Académique Documents

Professionnel Documents

Culture Documents

M6 CV RC G 007 (R2)

Transféré par

ksshashidharTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

M6 CV RC G 007 (R2)

Transféré par

ksshashidharDroits d'auteur :

Formats disponibles

TCE Consulting Engineers Limited

SECTION: TITLE

SHEET

OF 4

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

iOF iii

DESIGN GUIDE FOR RC CHIMNEYS

FILE NAME: TCE.M6-CV-RC-G-007(R2) . DOC

REV.NO

R0

R1

R2

INITIALS

SIGN

INITIALS

SIGN

INITIALS

PPD.BY

VTK

Sd/-

KSS

Sd/-

KSS

CKD.BY

SNM

Sd/-

MSCN

Sd/-

BRR

APP.BY

MRR

Sd/-

MGK

Sd/-

SMP

DATE

1981-03-12

2000-02-15

ISSUE

SIGN

INITIALS

SIGN

R2

30-10-2009

TCE FORM NO. 020R3

TCE Consulting Engineers Limited

SECTION:REV STAT

ii

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SHEET

OF iii

CONTENTS

SECTION

TITLE

SHEET NO

1.0

SCOPE

2.0

APPLICABLE CODES AND BOOKS

3.0

NOTATIONS

4.0

GENERAL ARRANGEMENT

5.0

INPUT DATA

6.0

LOADS

7.0

LOAD COMBINATIONS

23

8.0

PERMISSIBLE STRESSES

24

9.0

DESIGN PROCEDURE

25

10.0

CHIMNEY PROGRAM

34

11.0

DESIGN EXAMPLE

34

12.0

DESIGN OF STRAKES

85

REVISION STATUS SHEET

ISSUE

R2

FORM NO.120R2

TCE Consulting Engineers Limited

SECTION:REV STAT

iii

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

REV.NO.

R1

DATE

2000-02-15

R2

30-10-2009

SHEET

OF iii

DESCRIPTION

DESIGN GUIDE REVISED TO

SATISFY IS:4998(PART 1)-1992

GENERALLY REVISED

ISSUE

R2

FORM NO.120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

1.0

SECTION: WRITE-UP

SHEET 1 OF 89

SCOPE

This guide sets out the procedure to be followed for the design of

reinforced concrete chimney shell, for single or multiflue chimneys. Method

of estimation of loads due to wind as per IS:4998 is also explained. Design

of corbels is covered in M6-CV-RC-P-015.

2.0

APPLICABLE CODES AND BOOKS

(a)

IS 4998 (Part 1) : 1975* :

Criteria for design of reinforced

concrete chimneys Design

Criteria

(b)

IS 4998 (Part 1 ) : 1992* :

Criteria for design of reinforced

concrete chimneys Assessment

of Loads

(c)

IS 456 : 1978

Code of practice for plain and

reinforced concrete

(d)

IS 1893 : 1984

Criteria for earthquake resistant

design of structures

(e)

IS 875 : 1987

Code of practice for design loads

(other than earthquake) for

buildings and structures

(i)

(ii)

(iii)

Part 1

Part 2

Part 3

:

:

:

Dead loads

Imposed loads

Wind loads

(f)

ACI 307 : 1979**

Specification for the design and

construction of reinforced

concrete chimneys

(g)

Tall chimneys

Design & Construction

S.N.Manohar

(h)

Reinforced concrete chimneys & towers G.M.Pinfold

NOTE *

3.0

IS:4998-1992 gives procedure for Assessment of wind loading only. All

other requirements including design criteria is as per IS:4998-1975

**

ACI 307-1979 being followed even though 2008 issue for strength

method of design is available as IS still follows Working Stress Method

of design

NOTATIONS

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

FZ

pZ

=

=

CD

dz

Vcri

fi

d

=

=

=

=

=

Sn

oi

=

=

CL

H

zi

=

=

=

Ksi

s

=

=

=

mei

=

=

Fzoi

Mzoi

mz

Fzm

=

=

=

=

G

gf

=

=

r

B

=

=

S

VID

=

=

CL

=

=

=

ka

Moe / Moi

rm

=

=

=

SECTION: WRITE-UP

SHEET 2 OF 89

Along wind load or drag force per unit height.

Design wind pressure obtained in accordance with IS 875

(Part 3)

Height of any section of the chimney (mts) measured from

top of foundation

Drag co-efficient of the chimney

Diameter of chimney at height z in mts.

Critical wind speed for the ith mode of vibration

Modal frequency for ith mode of vibration.

Effective diameter of chimney i.e., the average diameter over

the top 1/3 height of chimney.

Strouhal number to be taken as 0.2.

Peak tip deflection due to vortex shedding in the I th mode of

vibration in m.

Peak oscillatary lift co-efficient to be taken as 0.16

Height of chimney in m above ground level

Mode shape function normalised with respect to the dynamic

amplitude at top of the chimney in the Ith mode of vibration.

Mass damping parameter for the Ith mode of vibration

Logarithmic decrement of structural damping = 2

Structural damping as a fraction of critical damping to be

taken as 0.016

Mass density of air to be taken as 1.2 kg/m3.

Equivalent mass per unit length in kg/m in the I th mode of

vibration.

Shear force at any height zo for the Ith mode of vibration

Bending moment at any height zo for Ith mode of vibration

Mass per unit length of the chimney at section z in kg/m.

Wind load in N/m height due to Hourly Mean Wind (HMW)

at height z.

Gust factor

Peak factor defined as the ratio of the expected peak value to

RMS value of fluctuating load

Twice the turbulance intensity

Background factor indicating the slowly varying component

of wind load fluctuation

A measure of the available energy in the wind at the natural

frequency of chimney

Size reduction factor

Hourly mean wind speed in m/sec. at 10 m above ground

level

RMS lift co-efficient to be taken as 0.12

Equivalent aspect ratio = H/d

Correlation length in diameters, which may be taken as 1.0 in

the absence of field data.

Aerodynamic damping co-efficient to be taken as 0.5

External and internal ring moments

Mean radius of the shell at the section under consideration in

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

Tx

t

tb

T

To

=

=

=

=

=

Cb

CC

CS

Db

Dbi

DC

DCi

DCO

DS

K1

=

=

=

=

=

=

=

K2

Kr

KS

rq

Mk

W

e

=

=

=

ts

cu

=

=

SECTION: WRITE-UP

SHEET 3 OF 89

m.

Temperature gradient

Thickness of concrete shell in m.

Thickness of lining in m.

Maximum temperature of gas inside chimney in 0C

Minimum temperature of outside air surrounding chimney in

0

C

Co-efficient of thermal conductivity of chimney lining in kilo

calories per metre per hour per degree centigrade difference

of temperature

Co-efficient of thermal conductivity of the concrete of

chimney shell in kilo calories per metre per hour per degree

centigrade difference of temperature

Co-efficient of thermal conductivity of insulation between

lining and shell in the kilo calories per metre per hour per

degree centigrade difference of temperature

Mean diameter of lining in m.

Inside diameter of lining in m.

Mean diameter of concrete chimney shell in m.

Inside diameter of concrete chimney shall be in m.

Outside diameter of concrete chimney shell in m.

Mean diameter of space between lining and shell in m.

Co-efficient of heat transmission from gas to inner surface of

chimney lining when chimney is lined or to inner surface of

chimney shell when chimney is unlined in kilo calories per

square metre per hour per degree centigrade difference of

temperature.

Co-efficient of heat transmission from outside surface of

chimney shell to surrounding air in kilo calories per square

metre per hour per degree centigrade difference of

temperature.

Co-efficient of heat transmission by radiation between

outside surface of lining & inside surface of concrete chimney

shell in kilo calories per square metre per hour per degree

centigrade difference of temperature

Co-efficient of heat transfer between outside surface of lining

and inside surface of wall for chimney with ventilated air

space in kilo calories per square metre per hour per degree

centigrade difference of temperature.

Ratio of heat transmission through chimney shell to heat

transmission through lining for chimneys with ventilated air

spaces.

Moment due to corbel in N-m.

Load due to corbel in N.

Distance between centre line of the shell and the centre of

gravity of the load in m.

Thickness of the shell at the section under consideration in m.

28 days ultimate cube strength of concrete in kg/cm2

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

sy

m

p

np

r

W

M

e

fc

fc(max)

=

=

=

=

=

=

=

=

=

=

fs

fsh

fsc

Ft

=

=

=

=

Ec

k

a

=

=

=

t

ctc

=

=

P1

Z1

Es

STC

=

=

CWCT

CWCC

SWCT

WP

r

=

=

t1

f"CWC

SECTION: WRITE-UP

SHEET 4 OF 89

Yield or proof stress of steel in kg/cm2

Modular ratio

Ratio of area of steel to concrete

Mp/(1-p)

Mean radius of chimney shell in stress calculation

Axial load in stress calculation`

Moment in stress calculation

M/W

Vertical stress in concrete due to axial and moment

Maximum vertical stress in concrete due to axial load and

moment

Maximum vertical stress in steel due to axial load and

moment

Compressive stress in steel on hot face

Tensile stress in steel on cold face.

Fictitious stress = 0.5 x x Ec x Tx

Co-efficient of linear expansion for concrete and steel = 11 x

10-6 / 0C

Modulus of elasticity of concrete

Ratio of steel area on hot face to total steel area

Ratio of steel cg distance from inner surface of chimney shell

to total shell thickness.

Total shell thickness

Maximum circumferential stress in concrete due to

temperature alone.

Co-efficient of linear expansion for concrete and steel = 11 x

10-6 / 0C

Ratio of circumferential steel area to total shell area per unit

height

Ratio of outside circumferential steel cg distance from inner

surface of chimney shell to total shell thickness

Modulus of elasticity of steel

Maximum circumferential tensile stress in steel due to

temperature alone

Maximum circumferential tensile stress in concrete due to

wind induced ring moment.

Maximum circumferential compressive stress in concrete due

to wind induced ring moment

Maximum circumferential tensile stress in steel due to wind

induced ring moment

Wind pressure in kg/cm2

Mean radius of chimney shell at section under consideration

in cm

Thickness of shell from compression face to centre line of

circumferential steel

Maximum circumferential compressive stress in concrete due

to wind induced ring moments

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

4.0

fswc

SECTION: WRITE-UP

SHEET 5 OF 89

Ratio of inside face circumferential reinforcing steel area to

the outside circumferential reinforcing steel area.

Maximum tensile stress in circumferential reinforcement due

to wind induced ring moments.

GENERAL ARRANGEMENT

A reinforced concrete chimney is usually of two types

(a) Single flue - when one chimney serves one boiler

(b) Multi flue - when one chimney serves more than one boiler

Both single flue and multiflue chimneys can have either brick lining or steel

lining.

In case of single flue chimneys with brick lining, the lining is supported on

corbels or a grid work of beams at every 10 m intervals or less. If the lining

is of steel, then major portion of lining is supported from the top of

chimney (top hung) and a small portion of lining is supported at the bottom.

Lateral restraint is provided for the lining at certain intervals.

In case of multiflue chimneys with brick lining, the lining is supported on a

grid work of beams with platform at every 10 m intervals or less. If the

lining is of steel then again a major portion of lining is supported from the

top of chimney (top hung) and a small portion of lining is supported at the

bottom. Lateral restraint is provided for the lining at certain intervals.

Internal platforms with a grid work of beams are provided to access the

flues. A roof slab at top covers the chimney with provision to access it

through a manhole at roof level. There is also a provision to collect rain

water at roof level, bring it down through downtake pipes and collect it in a

sump.

Design of steel flue is covered in M6-CV-034

5.0

INPUT DATA

The following information is required before proceeding with the design of

chimney shell.

5.1

Data from Mechanical Department

(i)

(ii)

(iii)

(iv)

(v)

Height of the chimney

Location, number and sizes of flue duct openings

Internal diameter of the flue at top and at duct opening level

Maximum temperature and velocities of flue gases

Volume and density of ash to be collected

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

5.2

Location and number of Aviation warning lights

Location and number of openings for instrumentation

Requirement for Rack and Pinion type Lift

Project Data

(i)

(ii)

(iii)

6.0

SHEET 6 OF 89

Data from Electrical and Instrumentation Department

(i)

(ii)

(iii)

5.3

SECTION: WRITE-UP

Maximum and minimum ambient temperatures

Basic wind speed and terrain factor as per IS:875 (Part 3)

Seismic zone

LOADS

As per IS 4998 : 1992, the following loads shall be considered to act on the

chimney shell

(a)

(b)

(c)

(d)

(e)

(f)

6.1

Dead loads

Imposed loads

Wind loads

Earthquake loads

Temperature effects or Thermal loads

Moment due to corbel loads

Dead Loads

Dead loads shall include the weight of chimney shell, liners, liner supports,

other accessories and load of ash and soot as applicable. Unit weight of the

materials shall be taken in accordance with IS 875 (Part 1). Unit weight of

certain materials are listed below :

Concrete

Brick lining

Acid proof tiles

Mortar

Cellular concrete

Ash (Flue dust, dry)

Steel

Insulation around flue

6.2

=

=

=

=

=

=

=

=

25 kN/m

20 kN/m

20 kN/m

20.4 kN/m

24 kN/m

7.05 kN/m

78.5 kN/m

0.80 kN/m3

Imposed Loads

Imposed loads shall be taken in accordance with IS 875 (Part 2). The

imposed loads on internal platform and roof of multiflue chimneys shall

include appropriate loads during construction. For the overall design of

chimney shell and foundation, imposed loads need not be considered.

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 7 OF 89

However, for design of individual structural elements such as platforms,

etc. and for local strengthening of the shell, appropriate imposed loads shall

be considered. In the absence of data, the live load on platform can be

assumed as 5 kN/m2. Roof supporting steel framing beams, in the case of

steel flues shall be designed to support concentrated load transmitted by

flue erecting structures. In addition this slab shall also be designed to

support a live load of 15 kN/m2

6.3

Wind Loads

The method of estimating wind loads is given in Annex A of IS 4998 (Part

1) : 1992. In order to estimate the dynamic wind loads, the mode shapes

and frequencies of the chimney shell is necessary. Hence, prior to the

calculation of the wind loads, a free vibration analysis of the chimney shell

has to be done considering it to be a cantilever fixed at base. Any standard

method like STAAD-III, involving discretization of the structure and

assuming it to be made of a homogeneous material with a suitable value of

elastic modulus can be used. The following values of the modulus of

elasticity of concrete shall be considered for calculating the natural

frequencies.

Grade of Concrete

M25

M30

M35

M40

Modulus of Elasticity (N/m)

3.20 x 1010

3.35 x 1010

3.50 x 1010

3.60 x 1010

Wind effect on chimney shell are

(a)

Static or Along-wind load with or without aerodynamic interference

This load induces vibrations in chimneys in the direction of wind.

(b)

Unsteady force with or without aerodynamic interference This force

induces vibrations in chimneys in a direction perpendicular to the

direction of wind flow. The force induced in the direction of wind is

called Along-wind force and that perpendicular to the direction of

wind as Across wind force.

As per IS 4998 (Part 1) : 1992, both the along and across wind forces shall

be calculated by two methods

(i)

(ii)

Simplified method As indicated in clause A-4 and

Random response method As indicated in clause A-5.

The method which yields higher moments shall be considered for the design

of chimney shell.

FORM NO. 120R2

TCE Consulting Engineers Limited

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 8 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

As the formulae given in the code are not fully explicit, they have been

listed here along with a brief explanation.

6.3.1

Simplified method

6.3.1.1

Along-wind load or drag force

The along wind load or drag force per unit height of the chimney at any

level shall be calculated from the equation

Fz = pz . CD . dz

---------(1)

pz = design wind pressure obtained in accordance with IS 875 (Part 3)

z = height of any section of the chimney in mts measured from top of

foundation

CD = drag coefficient of the chimney

dz = diameter of chimney at height z in mts

The design wind pressure (pz) shall be calculated using the 3 seconds gust

wind indicated in clause 5.3 and 5.4 of IS 875 (Part 3). Risk coefficient

factor (k1) is read from Table 1 of IS 875 (Part 3) with the following

condition : The mean probable design life of structure is taken as 25 years

for Shell only condition and as 100 years for shell & lining condition.

Terrain, height and structure size factor (k 2) is read from Table 2 of IS 875

(Part 3) and topography factor (k3) is generally taken equal to 1.

The drag coefficient (CD) of the chimney shell shall be taken as 0.8.

However, if strakes are mounted on the surface of chimney, the drag

coefficient shall be modified as indicated in Table 1 of IS 4998 (Part 1) :

1992.

The moments in the chimney shell shall be calculated treating the chimney

as a free standing structure. For this purpose, sections in the chimney shell

shall be taken at 10m intervals along the height of shell or at every corbel

level whichever distance is less. The load at any section shall be calculated

by suitably arranging the loads above and below it.

6.3.1.2

Across-wind loads

In order to calculate across-wind loads, the following procedure shall be

followed.

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

(a)

SECTION: WRITE-UP

SHEET 9 OF 89

Calculate the effective diameter (d) of chimney shell This is taken as

average diameter over the top 1/3 height of chimney.

For ex. Case 1 For a 150 m high chimney with following

configuration for top 1/3 height (Refer fig.1)

Average dia is calculated as d =

5000 + 7000

--------------- = 6000 mm

2

Case 2 For a 150 m high chimney with following configuration for

top 1/3 height (Refer fig.2)

Average dia is calculated as d =

5000 + 7000

--------------- = 6000 mm

2

This is on the conservative side.

(b) Calculate the wind speed at 5/6 height of chimney using the factors k 1,

k2 and k3 as obtained in clause 6.3.1.1.

(c)

Calculate the critical wind speed (Vcri) for the ith mode of vibration

from the following equation

FORM NO. 120R2

TCE Consulting Engineers Limited

TCE.M6-CV-RC-G-

DESIGN GUIDE FOR RC CHIMNEYS

SECTION: WRITE-UP

SHEET 10 OF 89

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 11 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

fi x d

Vcri = ----Sn

----------(2)

Where fi is the modal frequency for ith mode of vibration

d is the effective diameter as calculated in (a) above and

Sn is strouhal number to be taken as 0.2.

All the modes which give a critical wind speed upto 10% more

than wind speed calculated in item (b) above shall be considered

for subsequent analysis.

(d) For the ith mode of vibration, calculate the amplitude of vortex excited

oscillation perpendicular to the direction of wind by the formula

dz zi dz

o

oi

-----------------

CL

-----------------

----------(3)

2zi dz

4 S2n Ksi

oi = peak tip deflection due to vortex shedding in the ith mode of

vibration in m.

CL = peak oscillatory lift coefficient to be taken as 0.16

H

= height of chimney in m

Sn

= Strouhal number to be taken as 0.2

zi = mode shape function normalized with respect to the dynamic

amplitude at top of the chimney in the ith mode of vibration

Ksi = mass damping parameter for the ith mode of vibration

2mei s /(d 2 )

----------

(4)

s

= logarithmic decrement of structural damping = 2

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 12 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

= structural damping as a fraction of critical damping to be

taken as 0.016

= mass density of air to be taken as 1.2 kg/m

= effective diameter as calculated in (a) above

mei = equivalent mass per unit length in kg/m in the ith mode of

vibration

H

mz zi dz

o

-----------------

----------(5)

zi dz

o

All the above parameters are calculated by integrating over the total

height of the chimney. In the actual case, the integration can be

achieved by dividing the chimney into large number of small segments

and calculating the value of the integrals at the middle of each

segment. The values so obtained are summed over the total height of

the chimney.

The above calculation of oi is acceptable upto 4 percent of the

effective diameter. If the so computed value of oi exceeds 4 percent

of the effective diameter, the amplitude of oscillation oi shall be

increased as follows :

Amplitude of oscillation oi (for computed value of oi 0.04d)

= (computed value of oi) / (0.4d)

(e)

----------(6)

For the ith mode of vibration, calculate the shear force Fzoi and bending

moment Mzoi at any height zo of the section from the equations

H

Fzoi = 4 fi oi mz zi dz

zo

----------(7)

Mzoi

= 4 fi oi mz zi (z zo) dz

zo

----------(8)

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

fi

SECTION: WRITE-UP

SHEET 13 OF 89

= natural frequency of the chimney in Hz in the ith mode of

vibration

mz = mass per unit length of the chimney at section z in kg/m

(f)

Repeat steps (d) and (e) for all the modes to be considered as per step

(c) above.

6.3.2

Random response method

6.3.2.1

Along-wind response

The along-wind response of a chimney shall be calculated by the Gust

Factor method. The use of Gust Factor method requires a knowledge of

Hourly Mean Wind Speed (HMW). Hourly mean wind speed at any height

(z), shall be obtained as per IS 875 (Part 3).

The along-wind load per unit height at any height z on a chimney shall be

calculated from the equation

Fz = Fzm + Fzf

----------(9)

Where, Fzm is the wind load in N/m height due to HMW at height z and is

given by

_

Fzm = pz . CD . dz

----------(10)

The design wind pressure (pz) shall be calculated using the HMW speed

indicated in clause 8.2 and 8.3 of IS 875 (Part 3). Factors k 1 and k3 will be

the same as calculated in clause 5.3.1.1. Terrain, height and structure size

factor (k2) shall be read from Table 33 of IS 875 (Part 3).

The drag coefficient (CD) of the chimney shell shall be taken as 0.8.

however, if strakes are mounted on the surface of chimney, the drag

coefficient shall be modified as indicated in Table 1 of IS 4998 (Part 1) :

1992.

Fzf is the wind load in N/m height due to the fluctuating component of wind

at height z and is given by

Fzf

3 (G-1) z H

= -------- --- Fzm . z . dz

H

H o

----------(11)

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 14 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

H is height of chimney above ground level

G is the Gust Factor which shall be calculated from the equation

G = 1 + gf . r

{B ( SE / )}

----------(12)

Where

gf = peak factor defined as the ratio of the expected peak value to RMS

value of the fluctuating load

=

0.577

(2 log e T

2 log e T

----------(13)

r = twice the turbulence intensity

= 0.622 0.178 log10 H

----------(14)

B = background factor indicating the slowly varying component of

wind load fluctuation

-0.88

1+

0.63

----265

----------(15)

E = a measure of the available energy in the wind at the natural

frequency of chimney

_

[ 123 ( f1 / v10 ) . H0.21 ]

= -------------------------------------------------(16)

_

[ 1 + ( 330 f1 / v10 ) . H0.42 ] 0.83

S = size reduction factor

_

= [ 1 + 5.78 (f1 / v10 )1.14 . H0.98 ]-0.88

3600 f1

T = ----------------1 + B 1/2

SE

----------(17)

----------(18)

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 15 OF 89

f1 = natural frequency of chimney in the first mode of vibration in Hz

_

v10 = hourly mean wind speed in m/sec at 10 m above ground level

_

= Vb . k2

----------(19)

6.3.2.2

Across-wind loads

In order to calculate across-wind loads, the following procedure shall be

followed

(a)

Calculate the effective diameter (d) of chimney shell as explained in

clause 6.3.1.2 (a).

(b)

Calculate the wind speed at 5/6 height of chimney using the factors

k1, k2 and k3 as given in clause 6.3.2.1.

(c)

Calculate the critical wind speed (Vcri) for the ith mode of vibration

as explained in clause 6.3.1.2 (c). All the modes which give a critical

wind speed upto 10% more than wind speed calculated in item (b)

above shall be considered for subsequent analysis.

(d)

Calculate the taper of chimney. Taper is defined as 2(d av dtop) / H

where dav is the average outer diameter over the top half of chimney,

dtop is the outer diameter at top and H is the height of chimney above

ground level.

(dtop + dmidheight)

dav is calculated as --------------------- irrespective of the

2

chimney profile between the two levels.

For example:

Case 1 For a 150 m high chimney with following configuration for

top half of chimney (Refer fig.3)

dav

5000 + 7000

= --------------- = 6000 mm

2

2 (6000 5000)

Taper = -------------------- = 0.01333 = 1 in 75

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 16 OF 89

150000

Case 2 For a 150 m high chimney with following configuration for

top half of chimney (Refer fig.4)

dav

5000 + 7000

= --------------- = 6000 mm

2

2 (6000 5000)

Taper = -------------------- = 0.01333 = 1 in 75

150000

(e)

If the taper of chimney is less than or equal to 1 in 50, calculate the

peak response amplitude (oi) for the ith mode of vibration by the

formula

_

1.25 CL . d . (Hi) x d

_ L _

2

S n

mei

2 ( +2)

oi = ----------------------------------------------------H

1 _ 2zi dz

H

1/2

------(20)

1/2

- ka d

mei

Where

_

CL

= equivalent aspect ratio = H/d

= RMS lift coefficient to be taken as 0.12

FORM NO. 120R2

TCE Consulting Engineers Limited

TCE.M6-CV-RC-G-

DESIGN GUIDE FOR RC CHIMNEYS

SECTION: WRITE-UP

SHEET 17 OF 89

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

(f)

SECTION: WRITE-UP

SHEET 18 OF 89

= correlation length in diameters, which may be taken as 1.0 in

the absence of field data

ka

= aerodynamic damping coefficient to be taken as 0.5

If the taper of chimney is greater than 1 in 50, calculate the peak

response amplitude (oi) for the ith mode of vibration by the formulae

_

CL(d4ze) zei (Hi)

L 1/2

2t

oi = ------------------------------------------------------(21)

H

2 S n mei 2zi . dz .

2

- ka d

mei

1/2

where

Zei = height in mt. at which d4z zi is maximum in the ith mode

t

of vibration

t =

- _ (dz) + . dz

z

z

----------(22)

z = zei

= Power law exponent and shall be taken as given below

Terrain category

1

2

3

4

3 km from sea shore

0.10

0.14

0.18

0.34

0.12

In the above equations both zei and t are unknowns. Hence initially

it is assumed that ze = H and the value of t is calculated. Then the

term d4z zi (say equal to x) is evaluated.

t

The value of z is progressively decreased and the value of x is

evaluated. The value of oi is calculated at height z where x is

maximum. The procedure is repeated for all significant modes.

For very tall chimneys oi may not show a maximum in any of the

modes. In such a case the value of ze shall be taken as that value

where Vcr for that mode equals the maximum expected wind

velocity Vz at ze.

FORM NO. 120R2

TCE Consulting Engineers Limited

SHEET 19 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

6.3.3

SECTION: WRITE-UP

(g)

Calculate the shear force Fzoi and bending moment Mzoi at any

height zo as explained in clause 6.3.1.2 (e).

(h)

Repeat steps (e) or (f) and (g) for all the modes to be considered as

per step (c) above.

Circumferential wind loads

The wind pressure distribution around a chimney is not uniform. This

induces circumferential ring moments. The circumferential moments due to

wind are calculated by the formula

Moe or Moi = 0.33 pz . rm in N-m/m height

----------(23)

Where

Moe and Moi = external and internal ring moments

pz

= design wind pressure at height z in N/m and

rm

= mean radius of the shell at the section under consideration

in mts

The design wind pressure (pz), for the circumferential ring moments, shall

be obtained in accordance with IS 875 (Part 3) clause 5.3 and 5.4, treating

the chimney as class A structure.

The hoop force and shear due to ovalling need not be considered.

6.3.4

Ovalling oscillations

Because of the relatively small thickness of the chimney at the top

compared to its diameter, possibilities of ovalling oscillations will have to

be examined only if the diameter of the chimney exceeds 75 times the wall

thickness at top.

6.3.5

Aerodynamic interference

All the above calculations for wind load are for isolated chimney. When a

cluster of chimneys is present, aerodynamic interference between them may

increase the total wind load. Aerodynamic interference shall be considered

for along-wind load only if the spacing between the centre lines of the

chimneys is less than 3 times the effective diameter of the largest chimney.

The enhancement in wind loads will be due to an increase in the value of

CD. The value of CD for each chimney located within a distance of 3 times

the effective diameter, may be calculated by assuming the value of CD to be

increasing linearly from 0.8 (for a spacing of 3 effective diameters) to a

FORM NO. 120R2

TCE Consulting Engineers Limited

TCE.M6-CV-RC-G-

DESIGN GUIDE FOR RC CHIMNEYS

SECTION: WRITE-UP

SHEET 20 OF 89

value of 2.0 (for a hypothetical spacing of 1 effective diameter which

implies that the two chimneys touch each other if they are cylindrical and

identical). These values of CD apply up to the height of the nearest

interfering chimney, if the chimneys are of unequal height. It is permissible

to obtain more accurate values of CD by carrying out properly conducted

model tests in wind tunnels.

When identical chimneys are spaced at less than 20 times the diameter at

2/3rd height, the amplitudes of oscillation of the downstream chimneys are

found to be magnified due to aerodynamic interference. The term

magnification is used to denote the ratio of the amplitude of across-wind

oscillation when there is periodic vortex induced aerodynamic interference

to the amplitude of across-wind oscillations when there is no aerodynamic

interference. For a given configuration of identical chimneys, the

magnification factor for the across-wind amplitude oi (calculated as per

clause 6.3.1.2 or 6.3.2.2) is indicated in Fig.1 of IS 4998 (Part 1) : 1992. In

case of dissimilar chimneys a model study is necessary to determine the

magnification factor.

6.3.6

Remedial measures for suppressing across wind oscillation

The across wind oscillations can be suppressed by providing discrete

strakes on the outer surface of the chimney. Clause A-7 of IS 4998 (Part1) : 1992 gives the details of strakes. The provision of strakes increases the

drag coefficient over the height where they are mounted. The incremental

drag coefficient is indicated in Table 1 of IS 4998 (Part 1) : 1992, and they

should be added to the basic drag coefficient CD = 0.8.

Discrete strakes can also be used to suppress or minimize large across-wind

amplitudes in single chimneys. In such cases, magnification in Table 1 shall

be taken as the ratio of the calculated across-wind amplitude to the alongwind amplitude.

6.4

Seismic Loads

The seismic loads on a chimney are estimated using the response spectrum

method. The mode shapes and natural frequencies obtained for dynamic

wind load analysis can also be used to conduct a seismic analysis for the

chimney. Usually the first five modes are considered for analysis. In the

absence of a site specific response spectrum, the spectrum indicated in IS

1893 shall be used for the estimation of earthquake loads.

In order to estimate the seismic loads, the chimney shall be considered as a

cantilever fixed at base and any standard method like STAAD III involving

discretization of the structure and lumping the mass at the nodes can be

used.

6.5

Thermal Loads

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 21 OF 89

Thermal loads are induced due to temperature gradients present in chimney

shell. The temperature gradients are significant for single flue chimneys with

or without ventilated air space. Those chimneys which enclose well

insulated flues situated some distance from the shell and in which the

intermediate space is sufficient to provide access for inspection, rarely have

temperature design problems.

6.5.1

Estimation of temperature gradient

Clause D-2.2.3 of IS:4998 (Part 1) 1975 gives the formula for calculating

temperature gradient across chimney shell. Four cases have been considered

(a) Unlined chimneys

(b) Lined chimneys with insulation completely filling the space between

the lining and shell

(c) Lined chimneys with unventilated air space

(d) Lined chimneys with ventilated air space.

Case (a), (b) and (c) are now obsolete. Hence Case (d) has been dealt

further.

As per clause C-1 of IS:4998 (Part 1) 1975, chimneys with ventilated air

space should satisfy the following conditions:

(i)

Air inlets shall be provided near the base with proper covering for the

openings so as to prevent any dirt or tiny creatures entering the air

gap.

(ii)

The number and size of openings in the chimney wall and each corbel

shall be such as to have a total area of not less than two-thirds of the

area of minimum air gap.

(iii) Such openings in shell may be distributed in more than one layer, if

required, to minimize the reduction in shell area which may otherwise

weaken the shell.

(iv) Adequate arrangement should be made at the top of chimney for

egress of the heated air.

As per equation 15 of IS 4998 (Part 1) 1975, temperature gradient

tDbi

Tx = -----(24)

CcDc

T - To

------------------------------------------------1_+

tb Dbi_ +

rqK1 rqCbDb

Dbi +

KsDs

tDbi +

CcDc

------

Dbi _

K2 Dco

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 22 OF 89

NOTE : The research data available to establish the coefficients of heat

transfer through chimney lining and wall, specially as they concern

the heat transfer from gases to the surfaces and through ventilated

air spaces between lining and wall, are somewhat meagre. Unless

complete heat balance studies are made for the particular chimney,

it is permissible to use constants as stated below. These constants

when entered into the equations for temperature differential

through the chimney shell,Tx, will give values of accuracy in

keeping with the basic design assumptions:

rq = 0.5

K1 = to be determined from curves in Fig.3 of

IS:4998(part1)-1975

Cc = 1.488

K2 = 58.59

Cs and Cb = to be obtained from the manufacturer of the

materials used

Kr = 0.0732 T + 1.3

Ks = 0.0586 T + 1.0

The value of rq = 0.5 shall apply only where the distance between

the lining and the chimney shell is not less than 100 mm

throughout the entire height of the lining and air inlet openings are

provided through the chimney shell at the bottom of the lining

having an area in square centimetres numerically equal to twenty

times the inside diameter in centimetres of the chimney shell at the

top of the lining. Local obstructions in the air space between the

lining and the chimney shell shall not restrict the area of the air

space at any horizontal section to less than that specified for air

inlet at the bottom of the lining.

6.6

Moment due to Corbel Loads

As per clause 5.5 of IS 4998 (Part 1) : 1992,

Moment due to loads on corbels, MK is

MK = . W.e

----------(25)

Where

MK = moment due to corbel in N-m

W = load due to corbel in N and

e = distance between centre line of the shell and the centre of gravity of

the load in m

whenever the corbel is above or below an opening, the moment M K shall be

taken = W.e

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 23 OF 89

In the above formula (+) and (-) refer to the tension on inner face of the

shell above the corbel and outer face of the shell below the corbel

respectively. The effect of this may be taken as distributed over a length

equivalent to the depths of the corbel at the junction with the shell or 0.76

(rmts), in m whichever is greater, where

rm = mean radius of the shell at section under consideration in m

ts

7.0

= thickness of the shell at the section under consideration in m

LOAD COMBINATIONS

As per clause 5.3 of IS 4998 (Part 1) : 1992, the various load combinations

to be considered for the design of chimney shell shall be :

(a)

(b)

(c)

(d)

(e)

(f)

(g)

(h)

(i)

Dead loads

Dead loads + Wind loads

Dead loads + Earthquake loads

Dead loads + Thermal loads

Dead loads + Wind loads + Thermal loads

Dead loads + Earthquake loads + Thermal loads

Circumferential effect due to wind

Circumferential effect due to temperature

Circumferential effect due to wind + temperature

NOTES

1. Across-wind loads shall be combined with the coexisting along-wind

loads. The combined design moment at any section shall be taken as the

root sum square of the moments due to the across-wind loads and the

co-existing along-wind loads.

2. Loading conditions (b) and (c) shall be considered for shell alone case

also.

3. Secondary effects due to deflection shall be considered for one cycle.

4. Design should also consider effects due to local loads, if any, on the

shell.

8.0

PERMISSIBLE STRESSES

As per clause 7 of IS:4998 (Part 1) 1975, the stresses in concrete and

steel shall not exceed the following limits for various combinations of loads.

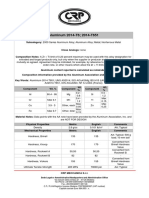

TABLE- 1 Permissible stresses

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 24 OF 89

Load Combination

Stress limit in Stress limit

concrete

in steel

Dead load + wind load

0.275 cu

0.57 sy

Dead load + earthquake force

0.40 cu

0.60 sy

Dead load + temperature effect

0.33 cu

0.55 sy

Dead load + wind load + temperature 0.50 cu

effect

0.65 sy

Dead load + earthquake

temperature effect

+ 0.50 cu

0.65 sy

Circumferential stress due to temperature

0.30 cu

0.50 sy

Circumferential stress

induced ring moment

wind 0.07 cu

(tensile)

0.50 sy

Circumferential stress due to combined 0.40 cu

effect of wind induced ring moment and (compressive

temperature

)

due

force

to

0.65 sy

cu = 28 days ultimate cube strength of concrete in kg/cm

sy = yield or proof stress of steel in kg/cm

Stress limits has not been specified for dead load alone case. For this case,

the value specified in (a) above may be used. The stresses in concrete due

to wind induced ring moments shall be estimated neglecting the effect of

reinforcement. If the tensile stress in concrete are less than the value

specified in (g) above, then minimum circumferential reinforcement shall be

provided. If the stress exceeds the limit, then circumferential reinforcement

shall be provided treating the section as a cracked section.

9.0

DESIGN PROCEDURE

9.1

Proportioning

The height of the chimney as well as the diameter at the top are normally

chosen so that exit velocity and dispersion of gases are within the specified

limits. The bottom diameter is more frequently controlled by the structural

requirements of both the concrete shell and the foundation. A height to

outside base diameter ratio in the range of 10-15 will provide good

proportion for the design of both the chimney and the foundation.

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 25 OF 89

In cases of multiflue chimneys, the internal diameter is usually kept constant

with only the shell thickness varying with height.

9.2

Minimum Requirements

The following requirements regarding the chimney shell shall be adopted

9.3

1)

The maximum width of the openings shall normally be limited to an

angle of not more than 60 subtended at the centre of the concrete

shell. Where the extent of shell left, between two openings, is limited

such that the subtended angle is less than 45, procedures as normally

adopted for column design, shall be adopted to check the adequacy of

the shell in this design.

2)

The minimum thickness of concrete shell shall be 200 mm for

chimneys with an internal diameter of 8500 mm or less. For portions

having an internal diameter exceeding 8500 mm, the minimum shell

thickness shall be increased by 5 mm for every 500 mm (or part

thereof) increase in diameter over 8500 mm. For multi-flue chimneys

with steel flues which are top hung, it is preferable to have a minimum

thickness of 300mm for the concrete shell.

3)

The grade of concrete in chimney shell shall be minimum M25 and

shall not be richer than M40 if slip forming is used.

Design Methodology

The chimney is designed as a cantilever beam of circular cross section.

Direct load is due to vertical load while moments are created by horizontal

wind or earthquake forces. The chimney is designed using working stress

method as explained in IS 4998 (Part 1) : 1975.

Stresses in the chimney shell are checked at various sections. Generally

these sections should be at 10 m intervals along the height of the shell or at

corbel levels whichever is less and in addition at the location of openings.

9.4

Formulae for stress calculation.

Appendix D of IS 4998 (Part I) 1975 gives the formulae for stress

calculation in chimney shell. But there is some difference in the formulae

when compared with ACI-307-1979. Text book Tall chimneys Design

and Construction by S. N. Manohar also gives a set of formulae for

calculating the stresses which match with the ACI code. Hence, the

formulae given in the text book have been reproduced below.(Refer fig.5 )

9.4.1

Vertical stress due to axial load and moment.

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 26 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

1.0Neutral axis within section.

(a) For < < -

----------(26)

D = Sin - Sin - ( - ) Cos

----------(26a)

E = (-2--) Cos + Sin - Sin + 2Cos. Sin

----------(26b)

1 2

2

2

cos 3 sin 2 sin 2 2 cos sin

1

4

----(26c)

G=

1 2 cos 2 0.25 2 cos 2.sin 2 3sin 2 sin 2

2

2 cos sin - 2cos .sin

(b) For -<<+

D = sin(-)-sin-(--)cos.

E = (---)cos-sin+sin(+)

----------(26d)

----------(27)

----------(27a)

----------(27b)

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 27 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

F=

1 2

2

2

cos sin 2( ) sin 2 2 cos (sin( ) sin )

1

4

----------(27c)

1

1

( )(1 2 cos 2 ) sin 2 sin 2( )

2

4

2 cos sin sin( )

----------(27d)

G=

(c) For +<<-

---------(28)

D = cos(2+-)-2cossin-sin+sin

----------(28a)

E ( ) cos sin sin

----------(28b)

1

1

( 2 )(1 2 cos 2 ) 3 sin 2 sin 2 2 cos 2 .sin 2

2

4

F=

2 cos (sin 2 cos .sin )

G=

----------(28c)

1

1

2

( )(1 2 cos ) (sin 2 3 sin 2 ) 2 cos . sin

2

4

-------(28d)

For cases (a), (b) and (c) above

C

cos cos

1 np D npE

c(cos cos )

cos cos

e 1 np F npG

cos

r 1 np D npE

np

mp

1 - p

---------(29)

---------(30)

---------(31)

----------(32)

2. Neutral axis outside section.

I=

1

1

( 2 ) (2 cos 2 .sin 2 sin 2 sin 2 )

2

4

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 28 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

sin sin 2 cos . sin

---------(33)

x

sin sin 2 cos . sin

1

r

2

---------(34)

1

1

1 e

X

X

(

( 1 )(1 cos ))

2(1 np) 2 I r

r

r

----------(35)

Vertical stress in concrete due to axial load and moment

fc

C.W

---------(36)

r t(1 - p)

Maximum vertical stress in concrete due to axial load and moment when

neutral axis lies within the section.

fc(max) = fc

1 2rcos (cos cos )

----------(37)

Maximum vertical stress in steel due to axial load and moment

fs Sm

W

rt (1 p )

----------(38)

3. Location of Neutral Axis.

The neutral axis will lie within a section for such values of the ratio e/r

when the corresponding values are less than - . The e/r ratio at which

= - for different and opening half angles are given in table below.

For given opening half angles, if the actual e/r value is greater than the

corresponding value given in table below, then the neutral axis will lie

within the section.

TABLE 2 e/r Values for = -

00

150

200

250

300

00

0.500

0.515

0.525

0.537

0.551

150

0.403

0.419

0.430

0.443

0.458

200

0.365

0.381

0.392

0.406

0.421

250

0.324

0.340

0.352

0.365

0.381

300

0.280

0.297

0.308

0.323

0.339

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 29 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

From the above table, check whether the neutral axis at a given section

falls within or outside the section. If the neutral axis falls within the

section, then by trial and error, find the value of such that the ratio e/r

calculated using equation 26 or 27 or 28 is equal to the actual e/r for that

section (i.e., M/Pxr). With this value of obtained, calculate the stresses

in concrete and steel using equations 36, 37 and 38.

In case the neutral axis falls outside the section, then calculate the stress in

concrete using equations 33, 34, 35 and 36.

9.4.2

Vertical stresses due to temperature alone(Refer fig 6)

The vertical stresses in concrete and steel due to temperature alone can be

calculated using the formulae given below.

Maximum compressive stress in concrete

= fc = n x x Tx x Ec

----------(39)

Compressive stress in steel on hot face

fsh = x Tx x Es (a + n 1).

----------(40)

Tensile stress in steel on cold face

fsc = x Tx x Es (a n).

----------(41)

Where

n = -mp +

9.4.3

2 2

m p 2mp a(1 k) k(1 a)

----------(42)

Vertical stresses due to axial load, moment and temperature

The vertical stresses in concrete and steel due to combined effect of

load, moment and temperature can be calculated using the formulae given

below.

Fictitious Stress ft =

Ec T x

2

----------(43)

(a) Leeward Side

(i) Neutral axis within section (ft > fc).

Compressive stress in concrete fc = fcomb

---------(44)

----------(44a)

Compressive stress in steel on hot face

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 30 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

fsh = {fcomb 2ft (1-a)} x m

----------(44b)

Tensile stress in steel on cold face

fsc = {2aft fcomb} x m

----------(44c)

Where

2

fc

(1 mp)

mp mp 2mp k(1 a) a(1 k)

f'

t

fcomb = 2ft

----------(44d)

(ii)Neutral axis outside section (ft < fc)

----------(45)

Compressive stress in concrete fc = (fcomb ft).

Compressive stress in steel on hot face

fsh = (fcomb 2ft(1-a)) x m

Compressive stress in steel on cold face

fsc = (fcomb 2aft) x m

-------(45a)

----------(45b)

----------(45c)

Where

f' t1 2mp(k(1 a) a(1 k))

fcomb = fc +

1 mp

----------(45d)

(b) Windward side.

(i) Neutral axis within section (fs < mft).

Maximum tensile stress in steel

fsc = m(2aft fcomb).

----------(46)

----------(46a)

Where

pfs

2

fcomb = 2ft mp mp 2mp k (1 a) a(1 k )

f 't

(ii)Neutral axis outside section (mft < fs)

Maximum tensile stress in steel

fsc = fs + 2mk ft (2a-1).

9.4.4

---(46b)

----------(47)

----------(47a)

The maximum circumferential compressive stress in concrete due to

temperature alone, CTC, can be calculated by the formula

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 31 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

CTC = LK Tx Ec

----------(48)

where

K = -pm + pm (pm + 2Z)

----------(49)

p = ratio of cross sectional area of the circumferential reinforcing steel

per unit of height to the cross sectional area of the chimney shell per unit of

height and

Z = ratio of distance between the inner surface of the chimney shell and

the circumferential reinforcing steel to the total shell thickness t

9.4.5

The maximum circumferential tensile stress in steel due to temperature

alone STC can be calculated by the formula

STC = L (Z K) Tx Es

9.4.6

The maximum circumferential tensile stress in concrete due to wind induced

ring moment cwct can be calculated by formula

cwct = 2 x 10-4 Wp r/t

9.4.7

----------(51)

The maximum circumferential compressive stress in concrete due to wind

induced ring moment, cwcc can be calculated by formula

cwcc = 2 x 10-4 Wp r/t

9.4.8

----------(50)

----------(52)

The maximum circumferential tensile stress in steel due to wind induced

ring moment swct can be calculated by formula

swct = 4 x 10-3 Wpr/As t1

----------(53)

NOTE : In 9.4.9, 9.4.10 and 9.4.11 r, t and t 1 are in Cm, Wp in kg/m and

in kg/cm

9.4.9

Circumferential stresses in steel and concrete due to combined effect of

wind induced ring moments and that due to temperature can be calculated

by algebraic addition of stresses due to individual cause.

9.4.10

If the circumferential tensile stress in concrete, as calculated in clause 9.4.6,

exceeds the stress limits specified in clause 8.0, then design the shell as a

cracked section using the following formulae:

(a)

Maximum circumferential compressive stress in concrete due to wind

induced ring moments fcwc

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 32 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

M

1

fcwc = --- x K x t x ---------------------------------------------t

K + np [(K-1+Z) C + (Z-K) ]

3

----------(54)

where

M = circumferential ring moment calculated as per clause 5.3.3

t

= thickness of the shell at the section considered

K = -pn (C+1) + [pn (C+1)] + 2pn [Z+C(1-Z)]

--(55)

p = ratio of the cross sectional area of the circumferential

outside face reinforcing steel per unit of height to the

sectional area of the chimney shell per unit of

cross

height

C = ratio of inside face circumferential reinforcing steel area

the outside circumferential reinforcing steel area

to

Z = ratio of the distance between the inner surface of the

chimney shell and circumferential outside face

reinforcing steel to the total shell thickness, t

n = ratio of modulus of elasticity of the reinforcement to the

modulus of elasticity of the concrete

(b)

The maximum tensile stress in circumferential reinforcement due to

wind induced ring moments fswc

fswc = nfcwc [ Z 1 ]

K

9.5

----------(56)

Design Procedure

The following procedure may be followed for using the formulae:

(a) Compute the bending moment M due to wind or earthquake force

acting above the section under consideration.

(b) Compute the dead load W of the portions, of chimney, above the

section under consideration

(c) Determine e = M/W

(d) Determine e/r

(e) Assume p at the section under consideration

(f) Select the value of m for concrete grade to be used

FORM NO. 120R2

TCE Consulting Engineers Limited

SHEET 33 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

(g)

(h)

(i)

(j)

(k)

(l)

(m)

9.6

SECTION: WRITE-UP

Determine

Determine stresses

Calculate temperature stress in steel and concrete

Calculate stress in steel and concrete due to wind induced moments

Check combined stresses

Check stresses due to corbel moments

If stresses exceed the corresponding permissible stress limits, increase

shell thickness or reinforcement or both and repeat the steps.

Deflection

As per clause 8 of IS 4998 (Part 1) 1975, permissible deflection shall not

exceed 1/500 of height above top of foundation subject to the provisions in

clause C-1.1.3 of the above code. In case of self supported linings, chimney

deflection due to wind should be checked to ensure that shell does not

come into contact or exert pressure on the lining.

For the 3 sec. wind load, static modulus of elasticity of concrete shall be

used for deflection check. For the HMW with gust, dynamic modulus of

elasticity of concrete shall be used.

9.7

Detailing Practice and Requirements

The clear concrete cover over the vertical reinforcement in the shell shall

not be less than 50 mm. For other detailing requirements refer the standard

specification.

10.0

CHIMNEY PROGRAM

An in-house program called CHMND (Program No. TCE.M6-CV-AMC400) has been developed for the analysis and design of chimney shell. This

program can be used for the complete analysis and design of chimney shell

for both single flue and multiflue chimney.

11.0

DESIGN EXAMPLE

Example: A 150m tall RC chimney (single brick flue) for Jojobera thermal

power plant has been analysed and designed. The details of the structure are

as follows:

i) Shell profile

E.L. of ground level

E.L. of chimney top

E.L. of chimney bottom

Shell thickness at E.L. 150.000

Inner diameter of chimney at E.L. 150.000

Outside taper of chimney from E.L.150.000

0.000m

150.000m

(-) 2.000m

0.3m

4.6m

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 34 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

to E.L.100.000

1 in 500

Shell thickness at E.L. 100.000

0.4m

Shell thickness varies linearly from E.L.150.000 to

E.L. 100.000

Outside taper of chimney from E.L.100.000

to E.L. (-) 2.000

1 in 40

Shell thickness at E.L. 10.000

0.55m

Shell thickness varies linearly from E.L.100.000 to E.L.10.000

Shell thickness at E.L. (-) 2.000

0.55m

Shell thickness is constant from E.L.10.000 to E.L. (-) 2.000

ii) Shell material properties

Density of concrete

Concrete grade from E.L.150.000 to E.L.50.000

Concrete grade from E.L.50.000 to E.L.10.000

Concrete grade from E.L.10.000 to E.L. (-) 2.000

25 kN/m3

M25

M30

M35

iii) Opening details

3.05m wide opening from E.L.5.150 to E.L.8.85 at 90 and 270

1.1m wide opening from E.L.0.000 to E.L.2.100 at 270

1.2m wide opening from E.L.148.850 to E.L.149.450 at 0, 90,

180, 270

iv) Additional concentrated loads

These are due to brick lining, external platforms, hopper, internal

platforms etc. and have been considered as 260, 345, 345, 335, 345,

455, 360, 370, 555, 575, 720, 885, 900, 910, 640 and 110kN at

E.L.147.000, 137.000, 127.000, 117.000, 107.000, 97.000, 87.000,

77.000, 67.000, 57.000, 47.000, 37.000, 27.000, 17.000, 12.000 and

5.000 respectively.

v)

Temperature data

A constant temperature gradient of 55C across shell thickness has been

considered for the entire chimney height.

vi)

Wind data

Basic wind speed

Mean probable design life for shell only condition

Mean probable design life for lined condition

Terrain category number

Topography factor

47 m/s

25 years

100 years

2

1

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 35 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

Damping as a percentage of critical damping

1.6

Strouhal number

0.2

Magnification factor due to closeness of two

1.75

chimneys

Drag coefficient for entire chimney height

0.8

(It is assumed that strakes are not provided. If strakes are provided C d

shall be modified as per Table 1 of IS:4998(Part 1)-1992)

vii) Seismic data

Damping as a percentage of critical damping

Seismic zone number

Structure importance factor

Soil-foundation system factor

Performance factor

viii)

5

2

1.75

1

1

Others

Exit diameter of brick flue

Grade of reinforcement

Effective cover to vertical reinforcement

Effective cover to circumferential reinforcement

Number of chimneys

Spacing between chimneys

3.6m

Fe 415D

72mm

56mm

2

67.5m

The following sheets give the geometry and the loads considered for the analysis and design of

chimney shell

UNITS FOLLOWED FOR VARIOUS ITEMS

---------------------------------------SL NO. ITEM

UNIT

---------------------------------------1

2

3

4

5

6

7

8

9

10

ELEVATION

m

THICKNESS/DIA

m

WIDTH/HEIGHT

m

AREA

Sq.m

MOMENT OF INERTIA

m^4

UNIT WEIGHT

kN/Cu.m

WEIGHT

kN

VOLUME

Cu.m

CONCRETE STRENGTH

N/Sq.mm

ELASTIC MODULUS

kN/Sq.m

---------------------------------------SHELL PROFILE

------------TOP LEVEL OF CHIMNEY

CLEAR INNER DIA. AT TOP

NO. OF SHELL GROUPS

= EL+ 150.000

= 4.600

= 14

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 36 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

ELEVATION

SHELL THICK

150.000

0.300 0.300

147.000

0.306 0.306

100.000

0.400 0.400

97.000

0.405 0.405

57.000

0.472 0.472

50.000

0.483 0.483

47.000

0.488 0.488

17.000

0.538 0.538

12.000

0.549 0.549

10.000

0.550 0.550

6.000

0.550 0.550

5.000

0.550 0.550

4.000

0.550 0.550

0.000

0.550 0.550

-2.000

0.550 0.550

SLOPE

INTERVAL

1 IN500.000

1.000

1 IN500.000

10.000

1 IN 40.000

3.000

1 IN 40.000

10.000

1 IN 40.000

7.000

1 IN 40.000

3.000

1 IN 40.000

10.000

1 IN 40.000

5.000

1 IN 40.000

2.000

1 IN 40.000

2.000

1 IN 40.000

1.000

1 IN 40.000

1.000

1 IN 40.000

2.000

1 IN 40.000

2.000

MATERIAL PROPERTIES

------------------UNIT WEIGHT OF SHELL = 25.000

NO.OF GRADES

= 3

ELEVATION TO ELEVATION

CONCRETE

RATIO

150.000

50.000

10.000

50.000

10.000

-2.000

DETAILS OF OPENINGS

------------------NO. OF OPENINGS =

MODULAR

M 25.

10.98

M 30.

M 35.

8.12

E-STATIC

E-DYNAMIC

0.19120E+08

0.32000E+08

9.33

0.22500E+08

0.33500E+08

0.25860E+08

0.35000E+08

------------------------------------------------------ELEVATION TO ELEVATION WIDTH ALPHA

------------------------------------------------------OPENING 1

5.150

8.850

3.05

90.00

OPENING 2

5.150

8.850

3.05

90.00

OPENING 3

0.000

2.100

1.10

90.00

OPENING 4

148.850

149.450

1.20

0.00

OPENING 5

148.850

149.450

1.20

90.00

OPENING 6

148.850

149.450

1.20

90.00

OPENING 7

148.850

149.450

1.20 180.00

-----------------------------------------------------------DETAIL OF CONCENTRATED LOADS

----------------------------

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 37 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

-----------------------------NO. ELEV

LOAD

-----------------------------1 147.000

260.0

2 137.000

345.0

3 127.000

345.0

4 117.000

335.0

5 107.000

345.0

6

97.000

455.0

7

87.000

360.0

8

77.000

370.0

9

67.000

555.0

10

57.000

575.0

11

47.000

720.0

12

37.000

885.0

13

27.000

900.0

14

17.000

910.0

15

12.000

640.0

16

5.000

110.0

-----------------------------------------------------------*********************************

* TABLE OF SECTIONAL PROPERTIES *

*********************************

---------------------------------------------------------------------------------------------------------------------------------NODE ELEV

SHELL SHELL DIAMETER

THICK OUTER MEAN

AREA MOM OF BRICK LINING AREA

M of I

INERTIA THICK MEANDIA

AT MID_LEVELS

---------------------------------------------------------------------------------------------------------------------------------1 150.000

0.300

5.200

4.900

4.618

13.912

2 149.000

0.302

5.204

4.902

3.186

9.624

3 148.000

0.304

5.208

4.904

4.684

14.134

4 147.000

0.306

5.212

4.906

4.716

14.245

5 137.000

0.326

5.252

4.926

5.045

15.369

6 127.000

0.346

5.292

4.946

5.376

16.520

7 117.000

0.366

5.332

4.966

5.710

17.698

8 107.000

0.386

5.372

4.986

6.046

18.902

9 100.000

0.400

5.400

5.000

6.283

19.761

10

97.000

0.405

5.550

5.145

6.546

21.795

11

87.000

0.422

6.050

5.628

7.457

29.694

12

77.000

0.438

6.550

6.111

8.419

39.510

13

67.000

0.455

7.050

6.595

9.432

51.519

14

57.000

0.472

7.550

7.078

10.495

66.018

15

50.000

0.483

7.900

7.417

11.254

77.719

16

47.000

0.488

8.050

7.562

11.593

83.214

4.634

13.967

4.667

14.078

4.700

14.189

4.880

14.804

5.210

15.942

5.543

17.106

5.878

18.296

6.165

19.329

6.414

20.760

6.995

25.521

7.932

34.345

8.919

45.222

9.957

58.438

10.872

71.693

11.423

80.432

12.168

93.000

FORM NO. 120R2

TCE Consulting Engineers Limited

SECTION: WRITE-UP

SHEET 38 OF 89

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

17

37.000

0.505

8.550

8.045

12.756

103.610

18

27.000

0.521

9.050

8.529

13.968

127.479

19

17.000

0.538

9.550

9.012

15.232

155.185

20

12.000

0.549

9.800

9.251

15.956

171.287

21

10.000

0.550

9.900

9.350

16.156

177.157

22

8.000

0.550

10.000

9.450

12.912

109.308

23

6.000

0.550

10.100

9.550

13.086

113.568

24

5.000

0.550

10.150

9.600

16.588

191.716

25

4.000

0.550

10.200

9.650

16.674

194.721

26

2.000

0.550

10.300

9.750

16.240

186.477

27

0.000

0.550

10.400

9.850

16.413

192.410

28

-2.000

0.550

10.500

9.950

17.192

213.411

13.356

115.088

14.594

140.829

15.592

163.088

16.056

174.205

16.242

180.007

12.999

111.425

13.130

114.650

16.631

193.215

16.760

197.757

16.327

189.428

17.106

210.216

==================================================================================

********************

* TABLE OF WEIGHTS *

********************

NOTE:THE CUM. WT. AT TOPMOST NODE IS FICTITIOUS-A WEIGHT OF 10 HAS BEEN PUT TO

AVOID ZERO LOAD CONDITION

------------------------------------------------------------------------------------------------------------------------------------NODE ELEV

CORBEL GALLERY LANDING SLAB SHELL

LINING WT.

WITHOUT LINING WT.WITH LINING

NODAL CUM

NODAL CUM

----------------------------------------------------------------------------------------------------------------------------------------1

115.9

2

116.7

3

117.5

4

1219.9

5

1302.4

150.000

0.0

0.0

0.0

57.9

10.0

149.000

0.0

0.0

0.0

116.3

115.9

148.000

0.0

0.0

0.0

117.1

232.5

147.000

0.0

0.0

0.0

668.7

350.0

137.000

0.0

0.0

0.0

1261.2

1570.0

FORM NO. 120R2

TCE Consulting Engineers Limited

DESIGN GUIDE FOR RC CHIMNEYS

TCE.M6-CV-RC-G-

SECTION: WRITE-UP

SHEET 39 OF 89

6 127.000

0.0

0.0

0.0

1344.0

2872.4

1385.6

7 117.000

0.0 0.0

0.0

1427.5

4258.0

1469.3

8 107.000

0.0

0.0

0.0

1274.1

5727.3

1078.8

9 100.000

0.0

0.0

0.0

779.9

6806.1

481.1

10 97.000

0.0

0.0

0.0

1115.1

7287.2

1749.2

11 87.000

0.0

0.0

0.0

1866.3

9036.3

1983.3

12 77.000

0.0

0.0

0.0

2106.8

11019.7

2230.2

13 67.000

0.0

0.0

0.0

2360.0

13249.9

2489.7

14 57.000

0.0

0.0

0.0

2196.2

15739.6 1902.7

15 50.000

0.0

0.0

0.0

1379.7

17642.3

856.8

16 47.000

0.0

0.0

0.0

1949.6

18499.1

3042.4

17 37.000

0.0

0.0

0.0

3190.9

21541.5

3339.3

18 27.000

0.0

0.0

0.0

3494.1

24880.9

3648.9

19 17.000

0.0

0.0

0.0

2799.0

28529.8

1949.0

20 12.000

0.0

0.0

0.0

1375.9

30478.8

802.8

21 10.000

0.0

0.0

0.0

807.4

31281.6

812.1

22 8.000

0.0

0.0

0.0

816.4

32093.7

820.7

23 6.000

0.0

0.0

0.0

617.2

32914.4

413.6

24 5.000

0.0

0.0

0.0

414.7

33328.0

415.8

25 4.000

0.0

0.0

0.0

626.9

33743.8

838.0

26 2.000

0.0

0.0

0.0

842.3

34581.8

846.7

27 0.000

0.0

0.0

0.0

851.0

35428.5

855.3

28 -2.000

0.0

0.0

0.0

0.0

36283.8

-------------------------------------------------------------------------------------------------------------------------------------TOTAL

0.0

0.0

0.0

0.0

0.0

-------------------------------------------------------------------------------------------------------------------------------------===============================================================================

MATERIAL PROPERTIES

-------------------------------------------------------------------------------NODE ELEV CONCRETE MODULAR

E-STATIC

RATIO

-------------------------------------------------------------1

2

3

4

5

6

150.000

149.000

148.000

147.000

137.000

127.000

M 25.00

M 25.00

M 25.00

M 25.00

M 25.00

M 25.00

10.98

10.98

10.98

10.98

10.98

10.98

E-DYNAMIC

0.19120E+08

0.19120E+08

0.19120E+08

0.19120E+08

0.19120E+08

0.19120E+08

0.32000E+08