Académique Documents

Professionnel Documents

Culture Documents

Technical Service Pits Specification KEO

Transféré par

Vijay BarreyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Technical Service Pits Specification KEO

Transféré par

Vijay BarreyDroits d'auteur :

Formats disponibles

PROJECT SPECIFICATION

SECTION ---------

Technical Pit Equipment

NEW DELHI INTERNATIONAL AIRPORT

FIRST DRAFT FOR

READING

A

REV.

09 Dec 2016

DATE

Issued for Project Review

New Delhi International Airport

Delhi, India

NH

BY

PLE

PPM

SPECIFICATION NO.

Sheet 1 of 18

PDM

New Delhi International Airport

Technical service pits Hangar

SECTION A Technical Service pits

Date 09 Dec 2016

PART 1 GENERAL

1.1

A.

1.2

RELATED DOCUMENTS

Drawings and general provisions of the Contract, including Conditions of Contract and

Division 1 Specification Sections, apply to this Section.

SUMMARY

A.

1.3

This Section includes the requirements for supply and installation of 400 Hz Pop up Pit

Equipment also called nose pits.

SUBMITTALS

A.

Product data for pop up pit equipment.

B.

Shop Drawings detailing system. Include locations, conductor routing and connections,

and bonding and provisions.

C.

The contractor shall submitt a method statement including description of the

equipment, instalaltion, transport and proposed tet arrangements.

Qualification data for firms and persons specified in "Quality Assurance" Article to

demonstrate their capabilities and experience. Include data on listing. Include lists of

completed projects with project names and addresses, names and addresses and

owners, and other information specified.

E.

Factory test reports shall be submitted before shipment to the construction site.

Field inspection reports indicating compliance with specified requirements.

Manuals and as built drawings of the epuipment installed shall be submitted upon

provisional handover of the system.

1.4

QUALITY ASSURANCE

A.

Will be only considered Manufactures and installers that employ a Quality

Management System complying with the program described in ISO 9001-2000, or

similar system.

B.

Experience: Minimum 5 years in the Technical 400Hz Pit manufacturing.

C.

The manufacturer shall have a direct presence in the UAE/Middle East market. Having

already approved technical pits in NDIA project will be an added value for

standardization of systems and maintenance purpose.

D.

Demonstrate that the manufacturer has satisfactorily provided at least 5 project

references where Pop Up Pits have been installed in an airport, similar in design.

E.

Regional (Midle East) references shall be provided due to the existing environment

conditions in Doha.

Page 2 of 18

New Delhi International Airport

Technical service pits Hangar

1.5

Date 09 Dec 2016

DELIVERY, STORAGE, AND HANDLING

A.

Prepare equipment for shipping as follows:

1.

Protect internal parts against rust and corrosion.

2.

Protect threads, flanges faces, grooves, and weld ends.

PART 2 PRODUCTS

2.1

MANUFACTURERS

A.

Available Manufacturers: Subject to compliance with requirements, manufacturers

offering products that may be incorporated in the Work include, but are not limited to,

the following or Approved Equal:

1

2.2

Cavotec

GENERAL REQUIREMENTS

A.

Provide all equpment and materials new undaged and suitable for the

proximity of the Aribian Sea resulting saline atmosphere and high

temperatures. The intense solar radiation is also a cause of accelerated

materials, as is the significant accumulation of fine sand and dust due to the

local soils

corrosive

average

aging of

nature of

B.

All pits frames & covers should be made from Hop Dip galvanized steel due to

corrosion risk. All other equipment shall be properly protected against corrosion.

C.

When the pit system is closed, it is flush to the apron.

D.

In addition to the pit flange, a gasket above apron crown gradually slope to the apron

level in order to prevent water or any liquid entry.

E.

The vault access cover plate/lid for Pop Up pits will be provided for maintenance

access and made from Hot Dip Galvanized.

F.

Design load for Pit covers has to be in accordance with the EN124-F900, to carry a

90T point of load. A third party certificate is compulsory for showing the accordance

with the EN124-F900 norm.

G.

Waterproofing devices, resin coating, gaskets, shall resist to chemicals reaction, Jet

fuel, Skydol and extreme temperature changes.

H.

No hydraulic System can be included in the mechanism due to external conditions and

cheaper maintenance costs of the system.

I.

Opening and closing force of the pit cover should be less than 9lbs (4Kg). Counter

balanced opening system should be the mechanism to be used for this purpose in

order to prevent operator back issues.

J.

All pits shall have a counter lid mechanism when in open position so as to close the pit

hole and prevent any fall of object inside the pit or any human injury and also limit the

water volume going inside the pit case of rain.

K.

Screws, fixing elements & wire ropes have to be made of stainless steel.

L.

Roller guides will have to be used for guiding the 400Hz cables and flexible PCA

hoses, limiting the abrasion on cables/hoses and facilitating the pulling of the

400Hz/PCA connectors.

Page 3 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

M.

A foot locker will be integrated on the pit mechanism which will have two functions:

locking system when open (prevention against accidents) and obliging a foot pressure

for closing the pit.

N.

For the Nose pit (400Hz Pit and 28VDC pits) Cable dividers will be installed in the

concrete chamber in order to reel correctly the 400Hz cables and prevent them from

twisting inside the chamber.

O.

A bottom floor grid that could be integrated with the 400Hz cable dividers has to be

installed at the bottom of the pit in order to protect 400Hz cable from stagnant water

inside the concrete chamber.

P.

A GRP ladder will be fixed inside the pit in order to access to the pit chamber.

Page 4 of 18

New Delhi International Airport

Technical service pits Hangar

2.3

NOSE PIT Type A - Narrow Body (400Hz Pop Up Pit)

2.3.1

GENERAL SERVICES

A.

Date 09 Dec 2016

Nose pits have to be designed as Pop Up pits with a concrete chamber and will be

provided with the following services:

1. For Code C (1x90kVA): 1x 400Hz jet cable 400 Hz (15m), supplied by 1x90 KVA

converter

2. 1x Socket outlet 230 V, 3 poles, 16 Amps

3. 1x Socket outlet 400 V, 5 poles, 32 Amps

4. 2x RJ 45 data sockets

5. 2x compressed air outlets 1/ 2 with ball valve

6. 1x E stop with housing

7. 1x Earthing pin IFE200-0

8. 1x position light 230V

9. 1x cable devider with floor grid

10. 1 access ladder

The socket out lets will be mounted on the pop up frame at least 400mm above ground

level.

The equipment to be explosion proof or Eex protection degree according to EN60079

for all underground electrical equipment. (Termination box in Eex, polyamide for 50Hz

cables)

All electrical sockets above ground which are fixed on the Pop Up pit do not need to be

Explosion proof as they will be energerzised when pit is fully open (with a limit switch)

Each pit shall be illuminated by florescent lighting fixtures mounted in the concrete

chamber as shown on the drawings.Lighting fixtres will be controlled by a switch

mounted in the chamber.

Each pit will have a Maintenance cover, 60mm steel, machined and galvanized &

stainless steel access ladder

Each pit will have cable dividers (Cable basket) in order to separate the 400Hz cables

when rolled down into the pit in order to prevent tangled cables and a bottom floor grid

to prevent 400Hz cables from being in contact with the floor.

2.3.2

A.

CABLES BETWEEN GPUs EQUIPMENT AND POP UP PITS

This fixed cables is rated voltage 750V and temperature of 105 C suitable for fixed

installation. The cable is 7x35+18mm mm2 or 7x50+18mm mm2 which integrate both

power and control. The cable is constituted of a main cable from converter to 400Hz

terminal/junction boxes within the pit and the control cable can run parallel or be

integrated with the 400Hz main cable. The contol cable is composer of:

18 wires of 1mm over all screened for control and signalling distributed in symmetrical

way tinned and marked from 1 to 18.

Page 5 of 18

New Delhi International Airport

Technical service pits Hangar

2.3.3

A.

Date 09 Dec 2016

CABLES BETWEEN POP UP PITS & AIRCRAFT RECEPTACLES

The Pop Up Pit manufacturer is allowed to utilize two types of cables. He is allowed to

use only one of both types as appreciate.

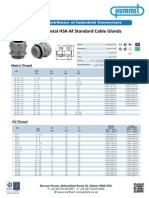

The first type of cable is composed of:

1.

Cable type: 4 times (1x70mm+4x1mm), highly flexible twisted with double

insulated TPE/PUR (Thermoplastic elastomer/Polyurethane) insulation, Halogen

free (IEC 60754-1), Low toxic gases (NFC 20454), No corrosive gases (IEC

60754-2), Flame retardant (IEC 60332-1), Skydrol resitant.

2.

The extremity of the cable ends by splitting the 4 conductors to enter the

termination box trough separate cable glands.

3.

Each of the four cables of the flexible link is 750V rated, is composed of:

a.

B.

2.3.4

1 main driver of section 70mm.

b.

4 wires of cross section 1mm for control and signalling distributed in

symmetrical way.

c.

Flexible copper tinned wires according to VDE 0295 IEC 60228 using

class 5 for control cables and class 6 for power cables. Power cable in

multi-thread tinned of diameter 0,2mm.

The second type of cable is composed of:

1.

Cable types: 3 times (1x70mm/25mm+8x1mm), ), highly flexible twistedwith

double insulated TPE/PUR (Thermoplastic elastomer/Polyurethane) insulation,

halogen free for 400Hz energy network operation and distribution. Voltage is

service 115/200 volts, nominal voltage specified 600/1000 volts, test at 4000

volts.

2.

Halogen free IEC 60754-1, VDE 0472 T.815, and gas free IEC 60754-2, VDE

0472 T.813, cable frame-proof according to IEC 60332-1/VDE 0472 part 804B,

yellow sheath resisting to the aeronautic oils IN 60811-2-1/24 h/100 C.

3.

Flexible copper tinned wires according to VDE 0295 CEI 60228 using class 5 for

control cables and class 6 for power cables. Power cable in multi-thread tinned

of diameter 0,2mm.

4.

Control wires: 3x8 wires of 1mm for control and signaling distributed in

symmetrical way tinned and marked from 1 to 24.

a.

Conductor operation temperature: 90C.

b.

Conductor operation temperature on short circuit: 200C.

ILLUMINATION SYSTEMS

A. Safety Flashing Lamp

1. A flashing lamp will be installed on the frame of the Pop Up in order to signal that

the Pop Up Pit is in use.

2. The second benefit of the lamp will be to make visible the Pop Up pit while in use

and open during the night.

B

Chamber Illumination

1

Lightig fixtures will be Ex Proof Zone 1 and fixed inside the pit on each side on the

wall for illumination of the concrete chamber.

Page 6 of 18

New Delhi International Airport

Technical service pits Hangar

2

2.3.5

Date 09 Dec 2016

Each lighting fixture will be equipped with an 60W Fluorescent lamp.

EMERGENCY STOP

Emergency push button to be installed on the frame of Pop Up Pit for shutting down

the energy in case of emergency.

Limit switch under the Pit cover in order to stop the electrical source when the pit is

closing.

2.3.6

DRAINAGE OF PITS

A submersible sump pump will be installed inside the concrete pit chamber with a

water flow of minimum 19 cubic meter per hour. The power supply to the submersible

pump shall be 3 phase 415 V by 50 Hz.

The submersible pump shall have an IP 68 protection and compliance with explosion

protection EEx-d II B T4

This sump pump will be controled by level switches as follows:

1. High level switch to start the pump.

2. Low level switch to stop the pump.

3. Alarm very high level

The control panel shall have the following features.

1

The control panel shall be IP 67. External surface shall be protected against the

environment by a coating. Key lock shall be provided on the front door.

The panel shall serve the pump in the pup op pit and the HOS pit.

The status of the pumps shall be indicated on the front of the panel by a number of

LED lamps.

The status of each pump shall be made available to the BMS system. Potential free

contacts shall be provided as follows:

i. High level alarm

ii. Pump trip fault status

iii. Very high level

iv. Low level

v. Pump run

vi. Selector switch for each pump indicating the selected status manual

automatic.

Page 7 of 18

New Delhi International Airport

Technical service pits Hangar

2.3.7

Date 09 Dec 2016

ELECTRICAL 400Hz CONNECTORS

From the aircraft connector, only when the aircraft connector is more than 80%

connected to the aircraft receptacle, controlled by auxiliary switch, the 400Hz can be

powered ON/OFF by integrated push buttons on aircraft connector. This function is

indicated by color LEDs located on the 400Hz aircraft connector.

Depending on the aircraft type, the usage of the 400Hz connectors shall be interlocked

to the converters outgoings in the way that power shall be ON only when the number

of plugs required by the aircraft are plugged-in. Power indicative LEDS should indicate

the power in use or not.

The aircraft connectors shall be equipped with thermal sensors of type PTC that

indicates when temperature at any phase exceeds 120C.

The 400Hz connector shall have interchangeable contacts pins, and connector housing

to conduct any repairs of the contact pins.

Page 8 of 18

New Delhi International Airport

Technical service pits Hangar

2.4

NOSE PIT Type B - Small Jets (28VDC Pop Up Pit)

2.4.1

GENERAL SERVICES

A.

Date 09 Dec 2016

Nose pits have to be designed as Pop Up pits with a concrete chamber and will be

provided with the following services:

1. For small jets (1x 28VDC): 1x 28VDC jet cable 400 Hz (12m), supplied by 28VDC

transformer

2. 1x 28VDC connector type 28XP-2 with 2 push buttons, microswitch and led

3. 2x Socket outlet 230 V, 3 poles, 16 Amps

4. 1x Socket outlet 400 V, 5 poles, 32 Amps

5. 1x Socket outlet 400V, 5 poles, 125 Amps

6. 1x RJ 45 data sockets

7. 2x compressed air outlets 1/ 2 with ball valve

8. 1x cold water outlet

9. 1x hot water outlet

10. 2x water hose reels with 30m hose with ball valve

11. 1x Earthing pin IFE200-0

12. 1x E-stop with housing

13. 1x position light 230V

14. 1x cable devider with floor grid

15. 1 access ladder

The socket out lets will be mounted on the pop up frame at least 400mm above ground

level.

The equipment to be explosion proof or Eex protection degree according to EN60079

for all underground electrical equipment. (Termination box in Eex, polyamide for 50Hz

cables)

All electrical sockets above ground which are fixed on the Pop Up pit do not need to be

Explosion proof as they will be energerzised when pit is fully open (with a limit switch)

Each pit shall be illuminated by florescent lighting fixtures mounted in the concrete

chamber as shown on the drawings.Lighting fixtres will be controlled by a switch

mounted in the chamber.

Each pit will have a Maintenance cover, 60mm steel, machined and galvanized &

stainless steel access ladder

Each pit will have cable dividers (Cable basket) in order to separate the 400Hz cables

when rolled down into the pit in order to prevent tangled cables and a bottom floor grid

to prevent 400Hz cables from being in contact with the floor.

Page 9 of 18

New Delhi International Airport

Technical service pits Hangar

2.4.2

Date 09 Dec 2016

ILLUMINATION SYSTEMS

B. Safety Flashing Lamp

3. A flashing lamp will be installed on the frame of the Pop Up in order to signal that

the Pop Up Pit is in use.

4. The second benefit of the lamp will be to make visible the Pop Up pit while in use

and open during the night.

B

2.4.3

Chamber Illumination

1

Lightig fixtures will be Ex Proof Zone 1 and fixed inside the pit on each side on the

wall for illumination of the concrete chamber.

Each lighting fixture will be equipped with an 60W Fluorescent lamp.

EMERGENCY STOP

Emergency push button to be installed on the frame of Pop Up Pit for shutting down

the energy in case of emergency.

Limit switch under the Pit cover in order to stop the electrical source when the pit is

closing.

2.4.4

DRAINAGE OF PITS

A submersible sump pump will be installed inside the concrete pit chamber with a

water flow of minimum 19 cubic meter per hour. The power supply to the submersible

pump shall be 3 phase 415 V by 50 Hz.

The submersible pump shall have an IP 68 protection and compliance with explosion

protection EEx-d II B T4

This sump pump will be controled by level switches as follows:

4. High level switch to start the pump.

5. Low level switch to stop the pump.

6. Alarm very high level

The control panel shall have the following features.

5

The control panel shall be IP 67. External surface shall be protected against the

environment by a coating. Key lock shall be provided on the front door.

The panel shall serve the pump in the pup op pit and the HOS pit.

The status of the pumps shall be indicated on the front of the panel by a number of

LED lamps.

The status of each pump shall be made available to the BMS system. Potential free

contacts shall be provided as follows:

i. High level alarm

ii. Pump trip fault status

iii. Very high level

iv. Low level

v. Pump run

Page 10 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

vi. Selector switch for each pump indicating the selected status manual

automatic.

Page 11 of 18

New Delhi International Airport

Technical service pits Hangar

2.5

PRE-CONDITIONNED AIR PIT

2.5.1

GENERAL SERVICES

A.

Date 09 Dec 2016

All Pre-Conditionned Air have to be designed as Pop Up pits in a croncrete chamber

and will be provided with the following equipment:

1. For Code C (1xPCA): 1 flexible spiral PCA hose 14" 10m long with A/C adapter 8"

2.

Hose guiding tubes and pit hole cover plate

3. 1x Termination box with push buttons for PCA unit ON/OFF and aircraft selector

switch, Ex proof

4. 1x Socket outlet 230 V, 3 poles, 16 Amps

5. 1x Socket outlet 400 V, 5 poles, 32 Amps

6. 1x Termination box in Eex, polyamide for 50Hz cables, incl cable glands and

Terminals

7. Limit switch in EEx for signaling of pit position, open

8. 1x earthing pin IFE200-0

9. 1x compressed air outlet 1/ 2 with ball valve

10. 1x cold water outlet

11. 1x hot water outlet

12. 2x water hose reels with 30m hose with ball valve

13. For the mass flow:

- 1x air delivery hose of 40 ft with 1x aircraft coupling/adapter for air delivery

- 1x Pneumatic valve Eex condition with signal switches and microvalves

- 1x roller system for the airstrat hose

- 1x storage bag for airstart hose

C

Each pit will have a Maintenance cover, 60mm steel, machined and galvanized &

stainless steel access ladder

2.5.2 ILLUMINATION SYSTEMS

C. Safety Flashing Lamp

5. A flashing lamp will be installed on the frame of the Pop Up in order to signal that

the Pop Up Pit is in use.

6. The second benefit of the lamp will be to make visible the Pop Up pit while in use

and open during the night.

B

Chamber Illumination

1

Lightig fixtures will be Ex Proof Zone 1 and fixed inside the pit on each side on the

wall for illumination of the concrete chamber.

Each lighting fixture will be equipped with an 60W Fluorescent lamp.

2.5.3 EMERGENCY STOP

Page 12 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

Emergency push button to be installed on the frame of Pop Up Pit for shutting down

the energy in case of emergency.

Limit switch under the Pit cover in order to stop the electrical source when the pit is

closing.

2.5.4 DRAINAGE OF PITS

A

A submersible sump pump will be installed inside the concrete pit chamber with a

water flow of minimum 19 cubic meter per hour. The power supply to the submersible

pump shall be 3 phase 415 V by 50 Hz.

The submersible pump shall have an IP 68 protection and compliance with explosion

protection EEx-d II B T4

This sump pump will be controled by level switches as follows:

7. High level switch to start the pump.

8. Low level switch to stop the pump.

9. Alarm very high level

The control panel shall have the following features.

9

The control panel shall be IP 67. External surface shall be protected against the

environment by a coating. Key lock shall be provided on the front door.

10 The panel shall serve the pump in the pup op pit and the HOS pit.

11 The status of the pumps shall be indicated on the front of the panel by a number of

LED lamps.

12 The status of each pump shall be made available to the BMS system. Potential free

contacts shall be provided as follows:

i. High level alarm

ii. Pump trip fault status

iii. Very high level

iv. Low level

v. Pump run

vi. Selector switch for each pump indicating the selected status manual

automatic.

Page 13 of 18

New Delhi International Airport

Technical service pits Hangar

2.6

FUEL EXHAUST PIT

2.6.1

GENERAL SERVICES

A.

Date 09 Dec 2016

All Fuel Exhaust pits have to be designed as Hatch pit inside a concrete chamber and

will be provided with the following equipment:

1.

Base plate with openable cover and counter weight system

2.

Outer dimensions of base plate, 1200x900x60mm

3.

Hot dipped galvanized with painted anti-slip outer surface, alu checker plate

4.

Water tight openable cover with gaskets and lock with handle

5.

Tank Ventilation 1x200mm inlet

6.

1 x 3m Flexible hose, 200mm, for connection to fixed underground duct

7.

1x adapter for connection of 200mm hose to pit, from aircraft side

8.

1x Termination box in Eex, polyamide for signal cables

9.

1x operation Box with push buttons for tank ventilation on/off with E-stop

10.

1x earthing pin

Page 14 of 18

New Delhi International Airport

Technical service pits Hangar

2.7

Fuselage Pit - Narrow Body (Electrical/Mechanical Pop Up Pit)

2.7.1

GENERAL SERVICES

A.

Date 09 Dec 2016

Fuselage pits have to be designed as hatch pits with a concrete chamber & counter

balance system and will be provided with the following services:

1. 4x Socket outlet 230 V, 3 poles, 16 Amps

2. 1x Socket outlet 400 V, 5 poles, 32 Amps

3. 1x RJ 45 data sockets

4. 1x compressed air outlet 1/ 2 with ball valve

5. 1x Cold Water outlet

6. 1x E stop with housing

7. 1x Earthing pin IFE200-0

The socket out lets will be mounted on the pop up frame at least 400mm above ground

level.

The equipment to be explosion proof or Eex protection degree according to EN60079

for all underground electrical equipment. (Termination box in Eex, polyamide for 50Hz

cables)

2.7.2

EMERGENCY STOP

Emergency push button to be installed on the frame of Pop Up Pit for shutting down

the energy in case of emergency.

Limit switch under the Pit cover in order to stop the electrical source when the pit is

closing.

2.7.3

DRAINAGE OF PITS

A submersible sump pump will be installed inside the concrete pit chamber with a

water flow of minimum 19 cubic meter per hour. The power supply to the submersible

pump shall be 3 phase 415 V by 50 Hz.

The submersible pump shall have an IP 68 protection and compliance with explosion

protection EEx-d II B T4

This sump pump will be controled by level switches as follows:

High level switch to start the pump.

Low level switch to stop the pump.

Alarm very high level

D

The control panel shall have the following features.

13 The control panel shall be IP 67. External surface shall be protected against the

environment by a coating. Key lock shall be provided on the front door.

14 The panel shall serve the pump in the pup op pit and the HOS pit.

Page 15 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

15 The status of the pumps shall be indicated on the front of the panel by a number of

LED lamps.

16 The status of each pump shall be made available to the BMS system. Potential free

contacts shall be provided as follows:

i. High level alarm

ii. Pump trip fault status

iii. Very high level

iv. Low level

v. Pump run

vi. Selector switch for each pump indicating the selected status manual

automatic.

Page 16 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

PART 3 EXECUTION

3.1

EXAMINATION

A.

Examine ducting system between head of standpit and pop up pit for compliance with

requirements for installation tolerances and other conditions affecting installation of

cables. Do not proceed with installation until unsatisfactory conditions have been

corrected.

B.

Examine concrete pup up pit before the installtion of equipment. Do not proceed with

the installation until unsatisfactory conditions have been corrected.

3.2

INSTALLATION

A.

Coordination: Coordinate with other trades as appropriate to properly interface the

installation with other work.

B.

Grounding: Ground non-current-carrying parts of electrical equipment, in accordance

with Division 16 Section "Grounding." Where the copper grounding conductor is

connected to a metal other than copper, provide specially treated or plated connectors

suitable for this purpose.

3.3

FACTORY TEST:

A.

Inspect and test each functional assembly at the factory prior to shipment. Employer or

his representaive maintain the right to witness these test.

B.

Provide a 30 day notification prior to performance of the test.

Submitt test procedures at least 30 days prior to the scheduled test fr review by the

engineer. The following shall be included:

3.4

Standard test procedures.

Test instruments and calibration certificates if applicable.

Submitt complete test reports approved and signed by the test engineer before

shipment of equipment.

FIELD TEST

Following installtion of the equipment the contracor shall make a complete test of the

system. The test shall include the complete functionallity of the equipment. Upon

completion of this test he shall inform the engineer to witness the field test.

Provide a 15 days notification prior to performance.

3.5

TRAINING AND MAINTENANCE

A.

Provide on site training of Employers staff.

B.

On site traing shall include training in the operation of the equipment and the

maintenace of the equipment.

Page 17 of 18

New Delhi International Airport

Technical service pits Hangar

Date 09 Dec 2016

END OF SECTION ---------

Page 18 of 18

Vous aimerez peut-être aussi

- Operator's Manual for NAVTEX Receiver NX-300Document65 pagesOperator's Manual for NAVTEX Receiver NX-300Bhavin DoshiPas encore d'évaluation

- PCA, GPU - CavotecDocument14 pagesPCA, GPU - CavotecVijay Barrey100% (1)

- Piller Airports - 140213 GB - Layout 2 PDFDocument8 pagesPiller Airports - 140213 GB - Layout 2 PDFMurad EliyevPas encore d'évaluation

- Internal Cabling GuidelinesDocument2 pagesInternal Cabling GuidelinesA.K.A. HajiPas encore d'évaluation

- Release Notes: RDL-3000 XP Edge v3.9Document8 pagesRelease Notes: RDL-3000 XP Edge v3.9alex BecerraPas encore d'évaluation

- Uputstvo Za FireRay 2000Document16 pagesUputstvo Za FireRay 2000Ivan MihajlovicPas encore d'évaluation

- 9171-5.6.1 SAT ProcedureDocument1 page9171-5.6.1 SAT ProcedureArdeleanu-Simion StefanPas encore d'évaluation

- Specification 50 or 60-400Hz Converter PDFDocument19 pagesSpecification 50 or 60-400Hz Converter PDFVijay BarreyPas encore d'évaluation

- Security Systems - Challenger Electromechanical Arm Barriers (B Series)Document3 pagesSecurity Systems - Challenger Electromechanical Arm Barriers (B Series)Fahrizal ScndPas encore d'évaluation

- EHS Approved Agencies for Fire Equipment TestingDocument8 pagesEHS Approved Agencies for Fire Equipment Testingtp101267Pas encore d'évaluation

- B207A - FTHE - Questions - 2020-2021-FirstDocument3 pagesB207A - FTHE - Questions - 2020-2021-FirstRama Naveed100% (1)

- SMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25Document38 pagesSMG 07-005 Application of Saudi Aramco Building Code To Contractors 2021-11-25baseet gazaliPas encore d'évaluation

- Fibre Optic Cable (Riyadh Cables)Document25 pagesFibre Optic Cable (Riyadh Cables)Cheche BurechePas encore d'évaluation

- Indx SaesDocument3 pagesIndx SaeskhaledPas encore d'évaluation

- Tyco FIber OSP ProductsDocument33 pagesTyco FIber OSP ProductsPeterLOW0218Pas encore d'évaluation

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistMeraj HassanPas encore d'évaluation

- LenelS2-Virtualization Products Compatibility ChartDocument1 pageLenelS2-Virtualization Products Compatibility ChartSimón SaysPas encore d'évaluation

- Installation Methodology for Video Wall at Islamabad AirportDocument17 pagesInstallation Methodology for Video Wall at Islamabad AirportDani SalimiPas encore d'évaluation

- Pds Project SetupDocument3 pagesPds Project SetupSRIKANTHPas encore d'évaluation

- Drill Floor Safety - ArabicDocument22 pagesDrill Floor Safety - ArabicEslam IsmaeelPas encore d'évaluation

- In Amenas Compression Project Fire Equipment FAT ProcedureDocument8 pagesIn Amenas Compression Project Fire Equipment FAT ProcedureDaoued HaouesPas encore d'évaluation

- Index For Checklist of ElectricalDocument16 pagesIndex For Checklist of ElectricalKamranPas encore d'évaluation

- Saudi Aramco Safety ReferencesDocument10 pagesSaudi Aramco Safety ReferencesFarhan MPas encore d'évaluation

- Fire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanDocument21 pagesFire Protection Contractor QA/QC Plan Sample: Selected Pages (Not A Complete PlanmarvinPas encore d'évaluation

- Scaffolding standards and rolesDocument20 pagesScaffolding standards and rolesMounir Boutaghane100% (1)

- 10090-Annexure-C-Scope of Work-Online UPSDocument3 pages10090-Annexure-C-Scope of Work-Online UPSenriqueramoscPas encore d'évaluation

- Fire & Smoke DamperDocument24 pagesFire & Smoke Dampershahin msPas encore d'évaluation

- Markem Imaje 9232 DS HQ C1Document2 pagesMarkem Imaje 9232 DS HQ C1aavr6792410% (1)

- Toledo Power Company: Terms of ReferenceDocument8 pagesToledo Power Company: Terms of Referencejet toledo100% (1)

- General Maintenance Works at QAFCODocument8 pagesGeneral Maintenance Works at QAFCOsumesh cPas encore d'évaluation

- Rotan OM ApproachDocument173 pagesRotan OM Approach8103 Anshu PatilPas encore d'évaluation

- OISD 225 ROs Oct2010Document17 pagesOISD 225 ROs Oct2010taranakgecPas encore d'évaluation

- Safety Interview Study Guide Updated VersionDocument24 pagesSafety Interview Study Guide Updated VersionakasalihsePas encore d'évaluation

- BTS Installation ProcedureDocument21 pagesBTS Installation Procedurepr3m4nPas encore d'évaluation

- General Instruction Manual: Na Power Operations Department Certification of High Voltage Cable SplicersDocument8 pagesGeneral Instruction Manual: Na Power Operations Department Certification of High Voltage Cable SplicersJithuRajPas encore d'évaluation

- Precautions for Semi-Automatic and Automatic WeldingDocument8 pagesPrecautions for Semi-Automatic and Automatic WeldingFaiz IshakPas encore d'évaluation

- Vmonitor Well Head MonitoringDocument2 pagesVmonitor Well Head MonitoringWatanabe KojiPas encore d'évaluation

- MV and LV cable technical requirementsDocument5 pagesMV and LV cable technical requirementsFor AppsPas encore d'évaluation

- p021.46 Db54 Mat Mep Mech 022 Ventilation FansDocument95 pagesp021.46 Db54 Mat Mep Mech 022 Ventilation Fansp4p7 projectsPas encore d'évaluation

- Diesel Fuel Oil System Commissioing ProcedureDocument34 pagesDiesel Fuel Oil System Commissioing ProcedureAdelPas encore d'évaluation

- 8.0 - General Workplace Amenities v3.1 EnglishDocument14 pages8.0 - General Workplace Amenities v3.1 EnglishjbdejhiuhwPas encore d'évaluation

- MTBF Calculation Flatpack2 TEC25Document6 pagesMTBF Calculation Flatpack2 TEC25santosh kumarPas encore d'évaluation

- Sen 1399 CSD Pur MR 052 01Document16 pagesSen 1399 CSD Pur MR 052 01Kamran JamilPas encore d'évaluation

- Anderson Greenwood POPRV Series 90 and 9000Document62 pagesAnderson Greenwood POPRV Series 90 and 9000HafziPas encore d'évaluation

- Saudi Aramco Office Furniture ProcurementDocument3 pagesSaudi Aramco Office Furniture Procurementmalika_00Pas encore d'évaluation

- Qcs 2014 - Sec21 p10 - Wiring Accessories and General PowerDocument9 pagesQcs 2014 - Sec21 p10 - Wiring Accessories and General PowerchandraPas encore d'évaluation

- Method Statement Pipe Re-Routing Saudi BinladinDocument11 pagesMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathPas encore d'évaluation

- (Package-2-Mech Works) : Clean Fuels ProjectDocument15 pages(Package-2-Mech Works) : Clean Fuels ProjectsarangpunePas encore d'évaluation

- Cable Gland Seal & Conduit Seal InstallationDocument19 pagesCable Gland Seal & Conduit Seal InstallationTariqMalikPas encore d'évaluation

- RAPID MULTI-ELEMENT EXTRACTION OF SEDIMENTS, SLUDGES, SOILS AND OILSDocument30 pagesRAPID MULTI-ELEMENT EXTRACTION OF SEDIMENTS, SLUDGES, SOILS AND OILSwrangel_2Pas encore d'évaluation

- Stack Emissions ReportDocument26 pagesStack Emissions ReportMohamed Irfan Z H100% (1)

- Chiang Ying Engineering PDFDocument23 pagesChiang Ying Engineering PDFSim Khoon AunPas encore d'évaluation

- Site Safety & Health Plan of The Contractor - Prescribed ContentsDocument8 pagesSite Safety & Health Plan of The Contractor - Prescribed ContentsSufiyan KhedekarPas encore d'évaluation

- Sabic M80064SDocument2 pagesSabic M80064STungdinh NguyenPas encore d'évaluation

- GS690 Installation Manual Rev ADocument63 pagesGS690 Installation Manual Rev Acasmadi casmadi100% (1)

- Dry Type Transformer Spec in Word FormatDocument25 pagesDry Type Transformer Spec in Word Formatarulraj1971Pas encore d'évaluation

- Technical SpecificationDocument17 pagesTechnical Specificationmohan agasthiPas encore d'évaluation

- ECP Electrical Enclosure Specification GuideDocument3 pagesECP Electrical Enclosure Specification GuideClaudia MondragónPas encore d'évaluation

- Feeder PillarsDocument43 pagesFeeder PillarsRyan BrittPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Data - Cavotec Hatch Pit PDFDocument2 pagesData - Cavotec Hatch Pit PDFVijay Barrey100% (2)

- Cavotec Pop-Up Pit SystemDocument2 pagesCavotec Pop-Up Pit SystemVijay Barrey100% (1)

- 400Hz / 28V DC Aircraft Cables: Single CableDocument2 pages400Hz / 28V DC Aircraft Cables: Single CableVijay Barrey100% (1)

- 2500+ Series Flyer - Lres PDFDocument4 pages2500+ Series Flyer - Lres PDFVijay BarreyPas encore d'évaluation

- Electrical Layout - Lighting Fixtures - 23.11.2016Document1 pageElectrical Layout - Lighting Fixtures - 23.11.2016Vijay BarreyPas encore d'évaluation

- Datasheet - PAC-DX - EU - Lres PDFDocument3 pagesDatasheet - PAC-DX - EU - Lres PDFVijay BarreyPas encore d'évaluation

- Specification 50 or 60-400Hz Converter PDFDocument19 pagesSpecification 50 or 60-400Hz Converter PDFVijay BarreyPas encore d'évaluation

- A4 Runway LayoutDocument55 pagesA4 Runway LayoutVijay BarreyPas encore d'évaluation

- TIA Nepal Approach Methodology 24-11-14Document52 pagesTIA Nepal Approach Methodology 24-11-14Vijay BarreyPas encore d'évaluation

- Electrical ContractorsDocument4 pagesElectrical Contractorsrdeepak99Pas encore d'évaluation

- Pse&G Labor Data Import/Export Training GuideDocument26 pagesPse&G Labor Data Import/Export Training GuideVijay BarreyPas encore d'évaluation

- SPV Power Technology in India: Satyendra Kumar Lanco Solar, IndiaDocument27 pagesSPV Power Technology in India: Satyendra Kumar Lanco Solar, IndiaVijay BarreyPas encore d'évaluation

- Guide To Forms of Separation - Low Voltage Switchgear and Controlgear - EEPDocument5 pagesGuide To Forms of Separation - Low Voltage Switchgear and Controlgear - EEPVijay BarreyPas encore d'évaluation

- Design of Earthing SystemDocument5 pagesDesign of Earthing SystemNishant SinhaPas encore d'évaluation

- Saniware CatalogueDocument90 pagesSaniware CatalogueSewei SiewPas encore d'évaluation

- RJ Testing & InspectionDocument25 pagesRJ Testing & Inspectionmuhamadrafie1975Pas encore d'évaluation

- Tall Timber Buildings: Introduction: Prof. Ian Smith, University of New Brunswick, FrederictonDocument4 pagesTall Timber Buildings: Introduction: Prof. Ian Smith, University of New Brunswick, FrederictonDesign explorer olomizanaPas encore d'évaluation

- Equivalent Grades of Cast IronsDocument2 pagesEquivalent Grades of Cast IronsVinh Do ThanhPas encore d'évaluation

- Third Year Civil Engg. 3rd Year Scheme Syllabus 2018-19 PDFDocument24 pagesThird Year Civil Engg. 3rd Year Scheme Syllabus 2018-19 PDFRishab SrivastavaPas encore d'évaluation

- 2) Green Concrete For The FutureDocument14 pages2) Green Concrete For The FutureSOMPas encore d'évaluation

- Routine Test Procedures On Standard Test Pieces Moulding: Sand-Preparation ofDocument2 pagesRoutine Test Procedures On Standard Test Pieces Moulding: Sand-Preparation ofFaizan Tahir100% (2)

- Hummel Metal HSK-M Standard Cable Glands: Metric ThreadDocument2 pagesHummel Metal HSK-M Standard Cable Glands: Metric Threadalexandresq4283Pas encore d'évaluation

- Exam 3 Material Science MATS 2001 UMN Fall 2012Document7 pagesExam 3 Material Science MATS 2001 UMN Fall 2012Zaki Smn100% (1)

- Kick-Off Meeting - Pipe CulvertsDocument12 pagesKick-Off Meeting - Pipe CulvertsShabbar Abbas MalikPas encore d'évaluation

- Greek ArchitectureDocument446 pagesGreek ArchitectureIlknur Balatkan Karabulut100% (2)

- Applications of Second Law of ThermodynamicsDocument18 pagesApplications of Second Law of Thermodynamicss100% (1)

- Division 7 Thermal and Moisture ControlDocument3 pagesDivision 7 Thermal and Moisture ControlDanielGazmen100% (1)

- Sangabattula - Lokesh - Motivation Letter - 1998-08-14Document2 pagesSangabattula - Lokesh - Motivation Letter - 1998-08-14Lokesh SangabattulaPas encore d'évaluation

- Solution To Problem 323 Torsion - Strength of Materials ReviewDocument1 pageSolution To Problem 323 Torsion - Strength of Materials ReviewMark ObcianaPas encore d'évaluation

- Avd - Vddci102Document8 pagesAvd - Vddci102faisalnadimPas encore d'évaluation

- 1 Introduction To Bridge EngineeringDocument46 pages1 Introduction To Bridge EngineeringRYAN JOSEPH QUIMOPas encore d'évaluation

- Microstructure and Mechanical Properties of Polypropylene/ Polycarbonate BlendsDocument4 pagesMicrostructure and Mechanical Properties of Polypropylene/ Polycarbonate BlendsMonali ChhatbarPas encore d'évaluation

- Datasheet MCBDocument3 pagesDatasheet MCBNanda ramadhanPas encore d'évaluation

- Bloomframe by Hurks GeveltechniekDocument1 pageBloomframe by Hurks GeveltechniekHolmes SherlockPas encore d'évaluation

- Pipe Rack Load CalculationDocument3 pagesPipe Rack Load CalculationKrunalpanchalPas encore d'évaluation

- Chemistry-Investigatory-Project - RISHABH TEWARIDocument16 pagesChemistry-Investigatory-Project - RISHABH TEWARIcheenujoshi2007Pas encore d'évaluation

- Effect of Welding Current on Mechanical Properties of Steel WeldsDocument9 pagesEffect of Welding Current on Mechanical Properties of Steel WeldsMuhammad Zuhdi SyihabPas encore d'évaluation

- Sertifikat ASTM 1BDocument18 pagesSertifikat ASTM 1BPrasetya Siregar100% (1)

- ASHRAEJournal SolarRefrigeration KleinReindl2005Document6 pagesASHRAEJournal SolarRefrigeration KleinReindl2005RutujaPas encore d'évaluation

- Jockey Pump 96517052 - CR - 520 - AFGJAEHQQEDocument8 pagesJockey Pump 96517052 - CR - 520 - AFGJAEHQQEShafa AlmaliyaPas encore d'évaluation

- C94C94M-15 Standard Specification For Ready-Mixed Concrete PDFDocument14 pagesC94C94M-15 Standard Specification For Ready-Mixed Concrete PDFdiego rodriguezPas encore d'évaluation

- LOAD-TESTS-ON-PILESDocument48 pagesLOAD-TESTS-ON-PILESFajrin M. NatsirPas encore d'évaluation

- Design Calculations For Pressure VesselsDocument32 pagesDesign Calculations For Pressure VesselsGeorge Georgian100% (3)

- BCS WS QS LMSW 105 23272r2Document8 pagesBCS WS QS LMSW 105 23272r2ddPas encore d'évaluation