Académique Documents

Professionnel Documents

Culture Documents

NXT-M Bop TMS

Transféré par

Sasan AbbasiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

NXT-M Bop TMS

Transféré par

Sasan AbbasiDroits d'auteur :

Formats disponibles

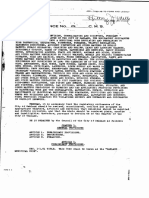

Technical Marketing Sheet

18-15m NXT-M BOP Assembly

*For reference only, please contact your local sales contact for more information.

BOP | Triple

BOP

Triple

BOP | Double

Height

Flange

Congfiguration C

14X14X14

35.9

53.9

71.9

26.4

46.4

66.4

93.1

Cavity

Outlet

Weight (lbs)

BOP

Double

65,000

BOP | Single

Height

Flange

Congfiguration

Cavity

Outlet

Weight (lbs)

14X14 SXF

73.3

N/A

35.6

53.6

25.4

45.4

45,700

14X14 FXF

N/A

89.8

35.6

53.6

25.4

45.4

51,850

BOP

Single

Height

Flange

Congfiguration C

Cavity

Weight (lbs)

14 SXS

N/A

N/A

41.0

N/A

14 SXF

55.4

N/A

N/A

36.1

39,000

38,500

14 FXF

N/A

72.12

N/A

36.1

62,100

Center of Gravity

Center of Gravity

DIM

C.G.

Door Configuration

BOP

14X14X14

DIM

Upper

14" U2B

Middle

14" U2B

Lower

14" U2B

Door Configuration

BOP

Upper

Lower

C.G.

14x14 SXF

14" U2B

14" PSLK 14" BTSR LFS

41.8 (1062)

DIM

C.G.

51.3 (1303)

C.G.

14x14 SXF

14" U2B

14" U2B

42.0 (1067)

14x14 SXF

14" MLNK 14" BSTR

14" MLNK 14" BSTR

42.1 (1069)

C.G.

14 SXF

14" U2B ILF

36.1 (916)

C.G.

C.G.

14 SXF

14 SXF

14" MNLK x 14" BSTR LFS

14" PSLK x 14" BSTR LFS

36.1 (916)

36.1 (916)

1"( 25mm)

C.G.

14X14X14

14" U2B ILF

51.3 (1303)

C.G.

C.G.

14X14X14

14" PSLK 14" BSTR LFS 14" PSLK 14" BSTR LFS 14" PSLK 14" BSTR LFS 51.3 (1303)

C.G.

14x14 FXF

14" PSLK 14" BSTR LFS 14" PSLK 14" BSTR LFS

42.2 (1072)

C.G.

14x14 FXF

14" U2B ILF

42.0 (1067)

14" U2B ILF

14" U2B ILF

18-15m NXT-M BOP Assembly Features

14" MNLK 14" U2B

14" U2B ILF

14" MNLK

14" MNLK

14" BSTR

14" BSTR

LFS

14"PSLK

14" BSTR

LFS

14"PSLK

14" BSTR

CVX

Operator Weight (w/ fluid)

2,590 lbs

3,040 lbs

3,070 lbs

3,455 lbs

3,655 lbs

3,950 lbs

3,840 lbs

OPEN

13.3 Gal

15.7 Gal

15.7 Gal

27.0 Gal

31.5 Gal

32.1 Gal

26.6 Gal

CLOSE

13.3 Gal

16.8 Gal

16.7 Gal

27.3 Gal

31.8 Gal

33.7 Gal

27.9 Gal

Max. Working Pressure

3,000 psi

3,000 psi

3,000 psi

3,000 psi

3,000 psi

3,000 psi

3,000 psi

Boltless BOP Doors

Shaffer NXT-M BOP Systems are unique in providing a means of significantly improving safety and

efficiency in the critical path of activity. With the replacement of the door bolts in ram BOPs, National

Oilwell Varco has eliminated the time consuming manual practice of using brute force to torque up

numerous large door bolts. A number of benefits have been realized with this development:

Reduced Weight (lightest BOP systems in the industry)

Reduced Height (smallest BOP systems in the industry)

Elimination of Manual Labor Under Time Pressure

Shaffer addresses the need for changing out rams on a tapered drillstring by offering Multi-Ram assemblies to cover a range of varying ODs of drill pipe:

Supported Inner Diameter Range:

3 1/2"- 5 7/8"

3 1/2" - 6 5/8"

4 1/2"- 6 5/8" HT

5"- 7 5/8"

14" U2B ILF

Hydraulic System

Operator Characteristics

Multi-Rams

Center of Gravity

1 ( 25mm)

BOP

14 SXF

Door Configuration

14" U2B

1"( 25mm)

36.0 (916)

Weldless Cavity

Hydraulic power to operate a Model NXT-M ram BOP can be furnished by any standard oil field accumuThe introduction of no weld cavities in previous Shaffer BOP designs is carried on in the NXT-M models.

lator system. Hydraulic passages drilled through the body eliminate the need for external manifold pipes

This feature introduces replaceable parts to the cavity to eliminate extensive in-shop repairs and post

between the hinges. Each set of rams requires only one opening and one closing line. There are two

weld heat treatments. The seal seat, skid plate and side pads can be replaced upgrading the BOP cavity

opening and two closing hydraulic ports, clearly marked, on the back side of the BOP. The extra hydrautolerances to as new condition.

lic ports facilitate connecting the control system to the preventer. A standard hydraulic accumulator unit

BOP Body- CREP Overview

Ring Groove

CREP- Corrosion Resistance Enhancement Package

Door Face

will close any Model NXT-M ram with rated working pressure in the well bore.

(Top and Bottom)

and Door

Seal

NXT-M Body-CREP Level 7

Ultra-Temp

Ring Groove

(Side Outlets)

The conservative Shaffer testing procedures call for maintaining pressure and temperature for the

duration of the test. Even with these stringent demands, the UltraTemp rams hold in witnessed testing.

Shaffer UltraTemp ram assemblies are designed to safely withstand wellbore pressures up to 15,000 psi

and extreme temperatures up to 350F (177C) for prolonged periods. This translates into rigsite capability to safely evacuate personnel and equipment in the event of a major high temperature, high pressure

kick.

Low Force Blind Shear (LFS) Rams

The force required to shear casing is reduced by at least 50%. The LFS Ram sever 14, 113ppf, Q-125 casing at 2700 psi with a 22 operator. Multiple shear and seal sequences can be performed with the same

assembly, including conditions where the drill pipe is hung-off below the shear ram cavity, enhancing

reliability and extending the length of the BOP stack deployment.

Less pressure requited to shear

Capable of centering pipe before sharing

Shearing range

Wireline to 14

Temperature Range: 30F to 300F (-1C to 149C)

14" Ultra Lock II (B) Door

Cylinder Head

Cylinder Seal

Hydraulic Port

(Manifold)

Hydraulic Ports

Packing Bore

Inlay/Coating

Door Seal

Inconel

Top Seat

Inconel

Bottom Seat (reversible cavity only)

Inconel

Hydraulic Ports

Inconel

Left/Right Face

Phosphate

Lock Rod Groove

Phosphate

Ring Groove

Inconel

NXT-M Door-CREP Levels*

Hydraulic Ports

Door Seal

Race Track

Body Area

Door Area

CREP Level H CREP Level J CREP Level K

Hinge Pin Hole

Phosphate

Phosphate

Inconel

Door Seal Race Track Inconel

Inconel

Inconel

Hydraulic Ports

Phosphate

Phosphate

Inconel

Cylinder Ports

Phosphate

Phosphate

Inconel

Packing Bore

Inconel

Inconel

Inconel

Lock Bar Groove

Phosphate

Phosphate

Phosphate

Cylinder Bore

Phosphate

Chrome

Inconel

National Oilwell Varco - All rights reserved - Rig Doc. No. 87360002

rig@nov.com

nov.com

Vous aimerez peut-être aussi

- ISUZU 4HK1 6HK1 Type Engine PDFDocument48 pagesISUZU 4HK1 6HK1 Type Engine PDFЙОРДАН ГЕОРГИЕВ90% (21)

- (Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesDocument7 pages(Highly Deviated and Horizontal Wells) : Pre-Recorded Sheet Keep This Data Sheet Current at All TimesSasan AbbasiPas encore d'évaluation

- Piston Separator TW714Document12 pagesPiston Separator TW714Mihai Matei100% (3)

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1C100% (1)

- Demco Gate Valve PDFDocument56 pagesDemco Gate Valve PDFyacine3516100% (1)

- DL Bop BrochureDocument4 pagesDL Bop BrochurekrishnsgkPas encore d'évaluation

- Vetco Gray Controls PartsDocument0 pageVetco Gray Controls PartsEgbe Iledi Edan AsiwajuPas encore d'évaluation

- Shaffer Bop Pipe Ram Model SL-LWS and LWPDocument2 pagesShaffer Bop Pipe Ram Model SL-LWS and LWPhebert perez100% (1)

- RP554 ManualDocument3 pagesRP554 ManualAdolfo Angulo100% (1)

- 3.06 10K EK Quad BOP PDFDocument25 pages3.06 10K EK Quad BOP PDFJose Leonardo Materano Perozo100% (1)

- Laurus As Built BOP Part Numbers - UnlockedDocument166 pagesLaurus As Built BOP Part Numbers - UnlockedEstuardo OlanPas encore d'évaluation

- Cameron LoadKing Drilling Riser 3.5 ManualDocument277 pagesCameron LoadKing Drilling Riser 3.5 ManualMadirley Pimenta83% (6)

- Cameron EB 538 D Rev D2 - Shear Rams - Op & MaintDocument7 pagesCameron EB 538 D Rev D2 - Shear Rams - Op & MaintCanrig RamdePas encore d'évaluation

- SD B312 Bop B011 02 01Document39 pagesSD B312 Bop B011 02 01krishnsgkPas encore d'évaluation

- MOM Petro Rig3 Loadking 3.5 Drilling Riser - CAMERON PDFDocument296 pagesMOM Petro Rig3 Loadking 3.5 Drilling Riser - CAMERON PDFAlejandro Sánchez López100% (1)

- Annular Bops D Bop DL Bop: To Contents PageDocument6 pagesAnnular Bops D Bop DL Bop: To Contents PageJohn Alexander Bonilla AngelPas encore d'évaluation

- Ds Shearing Blind Ram Tc1399Document2 pagesDs Shearing Blind Ram Tc1399Gregory StewartPas encore d'évaluation

- KTA38 M2 010 018 KTA 50 Cooling SystemDocument3 pagesKTA38 M2 010 018 KTA 50 Cooling SystemSpectrumRaijin0% (1)

- Onshore Product Reference Guide PDFDocument44 pagesOnshore Product Reference Guide PDFPedro RiveraPas encore d'évaluation

- H4 Connector - Reference OnlyDocument117 pagesH4 Connector - Reference OnlyDanielle Vasconcelos ParraPas encore d'évaluation

- Shaffer Ram & Spherical Blowout Preventer PartsDocument5 pagesShaffer Ram & Spherical Blowout Preventer PartsJIN WANGPas encore d'évaluation

- Logan Welded Cup Junk SubsDocument2 pagesLogan Welded Cup Junk SubsSasan AbbasiPas encore d'évaluation

- Hyundai Engine Catalog PDFDocument12 pagesHyundai Engine Catalog PDFahmed67% (3)

- Catalog PDFDocument222 pagesCatalog PDFLeandro100% (1)

- PVT Short Course For Cairo UniversityDocument52 pagesPVT Short Course For Cairo UniversityFan JackPas encore d'évaluation

- Optimist Tuning GuideDocument9 pagesOptimist Tuning GuideSasan AbbasiPas encore d'évaluation

- LEVEL I - ATA 49 Airborne Auxiliary PowerDocument36 pagesLEVEL I - ATA 49 Airborne Auxiliary PowerwagdiPas encore d'évaluation

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalhePas encore d'évaluation

- Catalog 2Document44 pagesCatalog 2Enrique HortaPas encore d'évaluation

- Saacke Dictionary PDFDocument68 pagesSaacke Dictionary PDFSanjin MehinovićPas encore d'évaluation

- Swivel Tool CatalogDocument16 pagesSwivel Tool CatalogVishal RamsookPas encore d'évaluation

- Drillquip MLS Ssystem Catalog ms15 - Mudline PDFDocument20 pagesDrillquip MLS Ssystem Catalog ms15 - Mudline PDFMoisesPas encore d'évaluation

- Demco DM Iom PDFDocument24 pagesDemco DM Iom PDFAshok SureshPas encore d'évaluation

- 3sfe ENGINE 1999 2000 PDFDocument65 pages3sfe ENGINE 1999 2000 PDFAnonymous MzdHp7QUm100% (1)

- 0700yrm1123 (03 2013) Uk enDocument70 pages0700yrm1123 (03 2013) Uk enJuan Francisco Canto DiezPas encore d'évaluation

- Cameron Catalog 2006 020819 PDFDocument162 pagesCameron Catalog 2006 020819 PDFTitanBOPPas encore d'évaluation

- Manhour NSRPDocument10 pagesManhour NSRPvazzoleralex6884Pas encore d'évaluation

- Cameron Bop PartsDocument62 pagesCameron Bop PartsSurya Prakash DubeyPas encore d'évaluation

- ADocument12 pagesAJulio ReisPas encore d'évaluation

- BOP Dimensions 13stackDocument3 pagesBOP Dimensions 13stackSasan AbbasiPas encore d'évaluation

- Access - Air Kelly Spinner Manual PDFDocument9 pagesAccess - Air Kelly Spinner Manual PDFadjoudj100% (1)

- Test Questions 2009Document69 pagesTest Questions 2009Dana CapbunPas encore d'évaluation

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorDocument12 pagesAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- Shaffer Type SL 13 5:8 Data SheetDocument7 pagesShaffer Type SL 13 5:8 Data Sheetlucas ronaldo coronel mendozaPas encore d'évaluation

- Well Service Products 2017Document83 pagesWell Service Products 2017pabloasotoPas encore d'évaluation

- Top Drive Warrior 250H14Document1 pageTop Drive Warrior 250H14Ricardo PrietoPas encore d'évaluation

- Operating Manual: Tubing TongDocument314 pagesOperating Manual: Tubing Tongwuillian barreto100% (1)

- Demco Gate Valves BrochureDocument56 pagesDemco Gate Valves BrochureVictor100% (1)

- DSQ4 10M SidedoorDocument15 pagesDSQ4 10M SidedoorДудла СтаніславPas encore d'évaluation

- Drill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsDocument7 pagesDrill and Tap Chart: Screw Size Tap Drills Clearance Hole DrillsSasan AbbasiPas encore d'évaluation

- Davis-Lynch Full Products PDFDocument53 pagesDavis-Lynch Full Products PDFNilo Llamocca Gutierrez67% (3)

- Anson Gate Valves, Manifolds, and TreesDocument9 pagesAnson Gate Valves, Manifolds, and TreesBala KrishnanPas encore d'évaluation

- LaMOT RD CatalogDocument20 pagesLaMOT RD CatalogSasan Abbasi0% (1)

- Hydril GK Annular DataDocument2 pagesHydril GK Annular DataAndrés Ramírez100% (3)

- A - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFDocument27 pagesA - Pistone - Eng PISTON ACCUMULATOR ENGINEERING PDFAnonymous hxV81ITD8kPas encore d'évaluation

- 18 - MonarchDocument1 page18 - MonarchBima MahendraPas encore d'évaluation

- Packer Dual Weatherford AROWDRILLDocument9 pagesPacker Dual Weatherford AROWDRILLRodolfo RiderPas encore d'évaluation

- U BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealDocument1 pageU BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealSasan AbbasiPas encore d'évaluation

- U BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealDocument1 pageU BOP Variable Bore Rams: BOP Size and Working Pressure (Psi) Pipe Size Range Ram Subassembly Ram Body Packer Top SealSasan AbbasiPas encore d'évaluation

- Corrosion AllowanceDocument35 pagesCorrosion AllowanceReni Mutiara Sari50% (2)

- MUD PUMP EXPENDABLES Emsco PDFDocument9 pagesMUD PUMP EXPENDABLES Emsco PDFleoPas encore d'évaluation

- Stripper TOT 2.50 10M DS34 TechMan1146Document13 pagesStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaPas encore d'évaluation

- Valvula Chek Cameron PDFDocument4 pagesValvula Chek Cameron PDFelisanaPas encore d'évaluation

- IRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Document68 pagesIRI-044 IRI Parts Manual Non-Controlled Rev - 2 - 0 10-09-2015 - 9901910937 - 01 - 6375912 - 01Tanyawat Sahsakmontri100% (2)

- Instructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Document7 pagesInstructions For The Safe Use of P-Quip Liner Retention Systems - Pt. No. 80000111 Revision Date August 9, 2006Heri VillaPas encore d'évaluation

- Wellhead Equipment CatalogDocument29 pagesWellhead Equipment CatalogDewy PambayunPas encore d'évaluation

- Circulating SwagesDocument1 pageCirculating Swageskaveh-bahiraeePas encore d'évaluation

- M60eh44 Man 001Document40 pagesM60eh44 Man 001Riski KurniawanPas encore d'évaluation

- Mud Guns: Bottom Type Mud GunDocument1 pageMud Guns: Bottom Type Mud GunPrime Energy Warehouse-YemenPas encore d'évaluation

- SP - FlyLine WinchFrameDocument24 pagesSP - FlyLine WinchFramehardevPas encore d'évaluation

- Retsco/Demco Mud Guns: Bottom TypeDocument1 pageRetsco/Demco Mud Guns: Bottom TypeGregory StewartPas encore d'évaluation

- Cameron - DL-Annular BopDocument1 pageCameron - DL-Annular BopAnonymous 48jYxR1CPas encore d'évaluation

- BPM CRS Operation Manual CompletoDocument49 pagesBPM CRS Operation Manual CompletoJose Mauricio SandovalPas encore d'évaluation

- Rebuild KitDocument3 pagesRebuild KitMehdi SoltaniPas encore d'évaluation

- Catalogo JUMBO InglesDocument8 pagesCatalogo JUMBO InglesDarko BogdanovicPas encore d'évaluation

- Screw-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsDocument8 pagesScrew-In Direct Operated Pressure Relief Valve (DBDE04) For Use in ManifoldsTejas MahadikPas encore d'évaluation

- Moog CartridgeValves DBD04 Catalog enDocument8 pagesMoog CartridgeValves DBD04 Catalog enTejas MahadikPas encore d'évaluation

- Chicago Pneumatic Breakers Brochure (US)Document12 pagesChicago Pneumatic Breakers Brochure (US)Sumit BhasinPas encore d'évaluation

- HYD. PumpDocument40 pagesHYD. Pumprohitbhat2345Pas encore d'évaluation

- 1930PA enDocument1 page1930PA enSasan Abbasi100% (1)

- Assistant Barge Supervisor 9-16-04Document3 pagesAssistant Barge Supervisor 9-16-04Sasan AbbasiPas encore d'évaluation

- Tap Drill CalculatorDocument1 pageTap Drill CalculatorSasan AbbasiPas encore d'évaluation

- 77 3001 TypeDDocument8 pages77 3001 TypeDSasan AbbasiPas encore d'évaluation

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaPas encore d'évaluation

- Guide To Contamination StandardsDocument8 pagesGuide To Contamination StandardsCarlos MejíaPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- oEeufSNWgZLzvE3jPkfBFeDfP PDFDocument30 pagesoEeufSNWgZLzvE3jPkfBFeDfP PDFSasan AbbasiPas encore d'évaluation

- Ifu 5902152 Emgy DSCNT DviceDocument12 pagesIfu 5902152 Emgy DSCNT DviceSasan AbbasiPas encore d'évaluation

- Cylinder To Regulator AdaptorsDocument2 pagesCylinder To Regulator AdaptorsSasan AbbasiPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- Pipe Racking System OJTDocument20 pagesPipe Racking System OJTDanang PrasetioPas encore d'évaluation

- Hard Versus Soft Shut inDocument15 pagesHard Versus Soft Shut inAgus AlexandriPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- Bit Breakers PDFDocument2 pagesBit Breakers PDFSasan AbbasiPas encore d'évaluation

- Rig MoveDocument10 pagesRig MoveSasan AbbasiPas encore d'évaluation

- Imperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)Document1 pageImperial U.S. - SI/Metric - Mixed Units (Imperial and Metric)OSCAR BUSTOSPas encore d'évaluation

- 0080A-60.3118 PublicationDocument1 page0080A-60.3118 PublicationSasan AbbasiPas encore d'évaluation

- Diverter SDocument12 pagesDiverter SSasan AbbasiPas encore d'évaluation

- Draw WorksDocument32 pagesDraw WorksSasan AbbasiPas encore d'évaluation

- 4 - Figures and Tables - Fluid FlowDocument22 pages4 - Figures and Tables - Fluid FlowCarlosCD17Pas encore d'évaluation

- Natural Aspirated EnginesDocument10 pagesNatural Aspirated EnginesakshithaPas encore d'évaluation

- 08 GRP04 All EnginesDocument32 pages08 GRP04 All Engineseurospeed2Pas encore d'évaluation

- Woodward 2301A Load Sharing and Speed ControlDocument3 pagesWoodward 2301A Load Sharing and Speed ControlRameez Ali FaridiPas encore d'évaluation

- Feedstocks For BiofuelsDocument26 pagesFeedstocks For Biofuelsdiksha surekaPas encore d'évaluation

- Speedster ManualDocument177 pagesSpeedster Manualabrakadabra111Pas encore d'évaluation

- 278 CMS PDFDocument266 pages278 CMS PDFRecordTrac - City of OaklandPas encore d'évaluation

- Bulletin 60 AFQRJOS Issue 27 Feb 2013 PDFDocument6 pagesBulletin 60 AFQRJOS Issue 27 Feb 2013 PDFpersadanusantaraPas encore d'évaluation

- PEM Study Guide Final V2 PDFDocument1 271 pagesPEM Study Guide Final V2 PDFPriscilla Higor GiurizattoPas encore d'évaluation

- Hazardous Zone Information-Safe Tank Distance-Levno Jan2018Document1 pageHazardous Zone Information-Safe Tank Distance-Levno Jan2018Bryan ChannelPas encore d'évaluation

- National Lodge: Opp. Tahseel Road, Kaiserganj, BahraichDocument8 pagesNational Lodge: Opp. Tahseel Road, Kaiserganj, BahraichMANJUL joshiPas encore d'évaluation

- Sagar Kumar Seminar Report PDFDocument20 pagesSagar Kumar Seminar Report PDFPRASHANTA BAL100% (1)

- 3300 - 440v Transformer Maintenance ProcedureDocument4 pages3300 - 440v Transformer Maintenance ProcedureGunadevan ChandrasekaranPas encore d'évaluation

- Catalytic Dewaxing ProcessDocument45 pagesCatalytic Dewaxing ProcessBóng Đá- Quán bia tổng hợpPas encore d'évaluation

- AMBO Feasibility Book 1 Non-ConfDocument327 pagesAMBO Feasibility Book 1 Non-Conf1mmahoneyPas encore d'évaluation

- A.S.T.M. Tables: Cargo Name CategoryDocument2 pagesA.S.T.M. Tables: Cargo Name CategoryIordache DumitruPas encore d'évaluation

- Gas Lift Installation DesignDocument6 pagesGas Lift Installation DesignsukunsurPas encore d'évaluation

- PVC Water Pumps PDFDocument26 pagesPVC Water Pumps PDFYulidar Wahyu RachmawanPas encore d'évaluation