Académique Documents

Professionnel Documents

Culture Documents

Design of MS Pipe Wall Thickness - Guwahati C 01

Transféré par

rvsingh17gmailcomTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design of MS Pipe Wall Thickness - Guwahati C 01

Transféré par

rvsingh17gmailcomDroits d'auteur :

Formats disponibles

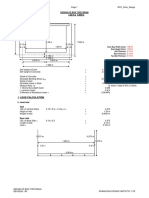

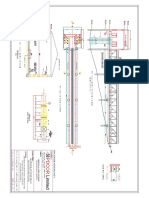

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

DESIGN DATA

Finished Internal Dia of MS Pipe

700

mm

Working Pressure

5.54

Kg/cm

Maxmimum Surge Pressure (As per CPHEEO)

20.27

Kg/cm

Hydraulic Test Pressure at Works

Partial Vacuum Pressure

25.8

Kg/cm

0.8

Kg/cm2

Modulus of Elasticity of Steel

= 2100000

Kg/cm

Modulus of Elasticity of Cement Mortar

280000

Kg/cm

Soil Modulus of Fill

70

Kg/cm

Thickness of outer coating (Epoxy)

0.6

mm

Thickness of inner Lining (Epoxy)

0.4

mm

Thickness of MS plate considered

5.1

mm

Internal Diameter

700.8

mm

Outer metal Diameter (Without Coating)

711

mm

Outer Diameter (After external coating)

712.2

mm

0.6

Hydraulic Pressure Design

Thickness of Pipe

PD/(2a * f * e + P)

Design Factor for working Pressure

Design Factor for Test Pressure

0.9

Yield stress of Pipe material (MS)

2500

Weld efficiency of the Joint (Shop)

0.9

Weld efficiency of the Joint (Field)

Thickness of Pipe required considering working

pressure

Thickness of Pipe required considering Hydraulic

Site Test pressure

0.8

1.6

mm

5.1

mm

Hence Pipe is

Kg/cm

Safe

PERMISSIBLE STRESSES

2

Yield Stress (fy) as per IS :2062 Table 2 Page No.5 is 2500 kg/cm . The permissible

stress in the pipe shell shall as per Clause 1 page 1 of IWWA manual M1 be related to yield

stress (fy) of pipe material making due allowance for weld efficiency of the joint.

a) Working stress for combined bending and direct tensile stress shall not exceed 60% of yield

stress of the material making due allowance for efficiency of weld joint.

b) Working stress for combined bending and direct compressive stress shall not exceed 50% of

yield stress making due allowance for weld efficiency.

c) For field welded joint, efficiency factor of 80%, whilst for shop welded joints 90% efficiency

is allowed as per IWWA manual M1 page 2 clause 1

Permissible Stress are :

In compression =

2500 x (50/100) x (80/100)=

1000

Kg/cm

In tension =

2500x (60/100) x (80/100)=

1200

Kg/cm

Page 1 of 6

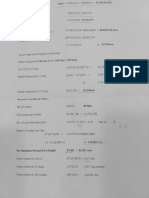

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

0.01105

cm

23214

cm-kg

Internal Diameter of Steel Pipe

0.7008

External Diameter of Steel Pipe

0.711

Density of Steel

7850

kg/m

Weight of steel pipe

88.74

kg/m

Internal Diameter of Pipe with Internal lining

0.7

Moment of Inertia of Steel

Is

Fill Load

External Diameter of Pipe with Internal lining

0.7008

Density of Internal lining material (Epoxy)

kg/m

Weight of Inner Lining material

0.00

kg/m

Internal Diameter of Pipe with external coating

0.711

External Diameter of Pipe with external coating

0.7122

Weight of external coating Material

0.0

kg/m

Density of water

1000

kg/m

Weight of water

384.65

kg/m

Total weight

473.39

kg/m

As per clause no 2 of IWWA Publication No. M1, the load due to pipe shell, lining and water is

partially transmitted to the ground and therefore only 50% of this load is considered in the design

Ws

236.69

kg/m

mm

Earth fill load

Side Clearance of Trench

300

Width of trench

Bd

1.3122

Density of compacted filling earth

1800

kg/m

Height of earth fill above pipe

m

m

Bc

0.7122

H/Bd

0.8

Load Coefficient

Cd

0.65

mg

IWWA M1

Earth Fill Load=

Wc

1093

kg/m

Wd

1330.12

kg/m

6250

kg

External Diameter of pipe(external coating)

Ratio of

Total dead load

Wc + Ws

Live Load

Cp x P x F

W L=

P = Axial Load(Class AA loading as per IRC)

L = Effective length of pipe

F = Impact Factor =1.0 as per IS 783 table 1 Page No 19

Bc/2H

0.3561

L/2H

0.5000

Page 2 of 6

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

Cp

0.35

Live Load

WL

2187.5

kg/m

Total Load

We

3517.62

kg/m

From Fig. 3 of IS 783

Deflection

For Total External load and Partial Vacuum Pressure

Deflection x

De x Ke x W e x R

EI + 0.061e'R - 2PeR Ke

Where

De =

Deflection lag factor varies from 1.0 to 1.5 as per Page No. 60 of AWWA M11

Ke =

Bedding constant and is 0.10 as per Page No. 61 of AWWA M 11 manual

Adopt De

Adopt Ke

1.5

0.1

We =

Total Load

35.18

R =

Radius of pipe

35.295

cm

EI =

Pipe Wall Stiffness

23214

cm-kg

e' =

Modulus of Soil Reaction in

70

Pe =

Partial Vaccum Pressure

0.8

kg/cm

kg/cm2

kg/cm

1.14

cm

11.38

mm

1.60

% of OD of pipe

The allowable deflection as per AWWA M11 Manual Page 61 and IWWA M1 manual page 15 is

5% of pipe diameter in case of pipes with lining and coating.

Hence

Safe

For Total external load as above and with Internal pressure

Deflection x

De x Ke x We x R3

EI + 0.061 e' R3 + 2 PiR3Ke

Pi =

Internal Working Pressure

x

5.54

kg/cm

0.89

cm

8.93

mm

1.26

% of OD of pipe

The allowable deflection as per AWWA M11 manual page 61 and IWWA M1 manual page 15 is

5% of pipe diameter in case of pipes with lining and coating.

Hence

Safe

Compressive Stress

External load with side supports and partial vacuum

Moment

Mb

Kb x W e x R x EI

3

EI + 0.061 e' R -2 Pe R Ke

Page 3 of 6

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

Bending Constant

Kb

Moment

Mb

22.19

Bending Stress

fb

Mb*6/t2

511.86

Kg cm

Kg/cm

Kg/cm

= Pe x d/(2xts)

f hoop

Hoop Stress

0.157

55.0

= fb + f hoop

Total Compressive Stress

566.83

Kg/cm2

<

1000

Kg/cm

Safe

Tensile Stresses

Tensile stress

ft

Kb x W e x R x E x ts

2 x (EI + 0.061e' R3 + 2 Pi R3 Ke)

ft

Kg/cm2

= Pi x d/(2xts)

f hoop

Hoop Stress

40.2

Total Tensile Stress

Kg/cm

420.83

Kg/cm

1200

Kg/cm

380.6

ft + f hoop

=

Allowable

Safe

Buckling

Pipe embedded in soil may collapse or buckle from elastic instability resulting from loads and

deformations. The summation of external loads should be equal to or less than the allowable

buckling pressure. The allowable buckling pressure qa may be determined by equation given in

AWWA M11 Manual 4th Edition 2004 using formula 6-7 at page No. 63

qa

3 1/2

(1/FS) x (32Rw B' E' x EI/D )

Where

FS

hw

Rw

Water buoyancy factor

1-0.33(hw/h)

height of water surface above top of pipe

hw

0.3

Rw

0.901

B'

Empirical coefficient of elastic support

(1/(1+4e-0.213H))

Height of fill above pipe in m

B'

E'

70

kg/cm

qa

2.77

kg/cm

0.236

Page 4 of 6

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

Check of pipe against buckling

As per AWWA M11 Manual 4th Edition Pg 64 eq (6-8) & (6-9)

a) Load Combination 1

Water Pressure + Earth Pressure + Vacuum Pressure

Wc

Earth Fill Load

= 1093.422

Pv

Partial Vaccum Pressure

w x hw + Rw (W c/D)+Pv <=qa

Allowable

kg/m

0.8

kg/cm

0.97

kg/cm

2.77

kg/cm

Safe in buckling

b) Load Combination 2

Water Pressure + Earth Pressure + Pressure due to Live Load

WL

Live Load

w x hw + Rw (W c/D)+(W L/D) <=qa

Allowable

2187.5

kg/m

0.48

kg/cm

2.77

kg/cm

Safe in buckling

Handling

Minimum plate or sheet thickness for handling of mortar lined and flexible coated steel pipe as per AWWA M11

Manual 4th Edition 2004 Page No. 50 equation (4-7)

t =

D/240

and in no case the shell thickness shall be less than

Hence pipe is

mm

2.96

mm

1.9

mm

Safe in Handling

Collapse Pressure

Any steel tube having t/d ratio less than 0.02 will fail by buckling when p = 4.62x 106 (t/d)3

as per page No. 22 of IS 5822 - 1986

As per AWWA M11 Pc

2E/(1-mue2) x(t/d)3

= 66000000 x (t/d)3

as per formula 403 at page no. 39 of AWWA

M11, where Pc is collapsing pressure in psi. To convert Pc in psi

to Ksc multiply by 0.07

Pc

= 66000000 x 0.07 x (t/d)3

As per AWWA M11 Manual 4th Edition Page No. 49 eq (4-4M) Collapsing Pressure for Buckling Failure

where t/dn o is 0.023 or less and Pc is 40.84 kg/cm2 or less Pc = 3529409.13 (t/dn)3

Ratio of thickness to Outside diameter of Pipe

Critical Collapsing Pressure

Pc

Total Load (Water Pressure + Earth Pressure+Vaccum Pressure)

t/dn

0.0072

1.30

kg/cm2

0.97

kg/cm

Page 5 of 6

JWIL RANHILL JV

MS RWPM Thickness Calculation for Pkg # 01

GMDA - Guwahati

Hence pipe is

Safe

Pipe Thickness Considered

5.1

mm

Corrosion Allowance

0.8

mm

Mill Allowance @ 12.5%

0.7

mm

Total Thickness Required

6.6

mm

Total Thickness Provided

7.0

mm

Page 6 of 6

Vous aimerez peut-être aussi

- Pipe Thickness Design For 1900mm DiameterDocument8 pagesPipe Thickness Design For 1900mm DiameterAjayvidyanand SharmaPas encore d'évaluation

- Design of Clear Water Reservoir and Pump House of MahishnadiDocument25 pagesDesign of Clear Water Reservoir and Pump House of MahishnadiMukhlish AkhatarPas encore d'évaluation

- Design of Thrust Blocks: A) 150 Dia 90 Degree BendDocument7 pagesDesign of Thrust Blocks: A) 150 Dia 90 Degree BendRajesh Babu100% (1)

- Design of Thrust BlockDocument3 pagesDesign of Thrust Blockvishnumani3011Pas encore d'évaluation

- Design Report 600 KL 25 MTR Gajabandh & BadkarliDocument70 pagesDesign Report 600 KL 25 MTR Gajabandh & BadkarlishailenderPas encore d'évaluation

- 2152-0.50LL Esr-Str-Cal-01 - R1Document30 pages2152-0.50LL Esr-Str-Cal-01 - R1sssmitPas encore d'évaluation

- L Shaped Reatining WAll With HORZONTAL Bach FillDocument29 pagesL Shaped Reatining WAll With HORZONTAL Bach Fillsarveshfdk48100% (2)

- ANCHOR BLOCK Design SheetDocument5 pagesANCHOR BLOCK Design SheetMohanSharma0% (1)

- Analysis and Design of Pump HouseDocument9 pagesAnalysis and Design of Pump HouseKandousi YassinePas encore d'évaluation

- Sita Rama Lift Irrigation Project: Head Regulator of Main CanalDocument19 pagesSita Rama Lift Irrigation Project: Head Regulator of Main CanalRaju Ranjan SinghPas encore d'évaluation

- 100KL Sump Cum PH - Bhopal DesDocument10 pages100KL Sump Cum PH - Bhopal DesMAHENDRAPas encore d'évaluation

- Design of Thrust BlocksDocument20 pagesDesign of Thrust BlocksBalaji Rao Ch100% (1)

- Anchor Block DesignDocument6 pagesAnchor Block Designharicv019100% (1)

- Anchor Block Design (Typical) AB-1Document9 pagesAnchor Block Design (Typical) AB-1Madhu KurmiPas encore d'évaluation

- Rising Main Design SampleDocument6 pagesRising Main Design SampleShashi Rana RawatPas encore d'évaluation

- Pipe CulvertDocument14 pagesPipe CulvertPraveen M balaramPas encore d'évaluation

- Box Culvert-Structural DesignDocument5 pagesBox Culvert-Structural Designsiva100% (1)

- Elevated Service ReservoirDocument35 pagesElevated Service ReservoirRamachandra SahuPas encore d'évaluation

- Intake Well Bridge DesignDocument58 pagesIntake Well Bridge DesignAjayKumarMishra100% (1)

- Anchor BlockDocument78 pagesAnchor BlockBishowkumar Shrestha100% (1)

- Design of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataDocument55 pagesDesign of 2 Vents Box Culvert 2 X 4.5 X 3.50: General DataBhaskar ReddyPas encore d'évaluation

- Structural Design Calculation of OHT-8, 200 KL-18 M StagingDocument41 pagesStructural Design Calculation of OHT-8, 200 KL-18 M StagingGopal SinghPas encore d'évaluation

- Design of Thrust BlockDocument6 pagesDesign of Thrust BlockHemant SonawadekarPas encore d'évaluation

- Super Passage Trough Design-User ManualDocument13 pagesSuper Passage Trough Design-User Manualpaaji100% (1)

- Thrust Block CalculationDocument12 pagesThrust Block CalculationMegatech Engineering Consultants100% (1)

- Design of - ESR (200KL)Document33 pagesDesign of - ESR (200KL)sanju middya100% (1)

- Pure Water SumpDocument8 pagesPure Water SumpVarad Sonawadekar100% (1)

- Anchor Block DesignDocument3 pagesAnchor Block Designrameshb308100% (1)

- Well Foundation DesignDocument4 pagesWell Foundation DesignArpan SahaPas encore d'évaluation

- Vertical Thrust Block Design (DN 600)Document25 pagesVertical Thrust Block Design (DN 600)ARSEPas encore d'évaluation

- Design As Per Is-456Document23 pagesDesign As Per Is-456ALOK THAKURPas encore d'évaluation

- Design and Calculation PDFDocument1 pageDesign and Calculation PDFYogendra MishraPas encore d'évaluation

- Afflux Calculation PDFDocument1 pageAfflux Calculation PDFAnonymous 2bHiuA100% (1)

- Ms Pipe DesignDocument6 pagesMs Pipe DesignMathiTwadCPas encore d'évaluation

- Final Design of DrainDocument17 pagesFinal Design of Drainayan khan0% (1)

- Name of Work:: NTR Telugu Ganga Project Package - 12 Design ReportDocument15 pagesName of Work:: NTR Telugu Ganga Project Package - 12 Design ReportVaraPrasadPas encore d'évaluation

- Design of Head Regulator - 400cumecsDocument23 pagesDesign of Head Regulator - 400cumecsGarg Tj100% (2)

- Penstock Anchor Block Stability Analysis: KG/M KN/MDocument5 pagesPenstock Anchor Block Stability Analysis: KG/M KN/MChris Angelo G CaadlawonPas encore d'évaluation

- Cable Trench Desiign Report 26.04.2020 PDFDocument50 pagesCable Trench Desiign Report 26.04.2020 PDFkkgcPas encore d'évaluation

- Report and DesignDocument53 pagesReport and Designkiran raghukiranPas encore d'évaluation

- Design of Circular ShaftDocument7 pagesDesign of Circular Shaftจอม อรรฐาเมศร์Pas encore d'évaluation

- Canal RegulatorDocument13 pagesCanal RegulatorBibhuti Bhusan Sahoo100% (1)

- 150 KLD NirmalpurDocument19 pages150 KLD NirmalpurHirak BhattacharyaPas encore d'évaluation

- Pedestal Design 3, 4,5 & 6Document2 pagesPedestal Design 3, 4,5 & 6munishant10% (1)

- Ilovepdf MergedDocument101 pagesIlovepdf MergedArbaaz ParvezPas encore d'évaluation

- Sump .XLS (7.00 Lakhs)Document58 pagesSump .XLS (7.00 Lakhs)subramanyam kumarPas encore d'évaluation

- Sump Well 20 KLDocument3 pagesSump Well 20 KLANKESH SHRIVASTAVA100% (1)

- Hydraulic Design of Check DamDocument2 pagesHydraulic Design of Check DamSooraj Kannan, P.V.Pas encore d'évaluation

- RCC Drain DesignDocument39 pagesRCC Drain DesignShubham AgrawalPas encore d'évaluation

- Design of Thrust BlockDocument35 pagesDesign of Thrust BlockBalaji Rao Ch100% (1)

- Design Report of Intz Type Water Tank-Bia-01.07.2015 PDFDocument56 pagesDesign Report of Intz Type Water Tank-Bia-01.07.2015 PDFGR Kanna100% (1)

- 35 KL DesignDocument10 pages35 KL DesigneduardoambientalPas encore d'évaluation

- 40 KL DesignDocument10 pages40 KL DesignSung Woong MoonPas encore d'évaluation

- Master CalculationDocument9 pagesMaster CalculationRANA1575100% (2)

- Design of Compound WallDocument4 pagesDesign of Compound WallMaku Rajkumar100% (2)

- Underground Pipe THK CalDocument12 pagesUnderground Pipe THK Calmkchy12100% (3)

- L 8 IhjnmklgfDocument27 pagesL 8 IhjnmklgfbrintopvPas encore d'évaluation

- Ibr CalcDocument4 pagesIbr CalcUmesh Kondkar100% (7)

- Penstock Embedded DesignDocument6 pagesPenstock Embedded Designgrahazen50% (2)

- Environmental Guideline For Smart Cities July 2015Document3 pagesEnvironmental Guideline For Smart Cities July 2015rvsingh17gmailcomPas encore d'évaluation

- Manuals ListDocument1 pageManuals ListAbdulkadir DinçerPas encore d'évaluation

- Abbreviations and Symbols Classification and LabellingDocument12 pagesAbbreviations and Symbols Classification and Labellingrvsingh17gmailcomPas encore d'évaluation

- 200ha SizingDocument1 page200ha Sizingrvsingh17gmailcomPas encore d'évaluation

- CPHEEO Manual - Air ValveDocument2 pagesCPHEEO Manual - Air Valvervsingh17gmailcomPas encore d'évaluation

- Slow Sand FilterDocument1 pageSlow Sand Filterrvsingh17gmailcomPas encore d'évaluation

- Cement Mortar Lining B-L Materials B-l.1 CementDocument3 pagesCement Mortar Lining B-L Materials B-l.1 Cementrvsingh17gmailcomPas encore d'évaluation

- S.No Node Number Elevation (M) Demand (L/S) Hydraulic Grade (M) Pressure (M H2O)Document2 pagesS.No Node Number Elevation (M) Demand (L/S) Hydraulic Grade (M) Pressure (M H2O)rvsingh17gmailcomPas encore d'évaluation

- Intake Well Methodology-Package 3C-GWSP - JWILDocument25 pagesIntake Well Methodology-Package 3C-GWSP - JWILrvsingh17gmailcom100% (1)

- Intake Dungarpur PDFDocument1 pageIntake Dungarpur PDFrvsingh17gmailcomPas encore d'évaluation

- IntakeDocument1 pageIntakervsingh17gmailcomPas encore d'évaluation

- Intake Dungarpur PDFDocument1 pageIntake Dungarpur PDFrvsingh17gmailcomPas encore d'évaluation

- Presentation On Smart Cities MissionDocument24 pagesPresentation On Smart Cities Missionrvsingh17gmailcom100% (1)

- Smart Water Solutions For Smart Cities by R V Singh - Water Digest MagazineDocument6 pagesSmart Water Solutions For Smart Cities by R V Singh - Water Digest Magazinervsingh17gmailcomPas encore d'évaluation

- Leachate GenerationDocument35 pagesLeachate Generationrvsingh17gmailcomPas encore d'évaluation

- Surge PressureDocument2 pagesSurge Pressurervsingh17gmailcomPas encore d'évaluation

- 033 Valve Chambers A1 1Document1 page033 Valve Chambers A1 1rvsingh17gmailcomPas encore d'évaluation

- 8717 PackagingDocument7 pages8717 Packagingrvsingh17gmailcomPas encore d'évaluation

- SORDocument2 pagesSORrvsingh17gmailcomPas encore d'évaluation

- Smart Water Solutions For Smart Cities by R V Singh - Water Digest MagazineDocument6 pagesSmart Water Solutions For Smart Cities by R V Singh - Water Digest Magazinervsingh17gmailcomPas encore d'évaluation

- XIX Paper 14 PDFDocument20 pagesXIX Paper 14 PDFMathiTwadCPas encore d'évaluation

- Hydrology Report From IIT RoorkeeDocument285 pagesHydrology Report From IIT Roorkeervsingh17gmailcomPas encore d'évaluation

- Break Pressure TankDocument53 pagesBreak Pressure TankParomita Mukherjee Misra100% (11)

- 033 Valve Chambers A1 1Document1 page033 Valve Chambers A1 1rvsingh17gmailcomPas encore d'évaluation

- DBR Civil & Electro-MechanicalDocument22 pagesDBR Civil & Electro-Mechanicalrvsingh17gmailcomPas encore d'évaluation

- Water Sewer Design GuideDocument60 pagesWater Sewer Design GuideJim Lawrence Perea OjedaPas encore d'évaluation

- Calc Pressure DropDocument24 pagesCalc Pressure Droprvsingh17gmailcomPas encore d'évaluation

- 26.00 MLD - STP at Nanded (Slides)Document11 pages26.00 MLD - STP at Nanded (Slides)rvsingh17gmailcomPas encore d'évaluation

- Lecture 4 2011Document51 pagesLecture 4 2011ahmadPas encore d'évaluation

- Plate GirderDocument11 pagesPlate GirderEzhil Kumar50% (2)

- Upheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCDocument2 pagesUpheaval & Lateral Buckling Calculations For Buried Pipelines - TR Engineering Consultancy LLCRaakze MoviPas encore d'évaluation

- LAB REPORT BUCKLING OF STRUTS (Reference)Document13 pagesLAB REPORT BUCKLING OF STRUTS (Reference)jajenPas encore d'évaluation

- 강의노트 기계요소설계-좌굴Document5 pages강의노트 기계요소설계-좌굴김영관Pas encore d'évaluation

- Question Bank: Department of Civil Engineering Design of Steel StructuresDocument61 pagesQuestion Bank: Department of Civil Engineering Design of Steel StructuresKaarthic EmayPas encore d'évaluation

- Steel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - 1Document46 pagesSteel Design Problems With Solution (Using NSCP 2001, 2010 and 2015) - 1jay tejano100% (4)

- Elevator Hoistway Equipment PDFDocument16 pagesElevator Hoistway Equipment PDFpersephonisePas encore d'évaluation

- Analysis of Biaxially Loaded ColumnsDocument178 pagesAnalysis of Biaxially Loaded ColumnsfefahimPas encore d'évaluation

- Seismic Performance of Mid-To-high Rise Modular Steel ConstructionDocument19 pagesSeismic Performance of Mid-To-high Rise Modular Steel ConstructionVinPas encore d'évaluation

- BucklingDocument16 pagesBucklingSowjanya VenigallaPas encore d'évaluation

- 4.9 Design of Singly Symmetric Cross-SectionsDocument11 pages4.9 Design of Singly Symmetric Cross-Sectionsengineering trimatraPas encore d'évaluation

- SC+ Design Guidelines EnglishDocument27 pagesSC+ Design Guidelines EnglishMyron OikonomakisPas encore d'évaluation

- ANSYS Fluent V2F Turbulence Model ManualDocument100 pagesANSYS Fluent V2F Turbulence Model ManualjemanuelvPas encore d'évaluation

- RCC 2 MarksDocument27 pagesRCC 2 MarksWilliam WhaitePas encore d'évaluation

- Chapter 11 CACCDHDocument60 pagesChapter 11 CACCDHmeda012Pas encore d'évaluation

- Structural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsDocument6 pagesStructural Analysis of Aircraft Wing J Nose Panel Using Mono and Multi Core Composite MaterialsstaedtlerpPas encore d'évaluation

- Excerpt PDFDocument27 pagesExcerpt PDFkamalnathPas encore d'évaluation

- Enhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Document15 pagesEnhancing The Seismic Performance of Batter Piles in Pile-Supported Wharves Using Fluid Viscous Dampers - P - 2018Halil Can EryasarPas encore d'évaluation

- 53-Steel Structures (Gantry Structure)Document13 pages53-Steel Structures (Gantry Structure)Sarmad HussainPas encore d'évaluation

- STR'L Calc. For Cuplock Scaffolding SystemDocument61 pagesSTR'L Calc. For Cuplock Scaffolding SystemZeeZ HPas encore d'évaluation

- Final Tower Analysis Report SST 65 M With Proposed LoadingDocument102 pagesFinal Tower Analysis Report SST 65 M With Proposed LoadingErpanBeanTarpoPas encore d'évaluation

- Behavior and Design of Gusset Plate Connections in CompressionDocument17 pagesBehavior and Design of Gusset Plate Connections in CompressionNaomi PratiwiPas encore d'évaluation

- Quay Walls - Combined - Wall - Buckling - TubesDocument12 pagesQuay Walls - Combined - Wall - Buckling - TubesHugo LeitePas encore d'évaluation

- Plate Girder BridgeDocument15 pagesPlate Girder BridgeFE3056 NAGARAJ.SPas encore d'évaluation

- Analytical Behavior of Concrete-Filled Aluminum Tubular Stub Columns Under Axial Compression, 2019 (Fa-Cheng Wang) PDFDocument10 pagesAnalytical Behavior of Concrete-Filled Aluminum Tubular Stub Columns Under Axial Compression, 2019 (Fa-Cheng Wang) PDFPhan Đào Hoàng HiệpPas encore d'évaluation

- Papp (2001) - Unified Object-Oriented Definition of Thin-Walled Steel Beam-Column Cross-SectionsDocument14 pagesPapp (2001) - Unified Object-Oriented Definition of Thin-Walled Steel Beam-Column Cross-SectionsGogyPas encore d'évaluation

- Strut Design SheetDocument84 pagesStrut Design SheetHafiz Kamarudin100% (2)

- Verify 88Document516 pagesVerify 88Dipak BorsaikiaPas encore d'évaluation

- Typology of Progressive CollapseDocument8 pagesTypology of Progressive CollapseNoble Obeng-AnkamahPas encore d'évaluation