Académique Documents

Professionnel Documents

Culture Documents

Angularity Number

Transféré par

malik ahmed awanCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Angularity Number

Transféré par

malik ahmed awanDroits d'auteur :

Formats disponibles

Determination of Angularity Number for the

given aggregate sample.

This test is also carried out for determining shape of the aggregates.

Based upon shape the aggregates may be classified as Rounded,

Angular or Flaky. Angular particles possess well defined edges

formed at the intersection of roughly planer faces and are

commonly formed in aggregates prepared by crushing of rocks.

Angularity in general is the absence of rounding of particles of an

aggregate. This test is performed to determine the angularity

number i.e. the absence of roundedness or the degree of angularity

of the aggregate specimen.

RELATED THEORY

SHAPES OF PARTICLES

The usual shapes of the particles are;

Rounded (river gravel)

Flaky (laminated rock)

Elongated

Angular (crushed rock)

ANGULARITY

It is the absence of roundness. An aggregate particle, which is more

rounded, is less angular and vice versa.

ANGULARITY NUMBER

Angularity number of an aggregate is the amount (to the higher

whole number) by which the percentage of voids in it after

compacting in a prescribed manner exceeds 33.

Where, 33 is the percentage of volume of voids, in a

perfectly rounded aggregate. 67 is the percentage of volume of

solids in a perfectly rounded aggregate.

The value of angularity number generally lies between 0 & 11.

In road construction angularity number of 7 10 is generally

preferred.

SIGNIFICANCE

The degree of packing of particles of single sized aggregate

depends upon the angularity of aggregate.

The angularity of the aggregate can be estimated from the

properties of voids in a sample of aggregate compacted in a

specified manner.

The angularity number ranges from 0 for a highly rounded

gravel to about 11 for freshly crushed angular aggregates.

Higher the angularity number, more angular and less workable

is the concrete mix.

In cement concrete roads (rigid pavements) rounded

aggregates are preferred because of better workability and

higher strength.

In bituminous or water bound macadam construction (like

flexible pavements), angular aggregates with high angularity

number are preferred because of high stability due to better

interlocking and friction.

Higher the angularity number, more angular and less workable

is the concrete mix.

In road construction, angularity number of 7 -10 is generally

preferred.

APPARATUS

A metal cylinder of about 3-liter capacity.

Temping rod of circular cross-section, 16mm , 60cm in length.

Rounded at one end.

A metal scoop.

A weighing balance.

PROCEDURE

This procedure is for aggregate size to No.4. If aggregate is

coarser than , a cylinder of large capacity shall be required but

amount of compactive effort or energy should be proportional to the

volume of the cylinder.

10 Kg of the sample is taken for the test. The material should

be oven dried. The aggregate is compacted in three layers, each

layer being given 100 blows using the standard tamping rod at a

rate of 2 blows/second by lifting the rod 5 cm above the surface of

the aggregate and then allowing it to fall freely. The blows are

uniformly distributed over the surface of the aggregate. After

compacting the third layer, the cylinder is filled to overflowing and

excess material is removed off with temping rod as a straight edge.

The aggregate with cylinder is then weighed. Three separate

determinations are made and mean weight of the aggregate in the

cylinder is calculated.

Calculations & Results

Method 1

Add measured quantity of water in the compacted

aggregate till all the voids are filled and water appears to the

surface. Volume of water added is approximately equal to the

volume of voids in the compacted aggregate.

Angularity Number

Volume of Water Added

100 33

Total Volume

Method 2

Angularity Number 67

100 W

CGs

where,

W = mean weight of the aggregate filling cylinder.

C = Weight/Volume of water that can completely fill the

cylinder

(= 3 liters = 3000 ml)

Gs = Specific Gravity of the aggregate.

Notes:

Method 1 determines the angularity number from the solids point

of view.

Method 2 determines the angularity number from the voids point

of view.

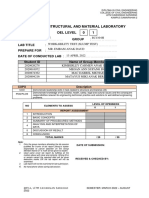

COMPUTATIONS & RESULTS

Specific gravity of the aggregate = 2.67

Total volume of the cylinder = 3 liters = 3000 ml

Empty

Cylinder

WEIGHT

(gm)

Cylinder + Cylinder Aggregat

Aggregate + Agg. + e

Water

COMMENTS

Volume

Water

Added

(ml)

of Angularity

Number

Method Method

#1

#2

Vous aimerez peut-être aussi

- Errors of Observation in Concrete Testing LabsDocument30 pagesErrors of Observation in Concrete Testing LabsSuryasis Dasgupta25% (4)

- Estimation and Costing PDFDocument51 pagesEstimation and Costing PDFPARVATHANENI SAI KRISHNAPas encore d'évaluation

- Ultrasonic Pulse VelocityDocument3 pagesUltrasonic Pulse VelocitySougata DasPas encore d'évaluation

- Elongation Index TestDocument2 pagesElongation Index TestBibhuti B. Bhardwaj60% (5)

- Water-Cement RatioDocument17 pagesWater-Cement RatioShazwanShahPas encore d'évaluation

- Workability Test (Slump Test) Lab ReportDocument10 pagesWorkability Test (Slump Test) Lab ReportMAC DARREL MICHAEL MAC DARREL MICHAELPas encore d'évaluation

- Water Cement Ratio (Gate60 Short Notes)Document4 pagesWater Cement Ratio (Gate60 Short Notes)akash rathodPas encore d'évaluation

- Standard Test Method For The Determination of The Normal Consistency of Hydraulic Cement PDFDocument3 pagesStandard Test Method For The Determination of The Normal Consistency of Hydraulic Cement PDFKamran AliPas encore d'évaluation

- Aggregate Angularity NumberDocument5 pagesAggregate Angularity NumberAdnan AhmadPas encore d'évaluation

- 3 Aggregate Abrasion Value TestDocument6 pages3 Aggregate Abrasion Value TestAbdur RazzakPas encore d'évaluation

- Los Angeles Abrasion TestDocument5 pagesLos Angeles Abrasion Testদেওয়ানসাহেবPas encore d'évaluation

- What Is Fineness Modulus and How To Calculate ItDocument3 pagesWhat Is Fineness Modulus and How To Calculate ItTahmidur RahmanPas encore d'évaluation

- Standard Test Method For The Determination of The Normal Consistency of Hydraulic Cement. (ASTM C 187-04)Document3 pagesStandard Test Method For The Determination of The Normal Consistency of Hydraulic Cement. (ASTM C 187-04)MazharYasin100% (1)

- Fresh Concrete Vebe TestDocument2 pagesFresh Concrete Vebe TestMarilyn Camenzuli100% (1)

- Compaction Factor TestDocument5 pagesCompaction Factor Testabhay9911Pas encore d'évaluation

- Determination of Consistency of Standard Cement PasteDocument3 pagesDetermination of Consistency of Standard Cement PasteAfifah FauziPas encore d'évaluation

- Test of AggregateDocument24 pagesTest of AggregatePriyank BhimaniPas encore d'évaluation

- Density For Soil by Sand Displacement Method: Scope Is Code ApparatusDocument2 pagesDensity For Soil by Sand Displacement Method: Scope Is Code ApparatusMastani BajiraoPas encore d'évaluation

- Tut 1 - Port, Air & RailDocument81 pagesTut 1 - Port, Air & RailJia SingPas encore d'évaluation

- WorkabilityDocument3 pagesWorkabilityyay94rebuildPas encore d'évaluation

- NDT Level 0 Rebound Hammer MaterialDocument5 pagesNDT Level 0 Rebound Hammer MaterialNadhirah LnfPas encore d'évaluation

- Compacting Factor TestDocument3 pagesCompacting Factor TestRahul SharmaPas encore d'évaluation

- Consolidation TestDocument2 pagesConsolidation TestTenzinKesang100% (1)

- Ecg354-Aggregate Impact TestDocument7 pagesEcg354-Aggregate Impact TestNurin AdlinaPas encore d'évaluation

- Determination of Flakiness and Elongation Index For The Given Aggregate Sample.Document4 pagesDetermination of Flakiness and Elongation Index For The Given Aggregate Sample.Huma AliPas encore d'évaluation

- 4.bulk Density of AggregatesDocument3 pages4.bulk Density of AggregatesRahul SharmaPas encore d'évaluation

- Los Angeles AbrasionDocument5 pagesLos Angeles AbrasionDDelGGulPas encore d'évaluation

- C2-Consistency Cement PasteDocument4 pagesC2-Consistency Cement PasteMuhamad FarhanPas encore d'évaluation

- Lab by Dks PDFDocument31 pagesLab by Dks PDFDhirean Kumar SunarPas encore d'évaluation

- Physical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachDocument8 pagesPhysical and Mechanical Properties of Some Common Nigerian Timber Species Based On Limit State Design ApproachSEP-PublisherPas encore d'évaluation

- Deternmination of Water Absorption and Density of BricksDocument7 pagesDeternmination of Water Absorption and Density of Bricksmahrbhojia80% (5)

- Cube TestDocument10 pagesCube Testridhuanzainal100% (1)

- Los AngelesDocument2 pagesLos AngelesAbdulelah SPas encore d'évaluation

- Soundness TestDocument3 pagesSoundness TestYasirPas encore d'évaluation

- Te Lab Shape of AggregateDocument8 pagesTe Lab Shape of AggregateShivpreet SharmaPas encore d'évaluation

- Quantitative Extraction of Bitumen From Bituminous Paving MixturesDocument12 pagesQuantitative Extraction of Bitumen From Bituminous Paving Mixturessebastian novoa0% (1)

- Initial and Final Setting Time of CementDocument4 pagesInitial and Final Setting Time of CementHamza MughalPas encore d'évaluation

- Civil Engineering Material Lab ReportDocument13 pagesCivil Engineering Material Lab Reportsharrmaa100% (1)

- Concrete Workability TestDocument3 pagesConcrete Workability TestEyzatul QhairinaPas encore d'évaluation

- Aggregate Crushing Value Test ApparatusDocument2 pagesAggregate Crushing Value Test ApparatusBiplab dattaPas encore d'évaluation

- AGGREGATE Shape TESTSDocument7 pagesAGGREGATE Shape TESTSBernard KitosiPas encore d'évaluation

- Ring and Ball TestDocument4 pagesRing and Ball TestMuhd Farhan Bin IbrahimPas encore d'évaluation

- Direct Shear TestDocument2 pagesDirect Shear TestUtkarsh KumarPas encore d'évaluation

- Experiments On Coarse AggregatesDocument9 pagesExperiments On Coarse AggregatesRuthra ManickamPas encore d'évaluation

- Bitumen Ductility TestDocument3 pagesBitumen Ductility TestSanthaKumar Muthu ThankaveluPas encore d'évaluation

- Bulk Density and Voids in AggregatesDocument3 pagesBulk Density and Voids in AggregatesJohn Reigh CatipayPas encore d'évaluation

- Flexural TestDocument13 pagesFlexural TestAliaPas encore d'évaluation

- Building Mat 08-09Document39 pagesBuilding Mat 08-09takishiPas encore d'évaluation

- Sorptivity Test 01Document5 pagesSorptivity Test 01Shaheer Ahmed KhanPas encore d'évaluation

- Normal ConsistencyDocument22 pagesNormal ConsistencyMujahid MzîrîPas encore d'évaluation

- Lab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Document3 pagesLab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Kashif IqbaljPas encore d'évaluation

- LabEx No. 7 Los Angeles Abrasion TestDocument4 pagesLabEx No. 7 Los Angeles Abrasion TestianzkieePas encore d'évaluation

- California Bearing RatioDocument8 pagesCalifornia Bearing RatioairpavsetPas encore d'évaluation

- CMT Lab Report #1Document5 pagesCMT Lab Report #1jae periasPas encore d'évaluation

- Compaction Factor Test&Slump Test ReportDocument1 pageCompaction Factor Test&Slump Test ReportMUN SIM SOHPas encore d'évaluation

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985D'EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985Pas encore d'évaluation

- Determination of The Flakiness and The Elongation Determination of Angularity NumberDocument8 pagesDetermination of The Flakiness and The Elongation Determination of Angularity NumberFaisal Sardar100% (2)

- Determination of The Angularity Number of The Given Aggregate Sample.Document3 pagesDetermination of The Angularity Number of The Given Aggregate Sample.Shaheer Ahmad100% (1)

- Angularity Number Test Aim of The ExperimentDocument4 pagesAngularity Number Test Aim of The ExperimentakhilaPas encore d'évaluation

- Transportation Engineering - I Sessional COURSE NO: 3502Document20 pagesTransportation Engineering - I Sessional COURSE NO: 3502Mohammad ParvejPas encore d'évaluation