Académique Documents

Professionnel Documents

Culture Documents

A3s Ti

Transféré par

Nguyen Xuan QuangTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A3s Ti

Transféré par

Nguyen Xuan QuangDroits d'auteur :

Formats disponibles

TI-P132-09

ST Issue 5

Cert. No. LRQ 0963008

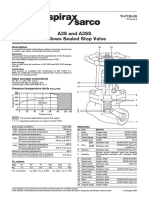

A3S

Bellows Sealed Stop Valve

ISO 9001

Description

15

14

A screwed and socket weld bellows sealed, in line stop valve for

use on steam, gas, liquid, condensate and water systems.

Sizes and pipe connections

", ", 1", 1", 1" and 2"

Screwed BSP (BS 21 parallel), NPT

Socket weld to BS 3799 /ANSI B 16.11

Limiting conditions

13

Body design conditions

Class 800

PMA Maximum allowable pressure

136 bar g

TMA Maximum allowable temperature

425C

Maximum operating pressure

99 bar g

PMO

Maximum operating pressure

40 bar g

for extended bellows life

TMO Maximum operating temperature

400C

Designed for a maximum cold hydraulic test pressure of 212 bar g

17

16

9

3

12

Temperature C

Operating range (Class 800)

11

425

400

300

Steam

saturation

curve

200

100

0

10

7

0

20

40*

60

80

Pressure bar g

99*

120

136

6

This product must not be used in this region.

Operating restrictions to conform to BS 5352.

* PMO Maximum operating pressure recommended for saturated

steam.

5

4

Materials

No.

1

2

3

4

Part

Body

Bonnet

Gland flange

Integral seat

Material

Forged steel

Forged steel

Forged steel

Stellite

Disc

Stainless steel

6

7

8

9

10

11

12

13

14

15

16

17

Bellows

Gaskets

Body bolts

Gland nuts

Gland studs

Stem packing

Gland follower

Handwheel

Wheel nut

Name-plate

Stem

Yoke nut

Stainless steel

Stainless steel /graphite

Carbon steel

ASTM A276 B7

Carbon steel

ASTM A194 2H

Stainless steel

AISI 410

Graphite

Stainless steel

ASTM A276 Type 410

Carbon steel

Carbon steel

Stainless steel

Stainless steel

ASTM A276 Type 410

Stainless steel

ASTM A582 Type 416

ASTM A105

ASTM A105

ASTM A105

Gr. 6

ASTM A276 Type 410

+ stellite Gr. 6

ASTM A479 Type 321

Certification

This product is available with certification to EN 10204 3.1.B.

Note: All certification /inspection requirements must be stated at the

time of order placement.

Standards

Valve bellows fatigue life conforms to BS 5352 for globe valves.

(see operating restrictions).

Seat leakage

Disc to seat shut-off conforms to API 598 and DIN 3230 leakage

rate B01.

Kv values

Size

Kv

"

1.3

For conversion:

"

3.2

1"

5.8

1"

9.0

Cv (UK) = Kv x 0.963

Local regulations may restrict the use of this product to below the conditions quoted.

In the interests of development and improvement of the product, we reserve the right to change the specification.

1"

17.0

2"

19.2

Cv (US) = Kv x 1.156

Copyright 2004

Dimensions /weights (approximate) in mm and kg

Size

"

"

1"

1"

1"

2"

80

90

110

127

155

170

B

(valve open)

136

144

167

194

220

230

Weight

70

90

110

110

130

180

1.7

2.3

3.6

5.9

8.5

11.6

Spare parts

The spare parts available are shown in heavy outline. Parts drawn

in broken line are not supplied as spares.

Available spares

Set of body gaskets

7

Disc and bellows assembly

5, 6

How to order spares

Always order spares by using the description given in the column

headed 'Available spares' and state the size and type of valve.

Example: 1 - Disc and bellows assembly plus 1 - Set of body

gaskets for a 1" Spirax Sarco type A3S bellows sealed stop valve

having screwed BSP connections.

Safety information, installation and maintenance

For full details see the Installation and Maintenance Instructions

(IM-P132-11) supplied with the product.

Install in the direction of flow given by the arrow on the body with the

handwheel in a suitable position. The preferred position is with the

spindle vertical.

7 (Graphite)

Disposal

The product is recyclable. No ecological hazard is anticipated with

the disposal of this product, providing due care is taken.

How to order

Example: 1 off Spirax Sarco A3S bellows sealed stop valve having

screwed BSP connections.

6

5

7 (Spirally wound graphite /steel)

Recommended tightening torques

or

Item Part

Size

Nm

mm

Body bolt

A3S Bellows Sealed Stop Valve

"

"

1"

1"

1"

2"

M10

M10

M12

M12

M14

M16

40

40

70

70

110

160

TI-P132-09

- 50

- 50

- 90

- 90

- 130

- 190

ST Issue 5

Vous aimerez peut-être aussi

- 25P 6inchDocument2 pages25P 6inchNguyen Xuan QuangPas encore d'évaluation

- D318 Type Solenoid ValvesDocument2 pagesD318 Type Solenoid ValvesNguyen Xuan QuangPas encore d'évaluation

- AEL6 Series Smart Electric Linear Actuators For DN15 To DN100 Control Valves-Installation Maintenance ManualDocument28 pagesAEL6 Series Smart Electric Linear Actuators For DN15 To DN100 Control Valves-Installation Maintenance ManualNguyen Xuan QuangPas encore d'évaluation

- Ael6 PDFDocument9 pagesAel6 PDFCarlos Rafael Pereyra SegoviaPas encore d'évaluation

- Process and Transaction - CHIDocument3 pagesProcess and Transaction - CHINguyen Xuan QuangPas encore d'évaluation

- A3S and A3SS Bellows Sealed Stop Valve: DescriptionDocument2 pagesA3S and A3SS Bellows Sealed Stop Valve: DescriptionNguyen Xuan QuangPas encore d'évaluation

- AEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationDocument9 pagesAEL5 Series Electric Linear Actuators For DN15 To DN100 Control Valves-Technical InformationNguyen Xuan QuangPas encore d'évaluation

- How To WriteDocument21 pagesHow To WriteLenin Darío DuchicelaPas encore d'évaluation

- HSBC 12072010 Vietnam MonitorDocument16 pagesHSBC 12072010 Vietnam MonitorNguyen Xuan QuangPas encore d'évaluation

- CFVG Toan 2007Document6 pagesCFVG Toan 2007Nguyen Xuan QuangPas encore d'évaluation

- Presentation Skills: Course GuideDocument32 pagesPresentation Skills: Course GuideNguyen Xuan QuangPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- A Comprehensive Review On The Genus: Mussaenda: Astalakshmi N and Sundara Ganapathy RDocument8 pagesA Comprehensive Review On The Genus: Mussaenda: Astalakshmi N and Sundara Ganapathy RSahabat Baljai100% (1)

- ASTM G5-94 Standard Practice PDFDocument12 pagesASTM G5-94 Standard Practice PDFMarcela BaronaPas encore d'évaluation

- C.02 - Gas-Freeing and Cleaning of TanksDocument7 pagesC.02 - Gas-Freeing and Cleaning of TanksmkkamarajPas encore d'évaluation

- Rition Feeaing: Ruminant AnatomyDocument30 pagesRition Feeaing: Ruminant AnatomySMP SeriesPas encore d'évaluation

- 11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadDocument3 pages11th Chemistry EM - Public Exam 2022 - Model Question Paper - English Medium PDF DownloadAshwini Shankar KumarPas encore d'évaluation

- WHMIS Handbook PDFDocument22 pagesWHMIS Handbook PDFNPas encore d'évaluation

- 04 Gue SF7 Unit2 T1 T3Document44 pages04 Gue SF7 Unit2 T1 T3Bill Wang100% (1)

- 9.4.6 Goulds 320L Spec Sheet7313Document7 pages9.4.6 Goulds 320L Spec Sheet7313LeonellePas encore d'évaluation

- Method Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaDocument4 pagesMethod Statement FOR Waste Polymer Slurry Disposal: PT Bauer Pratama IndonesiaFendi Rang TigorPas encore d'évaluation

- Omeprazole: by Jennica Mae V. CuicoDocument7 pagesOmeprazole: by Jennica Mae V. Cuicoジェンニカ メイPas encore d'évaluation

- RadioisotopesDocument28 pagesRadioisotopessivagurunathan.P100% (3)

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohPas encore d'évaluation

- Alkaline Earth MetalDocument33 pagesAlkaline Earth MetalSup FansPas encore d'évaluation

- Sunward SWE08B Operator's ManualDocument96 pagesSunward SWE08B Operator's ManualIisakki50% (2)

- Ips e PR 850 PDFDocument73 pagesIps e PR 850 PDFdeyanshu7Pas encore d'évaluation

- Archaea 2016 PDFDocument73 pagesArchaea 2016 PDFDr. Farokh Rokhbakhsh-Zamin50% (2)

- RE - Unit 1Document84 pagesRE - Unit 1Faraj NabiyevPas encore d'évaluation

- Special Process Audit Check Sheet - PlatingDocument8 pagesSpecial Process Audit Check Sheet - PlatingHariprasanth ChandranPas encore d'évaluation

- Chapter 4 and 5Document51 pagesChapter 4 and 5Kyla Gabrielle TutoPas encore d'évaluation

- Name of Elements Properties Use/S 1. ZinkDocument13 pagesName of Elements Properties Use/S 1. ZinkNora Alfaro BalsakiPas encore d'évaluation

- Sierra Gorda - Feasibility (2011)Document240 pagesSierra Gorda - Feasibility (2011)Nicolas CarrascoPas encore d'évaluation

- Chemical, Physical, and Baking Properties of Apple FiberDocument4 pagesChemical, Physical, and Baking Properties of Apple FiberHector FloresPas encore d'évaluation

- Slurry Pumps Parastaltic PumpsDocument9 pagesSlurry Pumps Parastaltic Pumpsmtl40Pas encore d'évaluation

- Chapter 5 CasesDocument21 pagesChapter 5 Casesejusdem generisPas encore d'évaluation

- Ceilcote 242 Flakeline coating specification for concreteDocument2 pagesCeilcote 242 Flakeline coating specification for concretenoto.sugiartoPas encore d'évaluation

- Essco Product CatalogueDocument23 pagesEssco Product CatalogueMohammedAasimUmairPas encore d'évaluation

- Properties of WaterDocument3 pagesProperties of WaterLupis HernándezPas encore d'évaluation

- PK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory IiiDocument21 pagesPK - FKK.PPM - Manual Makmal Che565: Chemical Engineering Laboratory Iiibedirtupak92% (12)

- S1XBIG58 M500 4 Tech InfoDocument15 pagesS1XBIG58 M500 4 Tech InfoFredy DanielPas encore d'évaluation

- Solutions of ElectrolytesDocument55 pagesSolutions of Electrolytesneha_dand1591100% (1)