Académique Documents

Professionnel Documents

Culture Documents

Jsa Lifting of Pits

Transféré par

eslamDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Jsa Lifting of Pits

Transféré par

eslamDroits d'auteur :

Formats disponibles

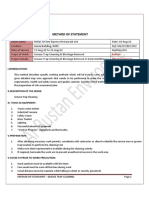

HSE-SAF-SFM-00-0018

Job Safety Analysis

Work Activity (Job):

Work Team

Lifting and Installation of Segment Steel Structure Bridge

Date: 13 February 2008

: M. Mustaffa / S. N. Kim / F.Magnampo / V. Bernabe

JSA Prepared by (Facilitator): V. Bernabe

______

Critical Questions:

Is a site visit to the job location required?

Is everyone ready and capable to work?

Has the potential for a spill or exposure been addressed?

Has the worst case been discussed?

Sequence of Basic Job Steps

Potential Incidents or Hazards

JSA Location: Q-Chem II Conference Room

Supervisor Approval:

Ways to Eliminate or Reduce Potential

Hazards

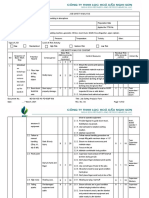

Mobilization of Personnel & Tools

Preparation of tools

Qatar Chemical Company Ltd.

Pinch point

Job Safety Analysis Form Rev 1.0 - Sept 2005

Obtain entry and work permits for all

personnel involved tools and

equipment.

A daily S.T.A.R.R.T (Safety Task Risk

Reduction Talk) meeting shall be

mandatory.

Emergency plan should be discussed

JSA points shall be discussed in the

STARRT meeting.

All tools must be in good condition.

All electrically operated tools must be

color coded and inspected by

competent person.

Any damage tools must be discarded.

Wearing of leather gloves

1/8

Job Safety Analysis

Tripping

Exposure to high temperature

environment

Preparation of Lifting Tackles

Lifting the segment of steel structure

bridge with crane

Arrival at the site

Wrong manual lifting position

unfamiliar with the local situation

Personnel injury

Congested area

Check work location for space

and obstacles.

Enter work location with cranes

collide with equipment

Rig lifting tackle on the crane

Wrong tackles

Qatar Chemical Company Ltd.

Job Safety Analysis Form Rev 1.0 - Sept 2005

HSE-SAF-SFM-00-0018

All crew involve must undergo required

Hazcom Training.

All of the materials shall be arrange

properly and proper housekeeping

should be implemented every end of

the day

Resting shade should be provided

Cool drinking water should be readily

available at the working area.

Supervisor shall ensure that personnel

proper break time is observed.

Proper manual lifting position should be

observed.

Emergency communication procedures

shall be established with process owner

All personnel to be fully briefed on the

task and responsibilities together with

the use of PPE

Cordon off the area.

Have obstacles removed.

Banksman shall escort the crane

Obtain general work permit

Supervision check shall check the lifting

tackle prior to lifting.

Site supv./supt. and crane operators

2/8

Job Safety Analysis

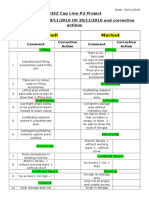

Lift item and bring to enough

horizontal position using one

crane.

Unexpected movement of load.

Serious personnel injury

Incompetent crane operator can

make mistakes and lead to accident

and serious injuries to personnel.

Overloading of Crane.

Unauthorized personnel, passers

may enter while lift is gong on and

be exposed to hazard to swing load.

High wind conditions

Qatar Chemical Company Ltd.

Adverse weather conditions (poor

visibility)

Job Safety Analysis Form Rev 1.0 - Sept 2005

HSE-SAF-SFM-00-0018

need to be aware that the activities is

with in the live operating facility and

near the

Use taglines.

No people under load.

Monitor weather conditions and

forecast. All equipment certified and as

described in the rigging plan.

Area will be barricaded

No unauthorized people in the area.

Crane operator shall be licensed and

certified

Refer to load chart, and follow the

approved rigging plan

Ensure that daily crane inspection is

carried out.

Barricade the operating range (Radius

of load swing) and post warning sign

such a heavy lift no unauthorized

entry etc.

No crane operation under heavy wind

condition Above 13 m/sec

Monitor wind speed conditions from

time-to-time.

Cease work on weather warning(foggy

weather

3/8

Job Safety Analysis

Communication failure between

crane operator and signal man

Poor visibility and raining. Wind speed

exceeding 13 m/sec. & Obey the

nature and be safe.

Trained & certified signal man shall be

engaged.

Only one qualified experience rigger

wearing a red vest should be

authorized.

Banksman should be trained and

certified

Signal man shall be identified by

wearing reflective jacket.

Trained and certified signal man shall

be engaged.

All equipment certified and colour

coded and as described in the rigging

specification

Check all lifting tackles for any damage

prior to use.

Clear instruction and communication.

The operation area shall be barricaded

with hazard working tapes. No

unauthorized entry shall be allowed.

Simultaneous traveling operation

of crane.

Hoisting the bridge to horizontal

position

Failure of lifting equipment.

Detached lifting tackles from the

bridge using manlift after all bolts

and nuts were tightened to the

required specifications.

danger of crush

Falling objects

Qatar Chemical Company Ltd.

Job Safety Analysis Form Rev 1.0 - Sept 2005

HSE-SAF-SFM-00-0018

Tie all tools to be used in the activity

Use safety harness with 100% tie off.

4/8

HSE-SAF-SFM-00-0018

Job Safety Analysis

Prepared by: V. Bernabe

Qatar Chemical Company Ltd.

Checked by:

Reviewed by:

Job Safety Analysis Form Rev 1.0 - Sept 2005

Approved by:

5/8

Job Safety Analysis

HSE-SAF-SFM-00-0018

Safety equipment required to do this job:

Hazard Specific Additional PPE

Chemical Suit

___________________

Disposable Coveralls ___________________

Protective Clothing

___Long sleeve___

Special Gloves

___________________

Fire-retardant clothing ___________________

Hazard Specific Additional PPE

Breathing Air

__________________

Respirator

__________________

Dust Mask

__________________

Safety Harness

__________________

Fall Arrest Device __________________

Other Considerations

Barricades

___________________

Fire Extinguisher ___________________

MSDS

___________________

Isolation

___________________

PTW

___________________

NOTES:

A) Always follow method statement for this job.

B) Stop all work & suspend the permit, move to nearby assembly points, in case of emergency.stay upwind

and move to assembly point in case of toxic gas release.

C) Call 555 from field phone in case of any emergency related to this task.

Qatar Chemical Company Ltd.

Job Safety Analysis Form Rev 1.0 - Sept 2005

6/8

Job Safety Analysis

HSE-SAF-SFM-00-0018

Job Safety Analysis Form (contd)

NOTE: These are in addition to the Critical Questions listed on the front of the JSA form.

Are you qualified to facilitate the JSA for this work?

Is the JSA Facilitator from the department responsible for completing the work?

Have you done this job before?

Have the right people participated in creating the JSA?

Did you conduct the JSA at the job location?

Has the JSA been reviewed by others who are knowledgeable about the work?

Has the JSA been reviewed and upgraded / revalidated at the work site for current conditions?

Have you included a step that includes a post-job critique and JSA upgrade for future use?

Have you communicated with others who might be affected by the work, e.g., Production?

Do you have the necessary resources to do the work, e.g., equipment, right tools, manpower, qualified people and proper PPE?

Do you need detailed work procedures or vendor technical information for this job?

Do you have all the necessary work permits to do the work?

Have you considered potential human-factors in the JSA, e.g., body position, noise, heat and cold?

Is now the right time to be doing the work?

Qatar Chemical Company Ltd.

Job Safety Analysis Form Rev 1.0 - Sept 2005

7/8

Job Safety Analysis

Qatar Chemical Company Ltd.

Job Safety Analysis Form Rev 1.0 - Sept 2005

HSE-SAF-SFM-00-0018

8/8

Vous aimerez peut-être aussi

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchiePas encore d'évaluation

- JSA No. 9 - Safe Use of Pneumatic and Power ToolsDocument2 pagesJSA No. 9 - Safe Use of Pneumatic and Power ToolsAshok Suresh100% (1)

- Steel Erection JSADocument5 pagesSteel Erection JSASalah Abd Eldayem100% (1)

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajPas encore d'évaluation

- Portable Power Tools - Risk Assessment2Document3 pagesPortable Power Tools - Risk Assessment2Basit Nawaz100% (1)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa Tank CleaningDocument5 pagesJsa Tank CleaningASLAM MULANIPas encore d'évaluation

- JSA For Working at HeightDocument2 pagesJSA For Working at HeightXUE JIANPas encore d'évaluation

- Boom Lift PDFDocument2 pagesBoom Lift PDFcityofdarwingisPas encore d'évaluation

- JSA Basket TransferDocument3 pagesJSA Basket TransferCristina Rican100% (1)

- Job Safety AnalysisDocument4 pagesJob Safety AnalysisDedi Apriadi71% (7)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiPas encore d'évaluation

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- Scaffold TowerDocument20 pagesScaffold TowerAndhika HerdiawanPas encore d'évaluation

- JSA-Hydraulic Press Testing For PilesDocument6 pagesJSA-Hydraulic Press Testing For PilesUMUTPas encore d'évaluation

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 pagesR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalPas encore d'évaluation

- ARK JSA 0 Rev 00 Crane LiftingDocument6 pagesARK JSA 0 Rev 00 Crane LiftingREMYAPas encore d'évaluation

- 11 - JSA (Tower Crane) 12-9-06Document11 pages11 - JSA (Tower Crane) 12-9-06sattiPas encore d'évaluation

- JSA Forklift PDFDocument2 pagesJSA Forklift PDFfauziPas encore d'évaluation

- JHA Cutting of Asphalt Road For Replacement of Protection SlabsDocument5 pagesJHA Cutting of Asphalt Road For Replacement of Protection SlabsNasrullah JanPas encore d'évaluation

- HSF-PR-0063 Work at HeightDocument32 pagesHSF-PR-0063 Work at HeightChris Bonnington0% (1)

- JSA For Cleaning and Hydro Test of Test SeparatorDocument7 pagesJSA For Cleaning and Hydro Test of Test SeparatorNishantMittal100% (2)

- Method of Statement - Grease Trap CleaningDocument2 pagesMethod of Statement - Grease Trap CleaningAbdul Rahman75% (4)

- JSA 08 Gas WeldingDocument1 pageJSA 08 Gas Weldingmuthuswamy77Pas encore d'évaluation

- JSA NO 2-Piling WorkDocument3 pagesJSA NO 2-Piling WorkKarthik GanesanPas encore d'évaluation

- Glass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETDocument3 pagesGlass Installation - JOB SAFETY ANALYSIS (JSA) WORKSHEETusman rasheed100% (1)

- JsaDocument106 pagesJsaRoy Dwi PrasetyoPas encore d'évaluation

- TBT-Driving in FogDocument2 pagesTBT-Driving in FogImran KhanPas encore d'évaluation

- JSA Excavation PDFDocument6 pagesJSA Excavation PDFmohamedamine.zemouriPas encore d'évaluation

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelPas encore d'évaluation

- Operating A Telescoping Aerial Boom LiftDocument1 pageOperating A Telescoping Aerial Boom LiftTFattahPas encore d'évaluation

- Confined Spaces Toolbox TalkDocument3 pagesConfined Spaces Toolbox TalkWaSim AKramPas encore d'évaluation

- Brahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysisDocument2 pagesBrahmaputra Cracker and Polymer Limited Lepetkata, Assam: Job Safety AnalysiszebmechPas encore d'évaluation

- SOP Erection TC PDFDocument3 pagesSOP Erection TC PDFRashidi RahmanPas encore d'évaluation

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatePanchdev KumarPas encore d'évaluation

- Scaffold CampaignDocument9 pagesScaffold CampaignAdel SukerPas encore d'évaluation

- Jsa For PCCDocument6 pagesJsa For PCCCICON EngineersPas encore d'évaluation

- TBT Attendance Format - NRP WorkersDocument2 pagesTBT Attendance Format - NRP WorkersIsrael Raja AbhilashPas encore d'évaluation

- JSA Electrical WiringDocument10 pagesJSA Electrical WiringWeru Morris100% (1)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisDocument16 pagesSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh60% (5)

- Ladder Inspection Checklist: General Condition OK Needs Repair Not ApplicableDocument1 pageLadder Inspection Checklist: General Condition OK Needs Repair Not ApplicableWaqas KhanPas encore d'évaluation

- HIRA No. 02-Use of Access Scaffolding SBDDocument2 pagesHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- Jsa Slip FormDocument5 pagesJsa Slip Formputrasejahtra50% (2)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoPas encore d'évaluation

- CraneOperations PDFDocument2 pagesCraneOperations PDFIrshad AkhterPas encore d'évaluation

- Crane Jsa TGPDocument2 pagesCrane Jsa TGPSuryakant SurajPas encore d'évaluation

- JSA ScaffoldingDocument2 pagesJSA ScaffoldingHrishikesh UnnikrishnanPas encore d'évaluation

- Hse JsaDocument22 pagesHse JsaAnonymous y1pIqcPas encore d'évaluation

- Jsa of Boiler Drum LiftingDocument10 pagesJsa of Boiler Drum LiftingGyanendra Narayan NayakPas encore d'évaluation

- JSA To Check & Repair Heat Tracing System.Document12 pagesJSA To Check & Repair Heat Tracing System.Chung Trịnh100% (2)

- DR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutDocument4 pagesDR - Rescue Plan Water Tank Cleaning (002) Rev-With LayoutSachin DharnePas encore d'évaluation

- 3.jsa - Arc Welding-NDocument5 pages3.jsa - Arc Welding-NVivek NaikPas encore d'évaluation

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- Jsa Grinding W Angle GrinderDocument2 pagesJsa Grinding W Angle GrinderMichael Angelo SantePas encore d'évaluation

- The Handbook of Safety Engineering: Principles and ApplicationsD'EverandThe Handbook of Safety Engineering: Principles and ApplicationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Daily Report Form For AnimatorsDocument4 pagesDaily Report Form For AnimatorseslamPas encore d'évaluation

- Comments and Corrrective ActionDocument2 pagesComments and Corrrective ActioneslamPas encore d'évaluation

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk Assessmenta6free100% (8)

- Crosby SDocument1 pageCrosby SeslamPas encore d'évaluation

- Crane Lifting Plan Method Statement and Risk AssessmentDocument4 pagesCrane Lifting Plan Method Statement and Risk Assessmenta6free100% (8)

- Crane Inspection Checklist 2Document1 pageCrane Inspection Checklist 2eslamPas encore d'évaluation

- Basic Lifting PlanDocument2 pagesBasic Lifting Planeslam100% (1)

- 1 Scaffold LoadsDocument14 pages1 Scaffold LoadseslamPas encore d'évaluation

- Biomechanics of The Knee 1Document2 pagesBiomechanics of The Knee 1savitha sabuPas encore d'évaluation

- Pre Operative CareDocument3 pagesPre Operative CareMohammed AlOtaibi100% (2)

- The Benefits of Balance TrainingDocument3 pagesThe Benefits of Balance TrainingchikitaPas encore d'évaluation

- Neuropsychological Studies of The Frontal LobesDocument26 pagesNeuropsychological Studies of The Frontal LobesIcaroPas encore d'évaluation

- Test/Sign Procedure (+) INDDocument8 pagesTest/Sign Procedure (+) INDDesi SmithPas encore d'évaluation

- Chainsaw Safety Checklist Yes No N/A F/IDocument2 pagesChainsaw Safety Checklist Yes No N/A F/IKate Hopley20% (5)

- Fracture of The Talus and Calcaneus NickDocument43 pagesFracture of The Talus and Calcaneus NickTan Zhi HongPas encore d'évaluation

- Atls Transfer To Definitive CareDocument20 pagesAtls Transfer To Definitive CaresheisamarinkaPas encore d'évaluation

- Ming MethodDocument2 pagesMing Methodwalterego58Pas encore d'évaluation

- A School-Based First Aid Training Design For Teachers in Two Selected Municipalities of The IV District of QuezonDocument18 pagesA School-Based First Aid Training Design For Teachers in Two Selected Municipalities of The IV District of QuezonPsychology and Education: A Multidisciplinary JournalPas encore d'évaluation

- Mild Traumatic Brain Injury and Postconcussion SyndromeDocument111 pagesMild Traumatic Brain Injury and Postconcussion SyndromeMaria João LeitePas encore d'évaluation

- Toolbox Talk Chemical GlovesDocument6 pagesToolbox Talk Chemical GlovesBomber Man100% (1)

- Standard RA Template-1Document3 pagesStandard RA Template-1Bhuvanesh SriniPas encore d'évaluation

- Report of Traffic Accident Occurring in California: Read Important Information On BackDocument3 pagesReport of Traffic Accident Occurring in California: Read Important Information On BackThebomb3Pas encore d'évaluation

- CCB Indian Railways Locomotive Maintenance ManualDocument4 pagesCCB Indian Railways Locomotive Maintenance ManualumadeviPas encore d'évaluation

- Extensor Tendon Injury ProtocolDocument11 pagesExtensor Tendon Injury ProtocoltasneempichoriPas encore d'évaluation

- Gadar 220190401Document7 pagesGadar 220190401muhammad pratamaPas encore d'évaluation

- 2015 FIAT 500 Abarth Owners ManualDocument428 pages2015 FIAT 500 Abarth Owners ManualFiat500USAPas encore d'évaluation

- Safety Training Hydrojetting of Exchangers GeneralDocument15 pagesSafety Training Hydrojetting of Exchangers GeneralandinumailPas encore d'évaluation

- Ewrc SHP Gen Hse Jsa 00040Document12 pagesEwrc SHP Gen Hse Jsa 00040Rickz CabaloPas encore d'évaluation

- Transferring of ClientsDocument5 pagesTransferring of ClientsJaviePas encore d'évaluation

- Assignment Shoulder JointDocument7 pagesAssignment Shoulder JointMary Grace OrozcoPas encore d'évaluation

- Coaching PortfolioDocument74 pagesCoaching Portfolioapi-302326964Pas encore d'évaluation

- ScapulaDocument17 pagesScapulaMHKPas encore d'évaluation

- Diagnosis and Management of Polytraumatized.1Document6 pagesDiagnosis and Management of Polytraumatized.1María José Bueno MonteroPas encore d'évaluation

- DR'S Abcd - Primary Survey: To Do Rationale DemonstrationDocument4 pagesDR'S Abcd - Primary Survey: To Do Rationale DemonstrationJunTarePas encore d'évaluation

- Petronas Risk Matrix ProcedureDocument16 pagesPetronas Risk Matrix Procedureme_lokie100% (1)

- Splinter EssayDocument3 pagesSplinter EssaySupraja SaravanakumarPas encore d'évaluation

- Frenectomy PDFDocument6 pagesFrenectomy PDFzinniaPas encore d'évaluation

- Eathe.2016.1080p.webrip.x264.aac2.0 StuttershitDocument38 pagesEathe.2016.1080p.webrip.x264.aac2.0 StuttershitUmaPas encore d'évaluation