Académique Documents

Professionnel Documents

Culture Documents

United States-Patent 1191: Forshllfvudwt Al

Transféré par

fgkf4556Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

United States-Patent 1191: Forshllfvudwt Al

Transféré par

fgkf4556Droits d'auteur :

Formats disponibles

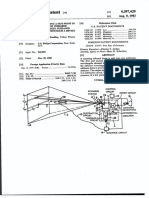

United States-Patent 1191

[11]

. 4,199,256

Forshllfvudwt al.

[45]

Apr. 22, 1980

[56]

[54] OPTICAL SYSTEM

[75] Inventors: Ragnar Forshufvud; Arnold

Johansson, both of Karlskoga,

Sweden

[73] Assignee: Aktiebolaget Bofors, Bofors, Sweden

References Cited

U.S. PATENT DOCUMENTS

3,672,607

3,699,341

6/1972

10/1972

3,820,742

6/ 1974

3,845,276

10/1974

Stauff et a1. ....................... .. 244/116

Quillinan et a1. ..

.. 356/152 X

Watkins ........... ..

Keudy et al. .................. .. 235/615

Primary Examiner-John K. Corbin

Assistant Examiner-Matthew W. Koren

Attorney, Agent, or Finn~Pol1ock, Vande Sande 8t

[21] AppLNo; 856,874

[22] Filed:

Priddy

[57]

Dec. 2, 1977

ABSTRACT

An optical system for determining the angular deviation

[30]

Dec. 2, 1976 [SE]

[51]

[52]

1

of a movable object from a preselected target, wherein

an objective lens projects an image of the target in a ?rst

Foreign Application Priority Data

Sweden .............................. .. 7613513

111:. C12 ............................... .. 601C 1/00

US. Cl. .................................. .. 356/247; 356/141;

356/152

focal plane and projects an image of the movable object

in a further focal plane. A prism divides the images,

with the target image being tramsmitted to anocular

and the movable object image being transmitted to a

detector.

[58] Field of Search ............. .. 356/141, 142, 143, 152,

356/245; 350/10, 194

14 Claims, 5 Drawing Figures

U.S*.\ Patent

Apr. 22, 1980

4,199,256

mm

17

Fig.4

4,199,256

up the sighting system. As a result measuring systems

OPTICAL SYSTEM

are, in order to obtain an acceptable measuring accu

racy, generally provided with means to control and

BACKGROUND OF THE INVENTION

adjust the line of sight of the telescope and the axes of

the measuring device.

The present invention relates to an optical system

capable of achieving a line of sight with a speci?c point

and including a measuring device for detecting the

angular deviation of a radiation source from a line of

sight with the point.

'

The invention is particularly intended to be used

when determining the angular deviation of a remote

object from the line of sight of an object or target to be

tracked. In such cases the optical system is usually di

rected towards a pointon the object to be followed. If

the object whose angular deviation is to be determined,

emits radiation, the angular deviation of the radiation

source from the line of sight to the object can be deter

mined by a measuring device. The radiation can be

OBJECTS OF THE PRESENT INVENTION

Accordingly it is an object of the present invention to

provide an optical system which eliminates the above

discussed drawbacks confronting the prior art. The

invention distinguishes from the prior art in that the

optics of the optical system is common for both the

sighting and position measuring functions. This means

that every change in the optical system gives rise to the

same changes in both of the devices, while the relative

position is unchanged. As a result, any control or adjust

ing means for maintaining the optics of each system is

not required.

generatedby a radiation :source located within a hous

ing of the remote object, or it can be generated by its 20 BRIEF DESCRIPTION OF THE DRAWINGS

propulsion motor, in which case the transmitted radia

The present invention will in the following be de

tion takes the form of an infrared radiation. The radia

scribed in more detail with reference to the accompany

tion may. also, however, be derived from re?ector ar

ing drawings, in which

ranged on the remote object. In such a case the radia

FIG. 1 schematically illustrates the optical system in

tion is. transmitted towards the remote object from a

which the radiation paths are indicated;

radiation source located at the site of the optical system.

FIG. 2 illustrates an alternative embodiment of the

A particularly interesting and advantageous applica

optical system formed according to the present inven

tion for the present invention is in combination with an

tion

optical sight of the type comprising a tracking telescope

FIG. 3 illustrates the means for facilitating the aiming

with cross hairs or other visual sight reference symbols

of the system;

employedito point at and follow a target, and a measur

FIG. 4 illustrates the measuring device and

ing device. which collects the radiation emitted by a

FIG. 5 is an enlarged view of the measuring device.

moving object and determines the deviation of the ob

ject from the line of sight with the target.

DETAILED DESCRIPTION OF THE

It is previously known in the art to provide the mea

PREFERRED EMBODIMENT

suring device with a movable measuring mask located

FIG. 1 schematically illustrates the optical system

in an image plane of an optical system so that the radia

formed according to the invention. The optical system

tion emitted by the radiation source altematingly passes

is particularly suitable to be included in an optical sight

through the mask and is prevented from penetrating the

unit and for purposes of explanation only, the present

mask...

invention

will be described in conjunction with an opti

The movable mask may consist of a glass surface

cal sight. The task of such a sighting assembly is to point

having a coating layer superimposed thereon. The layer

at, follow a target and while also collecting the radia

may take a form such that information regarding the

tion emitted by a movable object in order to compare

position of the radiation source can be derived from the

the trajectory of the movable with the line of sight and

relationtbetween the occuring ?uctuations of the radia

determine the deviation between them. The manner of

tion and the angular position of the measuring mask.

how the measuring operation is performed is immaterial

It is also previously known to employ an optical

to the operation of the present invention. Nevertheless,

system having a tracking telescope comprising an ob

jective lens, ocular and a sighting symbol, along with

some type of cross hairs comprising thin lines on a glass

surface located in the image plane of the objective. By

means of the ocular, it is possible for the operator to

view the target and its background and by means of

control knobs etc,.it is possible for the operator to point

and maintainthe symbol in line of sight with the target

the deviation determined by the measuring operation is

converted into an electrical signal and how this signal is

processed and evaluated is immaterial to the operation

of the present invention.

The optical system forming the present invention

includes a single entrance aperture with an objective

lens 1, a glass plate 2 and a prism 3 to split up the visual

Because of the fact that two different main functions,

light from the target and its background and the radia~

tion emitted by the radiation source of the object. The

ie..aiming and position measuring, have to be effectu

radiation source may for instance consist of a laser

during the target tracking operation.

ated, ithas up until now been necessary to use two

source, preferably a laser diode, disposed on the object

different optical systems,1ie an optical system for aiming

60 in such a way that laser radiation is transmitted towards

and an optical system for measuring the position of the

object. In order to attain an acceptable accuracy in the

the optical system. The objective lens 1 collects both

visual light and laser radiation and is designed in such a

way that the focal distance for visual light and diode

measuring Ioperation, it is important that the relative

laser radiation is different. From this it directly follows

position of the measuring and the aiming devices, re

spectively, is not influenced by mechanical deforma 65 that an image of the target and its background is pro

jected in the image plane F1 for visual light, while an

tions, temperature changes etc. A disturbance of an

image of the radiation source is projected in another

optical or mechanical element may cause a change of

image plane F2 for diode laser radiation. In FIG. 1 the

the relative position of the two optical systems making

4,199,256

ray path of the visual light is indicated by dotted lines,

tionary in which casethe visual sight reference symbol

while the laser radiation is indicated by continous lines.

may consist of cross hairs.

The ray paths are split up in the prism 3 in a conven

FIG. 3 shows a view of the glass surface located in

tional so that visual light passes through the prism and

the image plane F1 with the visual sight reference sym

out through an ocular 4 to the eyes of an operator, with

bol comprising concentric circles 8 and arcs 9 about the

the laser radiation, however, being re?ected by the

origin, which coincide with the line of sight 10. The

origin is preferably indicated by a small point indication

prism 3 and passing through a lens system 6 to a detec

tor 7.

15. The blurred spot 16 relates to the image of the radia

tion source which image is unsharp in the image plane

F] but sharply de?ned in the image plane P2. In this case

it is supposed that the wavelength of the radiation emit

In order to facilitate the tracking operation the opti

cal system is provided with a visual sight reference

symbol which consists of thin lines on a glass surface

located in the image plane F1 so that the operator is able

to view the target and its background together with the

visual sight reference symbol in the ocular 4. The sym

bol may consist of conventional cross hairs, but can also

ted by the radiation source is within the visible region of

the spectrum. It may be preferable, however, to allow

the wavelength of the transmitted radiation to be out

side the visible region of the spectrum, with no blurred

consist of one or more concentric circles 8 or arcs 9, see

image appearing in the image plane F1.

FIG. 3, having the line of sight 10 as the origin.

The embodiment employing concentric circles is

preferred in comparison with conventional cross hairs

FIG. 4 shows a view of the glass surface located in

when a measuring mask as discussed hereafter rotates 20

with the line of sight as the origin. The lines of the

the image plane, F; with the measuring mask 11, which

consists of a glass plate having a dichroic geometrical

pattern superimposed thereon. A coating layer 12 has

visual reference symbol must be so thin that they do not

been applied and so arranged such that the entire sur

face is transparent to visual light but partially opaque to

disturb the measuring device by blocking the light rays.

radiation emitted by the radiation source. By designing

For determining the angular deviation of the movable

radiation source from the line of sight the optical system

25

the boundary line 17 of the opaque layer in a special

way, information about the position of the radiation

to the target, there is provided a measuring device in

cluding a movable measuring mask 11, see FIG. 4, lo

occuring ?uctuations of the radiation and the angular

cated in the image plane F2. The measuring maskmay

position of the mask.

source can be derived from the relation between the

'

consist of a glass surface having a dichroic layer in the 30 In order to obtain an accurate measurement of the

form of a geometrical pattern superimposed thereon,

position of the radiation emitting object it is important

which layer is transparent to visual light but opaque to

that the boundary line 17, ie. the transition between the

laser radiation emitted by the radiation source. The

transparent part 16 and the opaque part 12 of the mask,

measuring mask must have such properties that it does

be clearly-de?ned. In practice, however, this is di?icult

not disturb the visual image and the visual sight refer

to achieve, as the dichroic layer consists of several thin

ence symbol even when the measuring mask is moved.

The distance between the two image planes F1 and

F2 is so large that the obscuring effect caused by the

lines of the visual sight reference symbol is small at the

same time as the measuring mask and the visual sight

reference symbol are disposed at the same optical ele

ment, for instance on each side of the glass plate 2 on the

side surfaces which coincide with the planes F1 and F2.

As the glass plate is common for both the sighting and

position measuring functions, every change in the opti 45

cal system gives rise to the same changes in both of the

devices, while the relative position of the two sets of

rays is unchanged. Any means for controlling and ad

justing the line of sight and the axes of the measuring

dielectric layers disposed on the top of each other. As a

result a transition zone is provided between the trans

parent and opaque parts of the mask, in which zone the

transmission changes from a high value to a low value.

How the edge sharpness of the dichroic layer can be

improved and the transition zone be diminished, is illus

trated in FIG. 5.

The edge of the layer adjoining the transparent part is

provided with a metallic layer 18 extending along the

boundary line of the layer and which layer is so narrow

that it does not disturb the transparency when the mea

suring mask is rotating. The edge layer preferably con

device are not required.

sists of a metal having a high accuracy form, for in

stance aluminium.

We claim:

Instead of one common glass plate, two thin glass

plates 13, 14 can be used, see FIG. 2, in which case the

deviation of a radiation source from a line of sight ex

1. An optical system for determining the angular

image plane F1 for the visual light preferably coincides

tending between a target object and said optical system,

with that surface of the glass plate 13 which faces the

and comprising:

operator. The image plane F2 for the laser radiation is 55 optical sensor means for projecting an image of said

by analogy required to coincide with that surface of the

target object in a ?rst image plane and for project

glass plate 14, which is facing the detector 7. Also, other

ing an image of said radiation source in a second

embodiments with two glass plates are possible, how

image plane spaced from said first image plane;

ever, the only condition that must be considered is that

transparent p1

means for receiving and directing

the glass surfaces on which the visual sight reference

said image of said target object toward an ocular

symbol and the measuring mask, respectively, are ap

and for receiving and directing said image of said

plied coincide with the associated image plane and that

radiation source toward a detector assembly;

both of the glass plates are so connected that they can

sighting means located within said first image plane

not be moved horizontally and vertically relative to

for visually aligning said optical sensor means with

each other. For the sighting function, it is necessary that 65

said target object; and

the glass plate 14 rotate. The glass plate 13 can be rig

masking means located within said second image

idly connected with the glass plate 14 and rotate with

plane for selectively blocking said image of said

the same number of revolutions but it may also be sta

radiation source from reaching said prism means.

4,199,256

2. An. optical system according to claim 1, wherein

said opticalusensor. means comprises an objective lens

assembly having a first focal length for visual ligh

twaves passing .therethrough, and a second, different

focal length for radiation waves passing therethrough,

?rst image plane, and a second transparent plate spaced

from said ?rst plate and having a ?rst side portion lo

cated at said second image plane.

9. An optical system according to claim 8, wherein

said ?rst side portions of each of said plates face one

whereby said ?rstimage plane is located at said ?rst

focal length andsecond image plane is located at said

second focallength.

3. An optical system according to claim 2, wherein

another and are spaced from one another.

10. An optical system according to claim 8, wherein

said ?rst and second transparent plates are mounted

within said optical system for joint horizontal and verti

cal movement;

and said second transparent plate is further mounted

for rotation about a transverse axis extending

said radiation source comprises a laser diode emitter.

4. An optical system according to claim 2 wherein

said optical sensor means further comprises a transpar

ent plate positioned such that a ?rst side portion of said

plate is located in said ?rst image plane and a second,

through said plates.

11. An optical system according to claim 10, wherein

said masking means comprises a dichroic layer of spe

ci?c geometrical shape imposed on a portion of the ?rst

opposite side pcrtionwof said transparent plate is located

in said second image plane of said objective lens.

5; An optical" system according to claim 4, wherein

said transparent plate isformed of a glass-like material.

6. An optical systemaccording to claim 4, wherein

side of said rotatable plate located within said'second '

image plane, with said dichroic layer being transparent

to visual light and opaque to radiation emitted from said

said sighting means comprises a visual reference symbol 20 radiation source, to selectively block the image of said

imposed on said ?rst side portion of said transparent

radiation source from reaching said prism means and

plate, with said reference symbol and said image of said

target object being alignable with one another within

said ?rst image plane to establish a line of sight between

said targetobjectiand said objective lens assembly.

7.An optical system according to claim 2, wherein

said detector assembly.

12. An optical system according to claim 11, wherein

25 a narrow metal strip forms a boundary between said

dichroic layer and the remaining side portion to im~

prove the sharpness of the boundary portion of said

dichroic layer.

13. An optical system according to claim 12, wherein

said masking means comprises a dichroic layer of spe

ci?cli geometrical \shape imposed on a portion of said

second sidelportion located at said second image plane,

with said dichroic layer being transparent to visual light 30 said narrow metal strip is formed of aluminum.

14. An optical system according to claim 8, wherein

and opaqueto radiation emitted from said radiation

said sighting means comprises a visual reference symbol

source,,to selectively block the image of said radiation

imposed on the ?rst side portion of said ?rst transparent

source fromreaching said prism means.

plate

for aligning said image of said target object with

8.:1An optical system according to claim 2, wherein

said optical sensor means further comprises a ?rst trans 35 said objective lens.

~

parent plate having a ?rst side portion locatedlat said

50

55

65

Vous aimerez peut-être aussi

- Optics and Optical Instruments: An IntroductionD'EverandOptics and Optical Instruments: An IntroductionÉvaluation : 4 sur 5 étoiles4/5 (5)

- 2 20 - I /, // Sf-I4: United States Patent (191Document4 pages2 20 - I /, // Sf-I4: United States Patent (191dgfhdg erePas encore d'évaluation

- Getzovspectrophotometer of The TypeDocument8 pagesGetzovspectrophotometer of The TypeAuthor AuthorPas encore d'évaluation

- Intelligent Active Range Sensor for Vehicle GuidanceDocument8 pagesIntelligent Active Range Sensor for Vehicle GuidanceUtsav V ByndoorPas encore d'évaluation

- Us5194847 PDFDocument12 pagesUs5194847 PDFgribas1Pas encore d'évaluation

- United States Patent (191: ObjectDocument6 pagesUnited States Patent (191: Object조용준Pas encore d'évaluation

- 2000 Opt Lett - Prism Intereferometer For Fourier-Transform SpectroscopeDocument3 pages2000 Opt Lett - Prism Intereferometer For Fourier-Transform SpectroscopeMihaela OmutPas encore d'évaluation

- Nikhil Lincoln Roll No - 47 S6 Me: Metrology and Machine Tools Assignment-2Document14 pagesNikhil Lincoln Roll No - 47 S6 Me: Metrology and Machine Tools Assignment-2Nikhil LincolnPas encore d'évaluation

- Speed of Light by Foucault's MethodDocument3 pagesSpeed of Light by Foucault's MethodJyothishraj NambisanPas encore d'évaluation

- United States Patent (191: I CE) Maw/Wm 'Document5 pagesUnited States Patent (191: I CE) Maw/Wm 'dgfhdg erePas encore d'évaluation

- High-Resolution Imaging Ellipsometer: Qiwen Zhan and James R. LegerDocument8 pagesHigh-Resolution Imaging Ellipsometer: Qiwen Zhan and James R. LegergitarcinayiPas encore d'évaluation

- Gerro Prinsloo Solar TrackingDocument11 pagesGerro Prinsloo Solar TrackingBoulos NassarPas encore d'évaluation

- Sensors: The Development of Sun-Tracking System Using Image ProcessingDocument12 pagesSensors: The Development of Sun-Tracking System Using Image ProcessingSojol KumarPas encore d'évaluation

- Visual TestingDocument48 pagesVisual TestingLeon Heart FCPas encore d'évaluation

- Us 5243553Document7 pagesUs 5243553fgkf4556Pas encore d'évaluation

- An Infrared Eccentric Photo-OptometerDocument12 pagesAn Infrared Eccentric Photo-OptometerCarpetali GatitaPas encore d'évaluation

- Tomographic Diffraction Microscopt A Review of Inversion and Recent DevelpmentsDocument18 pagesTomographic Diffraction Microscopt A Review of Inversion and Recent DevelpmentsAsim AsrarPas encore d'évaluation

- Patent US8081162Document8 pagesPatent US8081162Victor Von DoomPas encore d'évaluation

- h0502 PDFDocument13 pagesh0502 PDFYuniet Diaz LazoPas encore d'évaluation

- Us 3912197Document6 pagesUs 3912197dgfhdg erePas encore d'évaluation

- TEPZZ - 58759B - T: European Patent SpecificationDocument26 pagesTEPZZ - 58759B - T: European Patent Specificationzweisteine777Pas encore d'évaluation

- WO2012154508A1_Description_20240328_1456Document9 pagesWO2012154508A1_Description_20240328_1456Igor SilvaPas encore d'évaluation

- Q.4:-Elaborate With Diagram Working Principle, Salient Features, Solution:-Optical Coherence Tomography (OCT) Is A Non-ContactDocument4 pagesQ.4:-Elaborate With Diagram Working Principle, Salient Features, Solution:-Optical Coherence Tomography (OCT) Is A Non-ContactJay The PerfectPas encore d'évaluation

- Optical Inspection System For The Inner Surface of A Pipe Using Detection of Circular Images Projected by A Laser SourceDocument8 pagesOptical Inspection System For The Inner Surface of A Pipe Using Detection of Circular Images Projected by A Laser SourceRodrigo PaludoPas encore d'évaluation

- Total Station FundamentalsDocument15 pagesTotal Station FundamentalsvilmoskaPas encore d'évaluation

- Use CLSM Microscopy Measure Microscale Particle FlowDocument16 pagesUse CLSM Microscopy Measure Microscale Particle FlowCristina PetcuPas encore d'évaluation

- Profile ProjectorDocument13 pagesProfile ProjectorNikhil LincolnPas encore d'évaluation

- Inspeccion: Inspeccion Por Corrientes EddyDocument16 pagesInspeccion: Inspeccion Por Corrientes EddyndtqueretaroPas encore d'évaluation

- Sensors: Laser Sensors For Displacement, Distance and PositionDocument4 pagesSensors: Laser Sensors For Displacement, Distance and PositionLuis SánchezPas encore d'évaluation

- Us 5299499Document5 pagesUs 5299499wewewewPas encore d'évaluation

- Fiber Optic SensorDocument21 pagesFiber Optic SensorFahru Din Ahmad100% (1)

- Microspectrofluorimetry of Fluorescent Dyes and Brighteners On Single Textile FibresDocument18 pagesMicrospectrofluorimetry of Fluorescent Dyes and Brighteners On Single Textile FibresAnastasiya AlexandrovaPas encore d'évaluation

- United States Patent (191 (111 4,397,429: Fouilloy (45) Aug. 9, 1983Document7 pagesUnited States Patent (191 (111 4,397,429: Fouilloy (45) Aug. 9, 1983fgkf4556Pas encore d'évaluation

- Measuring Speed of LightDocument6 pagesMeasuring Speed of LightVestineoPas encore d'évaluation

- Chapter 8: Geometrical Measurements: Auto CollimatorDocument17 pagesChapter 8: Geometrical Measurements: Auto CollimatorRaghu KrishnanPas encore d'évaluation

- GPS Based Portable Dual-Axis Solar Tracking System Using Astronomical EquationDocument5 pagesGPS Based Portable Dual-Axis Solar Tracking System Using Astronomical EquationPrasanth YgPas encore d'évaluation

- Us 5815251Document10 pagesUs 5815251trtry34Pas encore d'évaluation

- Final ResearchDocument46 pagesFinal Researchapi-19728766Pas encore d'évaluation

- Ol 38 16 3103Document4 pagesOl 38 16 3103Aswin KumarPas encore d'évaluation

- The Optical Mouse Sensor As An Incremental Rotary EncoderDocument9 pagesThe Optical Mouse Sensor As An Incremental Rotary EncoderRobert PetersonPas encore d'évaluation

- Confocal MicrosDocument8 pagesConfocal MicrosSHREYA SENTHIL KUMAR IMS21286Pas encore d'évaluation

- Low Crosstalk Multi-View Tracking 3-D Display of Synchro-Signal LED Scanning Backlight SystemDocument9 pagesLow Crosstalk Multi-View Tracking 3-D Display of Synchro-Signal LED Scanning Backlight SystemSince K SajiPas encore d'évaluation

- 61 A ReviewDocument5 pages61 A Reviewhaden tetwPas encore d'évaluation

- Art and Integrated Project Topic Telescope PhysicsDocument8 pagesArt and Integrated Project Topic Telescope PhysicsAditya SinghPas encore d'évaluation

- Measurement of Focal Length of A Concave Mirror: Experiment-406 FDocument21 pagesMeasurement of Focal Length of A Concave Mirror: Experiment-406 FSantanuPas encore d'évaluation

- Autocollimator ProjectDocument11 pagesAutocollimator ProjectAryan VigneshPas encore d'évaluation

- An Efficient Auto Focus Method For Digital Still CameraDocument12 pagesAn Efficient Auto Focus Method For Digital Still CameraBhaskar RaoPas encore d'évaluation

- Fresnel Spiral Antenna Detects Visible and Far-InfraredDocument5 pagesFresnel Spiral Antenna Detects Visible and Far-Infraredalbert_kmusPas encore d'évaluation

- UNIT - 4: Interferometer and Screw Thread, Gear MeasurementDocument25 pagesUNIT - 4: Interferometer and Screw Thread, Gear MeasurementRoshan KumarPas encore d'évaluation

- TEPZZZ9675 - 4B - T: European Patent SpecificationDocument26 pagesTEPZZZ9675 - 4B - T: European Patent Specificationzweisteine777Pas encore d'évaluation

- A Fiber Optical Sensor For Non-Contact Vibration MeasurementsDocument2 pagesA Fiber Optical Sensor For Non-Contact Vibration MeasurementsEd TrawtmamPas encore d'évaluation

- Fibre-Optic Sagnac Interferometer Real Sensor Physical QuantitiesDocument4 pagesFibre-Optic Sagnac Interferometer Real Sensor Physical QuantitiesThiago CoelhoPas encore d'évaluation

- Dynamic Properties of Bacterial Pili Measured by Optical Tweezers - Arxiv14111598Document11 pagesDynamic Properties of Bacterial Pili Measured by Optical Tweezers - Arxiv14111598Antonio Vázquez MotaPas encore d'évaluation

- Theodolite and TS Survey LectureDocument15 pagesTheodolite and TS Survey LectureJoseph ZotooPas encore d'évaluation

- Fuel PatentDocument22 pagesFuel PatentCintia FuscoPas encore d'évaluation

- Displacement Measurement Principle Using Fiber Optic Sensors PDFDocument10 pagesDisplacement Measurement Principle Using Fiber Optic Sensors PDFTriananda MaulanaPas encore d'évaluation

- Chapter 1 Principles of Confocal Scanning Laser Ophthalmoscopy For The ClinicianDocument9 pagesChapter 1 Principles of Confocal Scanning Laser Ophthalmoscopy For The ClinicianSaraRosa1992Pas encore d'évaluation

- SpectroscopyOfDeepSpaceObjectsUsingHomemadeDobsonianTelescope by ConleyDitsworthJr Fall2004Document20 pagesSpectroscopyOfDeepSpaceObjectsUsingHomemadeDobsonianTelescope by ConleyDitsworthJr Fall2004neurolordPas encore d'évaluation

- Unitron MPS InstructionsDocument12 pagesUnitron MPS Instructionsrmans100% (1)

- Capturing Videos at 60 Frames Per Second UsingDocument12 pagesCapturing Videos at 60 Frames Per Second UsingalejandrofedePas encore d'évaluation

- Us 4220296Document8 pagesUs 4220296fgkf4556Pas encore d'évaluation

- United States Patent: Redano (45) Date of Patent: Mar. 25, 2008Document7 pagesUnited States Patent: Redano (45) Date of Patent: Mar. 25, 2008fgkf4556Pas encore d'évaluation

- Us 5428221Document8 pagesUs 5428221fgkf4556Pas encore d'évaluation

- Us 5243553Document7 pagesUs 5243553fgkf4556Pas encore d'évaluation

- Us 20100034424Document7 pagesUs 20100034424fgkf4556Pas encore d'évaluation

- United States Patent (191 (111 4,397,429: Fouilloy (45) Aug. 9, 1983Document7 pagesUnited States Patent (191 (111 4,397,429: Fouilloy (45) Aug. 9, 1983fgkf4556Pas encore d'évaluation

- United States Patent: Redan0 (10) Patent N0.: (45) Date of PatentDocument7 pagesUnited States Patent: Redan0 (10) Patent N0.: (45) Date of Patentfgkf4556Pas encore d'évaluation

- Determining Gem Dispersion On RefractometerDocument19 pagesDetermining Gem Dispersion On RefractometerParallaxster100% (1)

- H-14 MicroformingDocument29 pagesH-14 MicroformingVishwajeet GuptaPas encore d'évaluation

- Nabeel 221370204Document14 pagesNabeel 221370204Nabeel NazeerPas encore d'évaluation

- 28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFDocument41 pages28.3 Physica UG Question Paper Pattern of 5 & 6 Sem PDFthomasgunaseelanPas encore d'évaluation

- Laser Communication SystemsDocument2 pagesLaser Communication SystemsNilabjo Kanti PaulPas encore d'évaluation

- Luxel Vx9600 CTPM Embedded Firmware ReleDocument24 pagesLuxel Vx9600 CTPM Embedded Firmware ReleAlejandro SotoPas encore d'évaluation

- 1 Mirrors PDFDocument30 pages1 Mirrors PDFKevin MaylowPas encore d'évaluation

- Manual Set 130 RDocument182 pagesManual Set 130 RKarina Torres DinartePas encore d'évaluation

- Laser Beam Welding PDFDocument27 pagesLaser Beam Welding PDFFayaz latheef100% (5)

- Optical Properties of Metallic Films For Vertical Cavity Optoelectronic DevicesDocument13 pagesOptical Properties of Metallic Films For Vertical Cavity Optoelectronic DevicesKingkin PermadiPas encore d'évaluation

- Photonicsspectra201002 DLDocument108 pagesPhotonicsspectra201002 DLy2k_yah7758Pas encore d'évaluation

- The Point of Incidence Is Where An Incident Ray Makes Contact WithDocument2 pagesThe Point of Incidence Is Where An Incident Ray Makes Contact Withprecious yvettePas encore d'évaluation

- 1985 S30 Hitachi Optoelectronic Devices Data Book PDFDocument118 pages1985 S30 Hitachi Optoelectronic Devices Data Book PDFMartin FrankPas encore d'évaluation

- Em 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualDocument149 pagesEm 474 N 09 02 Cincinnati CL 7a Laser System With PC Control Operation Safety and Maintenance ManualManolo MedranoPas encore d'évaluation

- Module 3 LaserDocument25 pagesModule 3 LaserFaizan alamPas encore d'évaluation

- KIET - Final PUE Question Paper (Even Sem 2020-21) (KAS201T)Document14 pagesKIET - Final PUE Question Paper (Even Sem 2020-21) (KAS201T)Yashkant TyagiPas encore d'évaluation

- Laser Beam WeldingDocument45 pagesLaser Beam WeldingAhmed El Morsy0% (1)

- Komponen Sistem Komunikasi Serat OptikDocument84 pagesKomponen Sistem Komunikasi Serat OptikGamaliel SyikalPas encore d'évaluation

- Laser Beam MachiningDocument41 pagesLaser Beam MachiningAiswarya Ramesh me21b011Pas encore d'évaluation

- E.Physics-Assignments - Unit 3,4,5Document3 pagesE.Physics-Assignments - Unit 3,4,5Naresh SinghPas encore d'évaluation

- L1050108 - Spectrum 3 Trimode Spectrometer User's Guide en-USDocument102 pagesL1050108 - Spectrum 3 Trimode Spectrometer User's Guide en-USFrizki88Pas encore d'évaluation

- Helium-Neon Laser: History of Hene Laser DevelopmentDocument5 pagesHelium-Neon Laser: History of Hene Laser DevelopmentNaveen KumarPas encore d'évaluation

- Strahlenfolter Stalking - TI - Martina Cable - BLOG - Help For Targeted Individuals Facing Electronic Harassment and PsychotronicsDocument127 pagesStrahlenfolter Stalking - TI - Martina Cable - BLOG - Help For Targeted Individuals Facing Electronic Harassment and PsychotronicsParanoia-war-gesternPas encore d'évaluation

- 2018 Tek ProductCatalogQ1Document139 pages2018 Tek ProductCatalogQ1Apollos_80Pas encore d'évaluation

- Zeiss Visulas Yag III BrochureDocument16 pagesZeiss Visulas Yag III Brochuredavood salkhordehPas encore d'évaluation

- Service Manual: DVD / Av ReceiverDocument33 pagesService Manual: DVD / Av ReceiverJose Luis Rodriguez PolancoPas encore d'évaluation

- Luis Santana Blank Presentacion Bulgaria 2Document26 pagesLuis Santana Blank Presentacion Bulgaria 2namkay_tenzynPas encore d'évaluation

- Optical Fiber Communication-1finalDocument39 pagesOptical Fiber Communication-1finalTanima ChakrabortyPas encore d'évaluation

- Laser Engraving Software ManualDocument63 pagesLaser Engraving Software ManualnammarisPas encore d'évaluation

- Elementary Quantum Physics 20160926Document81 pagesElementary Quantum Physics 20160926Aruna KumarasiriPas encore d'évaluation