Académique Documents

Professionnel Documents

Culture Documents

E7884x PDF

Transféré par

pietrokoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

E7884x PDF

Transféré par

pietrokoDroits d'auteur :

Formats disponibles

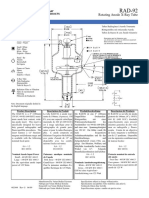

Product Information

ROTANODE

E7884X

Rotating Anode X-Ray Tube Assembly

Rotating anode X-ray tube assembly for high

energy radiographic and cine-fluoroscopic

operations.

The heavy anode is constructed with specially

processed rhenium-tungsten faced

molybdenum target which is 74 mm diameter

and has an improved coating to increase

thermal emissivity.

This tube has foci 1.2 and 0.6, and is available

for a maximum tube voltage 150 kV.

Accommodated with IEC60526 type

high-voltage cable receptacles.

General Data

IEC Classification .............................................................................................................. Class

Electrical:

Circuit:

High Voltage Generator ............................................... Constant potential high-voltage generator

Grounding .......................................................................................................... Center-grounded

Nominal Tube Voltage:

Radiographic ............................................................................................. Maximum 40 ~ 150 kV

Fluoroscopic .............................................................................................. Maximum 50 ~ 125 kV

Nominal Focal Spot Value:

Large Focus ............................................................................................................................. 1.2

Small Focus ............................................................................................................................. 0.6

Nominal Anode Input Energy (at 0.1s):

50 Hz

60 Hz

Large Focus ..................................................................................................... 50 kW

54 kW

Small Focus ..................................................................................................... 20 kW

22 kW

The information contained herein is presented only as a guide for the applications of our products.

No Responsibility is assumed by TOSHIBA ELECTRON TUBES & DEVICES CO.,LTD.(TETD) for any infringements of patents or other rights of the

third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of TETD or others.

The information contained herein may be changed without prior notice. It is therefore advisable to contact TETD before proceeding with the design of

equipment incorporating this product.

For further particulars apply to TETD.

No. PE-E7884X

2007-06-25

PI

E7884X

Motor Ratings

Stator: XS-AL

Duty

Starting

Running

Power source

(Hz)

50/60

50/60

Input power

(W)

910

83

(V)

130

40

(A)

7.8

2.3

(s)

0.8

(F)

44

44

Voltage

2)

Current

Min. Speed up

Capacitor

1) 3)

3)

Braking time

(s)

3s / 70 V (DC)

Note 1) The speed up time from normal speed to high speed is 2/3 times of the specified speed

up time from 0 to high speed, which is described on motor rating table.

2) The every applied voltage must be never exceeded 110% of the above specification.

3 The speed-up and braking time are allowed up to 110% of the above specification.

Anode Rotation Speed:

50 Hz ............................................................................................................ Minimum 2700 min-1

60 Hz ............................................................................................................ Minimum 3200 min-1

Stator impedance:

Common-Main Winding ...................................................................................................... 27.5

Common-Auxiliary Winding ................................................................................................ 58.0

Resistance between Housing and Low Voltage Terminals ........................................ Minimum 2 M

Normal operating range of the housing temperature ........................................................ 16 ~ 75

Mechanical:

Dimensions .................................................................................................. See dimensional outline

Overall Length .................................................................................................................. 479 mm

Maximum Diameter ....................................................................................................... 152.4 mm

Target:

Angle ........................................................................................................................... 12 degrees

Diameter ............................................................................................................................ 74 mm

Construction .................................................................... Rhenium-Tungsten faced Molybdenum

Permanent Filtration ................................................................. 0.9 mm Al / 75 kV IEC 60522 / 1999

Radiation Protection (To meet the requirements of IEC60601-1-3):

Leakage Technique Factor .................................................................................. 150 kV, 3.4 mA

X-ray Coverage .................................................................................. 354 354 mm at SID 835 mm

Weight (Approx.) ........................................................................................................................ 16 kg

High Voltage Receptacle ........................................................... To meet requirements of IEC60526

Cooling Method .................................................................................................. Natural or forced air

Housing (Including both end plates):

Model Number .................................................................................................................. XH-121

-2-

E7884X

Absolute Maximum and Minimum Ratings

(At any time, these values must not be exceeded.)

Nominal X-ray Tube Voltage:

Radiographic ...................................................................................................................... 150 kV

Fluoroscopic ....................................................................................................................... 125 kV

Maximum Voltage to Ground .................................................................................................... 78 kV

Minimum Tube Voltage ............................................................................................................. 40 kV

Maximum X-ray Tube Current:

Large Focus ...................................................................................................................... 700 mA

Small Focus ...................................................................................................................... 300 mA

Maximum Filament Current:

Large Focus .......................................................................................................................... 5.4 A

Small Focus .......................................................................................................................... 5.2 A

Filament Voltage:

Large Focus (At maximum filament current 5.4 A) ................................................... 11.9 ~ 16.1 V

Small Focus (At maximum filament current 5.2 A) ....................................................... 6.8 ~ 9.2 V

Filament Frequency Limits ................................................................................................ 0 ~ 25 kHz

X-ray Tube Assembly Input Power ......................................................................... 142 W (200 HU/s)

(Repeated radiographic exposure)

Thermal Characteristics:

Anode Heat Content ......................................................................................... 210 kJ (300 kHU)

Maximum Anode Heat Dissipation ................................................................. 750 W (1056 HU/s)

X-ray Tube Assembly Heat Content ................................................................ 900 kJ (1250 kHU)

Maximum Continuous Heat Dissipation:

Without Air-circulator ................................................................................ 180 W (15 kHU/min)

-3-

E7884X

Environmental Limits

Operating Limits:

Temperature ................................................................................................................ 10 ~ 40

Humidity ........................................................................................................................ 30 ~ 85 %

(No condensation)

Atmospheric Pressure .............................................................................................. 70 ~ 106 kPa

Shipping and Storage Limits:

Temperature .............................................................................................................. -20 ~ 70

Humidity ........................................................................................................................ 20 ~ 90 %

(No condensation)

Atmospheric Pressure .............................................................................................. 50 ~ 106 kPa

-4-

E7884X

Warning

Warning to Interface with X-ray Generator

1. Housing Rupture

Never input over-rated power to x-ray tube assembly.

If the input power is extremely higher than specification, it may cause the over temperature of

anode, insert tube glass shatter and ultimately the following serious problems due to generating

over-pressure by oil vaporization inside housing assembly.

In such a critical condition, the safety thermal switch can not protect x-ray tube even if it works.

* Housing sealing parts rupture

* Human injury including burns due to hot oil escape

* Fire accident due to flaming anode target

We strongly request that the x-ray generator should have a protective function which manages

input power to x-ray tube assembly.

-5-

E7884X

Cautions

Caution to Interface with X-ray Generator

1. Over Rating

X-ray tube assembly can be broken with applying just one over rated shot.

Please read the technical data sheets carefully and follow the instructions.

2. Permanent Filtration

The total filtration and the distance between x-ray focal spot and human body are regulated legally.

They should be complied with the regulation.

3. Safety Thermal Switch

X-ray tube assembly has safety thermal switch to prohibit further input power when the tube

housing reaches to the temperature of switch-open.

The switch should be hooked up with the x-ray generator which control output power to x-ray tube

assembly.

The switch is not recommended connecting stator coil in series circuit.

Even if the switch works, never turn the system power off and the cooling unit should be activated.

4. Unexpected Malfunction

X-ray tube assembly may have the risk to be unexpectedly malfunctioning due to life termination or

failure. If the serious problems caused by the above risk is expected, we recommend to have a

contingency plan to avoid such a case.

5. New Application

If you use the product with new application not to be mentioned in this specification or with different

type of x-ray generator, please contact to us for confirming its availability.

-6-

E7884X

Caution for Installation, Adjustment and Maintenance

1. Qualified Persons

Only qualified persons who have technical training and professional knowledge can handle x-ray

tube assembly.

2. Fragile Glass

X-ray tube is assembled with glass, therefore, it can be broken with the mechanical vibration or

pulsed shock over 19.6m/s2 (2G).

Careful handling is required to treat or transport.

3. Ground Terminal

X-ray tube assembly has ground terminal. Ground cable should be connected.

4. High Voltage

All x-ray tubes operate at voltages high enough to kill through electrical shock. Never touch the

high voltage delivered plugs or terminals.

When direct access to such parts is required, the primary circuit should be disabled and high

voltage capacitors/cables discharged.

5. High Voltage Plug

High voltage plug should be cleaned up and free from any physical damages. Silicon compound

application is required for high voltage stability.

6. Operation Atmosphere

X-ray tube assembly is not allowed to use in the atmosphere of flammable or corrosive gas.

7. Protective Cover

X-ray tube assembly is not allowed to use without the protective cover attached.

8. Handling

Appropriate jig or tools are required for tube installation to avoid physical damages.

9. Returning Tube

X-ray tube assembly should be repackaged with the original material when it is returned back for

quality examination in our factory.

Be careful to put the tube upside cathode.

If the packaging is not proper, the tube may not be

correctly examined.

-7-

E7884X

Caution in Operation

1. X-Ray Radiation

X-ray tube assembly should have the beam limiting equipment mounted on the x-ray port to protect

unnecessary radiation.

2. Dielectric Oil

X-ray tube assembly has dielectric oil contained for high voltage stability. As it is poisonous for

human health, if it is exposed to the non-restricted area, it should be disposed as following to the

local regulation.

3. Operation Atmosphere

X-ray tube assembly is not allowed to use in the atmosphere of flammable or corrosive gas.

4. Disposal

X-ray tube housing is lined with lead to protect unnecessary radiation.

The lead powder or vapor is harmful for human health.

Dispose the scrapped products according to the requirement of local regulation.

If you have any questions, please contact to our local sales representatives for further information.

5. X-Ray Tube Housing Temperature

Do not touch on X-ray tube housing surface just after operation due to high temperature.

Stay X-ray tube to be cooled.

6. Any Malfunction

Please contact to TETD immediately, if any malfunction of the X-ray tube assembly is noticed.

-8-

E7884X

Caution Label

(a) This label is a caution label to notify the user of the following point.

"Housing end cap is used to protect the electric shock and x-ray leakage."

Attachment position : X-ray tube assembly housing end cap

-9-

E7884X

Maximum Rating Charts

(Absolute Maximum Rating Charts)

T.B.D

- 10 -

E7884X

Maximum Rating Charts

(Spot-Film Rating Charts)

T.B.D

- 11 -

E7884X

Decreasing input power rating

Serial Load puts a severe thermal stress on the X-ray tube due to the large number of exposures made

in rapid succession. Intervals between exposures are fixed and so short that it is not possible for the

anode track to cool to any extent during the exposure series.

Therefore, the temperature of the anode track increases from exposure to exposure.

The kW values used in the Serial load at each thermal status of anode have been determined to

prevent damage to the anode as follows:

Table1. Radiographic Rating

T.B.D

Table2. Radiographic and fluoroscopic Rating

T.B.D

Note: The % HU is the ratio of anode storage heat amount per the nominal anode heat storage

capacity (230kHU).

- 12 -

E7884X

Emission & Filament Characteristics

T.B.D

- 13 -

E7884X

Thermal Characteristics

Housing Thermal Characteristics

900

200W

HEAT STORAGE [kJ]

800

700

600

500

400

COOLING

300

200

100

HEATING

0

0

60

120

180

240

300

360

TIME [min]

Anode Thermal Characteristics

180

160

COOLING

HEAT STORAGE [kJ]

140

120

100

80

60

142W

40

20

HEATING

0

0

TIME [min]

- 14 -

10

E7884X

Dimensional Outline

72

Unit mm

170

156

11.1

4-M5 10 DEEP

45

479

125.4

90

92

41.27

152.4

CENTRAL RAY AND REFERENCE AXIS

1 2

11.1

4-M6 8 DEEP

ANODE

81

CATHODE

C

140

1 2 3

NCNCNC

4 E

NC

M A

ET

TEMPERATURE RELAY

(NORMALLY CLOSED)

70

121

9 8 7 6 5

2-M63.5, P=1.27

81

53

11.1

TERMINAL CONNECTIONS

Note) Do not connect terminal No.1 and

No.5 or 6 in series circuit.

CENTRAL OF FOCAL SPOT

FOCAL SPOT

A1.5mmB1.5mm

NC : NON-CONNECTION

ET : EARTH TERMAINAL

: CENTERAL X-RAY

ANODE & CATHODE TERMINAL

: IEC 60526 TYPE

C : COMMON

L : LARGE FOCUS

S : SMALL FOCUS

M : MAIN WINDING OF THE STATOR

A : AUX. WINDING OF THE STATOR

- 15 -

E7884X

OVERSEAS SUBSIDIARIES AND AFFILIATES

EU REPRESENTATIVE

TOSHIBA ELECTRONICS EUROPE GMBH

HANSAALLEE 181 40549 DUSSELDORF, GERMANY

FAX +49 (0) 211 5296 402

PHONE +49 (0) 211 5296 107

For Sales & Technical Services, please contact the following representative:

TOSHIBA ELECTRONICS EUROPE GMBH

HANSAALLEE 181 40549 DUSSELDORF, GERMANY

FAX +49 (0) 211 5296 402

PHONE +49 (0) 211 5296 107

TOSHIBA AMERICA ELECTRONIC COMPONENTS, INC.

2150 EAST LAKE COOK ROAD, SUITE 310

BUFFALO GROVE, ILLINOIS 60089 USA

PHONE (847) 484-2400

FAX (847) 541-7287

TOSHIBA ELECTRON DEVICES &

MATERIALS TRADING (SHANGHAI) CO., LTD. (TEMS)

No.689, GUANG DONG RD, SHANGHAI, 200001,CHINA

RM607, HAITONG SECURITIES TOWER

PHONE (21) 6341-0055

FAX (21) 6341-0990

Sales & Marketing Department

1385 SHIMOISHIGAMI, OTAWARA-SHI, TOCHIGI-KEN, 324-8550, JAPAN

PHONE : +81-287-26-6666

FAX : +81-287-26-6060

http://www.toshiba-tetd.co.jp/

Toshiba Electron Tubes & Devices Co., Ltd.

meets the Environmental Management

System Standard, ISO 14001

Toshiba Electron Tubes & Devices Co., Ltd. meets

internationally recognized Standards for Quality

Management System ISO 9001, ISO 13485

Vous aimerez peut-être aussi

- Product Information: Rotanode™ E79039XDocument12 pagesProduct Information: Rotanode™ E79039XKamilPas encore d'évaluation

- Generations of CT Scan SystemsDocument7 pagesGenerations of CT Scan SystemspietrokoPas encore d'évaluation

- Product Information: Rotanode E7884XDocument16 pagesProduct Information: Rotanode E7884XpietrokoPas encore d'évaluation

- Manual Toshiba TuboDocument16 pagesManual Toshiba TuboJoseph Robert SelvasPas encore d'évaluation

- E7869X Xray Tube DatasheetDocument22 pagesE7869X Xray Tube DatasheetJordi Segura Farías100% (1)

- Pe E7894x - 2018 11Document10 pagesPe E7894x - 2018 11khawar mukhtarPas encore d'évaluation

- Pe E7876x - 2018 11Document8 pagesPe E7876x - 2018 11aplicacionista.imagenesPas encore d'évaluation

- Tubo de RX ToshibaDocument22 pagesTubo de RX ToshibaDeulin Natalia Tonguino TacanPas encore d'évaluation

- Product Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7254X E7254FX E7254GX Rotating Anode X-Ray Tube Assemblykhawar mukhtarPas encore d'évaluation

- Product Information: Rotanode™ E7239X E7239FX E7239GXDocument10 pagesProduct Information: Rotanode™ E7239X E7239FX E7239GXWael Fuad AL-MaktariPas encore d'évaluation

- Technical Data: Rotanode E7239X E7239FX E7239GXDocument16 pagesTechnical Data: Rotanode E7239X E7239FX E7239GXSuwandra I Gede PutuPas encore d'évaluation

- Product Information: Rotanode™ E7884X E7884FX E7884GX Rotating Anode X-Ray Tube AssemblyDocument10 pagesProduct Information: Rotanode™ E7884X E7884FX E7884GX Rotating Anode X-Ray Tube AssemblyKamilPas encore d'évaluation

- Product Information: Rotanode™ E7100XDocument10 pagesProduct Information: Rotanode™ E7100Xkhawar mukhtarPas encore d'évaluation

- Pe-E7884x FX GX 2018-11 PDFDocument10 pagesPe-E7884x FX GX 2018-11 PDFGrayCat007Pas encore d'évaluation

- Product Information: Rotanode™ E7255X E7255FX E7255GX Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotanode™ E7255X E7255FX E7255GX Rotating Anode X-Ray Tube Assemblykhawar mukhtarPas encore d'évaluation

- Pe-E7886x FX 2018-11Document10 pagesPe-E7886x FX 2018-11jojokawayPas encore d'évaluation

- Product Information: Rotanode™ E7823FXDocument12 pagesProduct Information: Rotanode™ E7823FXKamilPas encore d'évaluation

- Pe-E7242x Tubo CannonDocument10 pagesPe-E7242x Tubo Cannonaplicacionista.imagenesPas encore d'évaluation

- TCN CT Datasheet IOSK72.5 200-400Document1 pageTCN CT Datasheet IOSK72.5 200-400ERWIN ESCANILLAPas encore d'évaluation

- Toshiba E7242x Tube RXDocument10 pagesToshiba E7242x Tube RXcamv_847601Pas encore d'évaluation

- Pe E79016x - 2018 11Document14 pagesPe E79016x - 2018 11Ahmed AlkabodyPas encore d'évaluation

- Product Information: Rotanode™ E7290AXDocument14 pagesProduct Information: Rotanode™ E7290AXKamilPas encore d'évaluation

- Technical Data: Rotanode E7299X E7299FXDocument16 pagesTechnical Data: Rotanode E7299X E7299FXduong nguyenPas encore d'évaluation

- Tube X-Ray Product InformationDocument10 pagesTube X-Ray Product InformationDanny SaniPas encore d'évaluation

- E7239FX Data SheetDocument10 pagesE7239FX Data SheetLuis Fernando Garcia SPas encore d'évaluation

- Toshiba - E7239X DatasheetDocument16 pagesToshiba - E7239X DatasheetAlejandro50% (2)

- Product Information: Rotanode™ E79016XDocument14 pagesProduct Information: Rotanode™ E79016XKamilPas encore d'évaluation

- Product Information: Rotanode™ E7239X E7239FX E7239GXDocument10 pagesProduct Information: Rotanode™ E7239X E7239FX E7239GXAlfonso NiñoPas encore d'évaluation

- Solenoid / Alarm Driver: Advanced FeaturesDocument2 pagesSolenoid / Alarm Driver: Advanced FeaturesMark MassaPas encore d'évaluation

- Isolated Converter / SplitterDocument2 pagesIsolated Converter / SplittermijooPas encore d'évaluation

- Technical Data: Rotanode E7252X E7252FX E7252GXDocument22 pagesTechnical Data: Rotanode E7252X E7252FX E7252GXNguyen HaiPas encore d'évaluation

- NTE5470 Thru 5476 Silicon Controlled Rectifier (SCR) 5 Amp, TO64Document2 pagesNTE5470 Thru 5476 Silicon Controlled Rectifier (SCR) 5 Amp, TO64Seralmo1990Pas encore d'évaluation

- 1N4001 Thru 1N4007 1.0A Standard Recovery Rectifier: FeaturesDocument2 pages1N4001 Thru 1N4007 1.0A Standard Recovery Rectifier: FeaturesjohannaPas encore d'évaluation

- Repeater / Power SupplyDocument2 pagesRepeater / Power SupplyBoubekeur HamegPas encore d'évaluation

- Product Information: Rotanode™ XRR-4631GDocument10 pagesProduct Information: Rotanode™ XRR-4631Gkhawar mukhtarPas encore d'évaluation

- 3104-Pr EletronicsDocument2 pages3104-Pr EletronicsArif M. SírioPas encore d'évaluation

- 3CX800A7Document5 pages3CX800A7sPas encore d'évaluation

- Signal Converter 2255-1759-USDocument2 pagesSignal Converter 2255-1759-USNafees BadPas encore d'évaluation

- PR 3104Document2 pagesPR 3104Américo AlvesPas encore d'évaluation

- Model: LUC-8M: Specifications For Rotating Anode X-Ray Tube Ass'yDocument17 pagesModel: LUC-8M: Specifications For Rotating Anode X-Ray Tube Ass'yJairo Manzaneda100% (1)

- Abridged Data: MG4004 X-Band MagnetronDocument5 pagesAbridged Data: MG4004 X-Band MagnetronNamiJen LobatoPas encore d'évaluation

- Loop Powered IsolatorDocument2 pagesLoop Powered IsolatormatrixtnPas encore d'évaluation

- Pulse IsolatorDocument2 pagesPulse IsolatorChAnDiPa - DzPas encore d'évaluation

- NTE597 Silicon Rectifier Ultra Fast, 200V, 8A: DescriptionDocument2 pagesNTE597 Silicon Rectifier Ultra Fast, 200V, 8A: Descriptiondusan1962Pas encore d'évaluation

- PR 3108Document2 pagesPR 3108Américo AlvesPas encore d'évaluation

- Programmable TransmitterDocument2 pagesProgrammable TransmitterAmérico AlvesPas encore d'évaluation

- PR 3103Document2 pagesPR 3103Américo AlvesPas encore d'évaluation

- Toshiba E7242x PDFDocument16 pagesToshiba E7242x PDFJimmyPas encore d'évaluation

- Repeater / Power SupplyDocument2 pagesRepeater / Power SupplyGeorgios MariolisPas encore d'évaluation

- Nte 5899Document2 pagesNte 5899aleypaPas encore d'évaluation

- Product Information: Rotating Anode X-Ray Tube AssemblyDocument12 pagesProduct Information: Rotating Anode X-Ray Tube AssemblyKamilPas encore d'évaluation

- E7252X DatasheetDocument18 pagesE7252X DatasheetGopichandPas encore d'évaluation

- 2255 19090 UsDocument2 pages2255 19090 UsANGEL FLORESPas encore d'évaluation

- HART 7 Temperature Converter, Loop-PoweredDocument2 pagesHART 7 Temperature Converter, Loop-PoweredPrabhu DevPas encore d'évaluation

- Pt100 Converter: ApplicationDocument2 pagesPt100 Converter: ApplicationIngegneria EdilePas encore d'évaluation

- Sirio Dualband Ant CatalogDocument10 pagesSirio Dualband Ant Catalog10sd156Pas encore d'évaluation

- Valvole - Data Sheet El84Document3 pagesValvole - Data Sheet El84Renee WarnerPas encore d'évaluation

- El 84Document3 pagesEl 84corneliusflavius7132Pas encore d'évaluation

- 7255Document24 pages7255khawar mukhtarPas encore d'évaluation

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Electroanalysis: Theory and Applications in Aqueous and Non-Aqueous Media and in Automated Chemical ControlD'EverandElectroanalysis: Theory and Applications in Aqueous and Non-Aqueous Media and in Automated Chemical ControlPas encore d'évaluation

- 10099745H00 - PB500 Power Pack Assembly & Test ProcedureDocument30 pages10099745H00 - PB500 Power Pack Assembly & Test ProcedurepietrokoPas encore d'évaluation

- 10099745H00 - PB500 Power Pack Assembly & Test Procedure PDFDocument30 pages10099745H00 - PB500 Power Pack Assembly & Test Procedure PDFpietrokoPas encore d'évaluation

- GM60A Dimmensions 001 PDFDocument1 pageGM60A Dimmensions 001 PDFpietrokoPas encore d'évaluation

- Agfa CR 10 X User ManualDocument4 pagesAgfa CR 10 X User ManualpietrokoPas encore d'évaluation

- 2.4 Physical Characteristics: GM60A SeriesDocument1 page2.4 Physical Characteristics: GM60A SeriespietrokoPas encore d'évaluation

- (Wire Certified For Canada) Flexible Cord Certified For Canada UL Certification InfoDocument2 pages(Wire Certified For Canada) Flexible Cord Certified For Canada UL Certification InfopietrokoPas encore d'évaluation

- DV5950Document6 pagesDV5950pietrokoPas encore d'évaluation

- Toshiba - E7239X DatasheetDocument16 pagesToshiba - E7239X DatasheetAlejandro50% (2)

- (Drgem) GXR-SD Minimum Room SizeDocument1 page(Drgem) GXR-SD Minimum Room SizepietrokoPas encore d'évaluation

- RAD-92 PdsDocument12 pagesRAD-92 PdspietrokoPas encore d'évaluation

- Anydesk Benchmark PDFDocument5 pagesAnydesk Benchmark PDFpietrokoPas encore d'évaluation

- 01 Wiha Complete Product GuideDocument52 pages01 Wiha Complete Product GuidepietrokoPas encore d'évaluation

- Millenium VG Ch5-Electric Install RequirimentsDocument6 pagesMillenium VG Ch5-Electric Install RequirimentspietrokoPas encore d'évaluation

- Mayam 2.0 Setup NotesDocument3 pagesMayam 2.0 Setup NotespietrokoPas encore d'évaluation

- Medical Device Recalls GE INFINIADocument15 pagesMedical Device Recalls GE INFINIApietrokoPas encore d'évaluation