on the degradation of the

polymer to enable clearance of the material. In the following,

we will discuss polymers with incorporated acid-cleavable bonds.

The list ranges from simple linear polymers which have been

2084

Chem. Commun., 2013, 49, 2082--2102

Among the bioerodible linear polymers, polyorthoesters have

the longest history since they have been under investigation

since 1970. These polymers have already been extensively

reviewed by Heller et al.12,13 and will not be further discussed

in this article. An increasing interest has been shown in the

past few years for the design of linear polyacetals.1424 Heller

et al. first reported the synthesis of linear and cross-linked

polyacetal by condensation of polyols with divinyl ethers.14 This

reaction has been applied more recently by Tomlinson et al. to the

synthesis of water-soluble, biocompatible, amino-functionalized

polyacetals, suitable for drug conjugation (Fig. 3, 1).15 In vitro

studies showed that the polymers and their degradation products were nontoxic and the polyacetals showed no preferential

accumulation in the major organs. In the same group, Vicent

et al. used a similar system to incorporate a drug with a bishydroxyl functionality (non-steroidal oestrogen diethylstilboestrol

(DES)) into the polymer backbone (Fig. 3, 2).16 These bioresponsive DES-polyacetals tert-polymers are the first watersoluble anticancer polymeric drugs designed for acidic

pH-triggered release. Schacht et al. from Hellers group also

reported the synthesis of graft copolymers 3 comprised of a

polyacetal backbone with pendant poly(ethylene glycol) sidechains. These graft polymers were used to prepare a series of

thermogels with a lower critical solution temperature (LCST)

between 25 and 60 1C.17 Fine-tuning of the LCST was achieved

by carefully adjusting the hydrophilichydrophobic balance by

altering the PEG content. The LCST could then be targeted

towards the application, similar to PNIPAAm polymers.25 More

rapidly eroding thermogels were prepared by replacing the

polyacetal backbone with a poly(ortho ester) backbone (Fig. 3, 4).

This journal is

The Royal Society of Chemistry 2013

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Feature Article

Fig. 3

ChemComm

Linear polymers with degradable functional groups in the main chain.

Using a similar coupling reaction, Garripelli et al. reported the

synthesis of a novel thermo-sensitive multiblock copolymer 5,

which was obtained from a Pluronic triblock copolymer and

di-(ethylene glycol) divinyl ether.18 The aqueous solutions of

these polymers underwent gelation at body temperature, allowing

the release of FITCdextran (40 kDa) in a pH-dependent fashion.

In a dierent way, Jain et al. prepared poly(amidoamine)s by

the stepwise polyaddition of primary or secondary amines

to bis(acrylamide) monomers containing acid-degradable

acetaldehyde acetal and dimethyl ketal linkages (Fig. 3, 6).19

The molecular weights were rather low since the bis(acrylamide)

monomers degraded via hydrolysis of the acid-degradable functional group during polymerization. The rate of degradation was

influenced by the type of acetal structure used within the backbones (Fig. 3, 6).

Linear polyacetals have also been used by Murthys and

chets groups to obtain degradable microparticles for drug

Fre

delivery. Specifically, Heerman and Murthy formulated

dexamethasone-loaded polyketal nanoparticles containing poly(1,4-phenyleneacetone dimethyleneketal) (PPADK) (Fig. 4, 7).21

In the same group, Khaja et al. used the acyclic diene metathesis

(ADMET) polymerization to obtain a variety of polyacetals and

polyketals which could be processed into microparticles

(Fig. 4, 8).22 A library of polyurethanes and polyureas-based

polyacetals (Fig. 4, 9) has been prepared by Frechets group by

step-growth polymerization of bis(p-nitrophenyl carbamate/

carbonate) or diisocyanate monomers with an acid-degradable,

ketal-containing diamine.23 Interestingly, degradation studies

showed that the hydrolysis kinetics is closely related to the

hydrophobicity of the starting polymer. To further explore these

acid-degradable materials, microparticles were prepared from

polymer 10 to evaluate their potential as carriers for proteinbased vaccines. It has been demonstrated that particles made

This journal is

The Royal Society of Chemistry 2013

Fig. 4 Linear acid

microparticles.

degradable polymer used for the

preparation of

from polymer 10 are more eective in generating an immune

response compared to free protein and analogous particles

prepared from a slower degrading polymer.24

Even though the large majority of studies on linear aciddegradable polymers were based on polyacetal or polyorthoester

backbones, a few examples explored other types of acid-degradable

bonds. For instance, Zhou et al. synthesized pH-sensitive

multifunctional polyurethane micelle drug carriers based on

macrodiol containing acid-cleavable hydrazone linkers.26,27

Chem. Commun., 2013, 49, 2082--2102

2085

View Article Online

ChemComm

Also linear polyhydrazone28 and water soluble poly(cis-aconityl)29

have barely been investigated.

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Hydrogels and branched polymers

Hydrogels are usually formed from a polymer chain network,

creating a colloidal gel containing often more than 99% water.

They combine the advantages of high absorbency and permeability. The medical and pharmaceutical uses of hydrogels

include wound dressing, skin grafts, oxygen-permeable contact

lenses and delivery of drugs. For the latter application, the

synthesis of biodegradable materials, which disintegrate into

non-toxic degradation products, is highly desirable. Once again

the development of acetal or ketal-based polymer networks has

led the way. Several studies have focused on the development of

cyclic acetal biomaterials, that degrade into non-acidic products, terminated with diol and carbonyl end groups.30 More

recently, Sui et al. prepared an acetal-based polymer network by

combining reversible additionfragmentation chain-transfer

polymerization (RAFT) with addition reactions by reacting the

hydroxyl pendant groups of the polymer with 1,4-cyclohexanedimethanol divinyl ether.31 Chatterjee and Ramakrishna

reported the synthesis of hyperbranched polyacetals via a melt

transacetalization polymerization process of an AB2 monomer

bearing a single hydroxyl group and a dialkyl acetal.32 The

bulk degradation rates of these hyperbranched polyacetals

under mildly acidic pH (pH = 4) revealed the strong dependence

of the degradation rates on the nature of peripheral alkyl

substituents.

The chemistry of hydrazone conjugation via aldehyde

hydrazide cross-linking is also of great interest for the preparation of hydrogels. This is a straightforward and high yielding

reaction, which is well suited for drug design and delivery due

to the relevant pH range in which these materials degrade.

Particularly, this reaction can be performed in vivo, allowing the

preparation of injectable hydrogels, and does not have any

adverse tissue eects.33,34 These novel biomaterials can thus be

employed for controlled release of therapeutic agents at wound

sites. An array of studies has focused on the preparation of

hyaluronic acid hydrogels via hydrazone cross-linking.3542 This

cross-linking strategy has been chosen because the modification of HA to hydrazide and aldehyde functionalities is straightforward, and the reaction is very ecient, with gelation usually

occurring within a minute after mixing of the precursors. It has

been proven that the hydrazone hydrogels remain more stable

at physiological pH compared to their imine analogues.35

With the help of microfluidic technology, carbohydrate

hydrazone-cross-linked gels can also be obtained at the microscale for the design of smart microgel particles with sizes

ranging between E40 and 100 mm.43 Moreover, injectable

hydrogels based on a mixture of natural and thermo-sensitive

synthetic polymers were recently obtained by Patenaude and

Hoare.44 A series of synthetic oligomers of poly(N-isopropylacrylamide) (PNIPAM) and carbohydrate polymers (including

hyaluronic acid, carboxymethyl cellulose, dextran, and methylcellulose) were functionalized with hydrazide or aldehyde functional groups and mixed to create hydrazone-cross-linked hydrogels,

2086

Chem. Commun., 2013, 49, 2082--2102

Feature Article

which gelled in situ. Based on the same idea, analogues of

thermoresponsive PNIPAM hydrogels have been designed by

mixing aldehyde and hydrazide-functionalized PNIPAM oligomers. The hydrogels exhibit the same thermal swelling

deswelling responses as conventional PNIPAM hydrogels, but

can be degraded back into the reactive polymer gel precursors

via an acid-catalyzed hydrolysis process.45

However, only a few reports deal with the use of these aciddegradable hydrogels as drug carriers. Tian et al. developed a

new antibody (IgG) releasing system by covalently attaching IgG

to the biodegradable hyaluronic acid hydrogel using the hydrolytically unstable hydrazone linkage with the aim to deliver the

antibody to the injured brain.38 In pH 5 and 6 buer solution,

most of antibody (6080%) was released from the hydrogel

within 8 and 70 h, respectively, whereas the release was much

slower in pH 7.4 buer solution (over 400 h).

Cross-linked particles via copolymerization

with acid-degradable divinyl monomers or

via post-crosslinking

An omnipresent challenge in the field of drug delivery is the

development of ecient spherical delivery vehicles. Their ideal

characteristics would include a small tuneable size, a high

loading capacity of the cargo, good biocompatibility and a long

circulation time. Regarding this last aspect, it is important that

delivery vehicles can be responsive to their local environment

in order to retain their cargo until they reach their target. The

introduction of a stimuli-responsive cross-linker during the

preparation of the particles can trigger the disintegration of

the drug carrier and the release of the drug once the particle

reached its target.

The development of cross-linked microparticles using an

acetal crosslinker has been introduced and thoroughly studied

chet group since 2002. Following this trend, many

by the Fre

studies have focused on the design of acid-degradable nanogels, nanocapsules and cross-linked micelles. As a result, a

variety of cross-linkers with various functionalities and degradation profiles has been synthesized. The eciency of these

degradable systems in terms of drug release has been summarized in Table 1 and the corresponding crosslinkers are

displayed in Fig. 5 and 6.

Table 1

Hydrolysis half-life of acetal cross-linkers 1120 (Fig. 5 and 6)

Half-life time

Cross-linker

Ref.

pH 5.5 (min)

pH 7.4 (h)

11a

11b

12

13

14

15

16

17

18

19

20

46

47

48

49

50

51

51

51

23

52

53

5.5

5.5

1.6

n.a.

60

20

30

30

60

n.a.

14

24

24

6.8

n.a.

>20

>20

>20

>20

25

n.a.

29

This journal is

The Royal Society of Chemistry 2013

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Feature Article

Fig. 5

Fig. 6

ChemComm

Acetal cross-linkers used for the synthesis of acid-cleavable particles by inverse-emulsion polymerisation.

Acetal cross-linkers used for micelles stabilization.

Microgels/microparticles by inverse microemulsion

polymerization

The first example of acetal cross-linked, protein loaded hydrogels

microparticles, prepared by inverse microemulsion polymerizachet group in 2002.46 It involved

tion, has been described by the Fre

a benzaldehyde acetal cross-linker, which had the added advantage that the acid lability can be manipulated by introducing

substituents in the para position of the phenyl group.

It was therefore possible to engineer the hydrolysis kinetics of

these gels to suit the application. Therefore, the bisacrylamide

acetal cross-linker (11a) with a p-methoxy substituent was chosen

as the acid degradable linkage to ensure that the resulting

microgels hydrolyzed rapidly within the pH 5.0 environment that

is encountered in phagolysosomes. Indeed, hydrolysis was proven

to be extremely rapid at pH 5.0, with a half-life of 5.5 min, whereas

the system remained stable at pH 7.4, with a half-life of 24 h.

A more hydrophilic version of this cross-linker, containing a

hydrophilic triglyme moiety (11b), was synthesized by the same

group, resulting in similar degradation times.47 The triethylene

glycol pendant group incorporated in 11b increased the water

solubility, making it much more hydrophilic and therefore

more suitable for use in inverse emulsion polymerization than

This journal is

The Royal Society of Chemistry 2013

its para-methoxy substituted analogue, 11a. It was demonstrated

that the rate of protein release from these microgels was

pH-sensitive, with 80% release of encapsulated ovalbumin observed

in 6 h at pH 5.0, but only 10% at pH 7.4. This system was then used

to encapsulate plasmid DNA.54 Retention of the DNA payload at

physiological pH was achieved while the cargo was completely

released under acidic conditions at lysosomal pH. By trapping the

plasmid DNA within the cross-linked microparticle, enzymatic

degradation was prevented when exposed to serum nucleases.

The system was then optimised and evaluated by in vivo experiments. The ability of the protein-loaded particles to provide immunity against tumours in mice was investigated using the ovalbumin

model.55 The same cross-linker was also used to prepare aciddegradable cationic nanoparticles as carriers of a model antigenovalbumin for protein-based vaccine development.56

In 2004, Kwon et al. described the use of new functional

aliphatic monomers and cross-linkers for the preparation of

degradable microparticles with improved properties including

increased biocompatibility and faster hydrolysis.48 Since the

aromatic aldehyde liberated after hydrolysis of cross-linker 11

might react with intracellular proteins, they developed the alternative acid-labile cross-linker 12 that produces acetone as degradation product, a relatively nontoxic metabolic intermediate of

fatty acid oxidization. In addition, an acetal amine-functionalized

acrylate monomer was also designed for its ability to generate

small molecules upon acid hydrolysis. Cross-linker 12 was

hydrolyzed approximately 250 times faster at pH 5.0 than at

the physiological pH of 7.4 i.e. three times faster than the

benzylidene acetal 11. The pH-sensitive polyacrylamide particles were furthermore functionalized with the cell-penetrating

peptide polyarginine to promote cellular uptake.57

Meanwhile, Shi et al. used crosslinker 13 to obtain acid

labile poly(N-vinylformamide) (PNVF) nanogels by inverse

Chem. Commun., 2013, 49, 2082--2102

2087

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

ChemComm

microemulsion polymerization.58 Acid-labile PNVF nanogels showed

increased stability at neutral pH (pH 7.4; t1/2 > 56 h) compared to

rapid dissolution observed at lower pH (pH 4.7; t1/2 B 10 min).

Using dispersion polymerization and RAFT polymerization, Chan

et al. employed a new bisacrylate acetal cross-linker 14 to create

acid-cleavable coreshell nanoparticles for the delivery of hydrophobic drugs.50 The particles were cleaved in a pH dependent

manner similar to the acid-labile hydrolysis behaviour of the

cross-linker itself. The same group also investigated the degradation of a range of bisacrylate acetal cross-linkers (1417) of

dierent polarities, which were used to prepare PHEMA nanogels

particles.51 Comparison of the hydrolysis half-life of the crosslinkers 14 and 16 leads to the conclusion that the presence of the

hydroxyl group as a p-substituent group on the benzene ring

makes the crosslinker more susceptible to acid-catalyzed hydrolysis compared to the cross-linker with the methoxy group.

Influence of the polarity on the degradation was also discussed.

Nanocapsules

chets group prepared

More recently, Broaders et al. from Fre

acid-degradable microcapsules via interfacial polymerization.

The polyamide was formed by the reaction of acid chlorides

with ketal-containing diamine 18 along the wateroil interface.

Rapid degradation into biocompatible products and complete

release of the encapsulated material was triggered upon exposure to an acidic environment.59 In vitro studies showed that

equivalent non-degradable capsules do not lead to significant

cell death regardless of the toxicity of the encapsulant, whereas

acid-degradable capsules lead to high cytotoxicity when loaded

with paclitaxel. The release of the drug, thus the cytotoxic eect,

was only made possible by the ecient uptake of the nanocapsules by cells. Shi and Berkland reported the synthesis of acidlabile poly(N-vinylformamide) (PNVF) nanocapsules by free radical

polymerization of N-vinylformamide in the presence of crosslinker 13 on the surface of silica nanoparticles.60 The formamide

side group of PNVF was then hydrolyzed by extended exposure to

sodium hydroxide to produce polyvinylamine (PVAm) micro- and

nanocapsules. Both capsule types underwent an increasing dissolution rate as the pH decreased. The extent of cross-linking was

observed to influence the degradation rate of the capsules. For

example, doubling the molar content of crosslinker from 6.5% to

13.2% resulted in a 3-fold increase in capsule half-life at pH 5.0

and produced more gradual degradation kinetics.

Cross-linked micelles

Another popular drug delivery technique involves the use of

micellar systems, which are obtained by self-assembly of amphiphilic copolymers. It is well-accepted that the micellar carriers

potentially allow passive targeting of drugs to tumours via

enhanced permeation and retention eect. However, the one

major drawback is the premature dissociation of these structures

in in vivo conditions due to the high dilution upon exposure to

large volumes of body fluids. To overcome this problem, micelles

are often stabilized by crosslinking. Crosslinking strategies include

core or shell cross-linking, but also crosslinking on the interface

between both blocks is known.61 The use of a stimuli-sensitive

cross-linker is particularly interesting since the disassembly of the

2088

Chem. Commun., 2013, 49, 2082--2102

Feature Article

micelles and subsequent release of the drug can be triggered by

external stimuli, such as pH. Several studies reported the synthesis

of core-cross-linked micelles using an acetal cross-linker in conjunction with RAFT polymerisation.62 Two approaches were investigated: a radical crosslinking process where the acid-degradable

divinyl monomer was copolymerised inside the core of the micelle

to stabilize the structure63 or a post-crosslinking approach, where

the integrity of the micelle was enhanced by employing a difunctional crosslinker.

Zhang et al. used RAFT polymerization to chain-extend a

thermoresponsive block copolymer, poly(acryloyl glucosamine)block-poly(N-isopropylacrylamide), with the commercial orthoestertype cross-linking agent 21 after the block copolymer has been

self-assembled into micelles.64 Chan et al. used a similar approach

and polymerized an acid-cleavable diacrylate cross-linker 14 inside

the core region of the micelles, leading to the chain extension of

the living RAFT end groups. The core cross-linking process was

found to have a minor eect on the original size of the micelle and

the core-segment polarity.65 The same technique was employed by

Bhuchar et al. to generate core cross-linked micelles in a one-pot

process by RAFT polymerization in the presence of a shorter

derivative of the di-methacrylate acetal cross-linker.66

An alternative approach is the stabilisation of micelles using an

acid-degradable difunctional crosslinker. Duong et al. eciently

reacted diamino cross-linker 18 inside a pentafluorophenyl-bearing

micelle core, which was formed by self-assembly of PEB-b-P(vinyl

benzylchloride-co-pentafluorophenyl acrylate) diblock copolymer.67

The same cross-linker was used by Huynh et al. in a reaction

between pendant activated esters at the nexus between micelle core

and shell. The micelle was obtained from a triblock copolymer

of poly(oligo(ethylene glycol)methylether methacrylate)-b-poly(N-hydroxysuccinic methacrylate)-b-poly(1,1-di-tert-butyl-3-(2(methacryloyloxy)ethyl) butane-1,1,3-tricarboxylate), which was

designed for the improved delivery of cisplatin. The acid

degradable crosslinker was directly compared to a non-degradable

crosslinker in their cytotoxicity against cancer cell lines, showing

that the degradable micelle had a much faster mode of action.68

Shell cross-linking is an alternative possibility to enhance micellar

stability against micelle-destabilizing conditions, but it can also

delay the drug release at extracellular pH values. Lee et al. and

Li et al. used diamino cross-linkers 18 and 20 to perform shell

cross-linking of acid-bearing block copolymers.53,69 Tappingmode atomic force microscopy (AFM) was applied as an interesting alternative technology to demonstrate the disassembly of

the acid-labile cross-linked knedel-like (SCK) nanoparticles.53

Finally, cross-linking of some alkynylated micelles was readily

achieved by the alkyneazide click reaction using the azidefunctionalized cross-linker 19.52

pH-induced transformation of

self-assembled systems

Destabilizing micellar systems

One approach to the development of acid-sensitive drug

delivery systems has been to incorporate titratable groups such

as amines and carboxylic acids into the copolymer backbone,

This journal is

The Royal Society of Chemistry 2013

View Article Online

Feature Article

Table 2

Composition and release eciency of destabilizing micellar systems

Structure/

ref.

Shell

Core

Acid-sensitive group

Drug

22

PEG

Poly(aspartic acid)

Nile red

n.a.

60

2372

PEGdendritic

polyester

PEG

PNIPAM

Hydrophobic

acetals

P(tNEA)

P(OPD-co-CL)

Trimethoxybenzylidene

acetal

Trimethoxybenzylidene

acetal

Cyclic orthoester

Hydrazone

DOX

12

92

80

Nile red

5-Fu

5

9/20

5

48

100

88

0

76

73

24

2579

a

Time

(h)

Releasea (%)

Drug

loading

10

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

ChemComm

pH 5

pH 7.4

Values estimated from in vitro release profiles at both pH.

thus altering the solubility of the polymer upon protonation,

resulting in the disruption of the micelle. This approach has

already been reviewed elsewhere and will not be discussed in

the present article.5,70 Another way to induce a pH-dependant

drug release is to incorporate acid-degradable linkages into the

copolymer, causing a structural change of such magnitude that

micellar integrity is lost (Table 2). This approach, based on the

attachment of hydrophobic groups to one block of an amphiphilic copolymer via an acid sensitive linkage, was first proposed

chet and Gillies, who developed the acid sensitive copolymer

by Fre

micelles based on the PEG-b-P(aspartic acid) copolymer 22

(Fig. 7).10 After hydrolysis of the acetal, the hydrophobic block

takes on hydrophilic properties, thus destabilizing the micelle

and enabling fast release of the drug. In this study, cyclic

benzylidene acetals were used as the acid-sensitive linkage,

Fig. 7

because they combine a hydrophobic aromatic ring that will

contribute to micelle formation with a high rate of hydrolysis at

slightly acidic pH. The fast rate of hydrolysis was achieved by

the presence of electron-donating methoxy groups in the ortho

and para positions. Hydrolysis of the acetal results in a more

polar diol moiety, leading to disruption of the micellar assembly and the triggered release of the micellar content. The same

team further developed this system using a similar concept.

PEO with a dendritic end-functionality was functionalized at

the periphery with hydrophobic groups using acid-sensitive

acetal linkages (Fig. 7, 23).71 Upon hydrolysis and the loss of

the hydrophobic groups, the core-forming block becomes

hydrophilic, thus destabilizing the micelle and enabling escape

of the drug from the micelles. This system was tested for selective

release of DOX at acidic pH.72 Based on the same approach,

Structures of copolymers forming destabilizing micellar systems.

This journal is

The Royal Society of Chemistry 2013

Chem. Commun., 2013, 49, 2082--2102

2089

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

ChemComm

Feature Article

Huang et al. chose to use poly(acrylamide) with pendent

orthoester as hydrophobic block. The orthoester-containing

monomer, trans-N-(2-ethoxy-1,3-dioxan-5-yl)acrylamide (tNEA),

was used to obtain a block copolymer by ATRP that is both

pH-sensitive and thermoresponsive (Fig. 7, 24).73 Upon heating

above the critical aggregation temperature, the polymer underwent a phase transition and formed polymeric micelles with PEG

as the shell and PtNEA block as the core. Dissociation of the

micelles and the subsequent release of Nile Red were induced by

the acid-triggered hydrolysis of the orthoester groups. The same

group investigated other poly(meth)acrylamide derivatives with

pendent six-member cyclic orthoester groups, varying the alkyl

substitutes and the orthoester stereochemical structures.7476

Both thermo-sensitive properties and acid-triggered hydrolysis

behaviours of the polymers were found to be dependent on the

polymer structures. The combination of such acid-sensitive and

thermoresponsive properties was also investigated by other

research groups.77,78 A dierent strategy was developed by He

et al., who grafted thermoresponsive PNIPAM chains to a poly(2-oxepane-1,5-dione-co-e-caprolactone) (P(OPD-co-CL, 25)) via an

acid-sensitive hydrazone linker. As a result, dual-responsive

coreshell micelles with a PNIPAM shell were formed.79 The

graft polymeric micelles exhibited thermo-triggered decelerated

release at pH 7.4, and pH-triggered accelerated release at 25 1C.

An interesting approach was recently presented by Deng et al.

Polyvinylalcohol (PVA) was modified with PEG using an amide

functionality and with adamantane (Ad) pendant groups using a

cyclic acetal linker.80 Acid-catalyzed cleavage of those acetallinked Ad groups from the polymer results in destabilization of

the polymer micelles and release of its hydrophobic cargo.

Table 3

A very dierent type of crosslinker was recently employed to

cause the transition of liposomes to inverted micelles. Liposomes, build from amphiphilic molecules with acid-labile

vinylether linkers, were shedding their PEG layer in acidic

conditions resulting in an accelerated drug release.81

pH-responsive swelling of particles

The total loss of micellar integrity is only one way to trigger the

drug release. The introduction of acid-sensitive groups into

nanoparticles can lead to swelling without complete disintegration of the structure. A key design feature of these nanoparticles

is the hydrophobic to hydrophilic transformation upon exposure to a mildly acidic environment with subsequent swelling.

This phenomenon can be observed upon increasing the hydrophilicity of one part of the copolymer. This swelling usually

allows the triggered release of the nanoparticles payload

by enabling faster diusion (Table 3). Chen et al. exploited

chets cyclic acetal to design pH-responsive biodegradable

Fre

micelles by copolymerizing cyclic aliphatic carbonate monomers with PEG-OH using ROP (Fig. 8, 26).82 The hydrolysis of

the acetal turned the hydrophobic polycarbonate into a more

hydrophilic structure, resulting in significant swelling of the

micelle. Fine-tuning the length of the PEG hydrophilic block

of the same copolymer system also led to the formation of

polymersomes.83 In both cases, the micellar structures were

maintained even after complete acetal hydrolysis, which was

assigned to the fact that the hydrophilic polycarbonate is not

fully water soluble. Nonetheless, the systems were successful

in releasing the drugs rapidly in response to mildly acidic

pH (Table 3). A similar behaviour was observed by Lu et al.

Composition and release eciency of swelling micelles and particles

Micelle size (nm)

System

Composition

Acid-sensitive group

pH 5

pH 7.4

Drug

Drug

loading (wt%)

26

Micelles

PEGpolycarbonate

1000

150

2683

Polymersomes

PEGpolycarbonate

1000

120

2784

2885

Micelles

cd-Particles

PDM-co-HEA

Homopolymer

Trimethoxybenzylidene

acetal

Trimethoxybenzylidene

acetal

Cyclic acetal

Trimethoxybenzylidene

acetal

800

900

167

100

PTX

DOX

PTX

DOX

Nile red

PTX

3/13

3/12

3/7

2/4

n.a.

1

Ref.

82

Releasea (%)

Time (h)

pH 5

pH 7.4

48

68

89

56

56

68

90

42

44

31

37

10

1

48

6

24

Values estimated from in vitro release profiles at both pH.

Fig. 8

2090

Structures of copolymers forming swelling particles at acidic pH.

Chem. Commun., 2013, 49, 2082--2102

This journal is

The Royal Society of Chemistry 2013

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Feature Article

Their amphiphilic pH-sensitive copolymer poly(PDM-co-HEA)

(Fig. 8, 27) self-assembles into nanoparticles, which were able to

increase in size from nano-scale to almost micro-scale in acidic

environment due to the hydrolysis of the acid-labile acetals.84 Using

a dierent approach, Griset et al. reported the synthesis of expansible nanoparticles, which were prepared using a miniemulsion

polymerization technique. This approach combines high-energy

emulsification and free radical photopolymerization of a trimethoxybenzilidene acrylate monomer.85 The particles based on polymer 28

(Fig. 8) were cross-linked to be able to transform into a hydrophilic

nanogel structure at pH 5. The release of paclitaxel from the loaded

expansible nanoparticle was found to be pH dependent and related

to the hydrophobic to hydrophilic transformation.

Switching the solubility of dextrane particles

An acid-responsive biodegradable material was developed by

chet and coworkers based on acetal-derivatized dextran.86,87

Fre

Nanoparticles obtained from this material can be used as

triggered drug delivery systems thanks to its solubility switching

mechanism. Indeed, masking the hydroxyl groups of dextran as

acetals not only provides a hydrophobic material that can be

easily processed using various emulsion techniques, but also

provides a mechanism for introducing pH-sensitivity. Under

mildly acidic aqueous conditions, the pendant acetal groups

can hydrolyze, allowing a complete dissolution of the dextran

nanoparticles and their subsequent degradation (Fig. 9). Full

dissolution of the particles was observed after 24 h at pH 5,

whereas no degradation was observed at pH 7. This pH-dependent

degradation of Ac-DEX particles is further reflected in the

release profile of a model payload. Further studies on this system

demonstrated its eciency for the delivery of plasmid-DNA

ChemComm

and Si-RNA.88,89 More recently, the synthesis of ethoxy acetal

derivatized acetalated dextran has been reported, which presents the advantage of degrading into non-toxic products such

as ethanol, acetone, and dextran.90 Like Ac-DEX, Ace-DEX

microparticles have tunable degradation rates at pH 5 (intracellular) that can range from hours to several days by varying

the reaction time. These polymers could not only be used

to deliver traditional anti-cancer drugs but also hydrophobic

silver carbene complexes, which have strong anti-bacterial

properties.91

Polymerdrug conjugates

Besides encapsulation, another way to improve drug delivery is

by covalently attaching the drug to a macromolecular carrier.

Indeed, high molecular weight molecules and nano-sized

particles accumulate in solid tumours at much higher concentrations than in normal tissues or organs due to the Enhanced

Permeation and Retention (EPR) eect. Obviously, the stability

of the drugpolymer linkage is crucial. Based on the stability of

this bond, polymer conjugates may be classified into two broad

categories: permanent conjugates and prodrugs that usually

require the transformation of the prodrug to the drug within

the body to allow therapeutic action. Hence, the system should

be able to release the drug at the target site by using appropriate stimuli-responsive linkers. The literature on the release

of the drug from polymeric prodrugs by cleaving various

chemical linkages (esters, carbonates, carbamates, CN linkage,

and amides) has already been reviewed.92 Systems containing

acid-labile linkers, able to release the drug at slightly acidic pH,

have been quite popular for the design of intelligent carriers of

various architectures. Out of all acid-sensitive bonds, the hydrazone bond formed between the C13 carbonyl group of anthracyclines (i.e. Doxorubicin (Dox), daunomycin (Dau)) and polymer

hydrazides or the amide bond of a cis-aconityl residue containing

spacer is the most commonly used type for the preparation of

polymerdrug conjugates.

Linear polymerprotein conjugates

Fig. 9

Structure of dextran and its acetal-derivatives.

This journal is

The Royal Society of Chemistry 2013

The concept of macromolecular prodrugs, such as water

soluble polymerdrug conjugates, has been introduced by

Ringsdorf 30 years ago,93 and has been studied by many groups

since then. The most popular acid-sensitive system in that

category is probably the poly(N-(2-hydroxypropyl) methacrylamide)

(PHPMA)Doxorubicin (DOX) conjugate, formed through a

hydrolytically cleavable hydrazone bond with the keto group

of DOX in the C-13 position. Such graft polymer systems have

been extensively studied by Ulbrich and co-workers,8,94 and

have been proven to be ecient for therapeutic applications such

as chemotherapy and radiotherapy.95 The first example of HPMA

copolymers containing doxorubicin bound via pH-sensitive

linkage has been reported by Etrych et al. in 2001.96 While

the hydrazone bond is relatively stable at neutral pH, corresponding to the environment of the blood, the drug is released

under mildly acid conditions, such as in endosomes of tumour

cells, with half-lives in the order of hours. Based on this

approach, various PHPMA conjugates diering in the length

Chem. Commun., 2013, 49, 2082--2102

2091

View Article Online

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

ChemComm

Fig. 10

pHPMA hydrazide copolymer and keto-drugs commonly used for conjugation.

and structure of their spacer were studied, highlighting the

subtle relationship between the spacer structure and the rate of

DOX release.97 In vitro and in vivo studies on such systems

confirmed that this novel class of anticancer therapeutics

exhibits better pharmacokinetic and pharmacodynamic profiles and less side-toxicity in comparison with low molecular

weight drugs. More importantly, the polymeric conjugates

trigger an onset of specific anti-tumour immune response

and a profound therapeutic eect.98100 The HPMA grafted

copolymers have been more recently used in combination with

other therapeutics such as the anti-inflammatory and antiproliferative drug dexamethasone (DEX),101,102 as well as

the anticancer drugs paclitaxel (PTX), docetaxel (DTX),103 and

3-(9-acridinylamino)-5-hydroxymethylaniline (AHMA).104 In order

to obtain a hydrazone linkage, a ketone functionality needs to

be introduced on those drugs by esterification with levulinic

acid (LEV) or 4-(2-oxopropyl)benzoic acid (OPB) (Fig. 10), or by

selective acylation with thiazolidine-2-thione-activated carboxylic

acids in the case of AHMA. Table 4 sums up some drug release

experiments carried out by Ulbrich and co-workers for various

PHPMAdrug conjugates. Some studies still focus on the improvement of the PHPMADOX system by adjusting the molecular

weight, for instance by designing a high molecular weight graft

copolymer for enhanced passive tumour targeting,105 or by studying

the eect of narrow molecular weight distributions and

2092

Feature Article

Chem. Commun., 2013, 49, 2082--2102

well-defined molecular structures using RAFT polymerisation.106

Also, a thiol coupling strategy has been investigated for coupling

unmodified proteins/peptides lacking aldehyde/ketone functionality, or other thiol-containing molecules, to hydrazidederivatized PHPMA using heterobifunctional cross-linkers.107

Other candidates for the design of polymeric doxorubicin conjugates coupled via hydrazone functionality include poly(ethylene

oxide)108,109 and poly(methacryloyloxyethyl phosphorylcholine)

(polyMPC)110 as the main polymer.

Self-assembled systems

Although a substantial body of work is based on linear

copolymers, polymeric prodrugs can also be based on selfassembled micellar systems composed of amphiphilic block

copolymers. Indeed, in order to use polymeric micelles as drug

carriers, the loaded drug must be hydrophobic enough to

partition into the hydrophobic core of polymeric micelles.

The moderately water-soluble nature of some anticancer drugs

such as doxorubicin makes it dicult to physically load the

drug within the micelles in a sucient amount. This obstacle

can be overcome by conjugating the drug to the terminal end of

a hydrophobic polymer block. Acid-cleavable linkages, such as

hydrazone and cis-aconityl bonds, were first used for the

chemical conjugation of doxorubicin on a diblock copolymer of

polyethylene glycol-b-poly(L-lactic acid) by Yoo et al. (Fig. 11a).111

This journal is

The Royal Society of Chemistry 2013

View Article Online

Feature Article

Table 4

ChemComm

Examples of drug release from various PHPMAdrug conjugates

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Releasea (%)

Ref.

Linker

Spacer (X)

Drug

Drug loading (wt%)

Mn PHPMA (g mol 1)

Time (h)

pH 5

pH 7.4

96

Hydrazone

DOX

Hydrazone

Hydrazone

97

Hydrazone

102

101

Hydrazone

Hydrazone

Gly

Gly-Gly

Gly-Phe-Leu-Gly

b-Ala

Aminobenzoic acid

Aminohexanoic acid

Aminohexanoic acid

Aminohexanoic acid

99

104

cis-Aconityl

Hydrazone

Gly-Phe-Leu-Gly

(Oxohexyl)methacrylamide

9.5

10.5

10.2

7.6

8.2

7.9

9.5

10.5

6.8

6.8

4.7

2.3

5

6.6

4.4

6.3

25 700

19 600

38 900

33 500

34 200

15 800

25 700

21 100

25 600

38 400

35 700

30 000

41 000

56 000

38 800

21 500

48

106

103

Gly-Gly

Gly-Phe-Leu-Gly

Aminohexanoic acid

Aminohexanoic acid

85

75

80

90

80

85

85

75

71

92

96

93

90

86

75

98

10

5

3

38

5

11

10

6

7

16

5

22

42

50

3

8

DOX

PTXLEV

DTXLEV

DOX

DEXOPB

DEXLEV

DEXOPB

DOX

AHMA

9

24

48

6

24

48

24

Values estimated from in vitro release profiles at both pH.

The doxorubicin conjugated micelles were about 89 nm in diameter

and their critical micelle concentration was 1.3 mg ml 1.

Moreover, doxorubicin micelles showed more cytotoxicity

against cancer cells than free doxorubicin. This strategy has

also been used and thoroughly studied by Kataoka and co-workers

with the design of pH-sensitive polymeric micelles based on

Fig. 11

poly(ethylene glycol)poly(aspartate hydrazide) [PEGp(Asp-Hyd)]

block copolymers, synthesized by ring-opening polymerization of

b-benzyl-L-aspartate N-carboxy-anhydride (BLANCA) from an

amino-terminated linear PEG chain (Fig. 11b).112 Indeed, Bae

and co-workers applied this system to the delivery of various

anticancer drugs (Table 5).113118 Influence of various parameters

Structure of block-copolymerdrug conjugates prior to micellar self-assembly.

This journal is

The Royal Society of Chemistry 2013

Chem. Commun., 2013, 49, 2082--2102

2093

View Article Online

ChemComm

Table 5

Feature Article

Composition and release eciency of PEGP(Asp)-based micelles (Fig. 11b)

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Releasea (%)

Ref.

Spacer

PEGPAsp

Drug

Drug loading (wt%)

Micelle diameter (nm)

Time (h)

pH 5

pH 7.4

113

114

1237

1238

67.6%/asp

>31 wt%

65

o200

24

24

115

1240

Gly

125

1215

1235

125

1215

1235

125

1215

1235

1235

533

1235

42

137

85

44

45

40

11

25

43

86

62

44

38

38

259

24

116

ADR

DOX

GDMLEV

PTXLEV

PTXOPB

1 : 1 co-assembly

DOX

25

60

81

57.6

0

44.9

40

57

37

60

65

o30

78

45

45

45

55

58

o5

20

78

29.2

0

34

30

44

17

36

30

o30

39

10

38

28

40

49

Abz

117

118

a

Ester only

4-Acetylbutyric acid

6-Oxoheptanoic acid

7-Oxooctanoic acid

DEX

3PO

37.50%

87.50%

13

2.8

10.4

31.6

4.1

10.9

11.4

8.7

4.6

5.6

4.5

2.08

2.21

48

24

Values estimated from in vitro release profiles at both pH.

such as the poly(aspartate) block length and the nature of the linker

on the micelles size and release profile was investigated. It appears

that the drug loading was highly depending on the nature of the

drug and the linker. Moreover, the release time of those micellar

systems was overall slower than for the graft copolymers systems

(Table 5), and in general the dierences in release rate between

pH 5.5 and 7.4 was less noticeable. This can be explained by the

presence of the hydrophilic shell that protects the hydrazone linker

from the external media. Particularly, the micellar system designed

for the delivery of the glycolytic enzyme inhibitor, 3-(3-pyridinyl)-1(4-pyridinyl)-2-propen-1-one (3PO), showed only a small dierence

in the release profile at both pH after 3 hours, with a significant

drug release at pH 7.4. These results indicate that the micelles may

retain 3PO in the blood stream (pH 7.4) only for a short time. It is

also interesting to note that the method used for dialysis was found

to have a large influence on the drug release profiles.112 In vitro and

in vivo studies performed on the adriamycin-loaded system show

the eciency of this micellar system including the intracellular

pH-triggered drug release capability, tumour-infiltrating permeability as well as eective antitumor activity with extremely low

toxicity.119 A step further in the design of pH-sensitive polymeric

micelles as drug carriers is the introduction of targeting agents by

modification of the polymer backbone with piloting molecules for

cancer cells targeting. Bae et al. paved the way to such systems by

introducing folate (Fol) at the end of the shell-forming PEG chain to

enhance intracellular transport.120 More recently, Xiong et al. conjugated doxorubicin to poly(ethylene oxide)-block-poly(3-caprolactone)

(PEO-b-PCL) micelles decorated with the avb3 integrin targeting

ligand RGD4C on the micellar surface (Fig. 11c).121 The presence of

the targeting ligand allowed the accumulation of DOX in the

nucleus of sensitive cells and mitochondria of resistant cells.

Moreover, the micellar systems were found to be more eective

than free DOX in vivo in inhibiting the growth of DOX sensitive and

resistant tumours, respectively. The same team also proposed an

improved version of this system by designing a virus mimetic shell

that was conferred by attaching two ligands, i.e., the integrin

2094

Chem. Commun., 2013, 49, 2082--2102

specific ligand RGD4C for active cancer targeting and the

cell-penetrating peptide TAT for membrane activity, to eciently

co-deliver siRNA and DOX.122 Multifunctional folate decorated

micelles were also obtained by Hu et al. by co-assembling a PEGb-PLADox conjugated copolymer and a rhodamine B-conjugated

copolymer (PEG-b-P(LA-co-ME/RhB)) together with folate terminated block copolymer (FAPEG-b-PLA) (Fig. 11d).123 In parallel to

PHPMA based statistical copolymers, Ulbrich and colleagues also

designed an acid-degradable micellar system for the delivery of

DOX, using poly(ethylene oxide)-block-poly(allyl glycidyl ether)

(PEOPAGE) copolymers (Fig. 11e)124,125 and cholesterol-based

PHPMA copolymers.126 Recently, Binauld et al. reported the synthesis of micellar acid-degradable polymerplatinum conjugates by

postmodification of a POEGMEMA-b-PHEMA block copolymer

obtained by RAFT polymerization (Fig. 11f).127 Other examples of

self-assembled hydrazone-based acid-degradable prodrugs include

small micelles from amphiphilic macromolecules,128 and vesicles

formed by heterofunctional triblock copolymer for combined

tumour-targeted delivery of an anticancer drug and superparamagnetic iron oxide nanoparticles.129

Cross-linked micellar prodrugs

Recent work on polymeric micelles systems has been focused

on stabilization strategies to overcome premature dissociation

of micellar drug carriers in in vivo conditions. In the case of

micellar polymerdrug conjugates, some strategies have been

developed to introduce a second trigger in the system or to use

a drug derivative as a cross-linking agent. For instance, Wei

et al. used the free hydrazide group to crosslink the ADRconjugated system using dithiodiethanoic acid as a cross-linker

(Fig. 12a).130 Such cross-linked micelles take advantage of two

intracellular chemical triggers, namely, acid and disulfide

reduction, for the controlled release of ADR. It should exhibit

an eective release only when both low pH and disulfide

reduction conditions are present. Cross-linking via disulphide

bond was also achieved by Jia et al. using a dierent approach.131

This journal is

The Royal Society of Chemistry 2013

View Article Online

Feature Article

ChemComm

Table 6 Composition and release eciency of cross-linked micellar prodrugs

(structures from Fig. 12)

Ref. Polymer

Drug

130 PEO-b-PMAA ADR

131 P(PDSM)DOX

b-P(HPMA)

132 PEG-bDOX

P(HPMA-Lac)

133 PEG-b-PLA

Cisplatin

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Fig. 12 Structures of the polymers and cross-linkers precursors of the crosslinked micellar prodrugs.

In a one-pot reaction, the versatility of PDS groups on amphiphilic PPDSM-b-PHPMA, synthesized by RAFT polymerization,

was used to conjugate doxorubicin and simultaneously crosslink

the micellar assemblies via acid-cleavable hydrazone bonds and

reducible disulfide bonds (Fig. 12b), allowing the system to be

cleaved into unimers in a reductive intracellular environment.

Core-cross-linked biodegradable polymeric micelles composed of

poly(ethyleneglycol)-b-poly[N-(2-hydroxypropyl) methacrylamidelactate] (mPEG-b-P(HPMAmLacn)) were obtained by Talelli

et al. by polymerizing a DOX methacrylamide derivative using

free radical polymerization (Fig. 12c).132 The entire drug payload

was released within 24 h incubation at pH 5 whereas only around

5% release was observed at pH 7.4 (Table 6). Finally, Aryal et al.

proposed an original system for the controlled delivery of cisplatin,

by designing novel acid-responsive Bi(PEGPLA)Pt(IV) polymer

cisplatin prodrug conjugate nanoparticles (Fig. 12d).133 The

resulting particles showed excellent acid-responsive drug release

characteristics and potent cytotoxicity against ovarian cancer.

Polysaccharides

Due to their excellent physicochemical properties, biocompatibility

and biodegradability, polysaccharides have also been investigated

for developing macromolecular prodrugs. More specifically, the

design of derivatives with tuneable bio-responsiveness, targeting

or environmental triggering properties, has raised interest in the

past few years. One of the first examples of chemical conjugation

This journal is

The Royal Society of Chemistry 2013

Drug

Micelles

Releasea (%)

loading diameter Time

pH 5 pH 7.4

(wt%) (nm)

(h)

11

24.9

56

61

24

24

25

72

14

21

3040

80

24

100

86

24

83

55

Values estimated from in vitro release profiles at both pH.

of an anticancer drug to a polysaccharide via an acid-degradable

bond was reported by AI-Shamkhani and Duncan, who synthesized conjugates of alginate and the antitumor agent daunomycin

(DNM).134 High (Mw = 250 000 g mol 1) and low (Mw =

61 000 g mol 1) molecular weight alginateDNM conjugates

were prepared, with a low drug loading. Administration of LMW

alginateDNM conjugate resulted in a delay in tumour growth

and reduced toxicity when compared to free DNM. More recently,

Scomparin et al. reported the design of new polymer therapeutics

based on bioconjugation of DOX on pullulan via a hydrazone

linker.135 The polymer bioconjugation was found to prolong the

circulation time of the drug in vivo. More recently, low molecular

weight hyaluronan (LMWHA) oligomers were introduced on the

HPMA copolymer for enhanced targeting properties.136 The use

of a cis-aconityl acid-degradable linker also seems to be popular

for the design of such systems. For instance, Hu et al. synthesized

DOX conjugated stearic acid-g-chitosan oligosaccharide polymeric micelles using the acid-degradable cis-aconityl bond.137

The elevation of the pH resulted in a slightly decreased liberation

of the drug from the conjugates, which was studied using various

drug contents (Table 7). Son et al. described the preparation of

glycol-chitosanDOX nanoaggregates containing cis-aconityl

spacers. The GCDOX formed spontaneously micelle-like nanoaggregates in aqueous media with a diameter of about 250 nm.138

The resulting particles exhibited anti-tumour activity via EPR

eect. A similar system was employed later for the delivery of

adriamycin. Interestingly, the release of the drug was faster

(Table 7).139 However, free adriamycin showed in that case more

potent cytotoxicity than the conjugates.

Other architectures

Besides linear statistical copolymers and self-assembled micelles,

other systems can be used as reactive polymer scaold for

anticancer drug conjugation via an acid-degradable linker.

Examples include dendrimers, hyperbranched and star polymers, gold nanoparticles and more. Table 8 summarizes some

recent examples for the controlled release of doxorubicin, in

which the core is functionalized for the chemical conjugation

of DOX via a hydrazone or cis-aconityl linker and the shell is a

biocompatible hydrophilic polymer. Calderon et al. prepared

dendritic polyglyceroldoxorubicin prodrugs, which were

further post-modified with a poly(ethylene glycol) shell.140

The resulting system displayed pronounced acid-sensitivity,

good cellular internalization and a favourable toxicity profile.

Chem. Commun., 2013, 49, 2082--2102

2095

View Article Online

ChemComm

Table 7

Feature Article

Composition and release eciency of the glycopolymerdrug conjugates

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Releasea (%)

Ref.

Linker

System

Drug

134

Hydrazone

Alginate

LMW

HMW

Pullulan particles

Stearic

Acid-g-chitosan micelles

DNM

135

137

Hydrazone

cis-Aconityl

138

139

cis-Aconityl

cis-Aconityl

Glycol-chitosan nanoaggregates

Glycol-chitosan nanoaggregates

DOX

DOX

DOX

ADR

Drug loading (wt%)

0.8

1.3

6

3%

6%

10%

5

5

Particle diameter (nm)

Time (h)

n.a.

48

100150

40

70

106

238

238

48

48

48

48

pH 5

pH 7

63

23

100

42

37

28

9 (pH 4)

26 (pH 4)

3

3

10

31

28

15

2.5

6

Values estimated from in vitro release profiles at both pH.

Table 8

Composition and release eciency of hyperbranched micellar prodrugs and other nanoparticles

Releasea (%)

Ref.

Linker

Core

Shell

DOX loading (wt%)

Particle diameter (nm)

Time (h)

pH 5

pH 7

140

141

142 and 143

145 and 146

Hydrazone

Hydrazone

Hydrazone

cis-Aconityl

Dendritic polyglycerol

Dendritic polyglycerol

PAMAM dendron

PAMAM dendron

PEG

PEG

HPMA

PEG

Hydrazone

Hydrazone

Hydrazone

Hydrazone

Boltorn H40

Gold nanoparticle

Boltorn H40

PDA capsule

PEG-b-PLasp

PEG-b-PLasp

PEG-b-PLGlu

PMA

16.4

183

n.a.

83

18

16

50

2452

4491

300

24

24

24

48

147

150

148

149

5

2.1

11

1/4 18

1/16 8.5

1/32 6.4

16

17

16.2

75

70

90

4

8

24

76

70

85

85

o5

50

5

o1

o1

o1

12

10

10

20

24

24

24

12

Values estimated from in vitro release profiles at both pH.

A similar system was designed later on by Lee et al. starting

from a PEG-b-polyglycerol block copolymer.141 Ulbrich and

colleagues used their knowledge on the acid degradable

pHPMADOX conjugate to design equivalent star polymers with

the core formed by poly(amidoamine) (PAMAM) dendrimers

grafted with semitelechelic N-(2-hydroxypropyl)methacrylamide

(HPMA) copolymers.142,143 The polymer arms were attached to

the dendrimers through either stable amide bonds or via enzymatically or reductively degradable spacers, which enabled intracellular degradation of the high-molecular-weight polymer carrier.

Moreover, star polymer conjugates showed higher in vivo antitumour activities than the free drug or linear polymer conjugate

when tested in mice bearing EL4 T-cell lymphoma. These star

polymers were also compared to linear analogues to study their

in vivo distribution, elimination and tumour accumulation using

a fluorescent and cleavable model drug.144 The study showed the

superiority of the star polymers in terms of circulation time in the

body. PAMAM dendrons were associated to a PEG shell by Zhu

et al., in which DOX was conjugated through acid-sensitive cisaconityl linkage.145 Antitumor activity of the conjugates was

proved to increase along with the PEGylation degree. The release

rate of DOX appeared to be rather slow, even at acidic pH. The

same carrier was later on conjugated to RGD as a targeting agent,

which consequently improved the therapeutic eect against

murine B16 melanoma, compared to the previous system.146

Prabaharan et al. conjugated an amphiphilic block copolymer to

two types of core: commercial hyperbranched aliphatic polyester

(Boltorn H40),147 and gold nanoparticles.147 Both systems contained an hydrophobic poly(L-aspartate-doxorubicin) inner shell,

2096

Chem. Commun., 2013, 49, 2082--2102

and a hydrophilic and folate-conjugated poly(ethylene glycol)

outer shell. DOX was covalently conjugated onto the hydrophobic segments of the amphiphilic block copolymer chains by

pH-sensitive hydrazone linkage. In both cases, the release profiles

showed a strong dependency on the environmental pH values.

The same group also investigated a system based on H40-poly(L-glutamate-hydrazone-doxorubicin)-b-PEG that was conjugated

to RGD peptides and macrocyclic chelators to design multifunctional unimolecular micelles for cancer-targeted drug delivery

and PET imaging.148 An original approach was recently developed

by Carusos group, who immobilized DOXpoly(methacrylic acid)

(PMAA) conjugates onto mussel-inspired polydopamine (PDA)

nanocapsules via robust thiolcatechol reactions.149 Cell viability

assays demonstrated the enhanced eectiveness of DOX-loaded

PDA capsules in eradicating HeLa cancer cells, compared with

free Dox under the same assay conditions.

PolymerDNA complexes

Gene therapy holds great promise for the treatment of severe

diseases including cancer. In recent years the design of synthetic

carriers for nucleic acid delivery has become a research field of

increasing interest. Viral vectors that have been commonly used

are limited by their cargo loading and, more importantly, may

lead to immune reactions. In this context non-viral carriers for

plasmid DNA and Si-RNA have gained increasing interest in gene

therapy research during the past few years.151 The new trend is

now to design targeting and bio-degradable devices that will

allow improved eciency and lower side eects.

This journal is

The Royal Society of Chemistry 2013

View Article Online

Feature Article

ChemComm

Downloaded by King Abdullah Univ of Science and Technology on 18 February 2013

Published on 10 December 2012 on http://pubs.rsc.org | doi:10.1039/C2CC36589H

Degradable PEI-based polyplexes

Among the cationic polymers, polyethylenimine (PEI), a commercially available cationic polyamine, is one of the most

successful and widely studied gene delivery polymers. However,

the design of vectors that mediate gene transfer eciently but do

not cause appreciable toxic side-eects is still a major challenge

in this field. Indeed, transfection eciency and cytotoxicity of

PEI depend on its molecular weight. For instance, PEI with a

higher molecular weight (i.e. 25 kDa) shows high transfection

eciency and cytotoxicity. On the other hand, PEI with a lower

molecular weight (i.e. 1.8 kDa) shows low transfection and

cytotoxicity.152 Therefore, optimization can be achieved of the

adequate sizes of the biodegradable polycations, which allow

gene transfer as eective as their stable PEI counterparts but can

decompose into nontoxic degradation products.

To that purpose, Kim et al. synthesized degradable PEIs with

acid-labile imine linkers from low molecular weight branched PEI

(1.8 kDa) and glutardialdehyde (Table 9).153 An in vitro transfection assay showed that the transfection eciency of the acid-labile

PEIs was comparable to that of PEI25K. The toxicity assay reveals

however that the acid-labile PEI was much less toxic than PEI25K,

due to the degradation of acid-labile linkage. Knorr et al. applied a

similar strategy combining acetal cross-linkers MK and BAA

(Table 9) with linear oligoethyleneimine (OEI).154 Polyplexes with

acid-labile polymers showed an improved toxicity profile compared to those made with acid-stable polymer analogues. At low

cation/plasmid (c/p) w/w ratios the transfection eciency of

pH-sensitive polymers was slightly reduced, but it became similar

or superior to the eciency of acid-stable polymers at higher c/p